Microwave heating glass ceramic crystallization technology and device

A glass-ceramic and microwave heating technology, which is applied in the field of glass-ceramic crystallization, can solve the problems of temperature imbalance, low temperature, explosion of glass-ceramic products, etc., and achieve the effects of stress relief, simple process and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

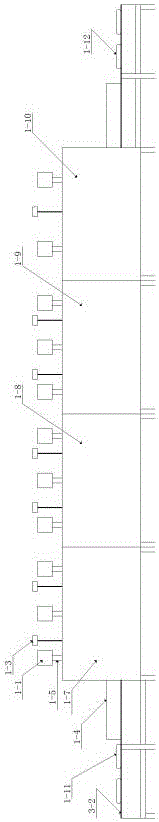

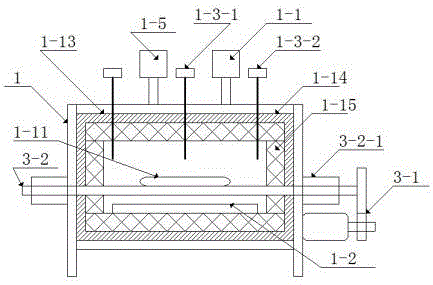

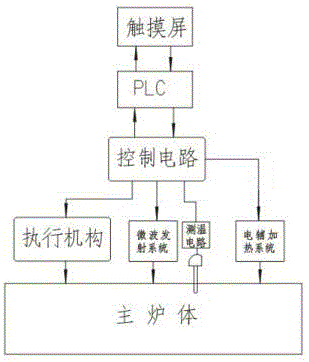

[0037] The microwave heating glass-ceramic crystallization method of the present invention comprises heating up, crystallization, cooling and cooling process, utilizes microwave heating to carry out crystallization treatment to glass-ceramic material, and its difference with prior art is: in heating up, crystallization and cooling process At the same time, the microwave heating system and the electric auxiliary heating system are used to crystallize the glass ceramic products, and the temperature of each section of the furnace body is controlled by adjusting the output power of the microwave; Temperature balance solves the problem of cracking in the process of crystallization of glass ceramic products.

Embodiment 2

[0039] The microwave heating glass ceramic crystallization method of this embodiment is different from that of Embodiment 1 in that the specific control flow of each process is as follows: (1) During the heating process, the output power of the microwave heating system is adjusted to be 10 to 30 of the maximum output power %, so that the temperature in the heating section rises to 400-600°C at a rate of 1-5°C per minute; adjust the output power of the electric auxiliary heating system so that the rate of temperature rise of the glass ceramic product to be crystallized is consistent with the heating section;

[0040] (2) After the heating process is completed, when the crystallized glass-ceramic products enter the crystallization process, adjust the microwave output power to 30-100% of the maximum output power, so that the temperature of the crystallization section is raised to 600 at a rate of 2-5 °C per minute. ~800°C; adjust the output power of the electric auxiliary heating ...

Embodiment 3

[0044] The microwave heating glass-ceramic crystallization method of the present embodiment, its difference with embodiment 1 or embodiment 2 is: each microwave source system of described microwave heating system comprises the microwave power source that is made up of filament transformer and high-voltage transformer and Magnetron, when the magnetron is initially working, the filament transformer provides energy to preheat the magnetron, delay for 30 to 50 seconds, and then apply high voltage to the anode after the filament emits electrons stably, turn on the high voltage transformer and make the magnetron The tube emits microwaves for 60 to 90 seconds. When the magnetron works stably, turn off the filament transformer, use the heat generated during the microwave emission process of the magnetron to maintain a certain temperature for the magnetron filament, continue to emit electrons, and use the anode resonant cavity The energy generated by the vibration is used to maintain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com