Method for producing semi-conductor device

A semiconductor and device technology, applied in the field of semiconductor device manufacturing, can solve problems such as poor consistency and unsuitable glass substrates, and achieve the effect of controlling and reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

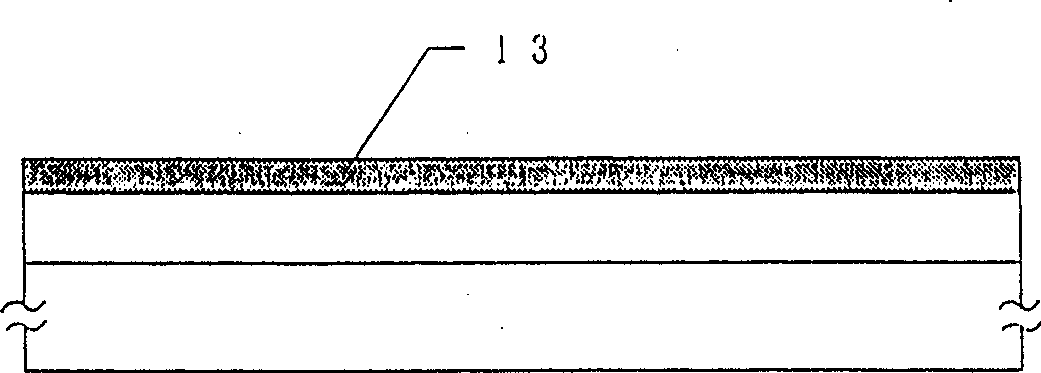

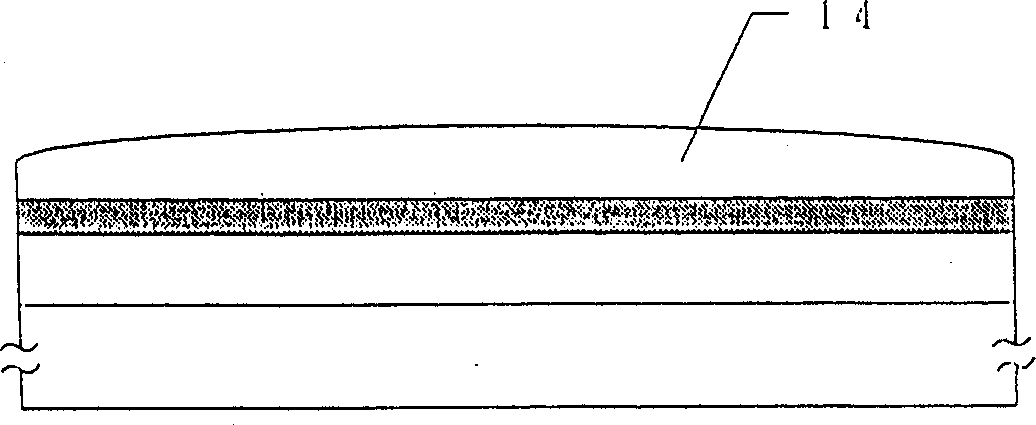

[0060] In this example, reference will be made to Figure 1A -1D discusses the process of heating and crystallizing a semiconductor film formed from an aqueous solution containing a catalyst, followed by crystallization by laser irradiation.

[0061] Prior to laser crystallization, the concentration of hydrogen contained in the amorphous silicon film should be as small as possible, for example, from 0.01 to 10 percent atmospheric pressure. Therefore, in order to release hydrogen from the silicon film, it is preferable to heat the amorphous silicon film at a temperature lower than the crystallization temperature. In an alternative, use 100-500 sccm of Si 2 h 6 Silane and 500 sccm of helium are used to form an amorphous silicon film by low pressure chemical vapor deposition at a relatively high temperature, for example, 430-500° C., wherein the concentration of hydrogen is within the above-mentioned range.

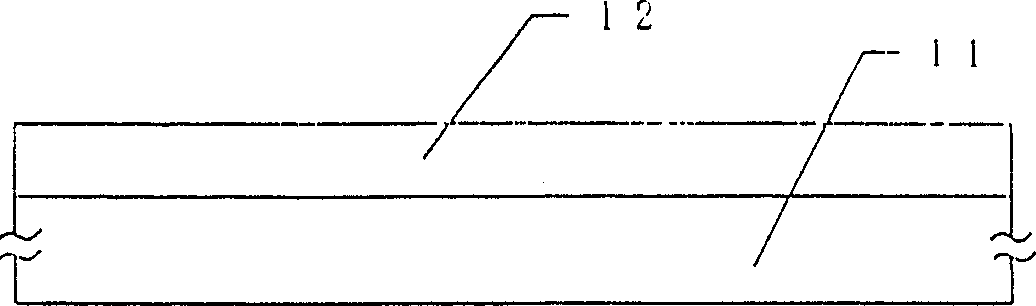

[0062] exist Figure 1A , reference numeral 11 denotes a Corning 7059...

Embodiment 2

[0072] This embodiment is exactly the same as the previous embodiment except that the concentration of nickel in the solution is changed to 1 ppm.

[0073] The silicon film in this example was observed with a microscope after the heat treatment, and as a result, it was found that the portion of the amorphous silicon film was larger than that of the above example, and the crystal nuclei were reduced.

[0074] Further, after laser crystallization, the sample was subjected to Secco-etched and observed with a scanning electron microscope. As a result, it was found that the size of each crystal was larger than that obtained in the previous example.

Embodiment 3

[0076] The present embodiment relates to a process for producing a TFT for a plurality of pixels of an active matrix liquid crystal display device or for a driving circuit using a crystalline silicon film produced by the process of the present invention. TFTs can be used not only in liquid crystal display devices but also in a wide range of fields generally called thin film integrated circuits (ICs).

[0077] see Figures 3A-3E , the process of manufacturing a TFT according to this embodiment will be described below. A silicon oxide film (not shown in the figure) was deposited to a thickness of 2000 Å as a base layer on the glass substrate. This silicon oxide layer is used to prevent impurities from penetrating the device from the glass substrate.

[0078] Then, in the same manner as in Example 1, an amorphous silicon film was deposited to a thickness of 500 Å. After removing the natural oxide film by treatment with hydrofluoric acid, an oxide film was formed to a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com