A kind of white light alloy quantum dot and its preparation method, electroluminescent diode and photoluminescent diode

A quantum dot and photoalloy technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of difficult control of quantum dot size and particle size distribution, high reaction temperature, long reaction time, etc., to achieve high color rendering index, reaction The effect of low temperature and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

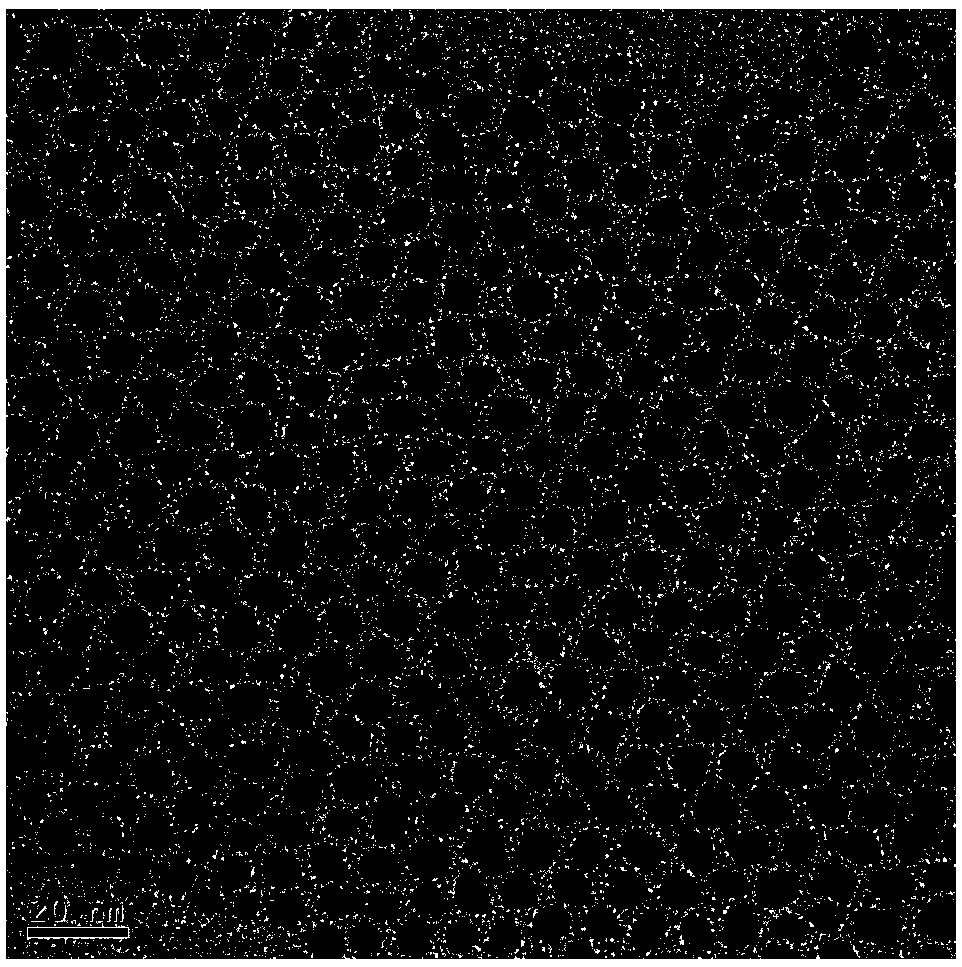

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of white light alloy quantum dots, comprising the following steps:

[0027] (1) Mix zinc source, cadmium source, ligand and non-coordinating solvent, and heat to obtain cationic precursor;

[0028] (2) inject sulfur source into the cation precursor that described step (1) obtains, carry out the first reaction and obtain quantum dot precursor;

[0029] (3) adding a selenium source to the quantum dot precursor obtained in the step (2), carrying out a second reaction to obtain a nanocrystal solution;

[0030] (4) adding a sulfur source to the nanocrystal solution obtained in the step (3), performing a third reaction to obtain white light alloy quantum dots.

[0031] In the present invention, the molar ratio of the zinc source, the cadmium source, the sulfur source in step (2), the selenium source and the sulfur source in step (4) is preferably 5-100:1:2-40:1- 20:3-60, more preferably 10-80:1:4-20:2-10:6-40, most preferably 20-4...

Embodiment 1

[0081] Dissolve 5mmol of zinc acetate and 1mmol of cadmium oxide in 3mL of oleic acid and 10mL of 1-octadecene, heat to 100°C; use a mechanical pump to evacuate for 40min, and pass argon as a reaction to protect the environment;

[0082] Continue to heat up to 300°C, inject 2mmol sulfur powder solution dissolved in 1mL 1-octadecene at the fastest rate, and keep warm for 10min to form alloy CdZnS crystal nuclei;

[0083] Raise the temperature to 310°C, add dropwise 1mmol selenium powder dissolved in 2mL tributylphosphine at a rate of 1mL / min, and keep warm for 1h to form a CdZnS / ZnSe core-shell structure;

[0084] Add dropwise 3mmol sulfur powder solution dissolved in 1mL 1-octadecene at a rate of 1mL / min, and keep warm for 40min to form CdZnS / ZnSe / ZnS core-shell quantum dots;

[0085] Cool to 50°C, inject a mixed solution of n-hexane and methanol with a volume ratio of 1:2, stir at 800r / min for 5 minutes, then stand still for 10 minutes, and the mixed solution is layered; the ...

Embodiment 2

[0090] Polyethylenedioxythiophene and polystyrene sulfonate were mixed at a molar ratio of 1:5, and an ethanol solution was prepared at a concentration of 1mol / L, which was spin-coated on conductive glass at a speed of 4500r / s for 40s, and then heated at 140°C Bake for 12 minutes to obtain a hole injection layer with a thickness of 20 nm;

[0091] Put the conductive glass with the hole injection layer into the glove box, spin-coat the chlorobenzene solution of 8g / L 4-butyl-N,N-diphenylaniline homopolymer on the surface of the hole injection layer, spin The coating rate is 2000r / s, put into a vacuum drying oven and bake at 100°C for 20min to obtain a first hole transport layer with a thickness of 20nm;

[0092] Spin-coat 1.5g / mL polyvinylcarbazole m-xylene solution on the surface of the first hole transport layer at a spin-coating rate of 2500r / s, spin-coat for 45s, and anneal at 170°C for 30min to obtain the first hole-transporting layer with a thickness of 20nm. Two hole tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com