Polyamide resin composition and molded article

A technology of polyamide resin and composition, which is applied in the direction of flat products, applications, household appliances, etc., can solve problems such as flashing and poor crystallization, and achieve excellent low bending performance, excellent bendability, and improved thin-wall formability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

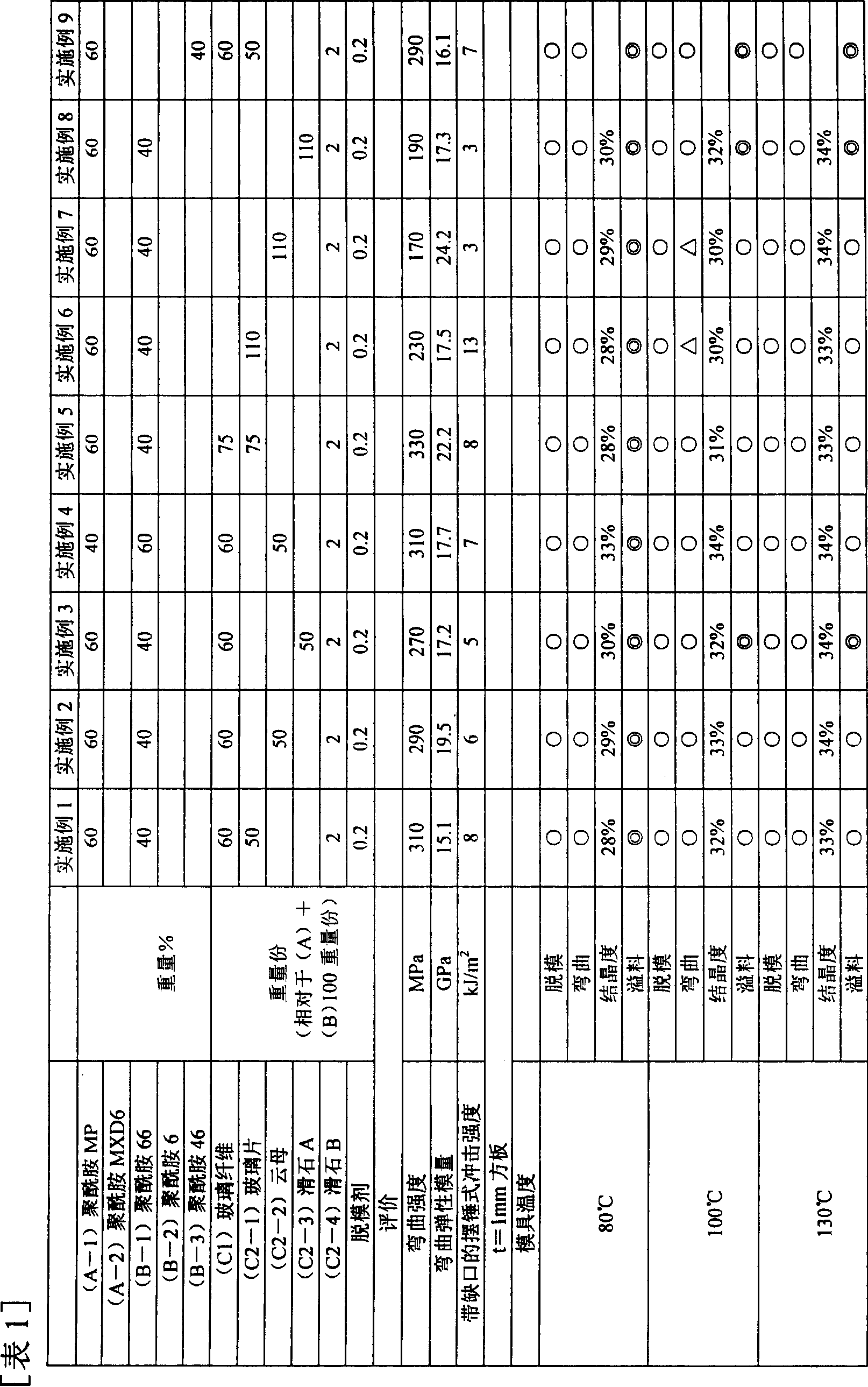

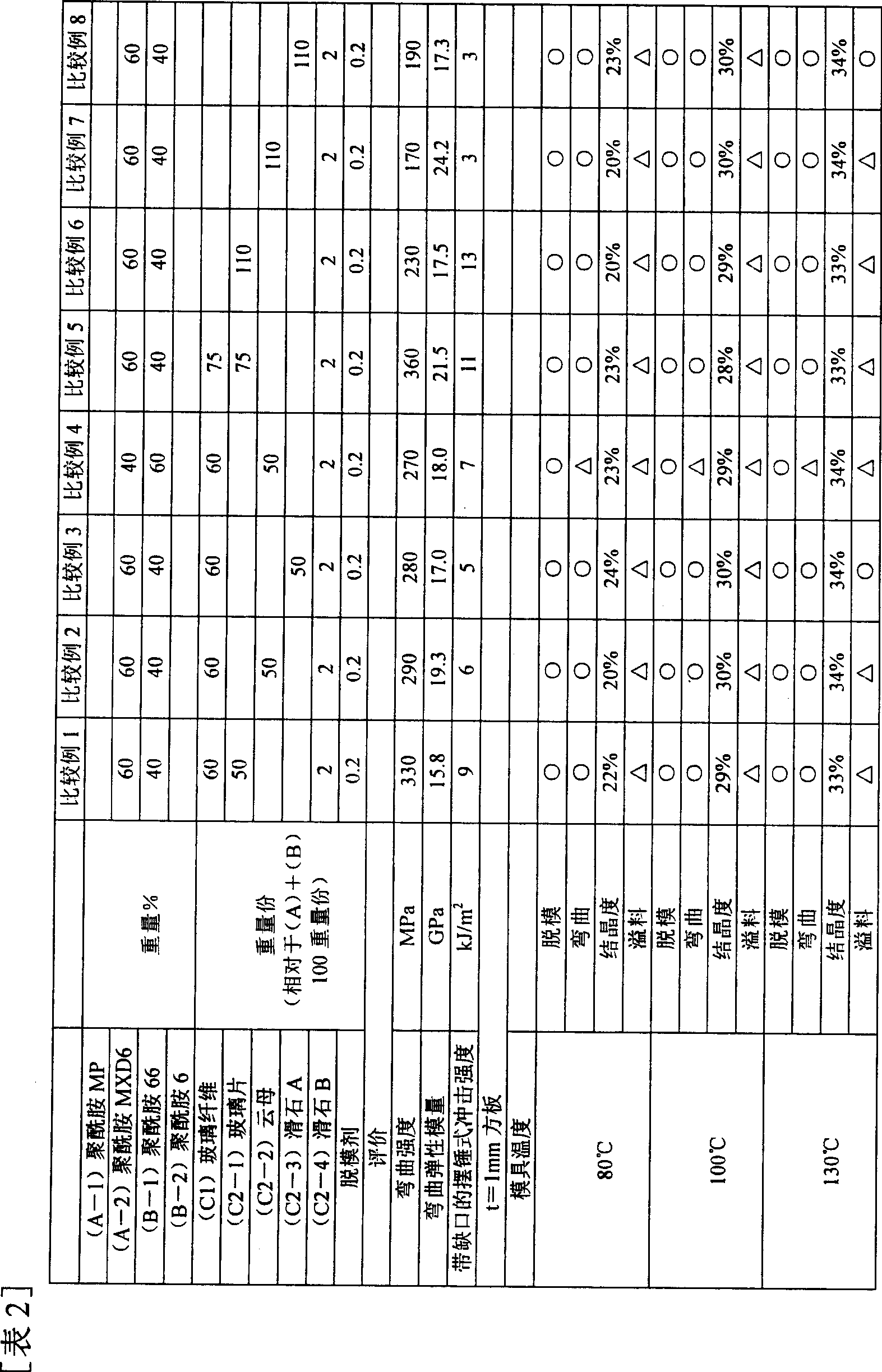

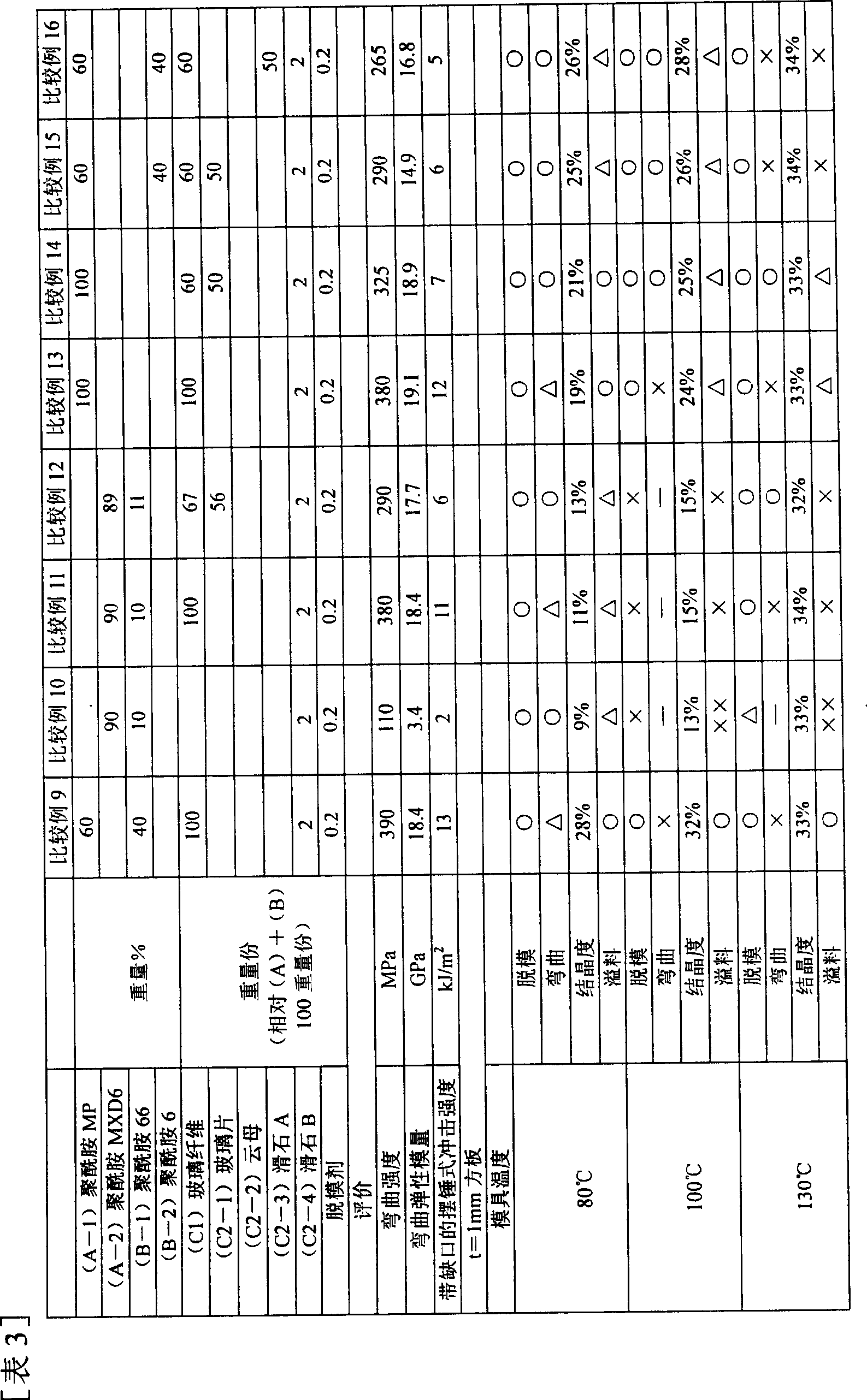

Embodiment 1~9 and comparative example 1~16

[0074] (1) The making of resin composition pellets:

[0075] With the composition shown in Tables 1 to 3, each component except the fibrous filler (C1) was weighed, mixed in a drum, and then obtained from a twin-screw extruder "TEM35B (drum consisting of 10 zones) produced by Toshiba Machine Co., Ltd. ” into the base and let it melt. Then, the component (C1) was side-fed into the seventh zone counted from the side of the hopper to make resin composition pellets. The temperature setting of the extruder was uniformly 280°C.

[0076] (2) Evaluation of flexural strength, flexural modulus, and pendulum impact strength

[0077]

[0078] The pellets of each resin composition obtained by the above method were dried at 80°C for 48 hours, and then using an injection molding machine "100T" manufactured by FANUC LTD. Seconds, cooling time 15 seconds, VP switch when filling about 95% resin, keep pressure in the range of no flash, up to 620kgf / cm 2 Hold for 25 seconds to form an ISO t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com