Preparation method of intelligent nano-foam oil-displacing agent

A technology of nano-foam and oil-displacing agent, applied in the field of oil-displacing agent, can solve the problems of cumbersome process, low recovery rate, difficult to control and control the hydrophilicity and lipophilicity of nanoparticles, and achieves the effect of rapid recovery and expansion of the swept area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Firstly, nano-scale ferric oxide is prepared: take a certain amount of FeCl 3 ·6H 2 Dissolve O in water first, pass nitrogen gas into the solution for 30 minutes, and then add appropriate amount of FeCl 2 4H 2 O to dissolve it completely. The appropriate dimethylaminoethyl methacrylate (DMA) was then added. The mixture was reacted at 80°C for 30 minutes. Finally, the obtained solution was separated, washed and dried. The obtained product is nano-scale ferric oxide.

[0026] 0.1g Fe 3 o 4 Disperse in 200 ml of deionized water and add 1 g of polyvinylpyrrolidone. The solution was purged with nitrogen for 30 minutes. Then, 1 g of N-isopropylacrylamide, 0.1 g of potassium persulfate, and 0.05 g of sodium p-styrenesulfonate were sequentially added. Heated to 80°C for 12 hours. Finally the resulting solution was dried by centrifugation. Nanoparticles that respond to temperature and magnetic fields are obtained.

[0027] The obtained nanoparticles were dispersed i...

Embodiment 2

[0030] 0.1 g magnetic nanoparticles MFe 2 o 4 (M=Ni, Co, Zn) was dispersed in 200ml of deionized water and 1g of dodecyltrimethylammonium bromide was added. The solution was purged with nitrogen for 30 minutes. Then, 1 g of methoxyethyl methacrylate, 0.1 g of ammonium persulfate, and 0.05 g of sodium vinylsulfonate were added in sequence. Heated to 80°C for 12 hours. Finally the resulting solution was dried by centrifugation. Nanoparticles that respond to temperature and magnetic fields are obtained.

[0031] The obtained nanoparticles are dispersed in water together with 1 g of sodium dodecylsulfonate foaming agent, and then stirred at a high speed for 5 hours to obtain smart nano-foam.

Embodiment 3

[0033] 0.1 g magnetic nanoparticles α-Fe 2 o 3 Disperse in 200ml deionized water and add 1g sodium dodecylbenzenesulfonate). The solution was purged with nitrogen for 30 minutes. Then, 1 g of 2-(N,N-dimethylamino)methacrylate, 0.1 g of sodium persulfate, and 0.05 g of sodium styrenesulfonate were added in sequence. Heated to 80°C for 12 hours. Finally the resulting solution was dried by centrifugation. Nanoparticles that respond to temperature and magnetic fields are obtained.

[0034] The obtained nanoparticles are dispersed in water together with 1 g of sodium dodecylbenzenesulfonate foaming agent, and then stirred at high speed for 5 hours to obtain smart nano-foam.

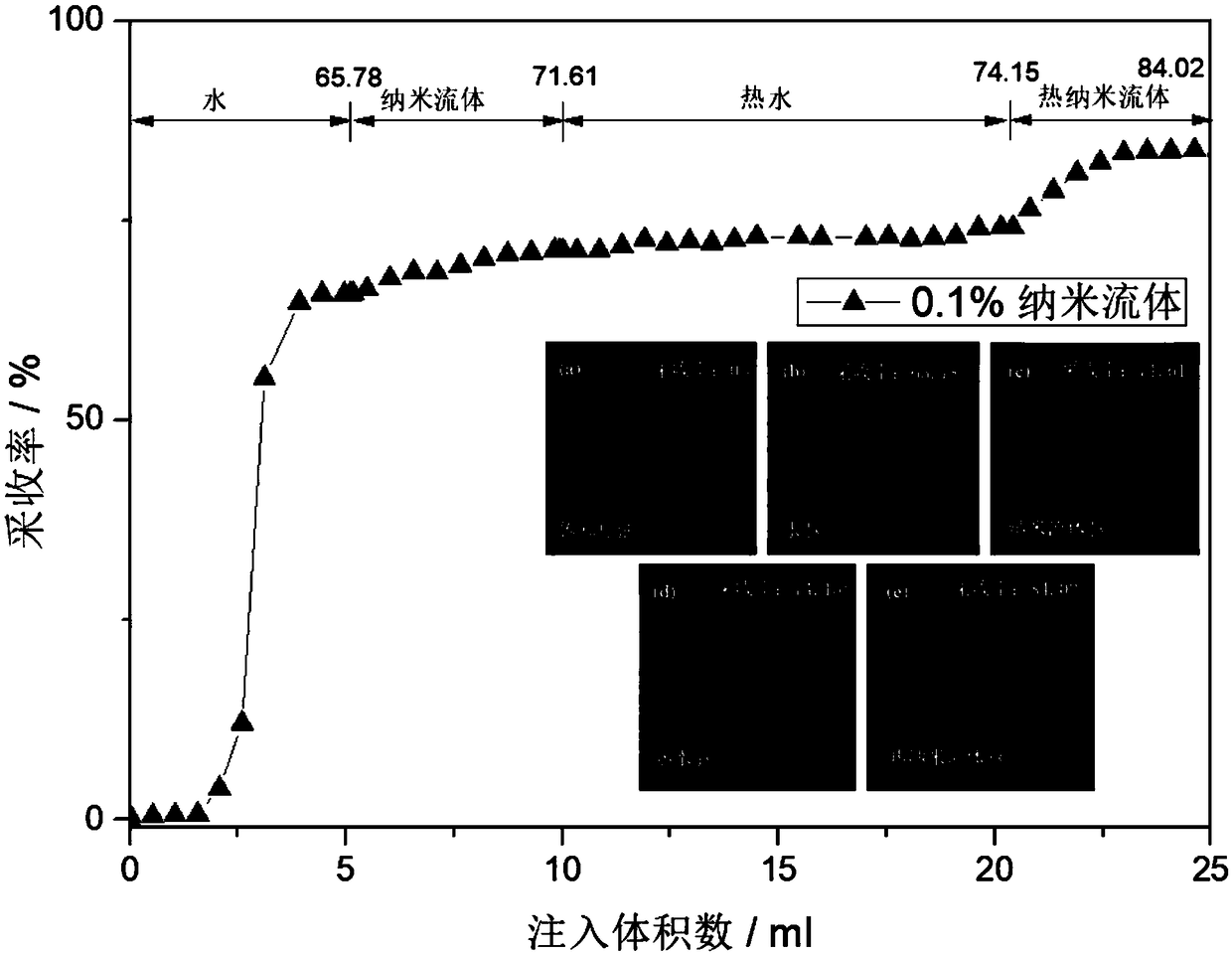

[0035] To sum up, the present invention prepares composite nanoparticles with temperature-sensitivity and magnetic response by grafting temperature-sensitive polymers onto the surface of magnetic nanoparticles, and the nanoparticles have the characteristics of stable foam. The feature of this oil displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com