Method for refining and grading lead powder

A technology of lead powder and classifier, applied in the direction of lead-acid battery electrodes, etc., can solve problems such as constraints, and achieve the effects of high production efficiency, improved utilization rate, and improved uniformity of active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

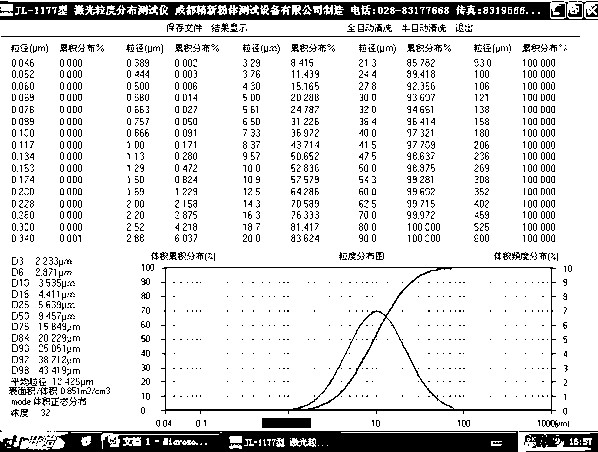

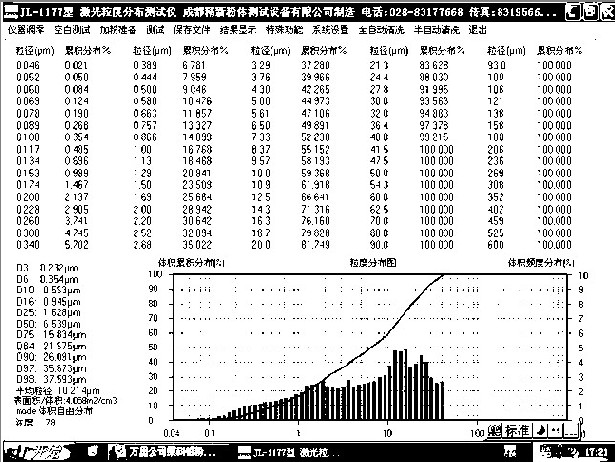

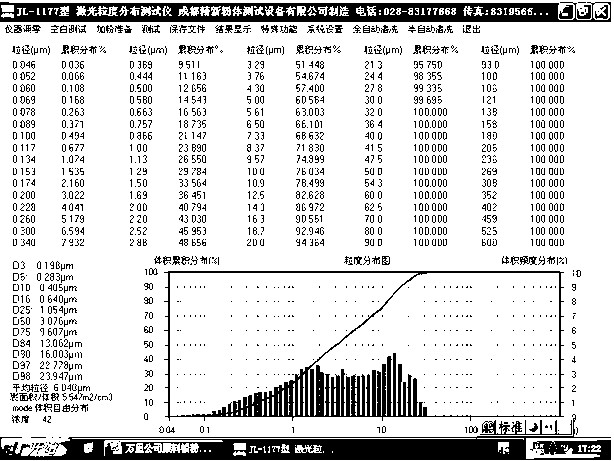

[0036] Such as Figure 6 , Figure 7 As shown, a method for refinement and classification of lead powder is carried out as follows: the lead ingot is pulverized into lead powder by the lead powder machine 5, and the lead powder is refined by the airflow classifier system and then divided into coarse and fine powders. Two types, the airflow classifier system is composed of feeder 1, classifier 2, bag collector 3, and induced draft fan unit 4, wherein feeder 1 is connected to the lower inlet of classifier 2 through a feed pipe, and the upper part of classifier 2 is connected to The bag collector 3 is connected, the bottom of the classifier 2 is the coarse lead powder outlet, the bag collector 3 is the outlet of the fine lead powder, and the induced draft fan unit 4 is communicated with the bag collector 3 through a pipeline; 1. The incoming lead powder enters from the feed pipe under the suction force of the induced draft fan unit 4, and is scattered into the rising airflow thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com