Centrifugal atomizing device

A technology of centrifugal atomization and centrifugal atomization disc, which is applied in the direction of spraying device, spraying device with movable outlet, etc., can solve the problems of limiting the size of atomized particles in the atomizing disc, breaking the atomizing disc, and limiting the rotation speed of the atomizing disc. , to achieve the effect of uniform irrigation and spraying, easier penetration, reduction of average particle size, and saving of liquid dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

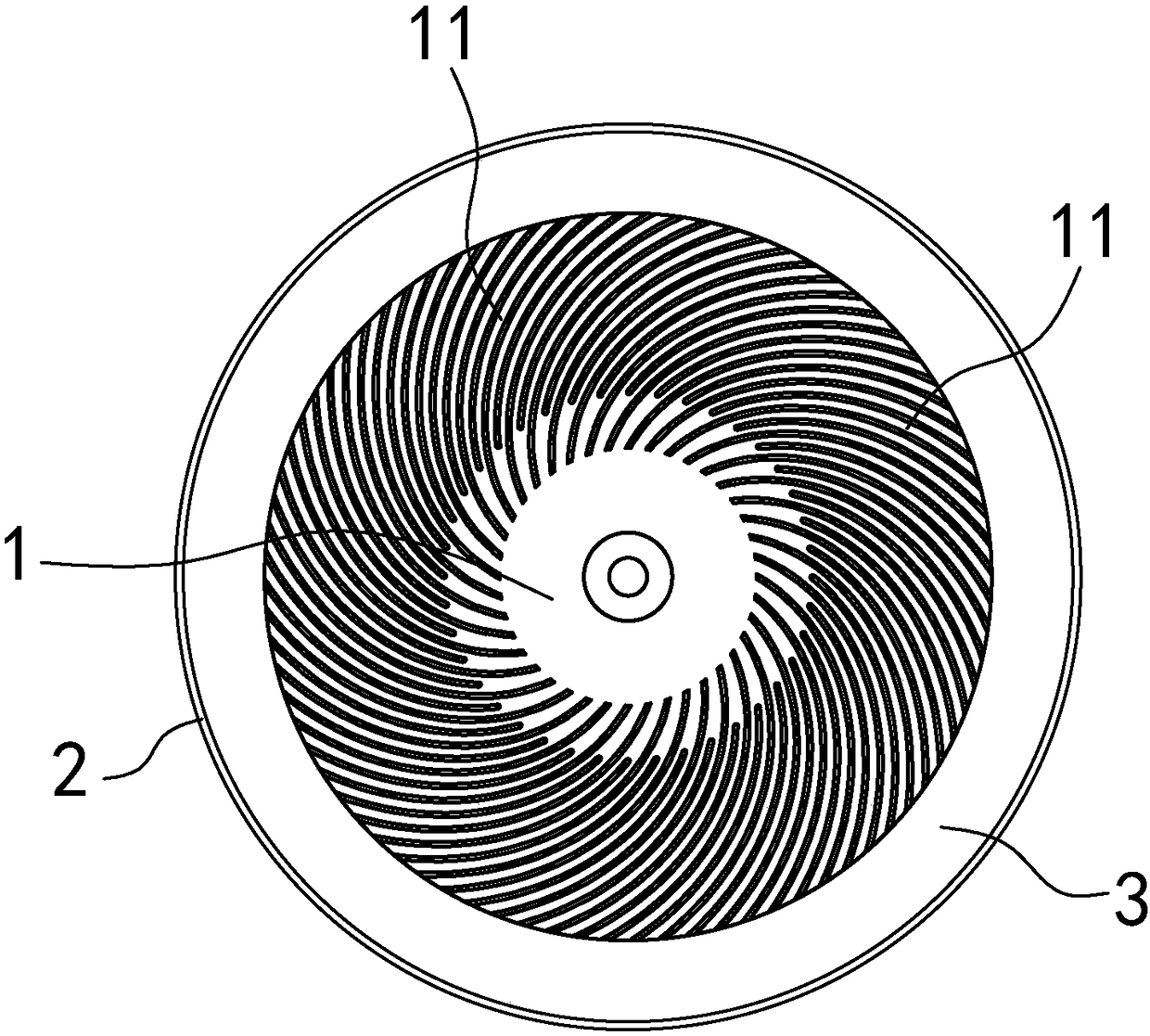

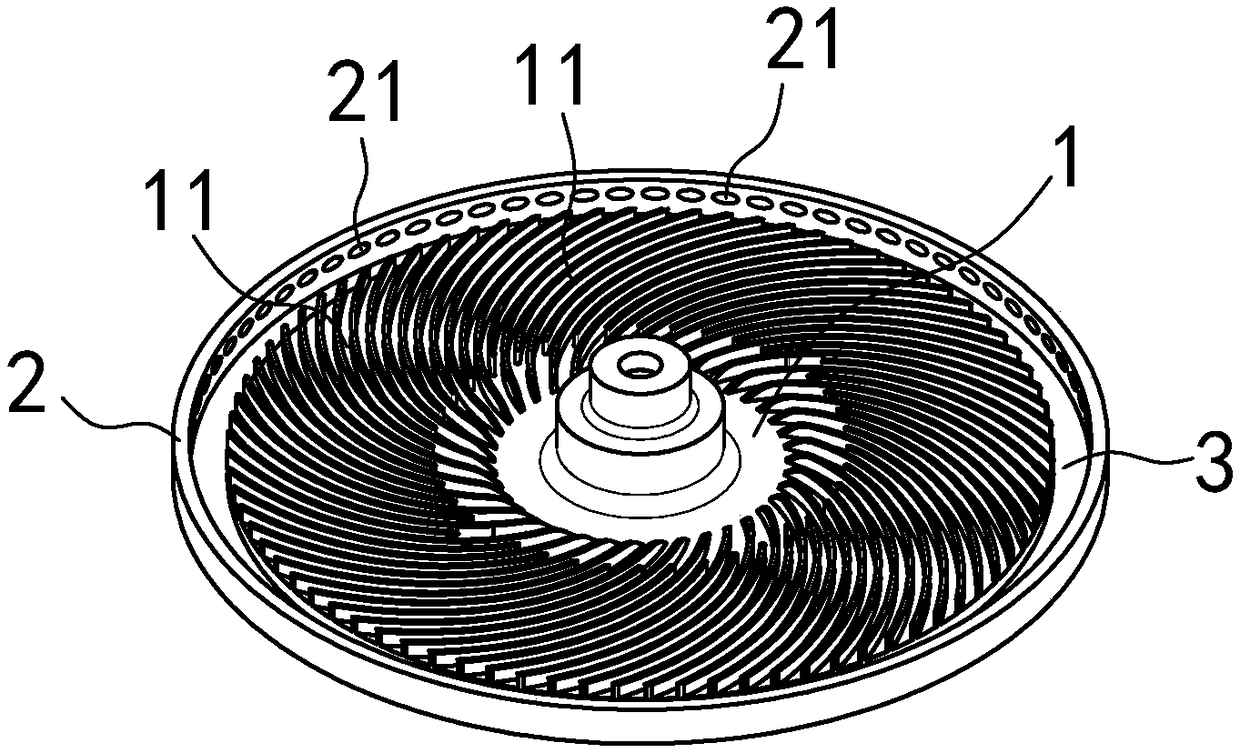

[0042] A centrifugal atomization device, set on a spraying device (handheld spraying device or spraying drone, etc.) A plurality of diversion grooves 11 are provided on the top, and each diversion groove 11 extends from the central position of the centrifugal atomizing disk 1 to the edge.

[0043] An annular body 2 is arranged on the outside of the centrifugal atomizing disc 1, and the annular body 2 is coaxial with the centrifugal atomizing disc 1 and is set in relative rotation, wherein, the centrifugal atomizing disc 1 is opposite to the spraying equipment The main body of the centrifugal atomizing disc 1 is rotated by a motor, and the annular body 2 is fixedly arranged relative to the main body of the spraying equipment, and there is a gap between the annular body 2 and the centrifugal atomizing disc 1 in its radial direction. A spacing of 3.

[0044] The annular body 2 is provided with a circle of air guide grooves along its circumference, and the inner peripheral surface ...

Embodiment 2

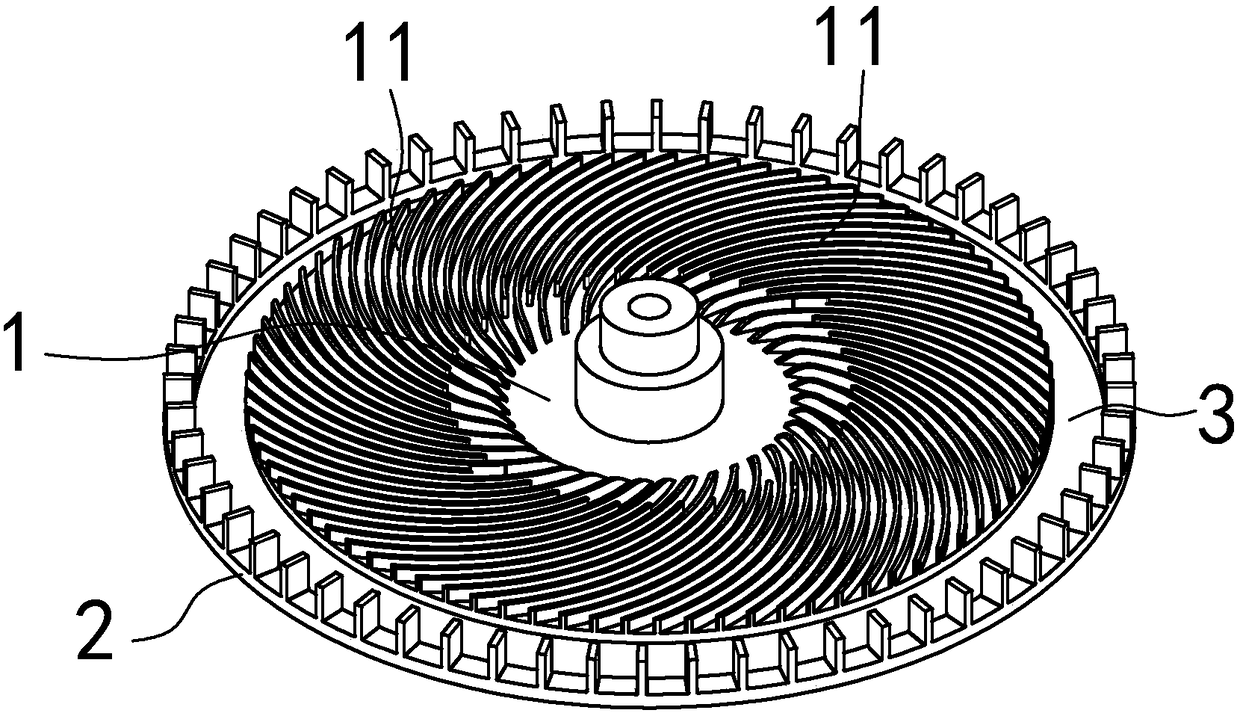

[0058] A centrifugal atomization device, which is set on a spraying device (handheld spraying device or spraying drone, etc.) Flow grooves 11, each flow guide groove 11 extends from the central position of the centrifugal atomizing disk 1 to the edge.

[0059] An annular body 2 is arranged on the outside of the centrifugal atomizing disc 1, the centrifugal atomizing disc 1 is rotated relative to the main body of the spraying equipment, and the annular body 2 is also rotated relative to the main body of the spraying equipment, and the centrifugal atomization The disc 1 and the annular body 2 are respectively driven and rotated by their corresponding motors. The annular body 2 is coaxial with the centrifugal atomizing disc 1 and rotates in opposite directions, and the annular body 2 and the centrifugal atomizing disc There is a distance 3 between the disks 1 in their radial direction;

[0060] The centrifugal atomizing disk 1 rotates to form a positive wind field around it, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com