Rare earth composite silicasol capable of repressing rice absorbing heavy metal

A technology of rare earth compounding and silica sol, which is applied in the fields of chemicals for biological control, animal repellents, botanical equipment and methods, etc. It can solve the problems of sol stability, large particle size, and complicated operation, etc. problems, to achieve the effect of clean production, mild conditions and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

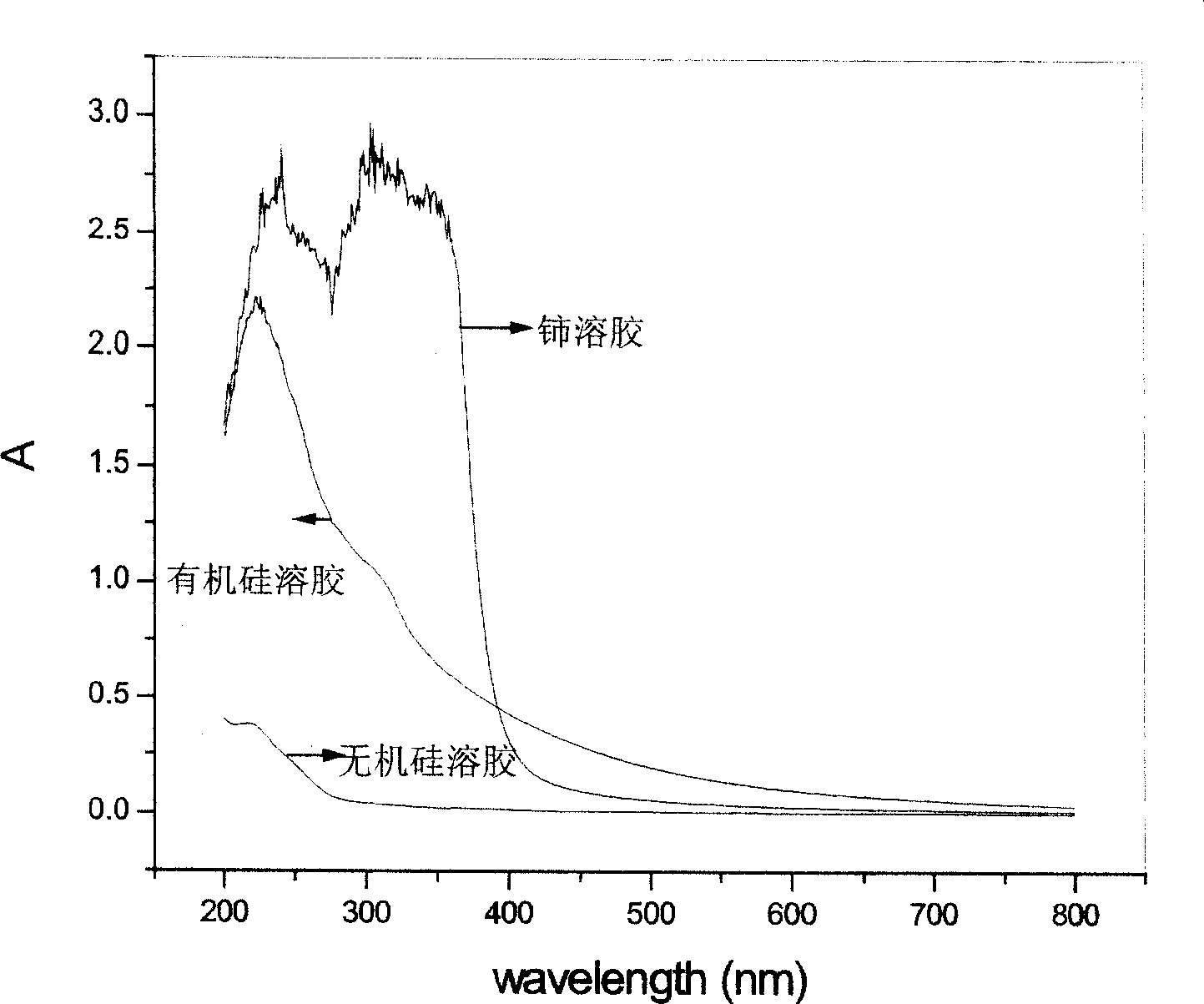

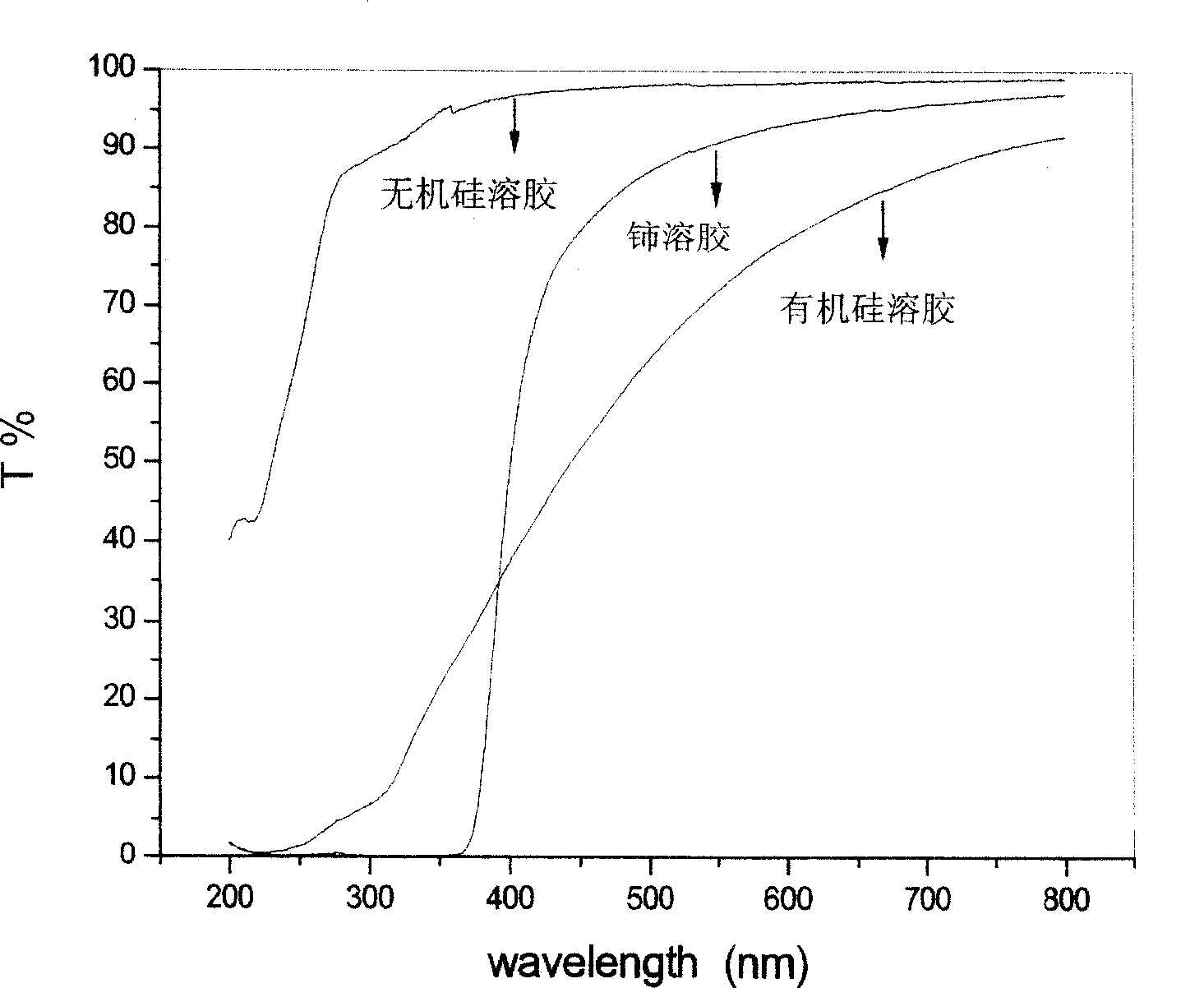

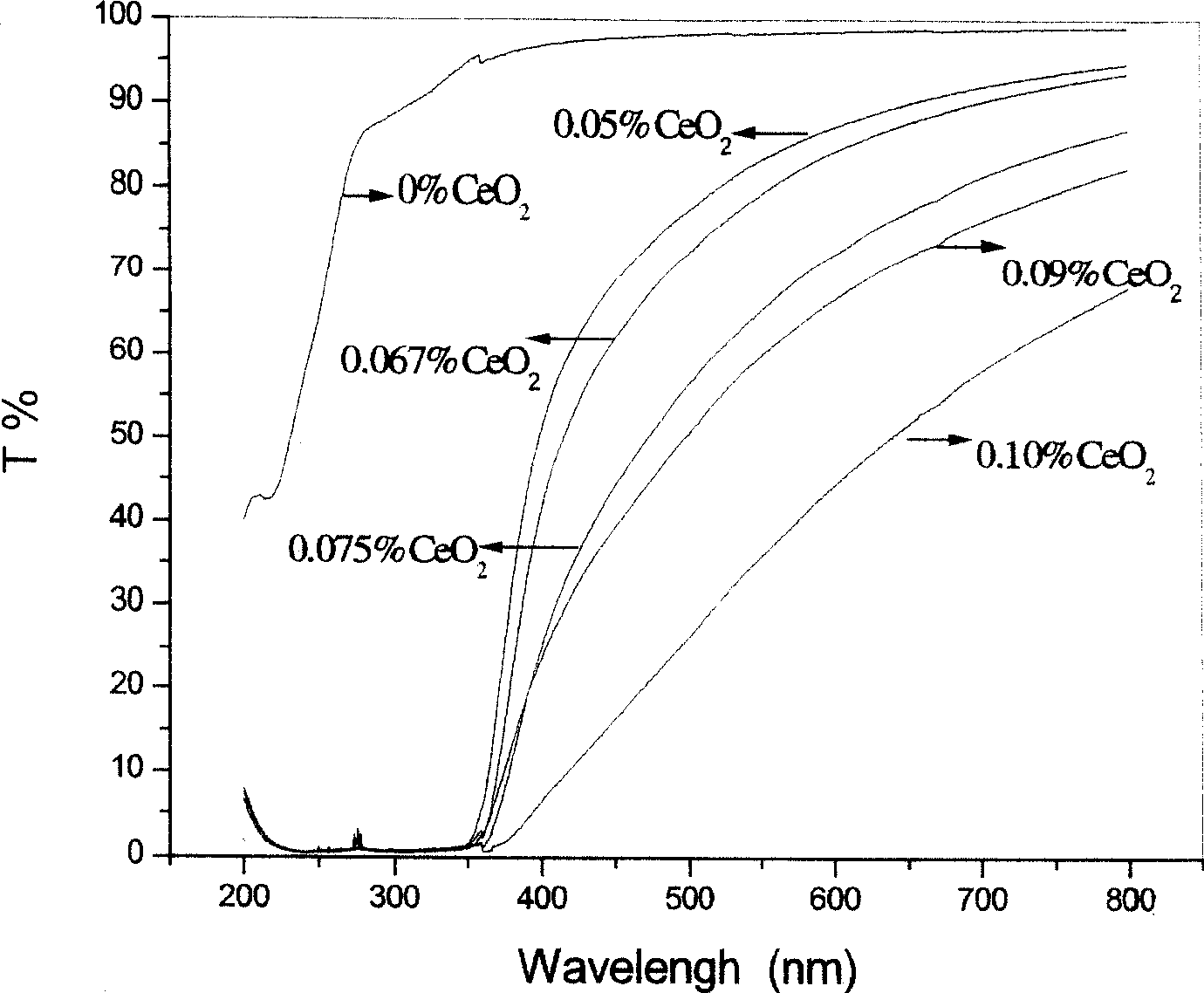

[0043] Example 1 Preparation of cerium-doped inorganic nano-silica sol with sodium silicate

[0044] Choose SiO 2 / Na 2 O sodium silicate with a molar ratio of 3 was prepared into 400 ml of a sodium silicate solution with a concentration of 10%, and magnetically stirred at a temperature of 30° C. for 2 h.

[0045] Measure 130ml of 10% hydrochloric acid and gradually add it dropwise in the separatory funnel. After the dropwise addition, the pH value of the solution is 9.5; % hydrochloric acid, the active silicic acid solution with a pH value of 2 can be obtained.

[0046] Prepare a potassium hydroxide solution with a concentration of 2% as a catalyst, heat it to 70°C with microwave stirring, add active silicic acid dropwise to it at a constant speed, control the pH value to 8, stop the dropwise addition, continue stirring for 75 minutes, and obtain a A stable transparent slightly alkaline high-purity nano-silica sol.

Embodiment 2

[0049] Example 2 Preparation of cerium-doped inorganic nano-silica sol by changing the method of preparing active silicic acid

[0050] Adopt the method for embodiment 1 to prepare 100ml of 10% sodium silicate solution, pass through 50ml (wet volume) hydrogen type strongly acidic cationic multi-stage resin exchange column at a uniform speed, control column outlet collection liquid pH value at 3, can obtain active silicic acid solution.

[0051] Prepare a potassium hydroxide solution with a concentration of 2% as a catalyst, heat it to 70°C with stirring in a water bath, add active silicic acid to it at a constant speed at a suitable rate, control the pH value to 8, stop the dropwise addition, continue to stir and react for 75 minutes, and complete the treatment A stable, transparent and slightly alkaline high-purity nano-silica sol is obtained.

[0052] Follow the steps of Example 1 to hydrolyze the precipitate, filter and wash, then add water to the filter cake and mix it ev...

Embodiment 3

[0054] Example 3 Preparation of cerium-doped organic nano-silica sol with tetraethyl orthosilicate

[0055] Measure 20ml of ammonia water with a concentration of 25-28%, add 10ml of high-purity water and 500ml of ethanol into a 1000ml self-made reactor, mix and stir evenly, heat to 45°C under water bath conditions, and then add 15ml of orthosilicon Ethyl acetate was added dropwise, and stirred for 3 hours after completion, and 10 milliliters of ethyl orthosilicate was added, and the reaction was continued for 3 hours, and the obtained product was diluted with 1000 milliliters of high-purity water, and the ethanol was removed by vacuum distillation and rotary evaporation, and then used a self-made dialysis device Dialyze until pH = 7 to obtain an organic nano-silica sol.

[0056] Follow the steps in Example 1 to hydrolyze the precipitate, filter and wash, then add water to the filter cake and mix evenly, add nitric acid with a concentration of 10%, adjust the pH to 1.0, stir at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com