Patents

Literature

39results about How to "Uniform crystal size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-sized particles, processes of making, compositions and uses thereof

InactiveUS20070140951A1Economical and efficientQuality improvementMaterial nanotechnologyToilet preparationsSolventPharmaceutical formulation

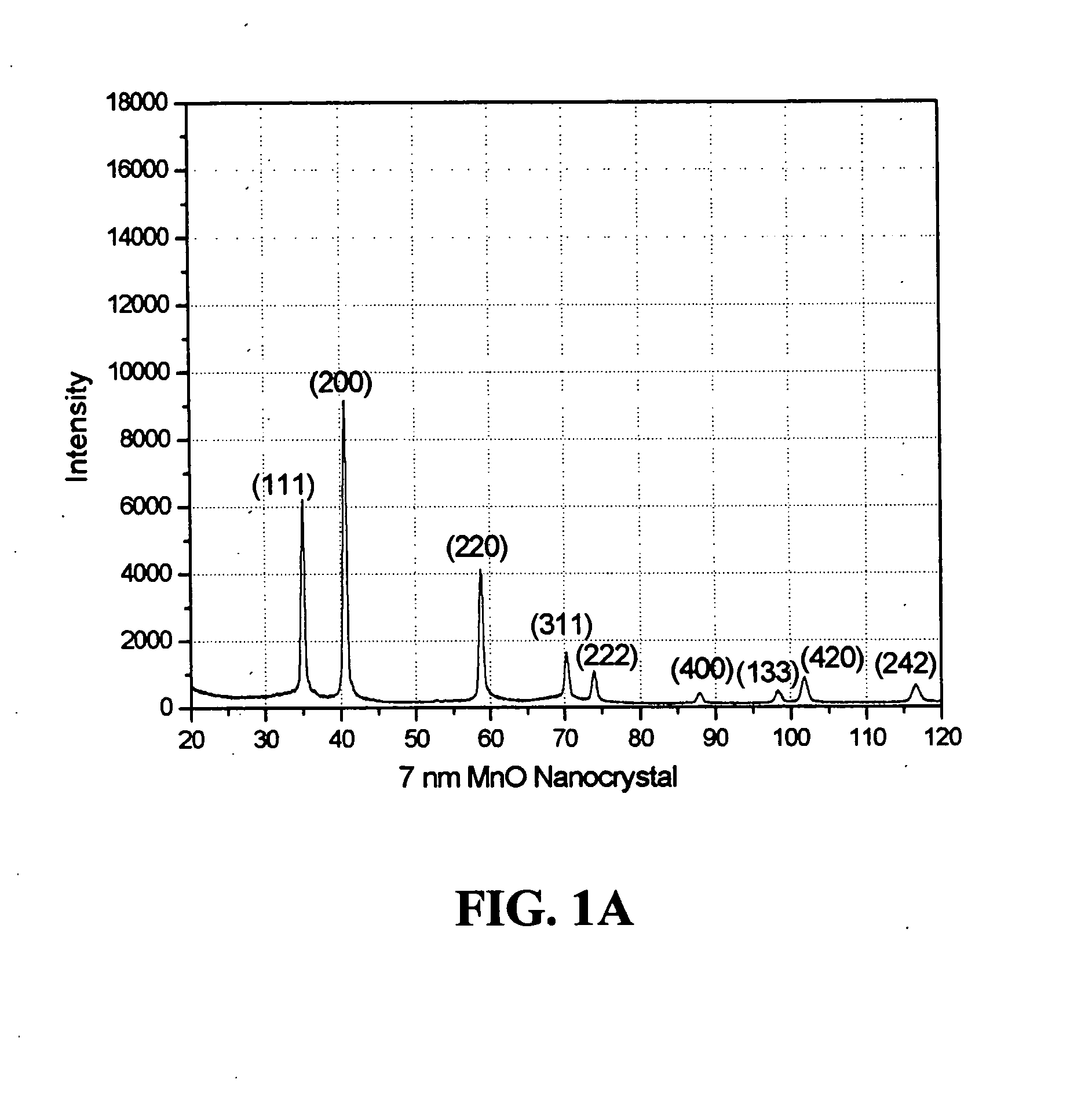

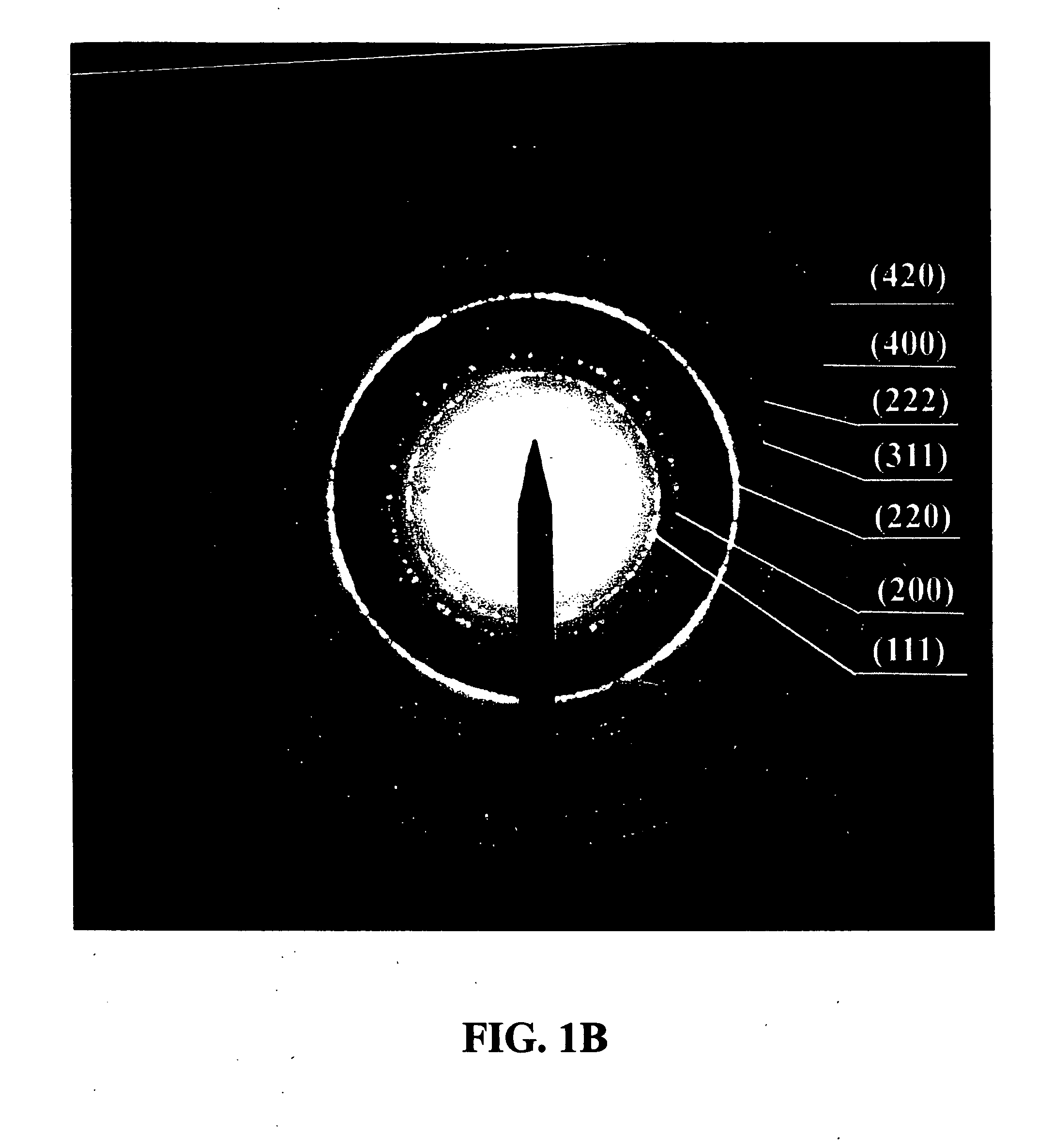

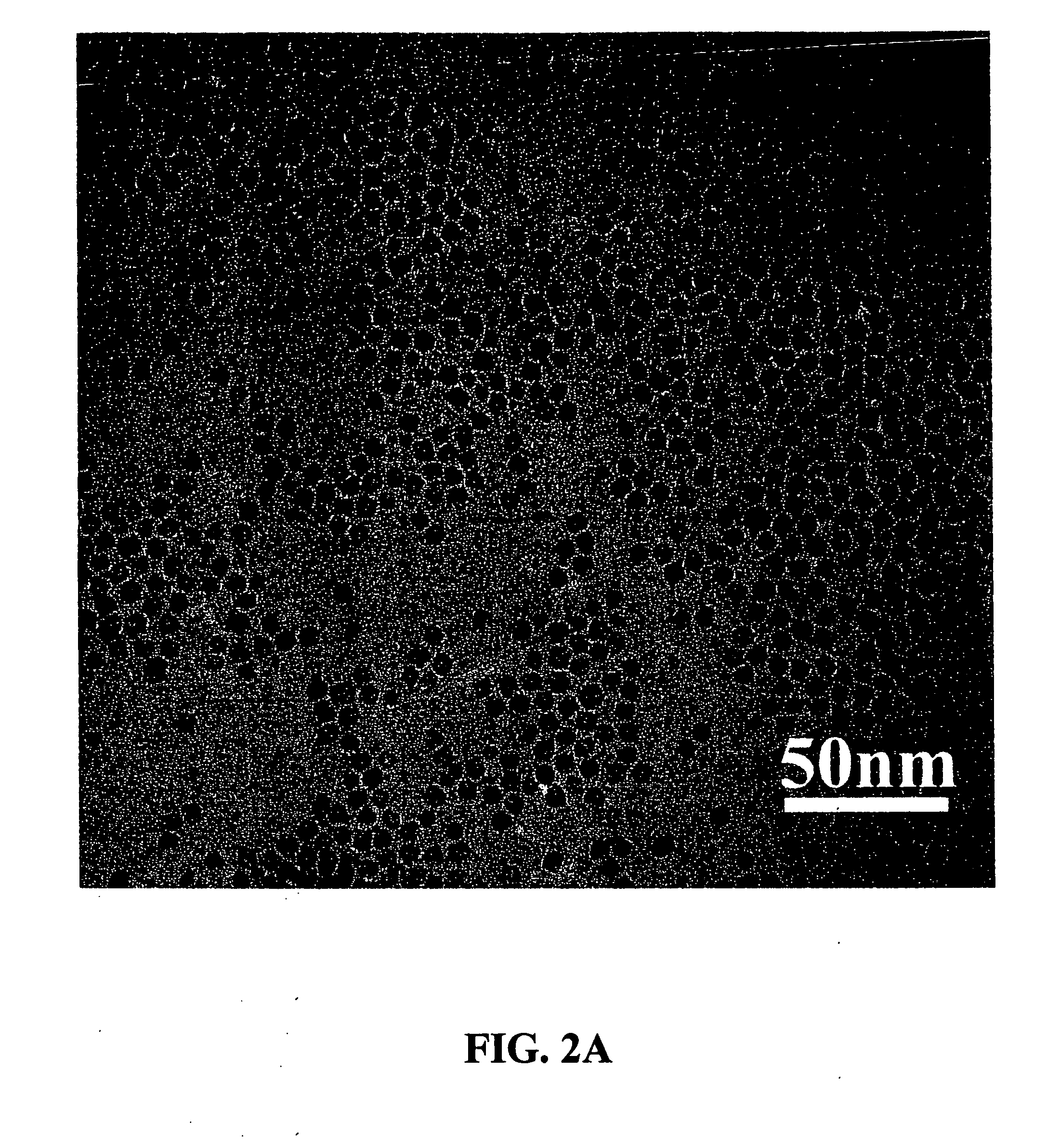

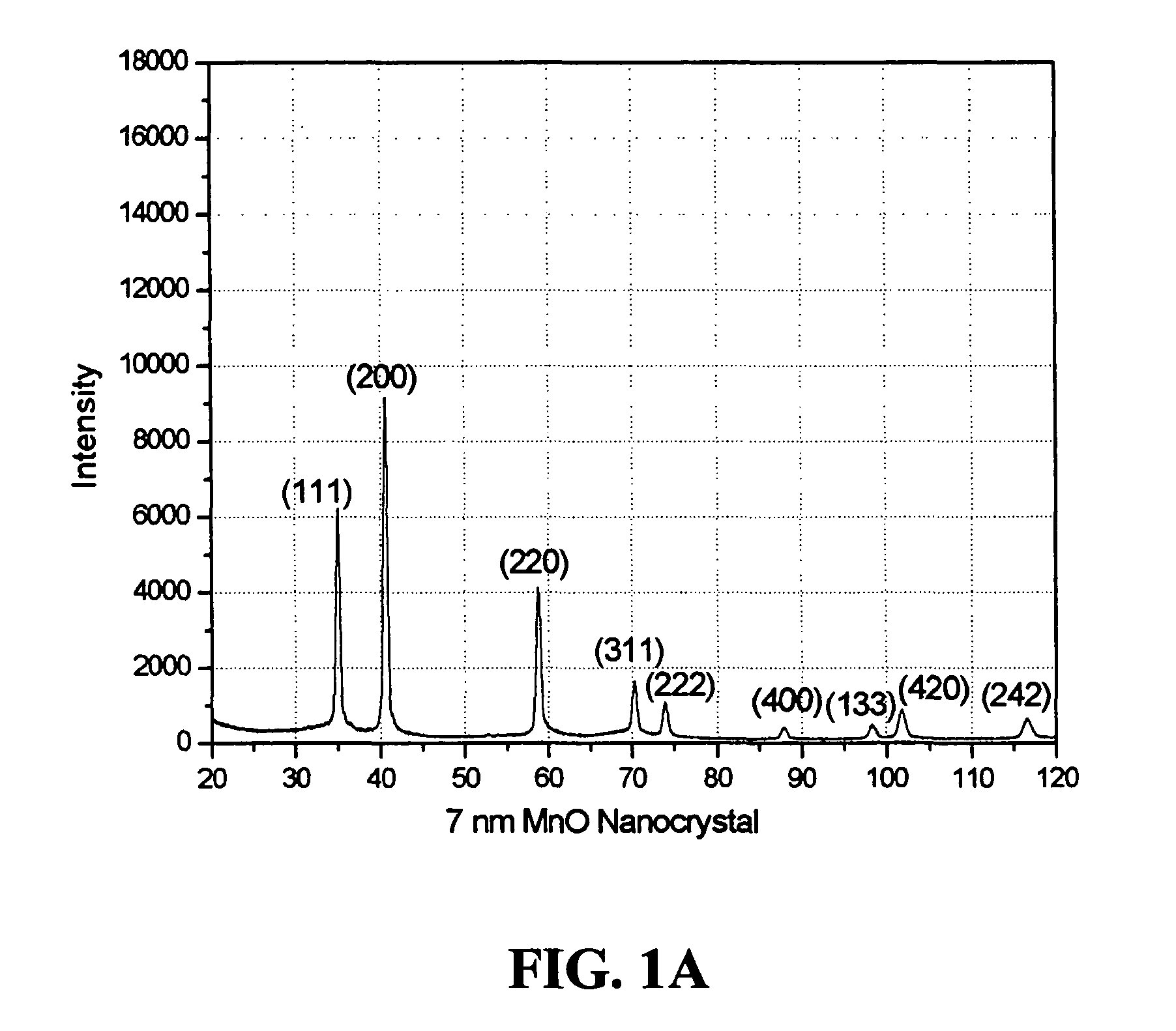

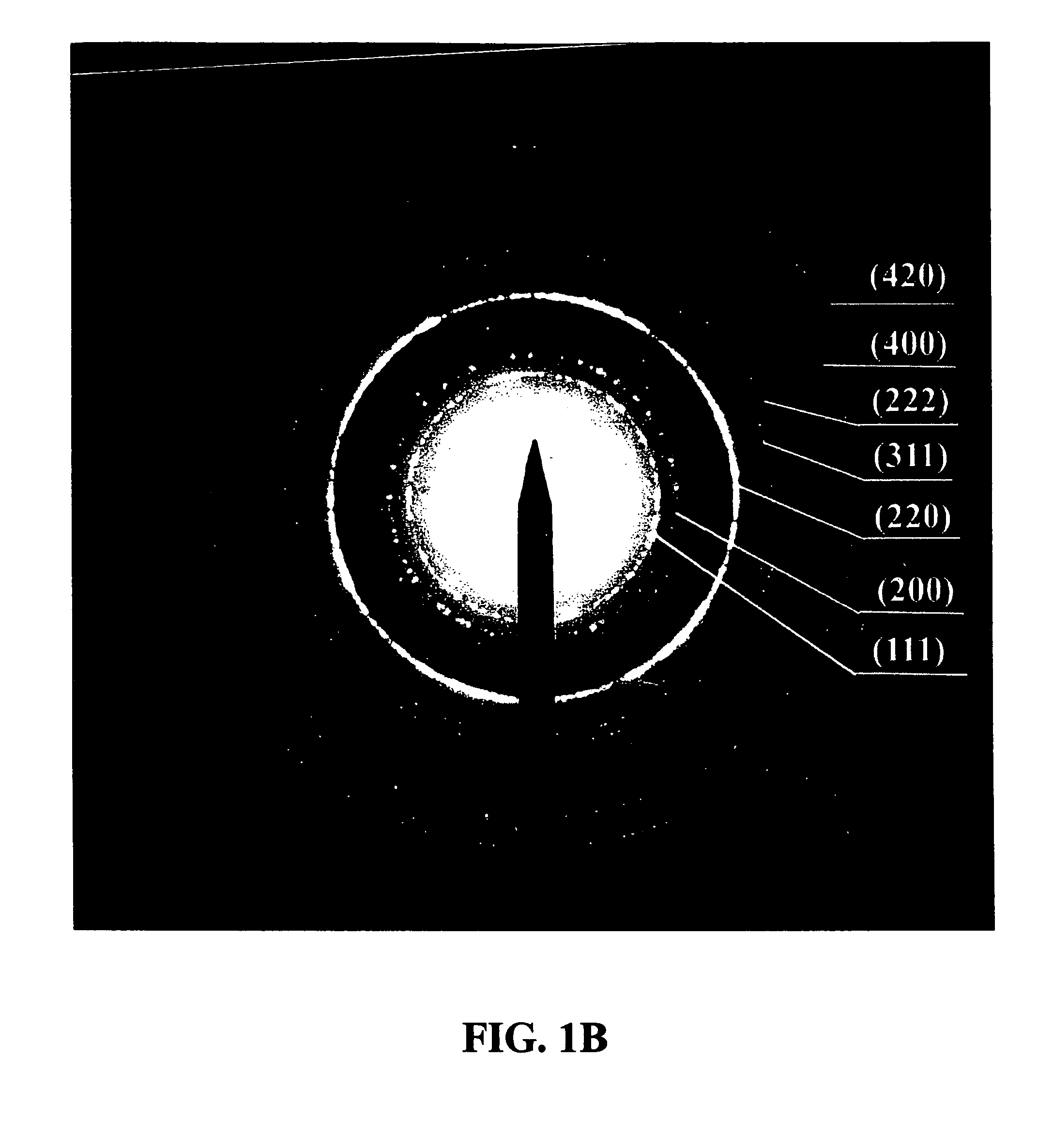

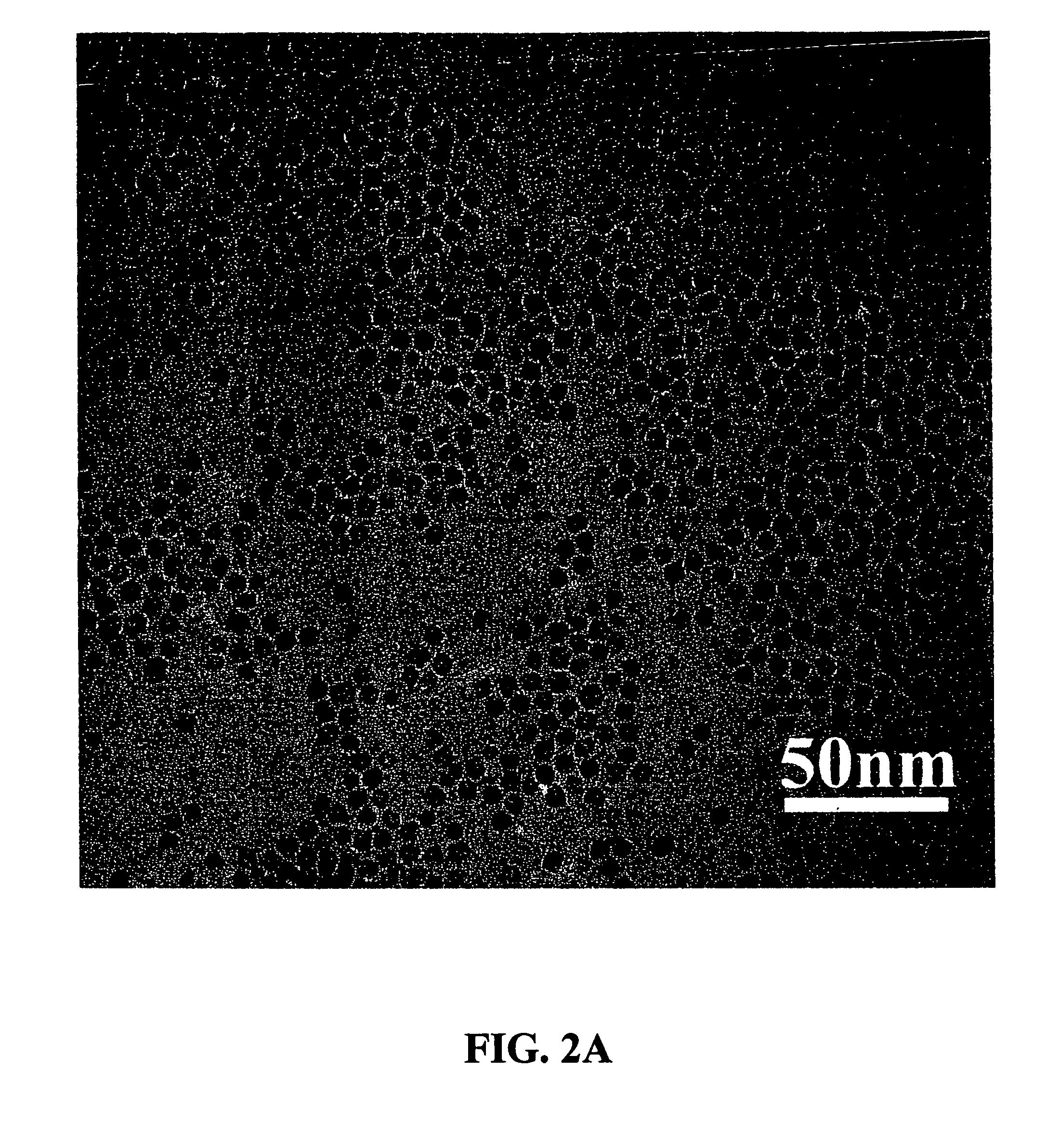

The present invention describes methods for preparing high quality nanoparticles, i.e., metal oxide based nanoparticles of uniform size and monodispersity. The nanoparticles advantageously comprise organic alkyl chain capping groups and are stable in air and in nonpolar solvents. The methods of the invention provide a simple and reproducible procedure for forming transition metal oxide nanocrystals, with yields over 80%. The highly crystalline and monodisperse nanocrystals are obtained directly without further size selection; particle size can be easily and fractionally increased by the methods. The resulting nanoparticles can exhibit magnetic and / or optical properties. These properties result from the methods used to prepare them. Also advantageously, the nanoparticles of this invention are well suited for use in a variety of industrial applications, including cosmetic and pharmaceutical formulations and compositions.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Nano-sized particles, processes of making, compositions and uses thereof

InactiveUS8182786B2Economical and efficientEfficiently tailoredMaterial nanotechnologyToilet preparationsSolventPharmaceutical formulation

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Method for producing natural bornite products

The invention relates to a production method of natural mottled copper products, belonging to the technical field of metallic material processing. The inventive method comprises the steps of sculpturing and molding, mould fabrication, molten mould duplication, pattern die fabrication, demoulding, smelting, casting, secondary crystallization, forging molding, polishing, sintering, mottle formation, dyeing, inspection and packaging, wherein the smelting step comprises: (a) directly adding metal elements (including Si, Al, Pb, Sb, S, Na, Ba, Ag, Mg, Zn, P and B) into the molten liquid of natural mottled copper when the smelting temperature reaches 1100-1280 DEG C, the usage amount of Zn being 1-10 percent and the rest 0.5-5 permillage; (b) the secondary crystallization and forging molding steps are added following the casting step. The other steps and operational conditions of the inventive method are the same as the prior art. Compared with the prior art, the invention has the advantages of delicate appearance, multi-crystalline property and uniform size of crystal type, good three-dimensional effect, and improved quality of natural mottled copper products.

Owner:张建中

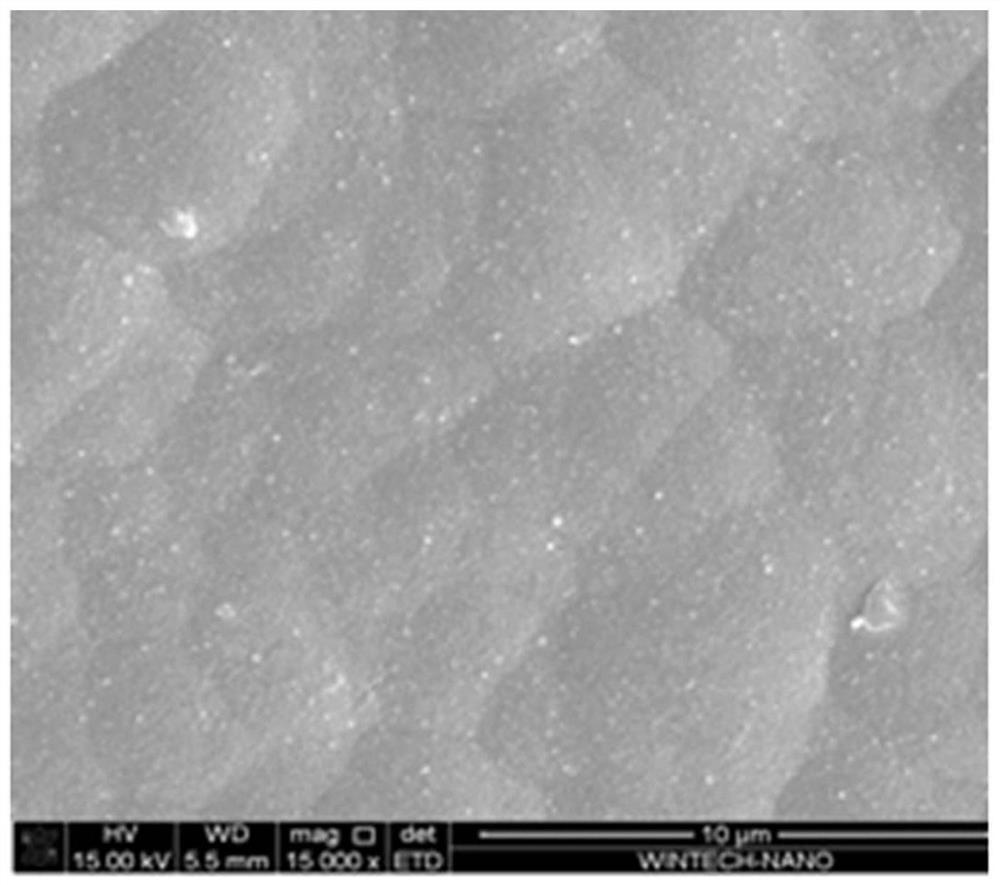

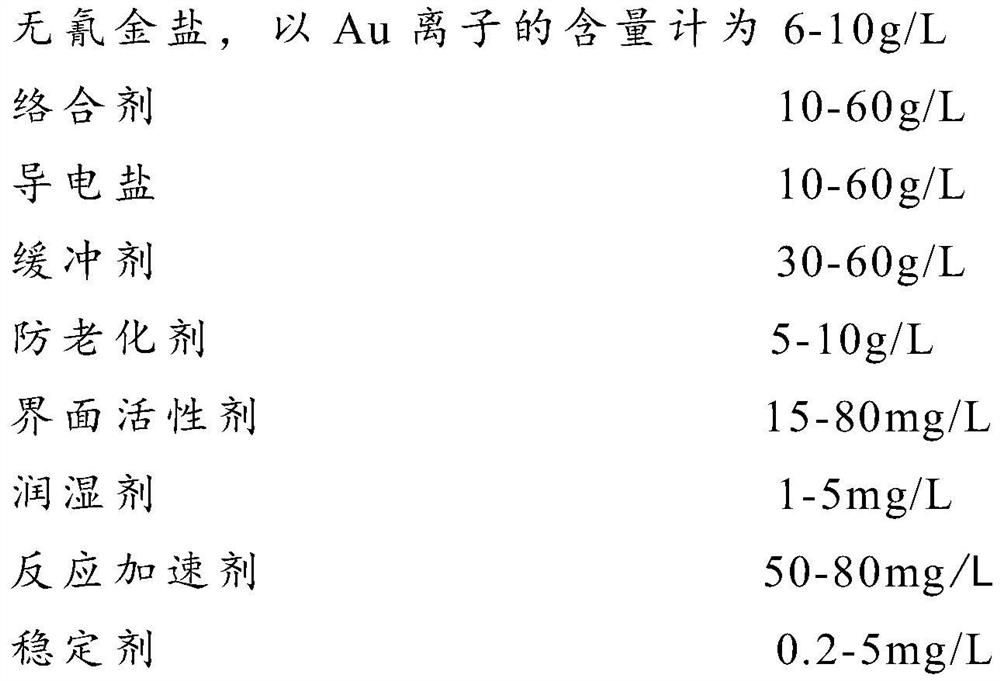

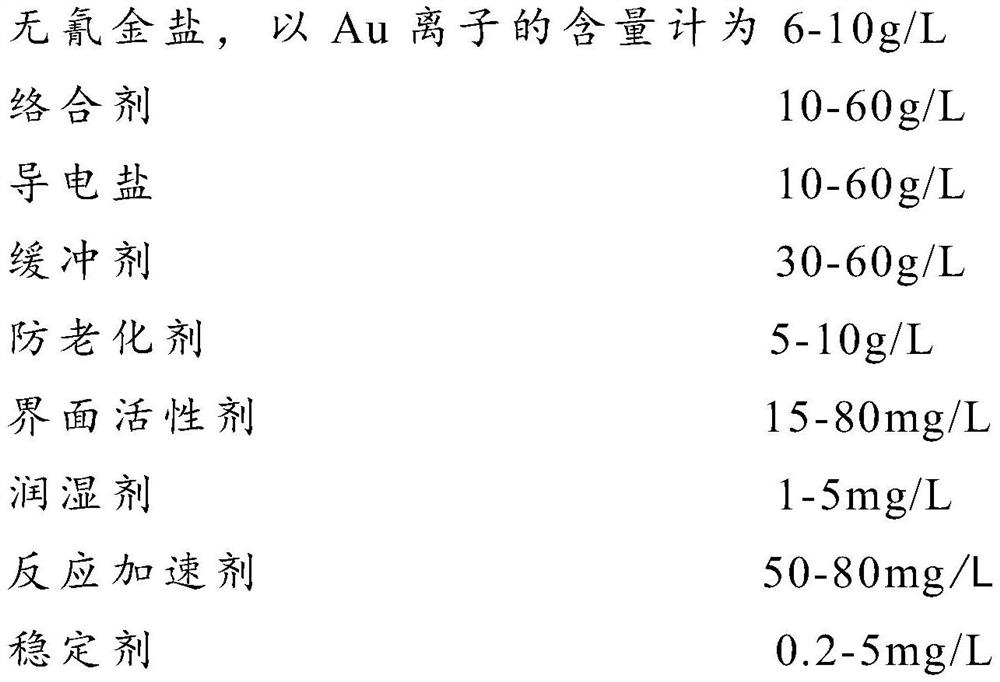

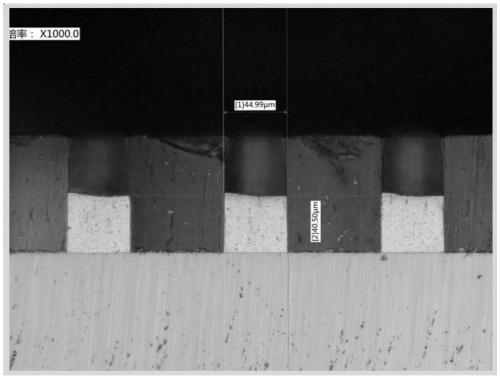

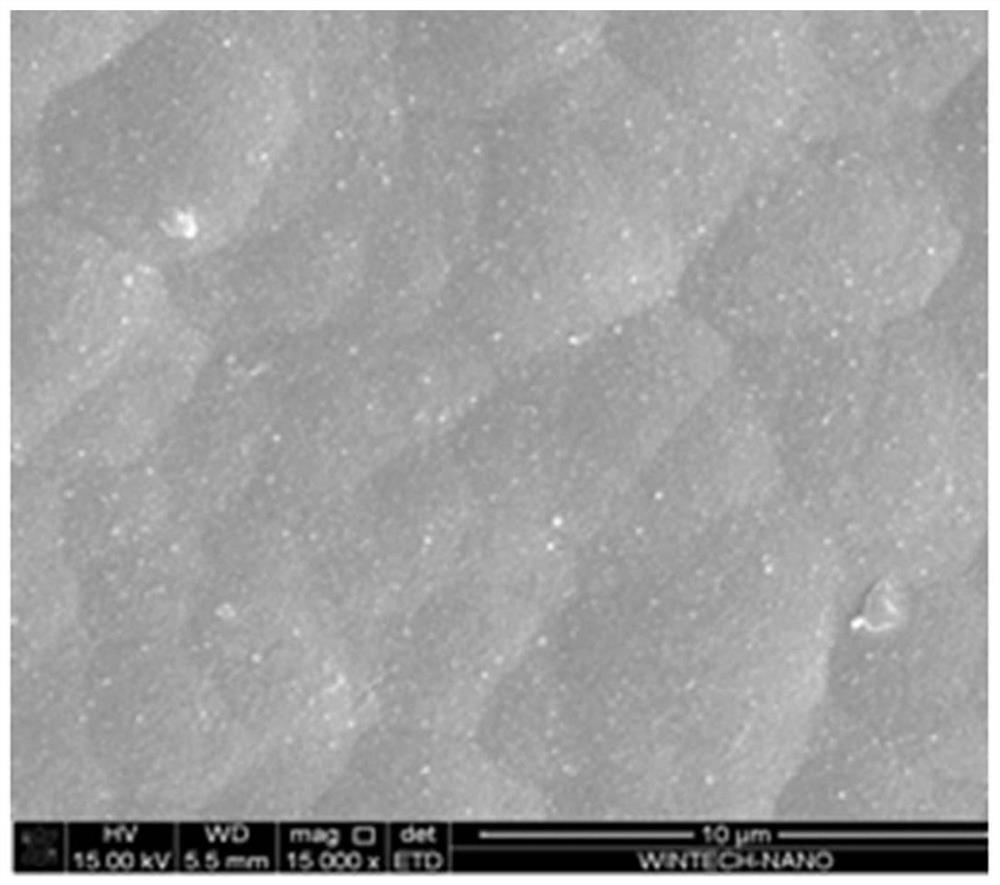

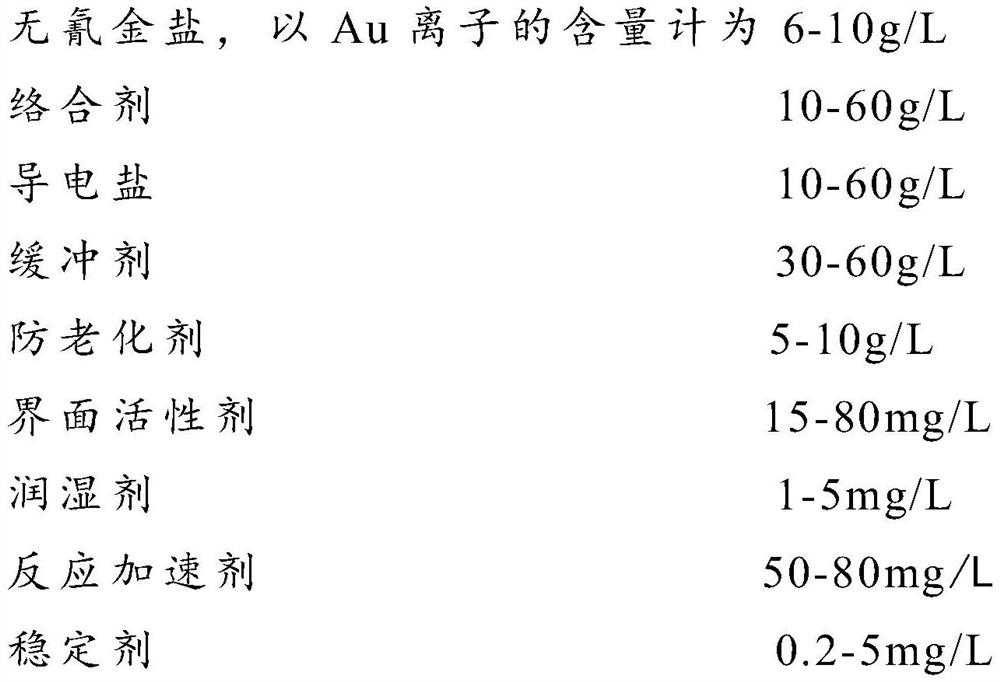

Cyanide-free chemical gold plating solution applied to advanced wafer packaging field and gold plating process thereof

ActiveCN113026068AAvoid narrow operating rangesSpeed up the activation reactionCellsSemiconductor devicesCyanideActive agent

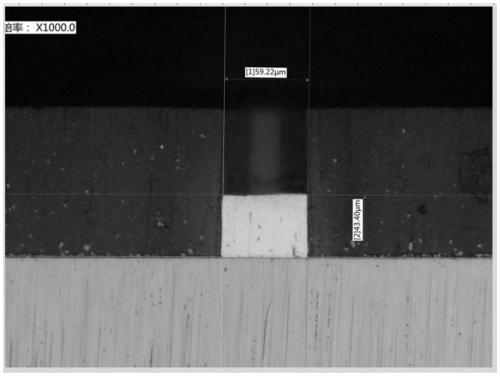

The invention discloses a cyanide-free chemical gold plating solution applied to the advanced wafer packaging field and a gold plating process thereof. The cyanide-free chemical gold plating solution is prepared from the following components: cyanide-free gold salt with the content of Au ions being 6-10 g / L, 10-60 g / L of a complexing agent, 10-60 g / L of conductive salt, 30-60 g / L of a buffer agent, 5-10 g / L of an anti-aging agent, 15-80 mg / L of an interfacial agent, 1-5 mg / L of a wetting agent, 50-80 mg / L of a reaction accelerator, and 0.2-5 mg / L of a stabilizer, wherein the reaction accelerator is a compound of 2,6-diaminopyridine and 3-pyridine methanol, and the mass concentration ratio of the 2,6-diaminopyridine to the 3-pyridine methanol is 2:1. The solution not only ensures the stability of the plating solution, but also enables a plated part to be easily spread on the surface of an electrode so as to achieve the purpose of uniform plating, and therefore the effect of void-free and seamless filling of wafer packaging micropores is further achieved.

Owner:SHENZHEN CHENGGONG CHEM

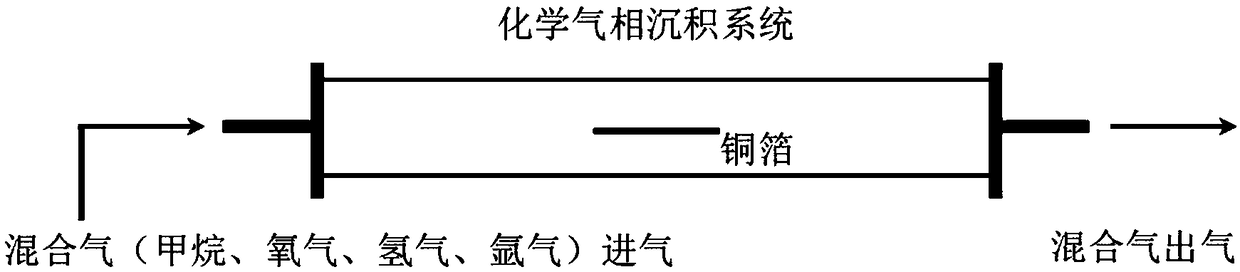

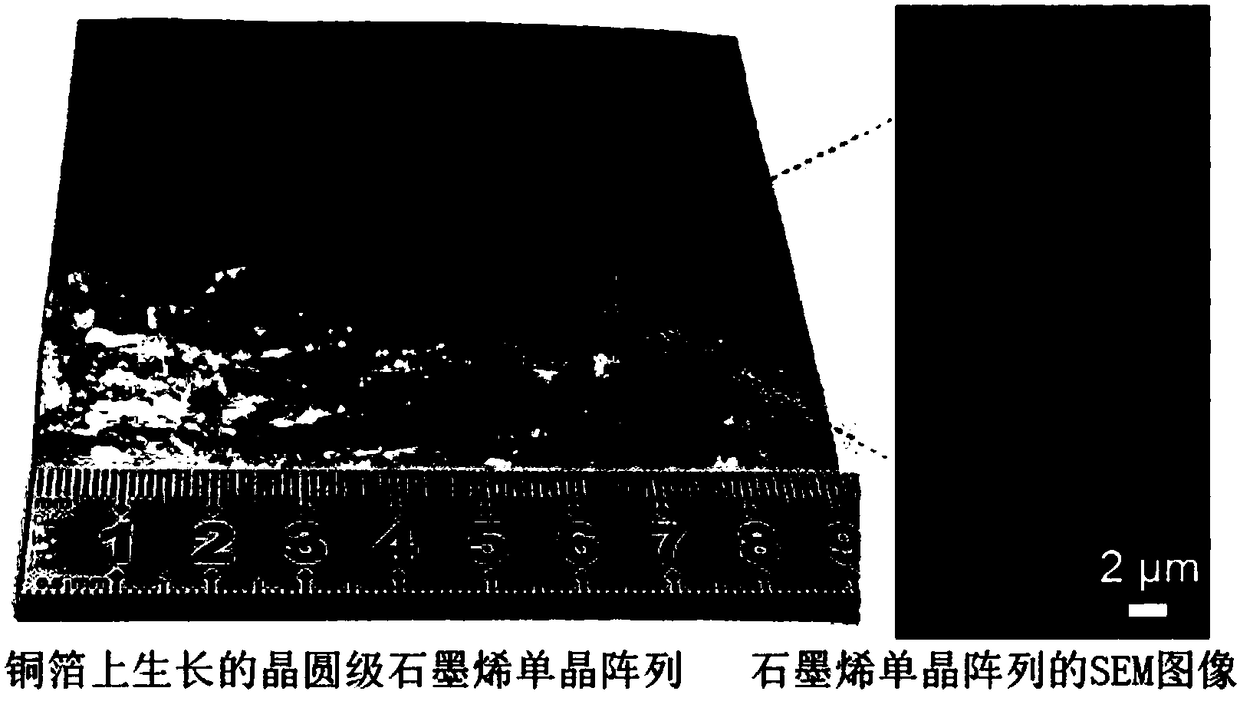

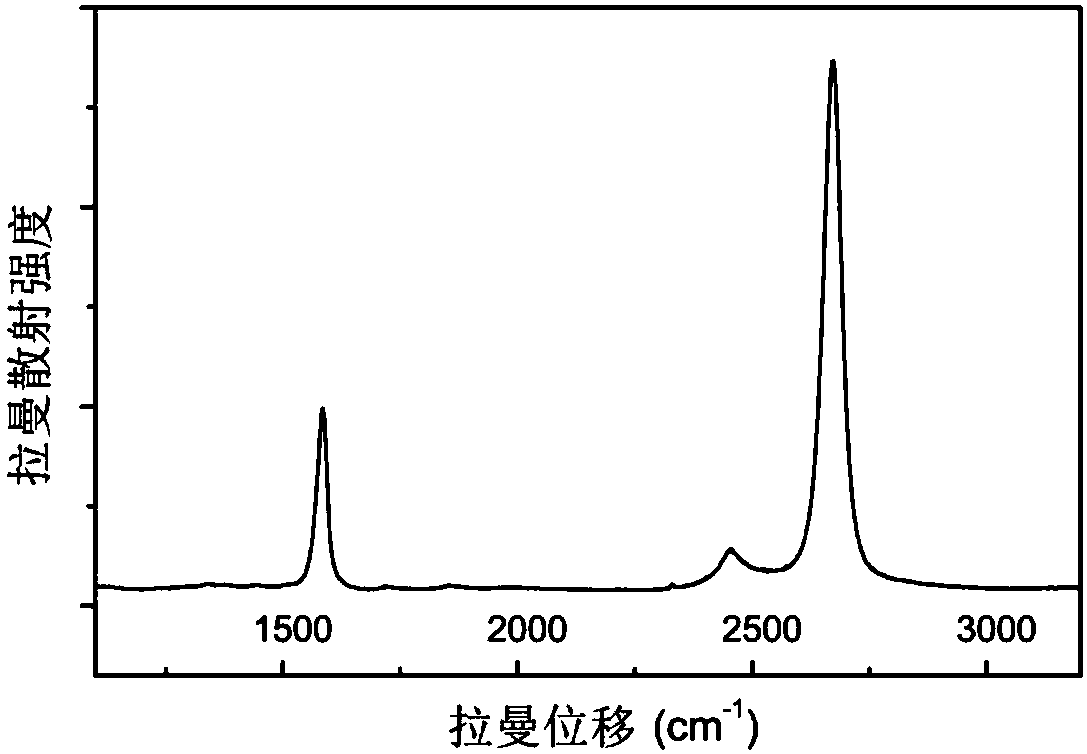

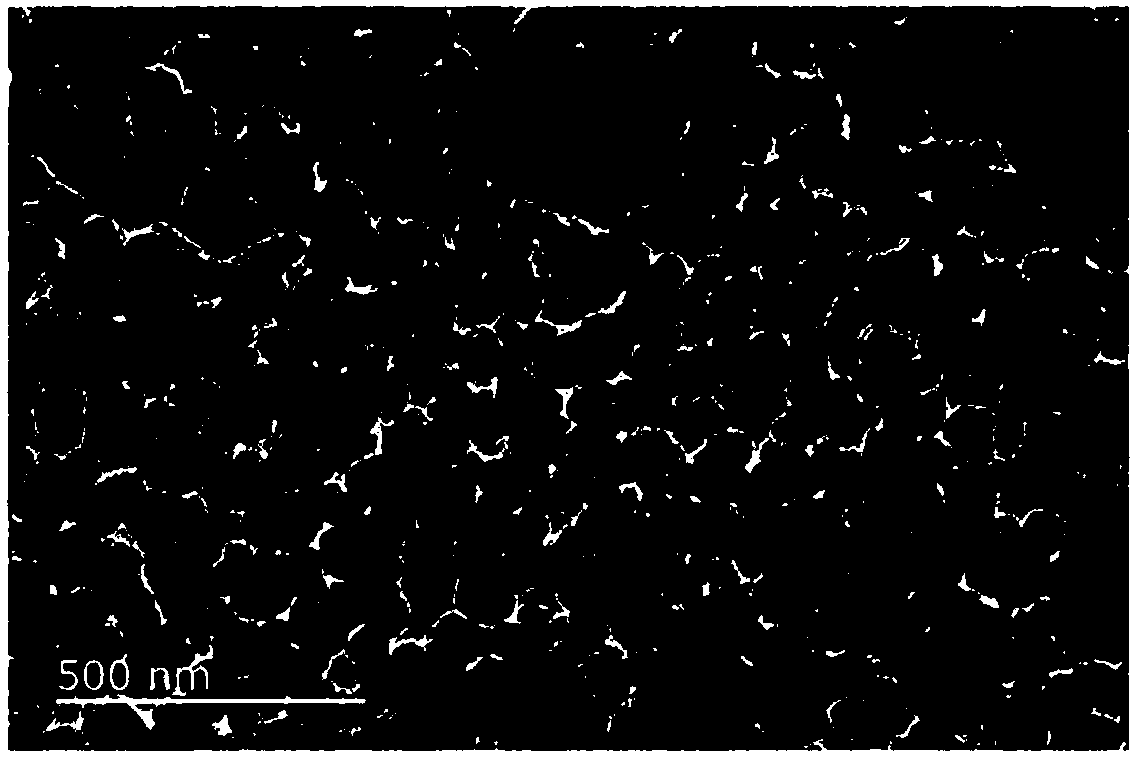

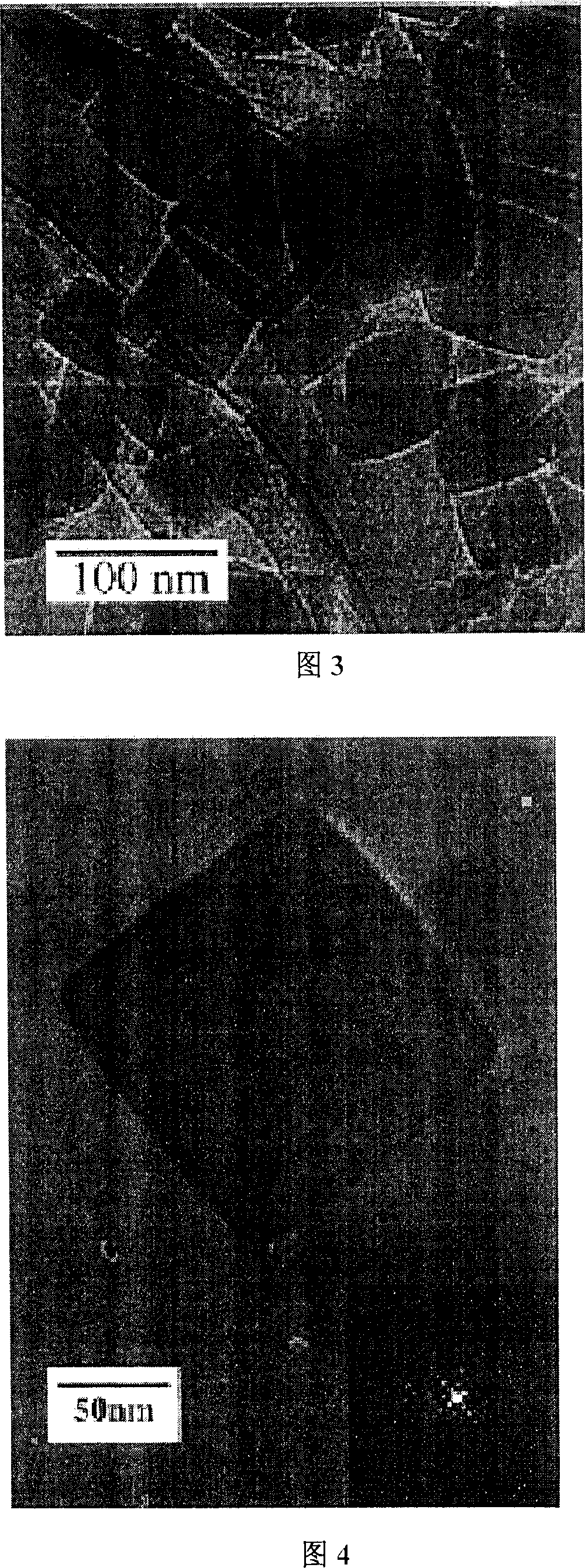

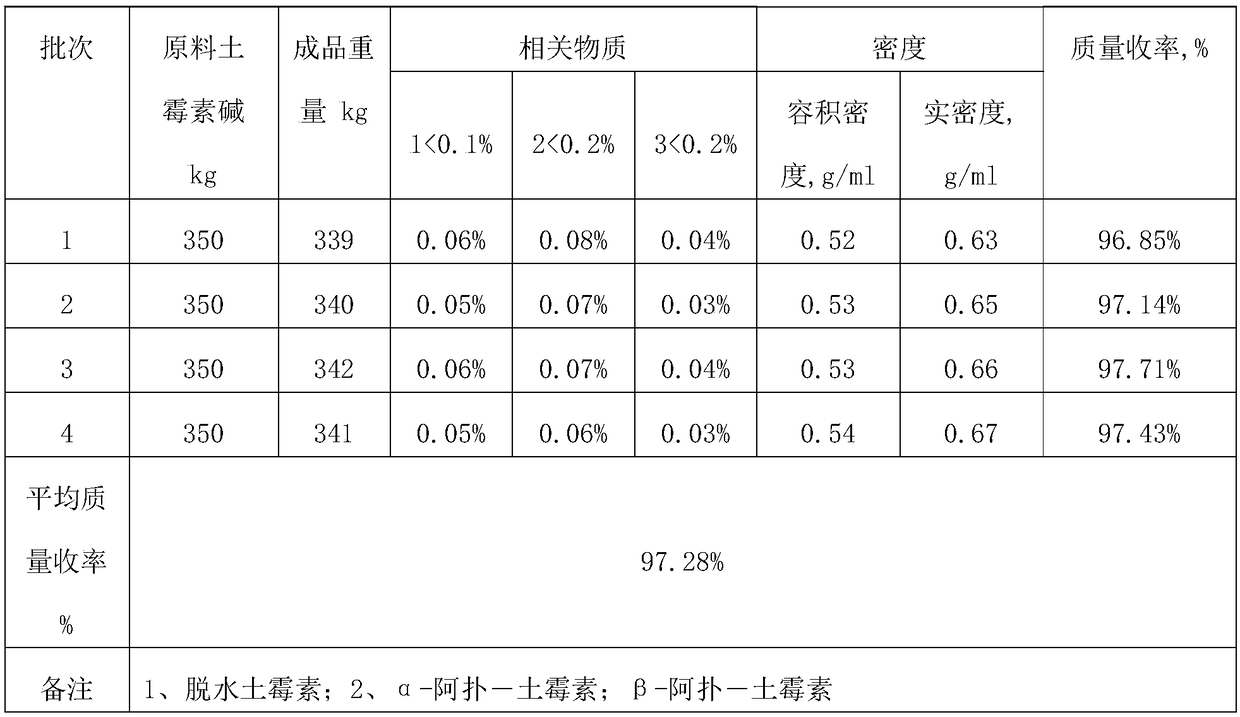

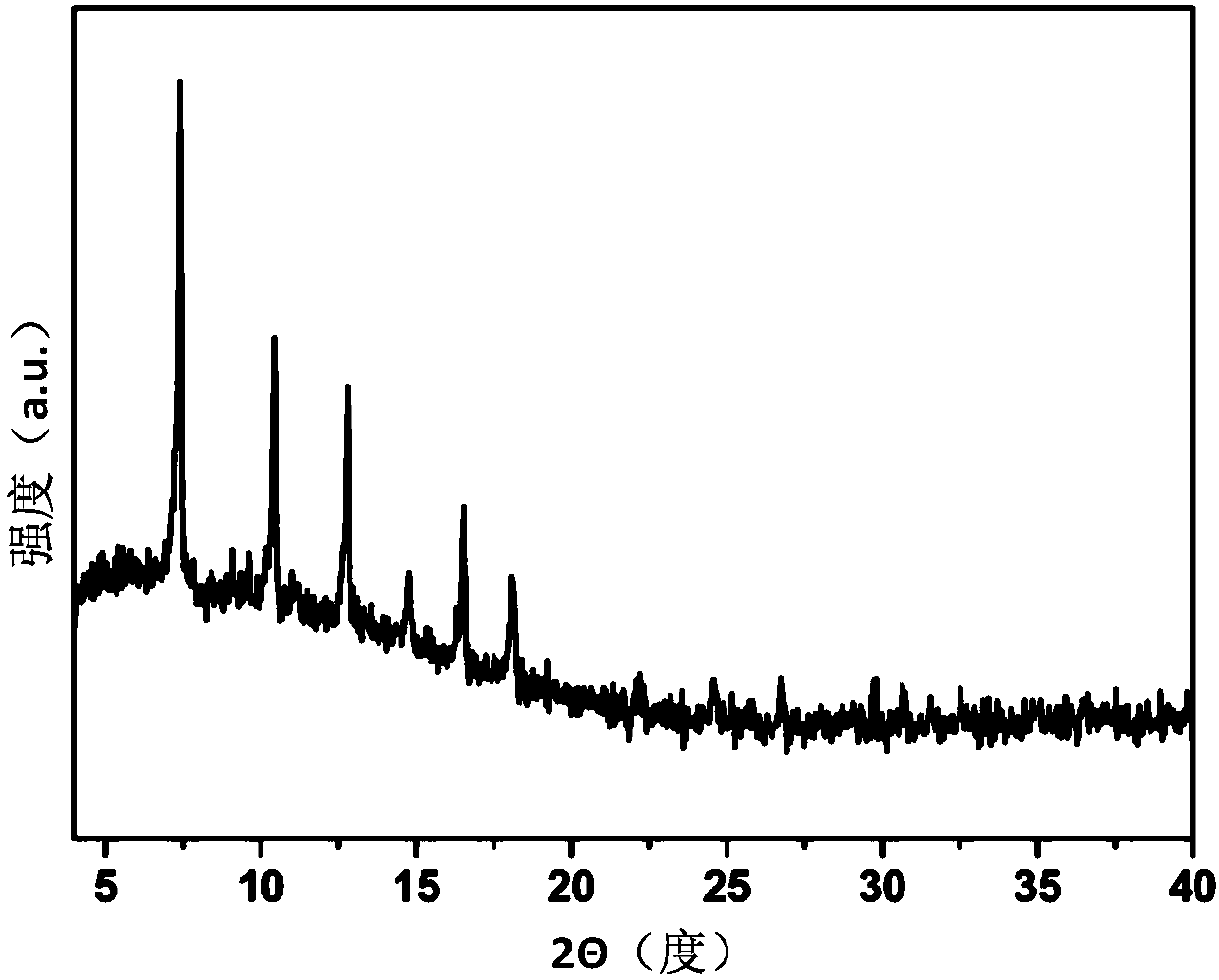

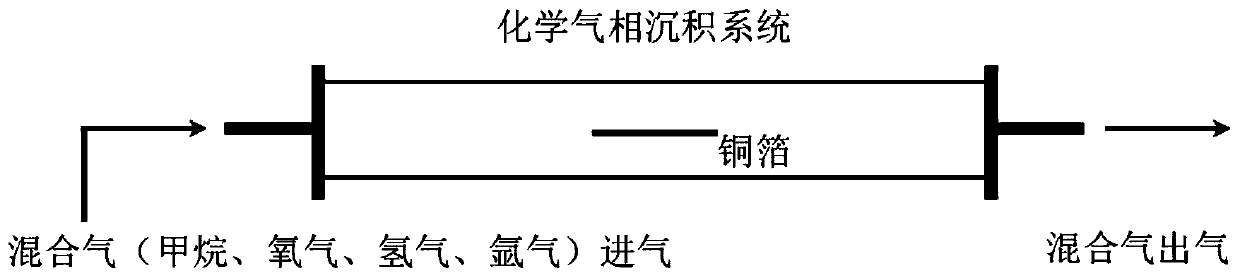

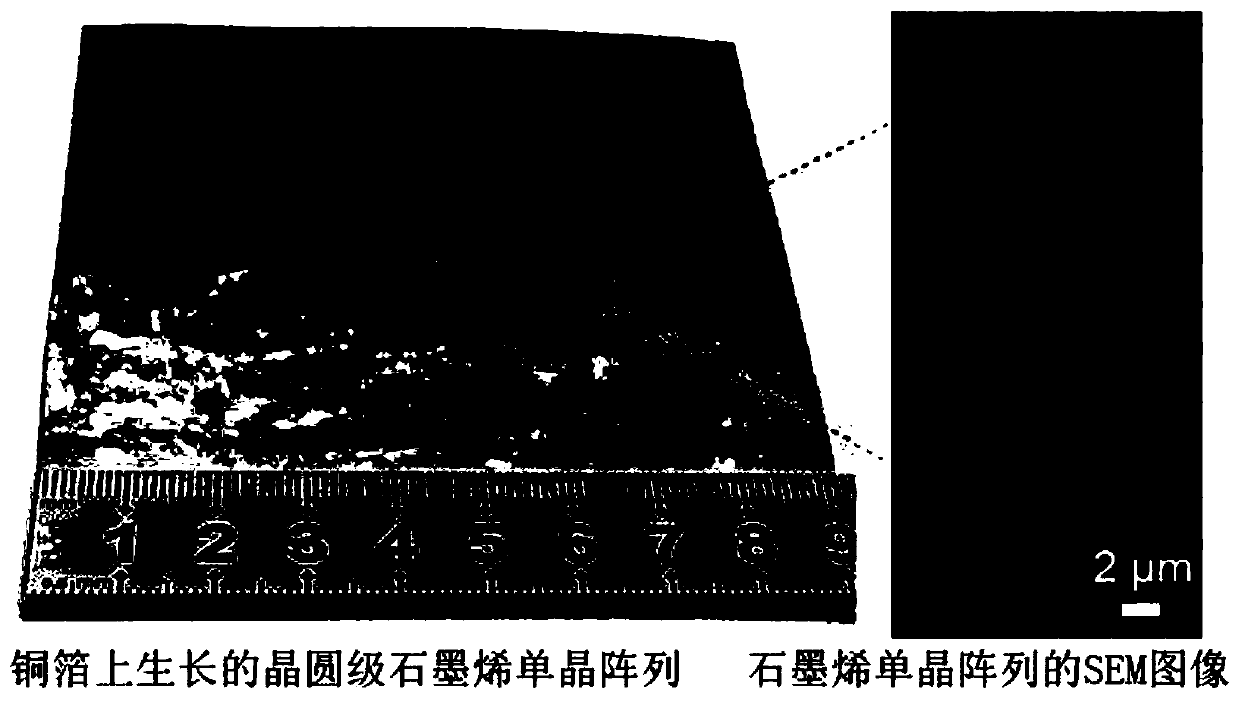

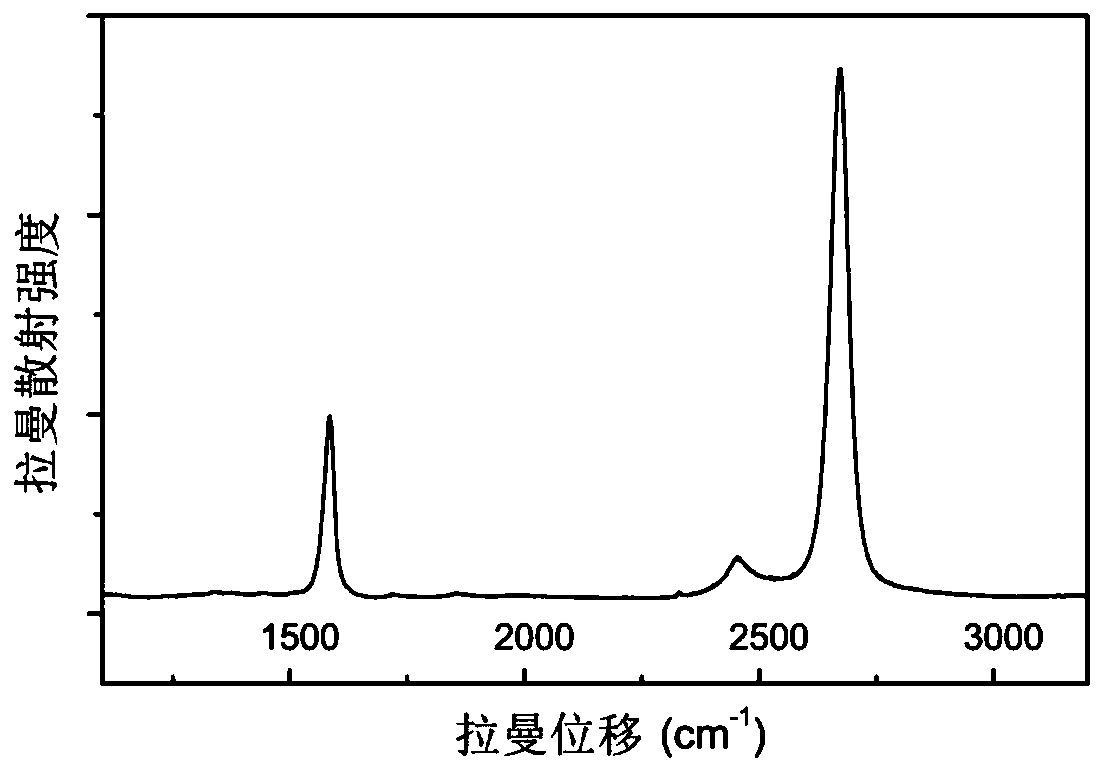

Preparation method of wafer level graphene micro-nano monocrystal array

InactiveCN108441948AUniform crystal sizeSingle crystal size continuous controlPolycrystalline material growthFrom chemically reactive gasesMicro nanoMaterial synthesis

The invention belongs to the technical field of graphene material synthesis and preparation and more particularly relates to a preparation method of a wafer level graphene micro-nano monocrystal array. The method comprises the steps of performing chemical vapor deposition on the surface of polycrystal copper foil in a mixed atmosphere containing methane and oxygen for growth to form the graphene micro-nano monocrystal array, wherein methane serves as a carbon source for graphene growth; the copper foil serves as a catalytical substrate for the graphene growth; and the oxygen serves as etchinggas in a formation process of the graphene monocrystal array. According to the method, a graphene array structure is directly prepared by a simple one-step chemical vapor deposition method; the disadvantage of complicated steps of complicated micro-nano machining, etching and the like required by a graphene film in a subsequent application is overcome; quick and low-cost preparation of a large area micro-nano graphene monocrystal is achieved; and the application in large-scale device preparation is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of sodium acetate

InactiveCN103833543ABest ratioRelaxed process conditionsOrganic compound preparationCarboxylic acid salt preparationSodium acetateGranularity

The invention discloses a preparation method of sodium acetate. According to the preparation method, optimal reactant ratio is determined based on researches on sodium acetate synthesis and crystallization technology, strong alkaline liquid filtration is not needed, condensation or proportion adjustment is not needed, conventional sample equipment is adopted, heating is not needed by technical processes, technical conditions are mild and stable, and requirements on equipment are low. Quality of obtained products is capable of meeting with requirements of Chinese pharmacopoeia 2010 and reagent grade standards; crystal size is uniform; yield is high; the preparation method is suitable for GMP industrial production of pharmaceutic adjuvants, and food-grade and reagent-grade industrial production.

Owner:TIANJIN KERMEL CHEM REAGENT

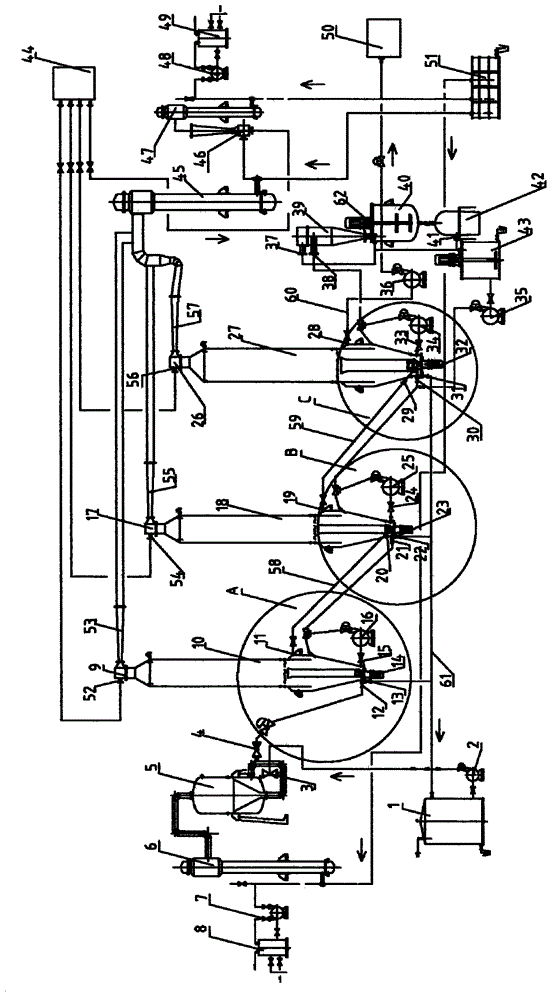

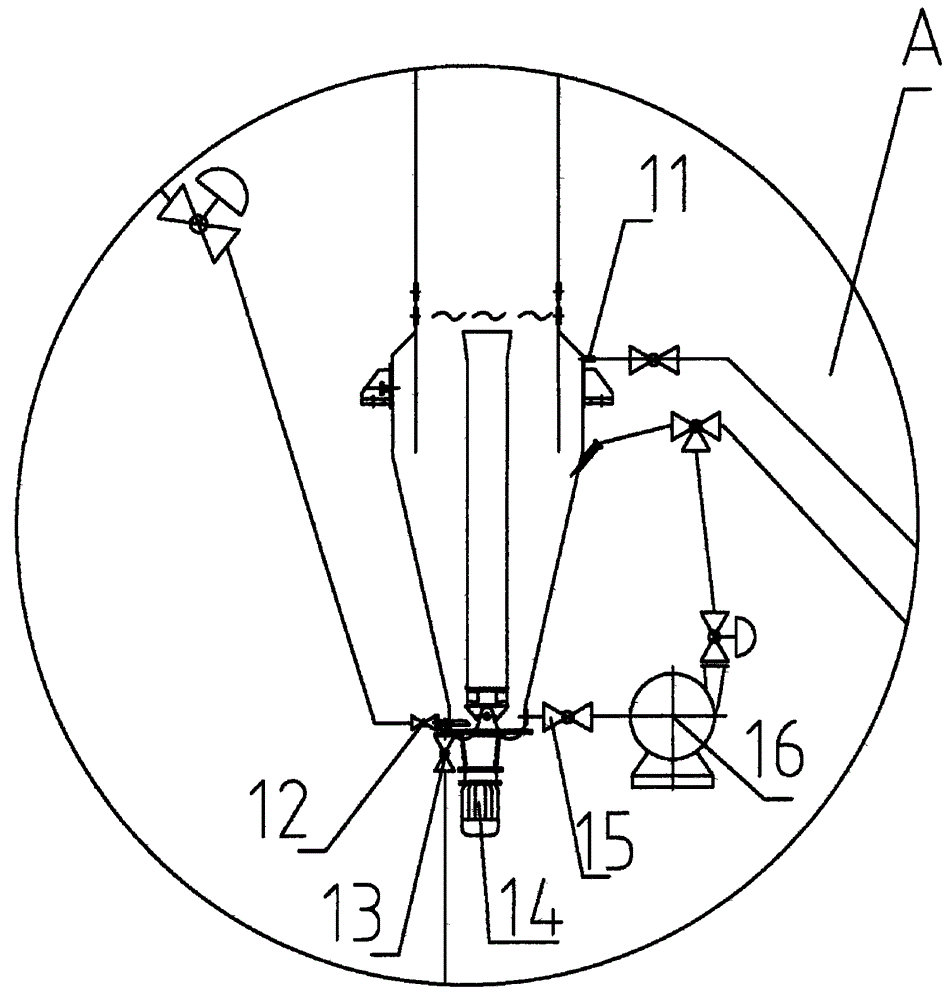

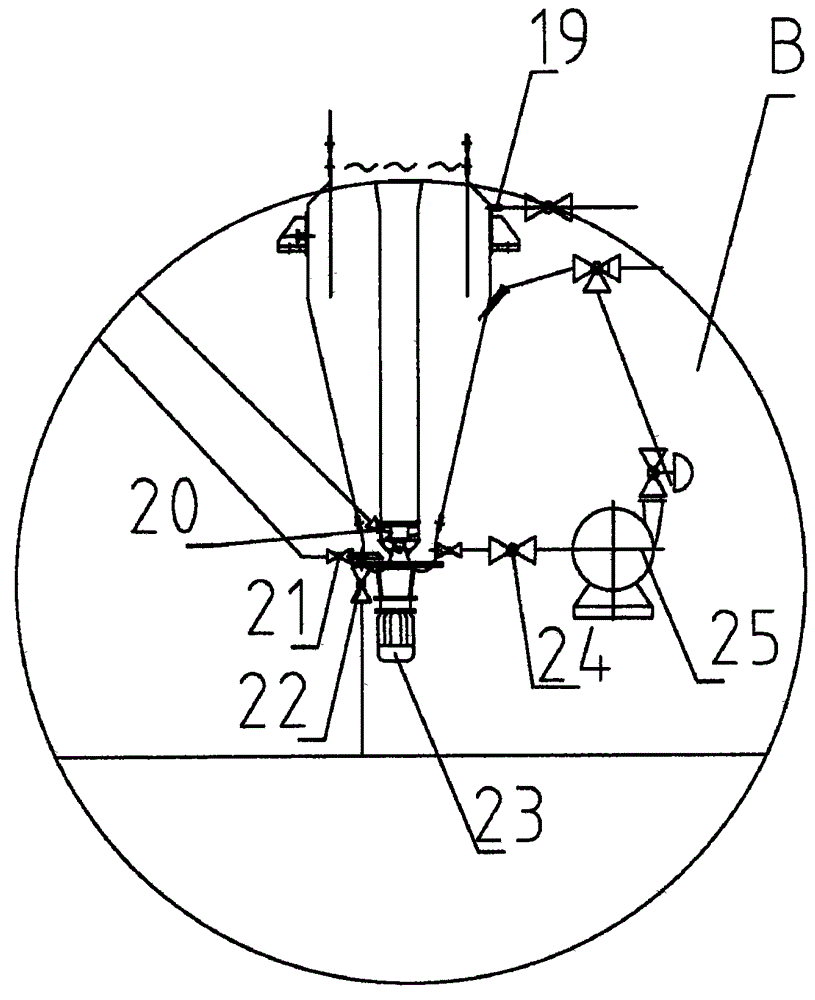

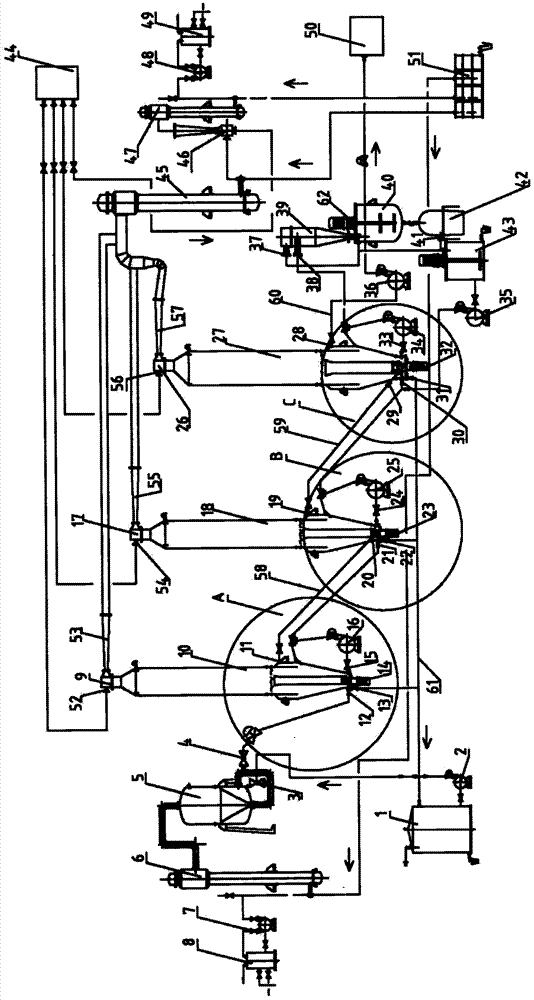

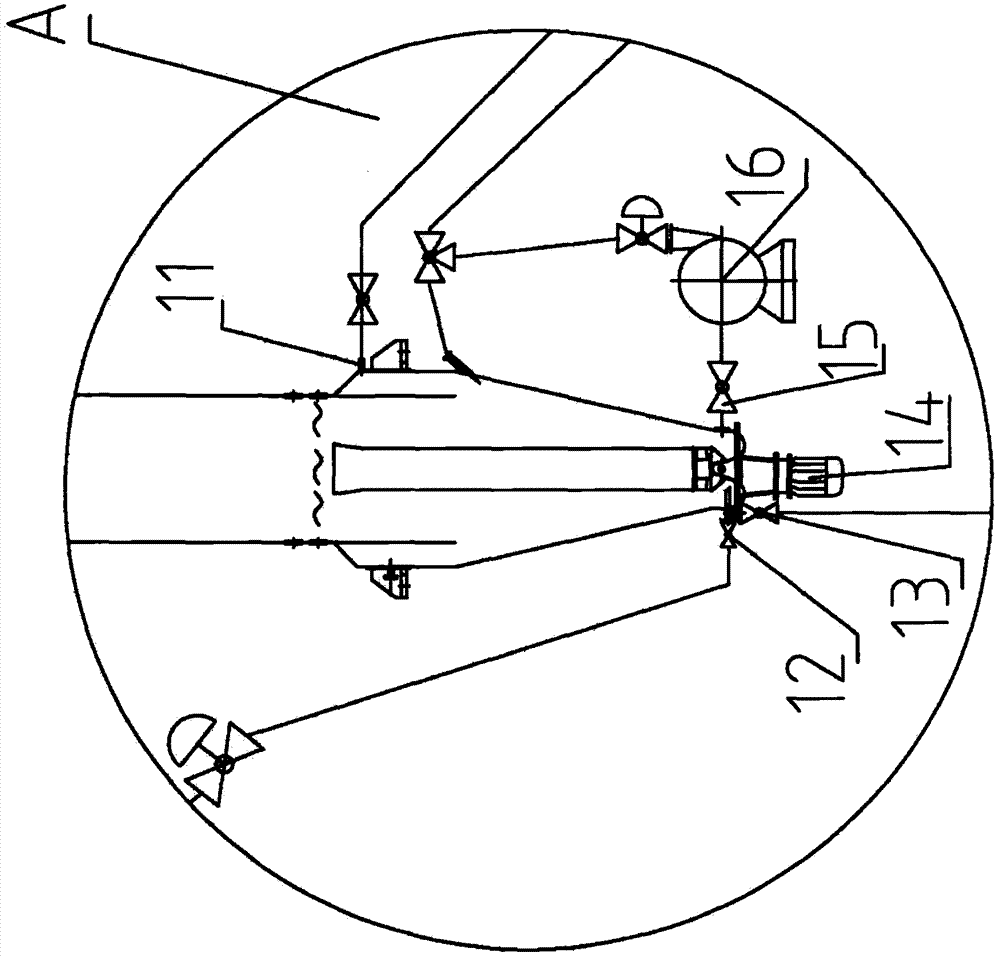

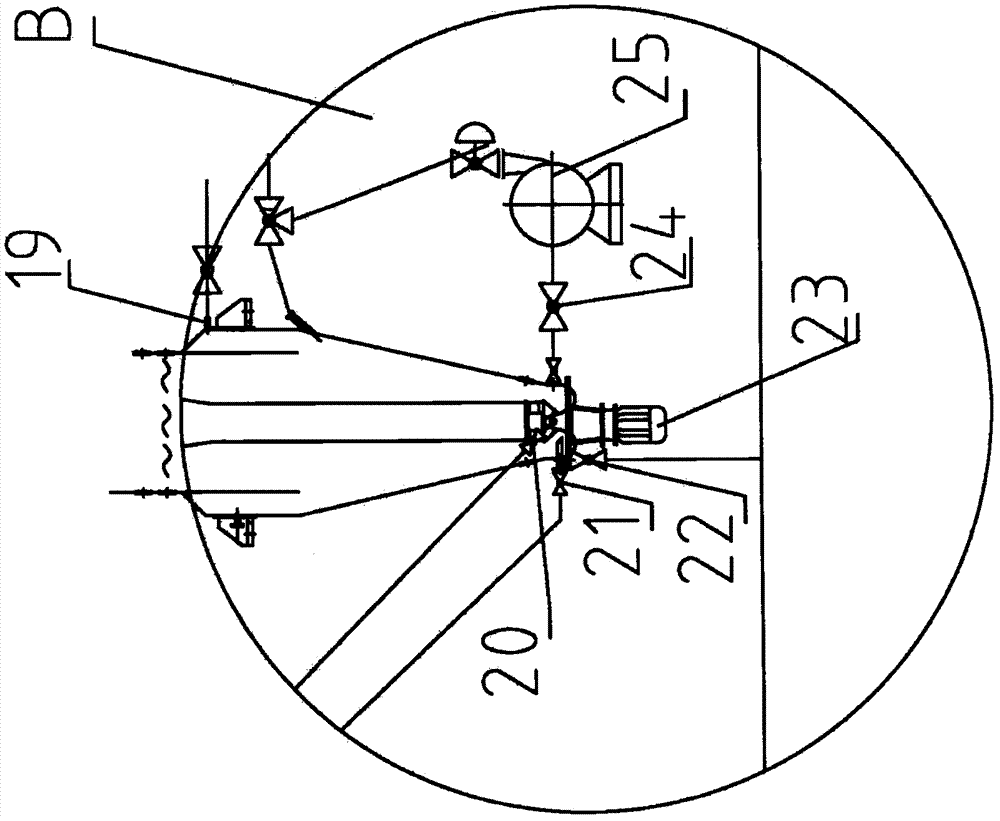

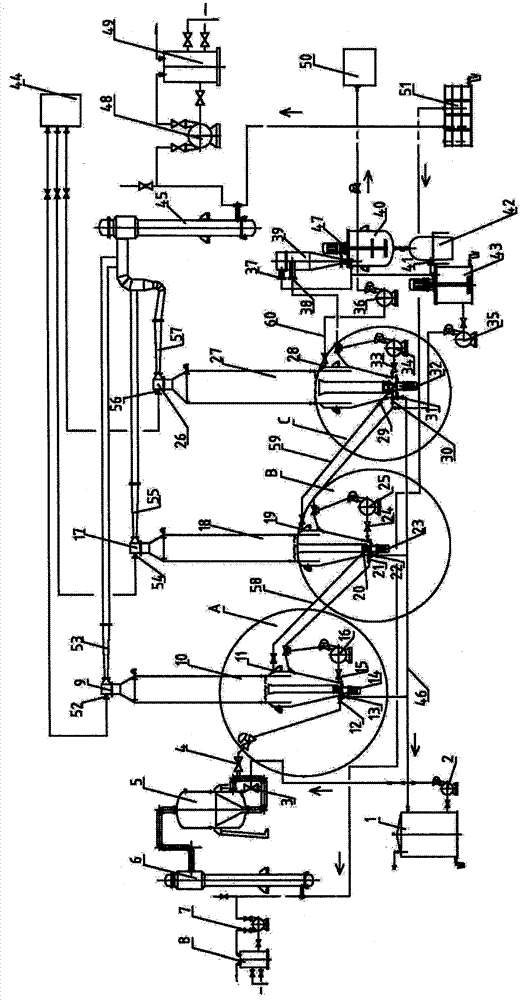

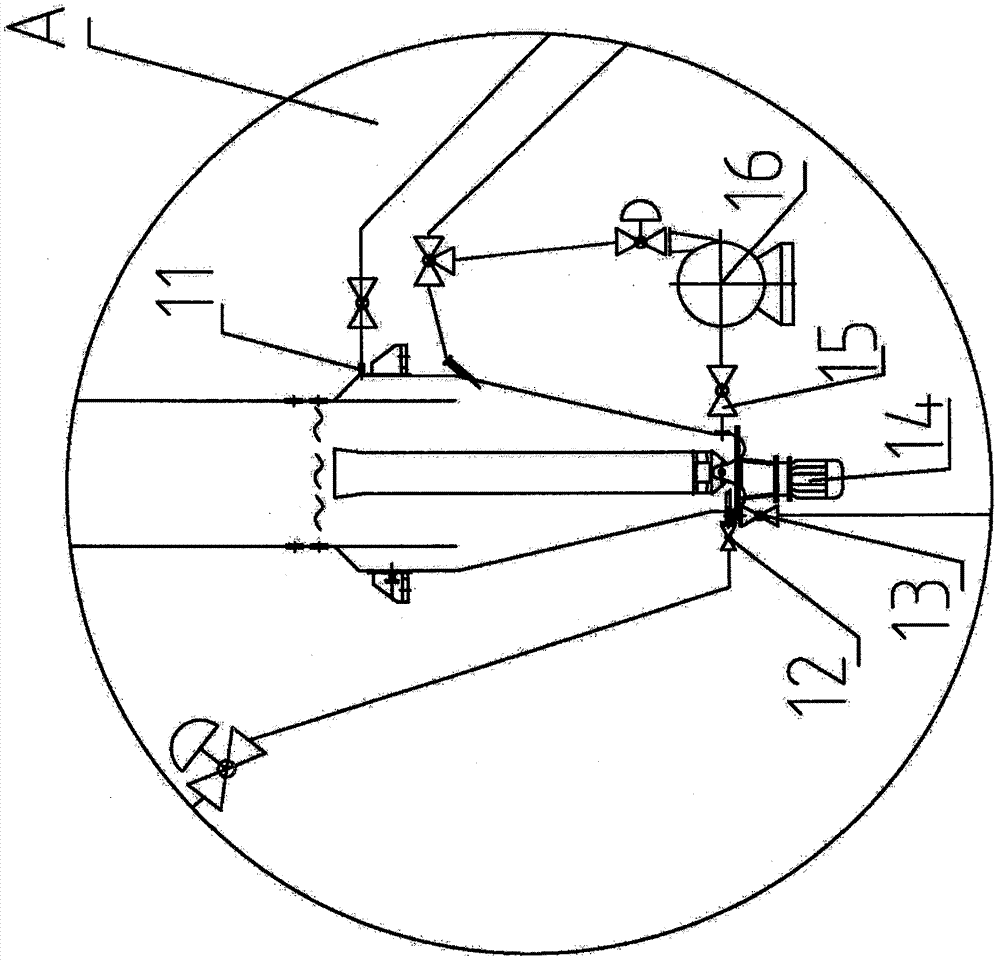

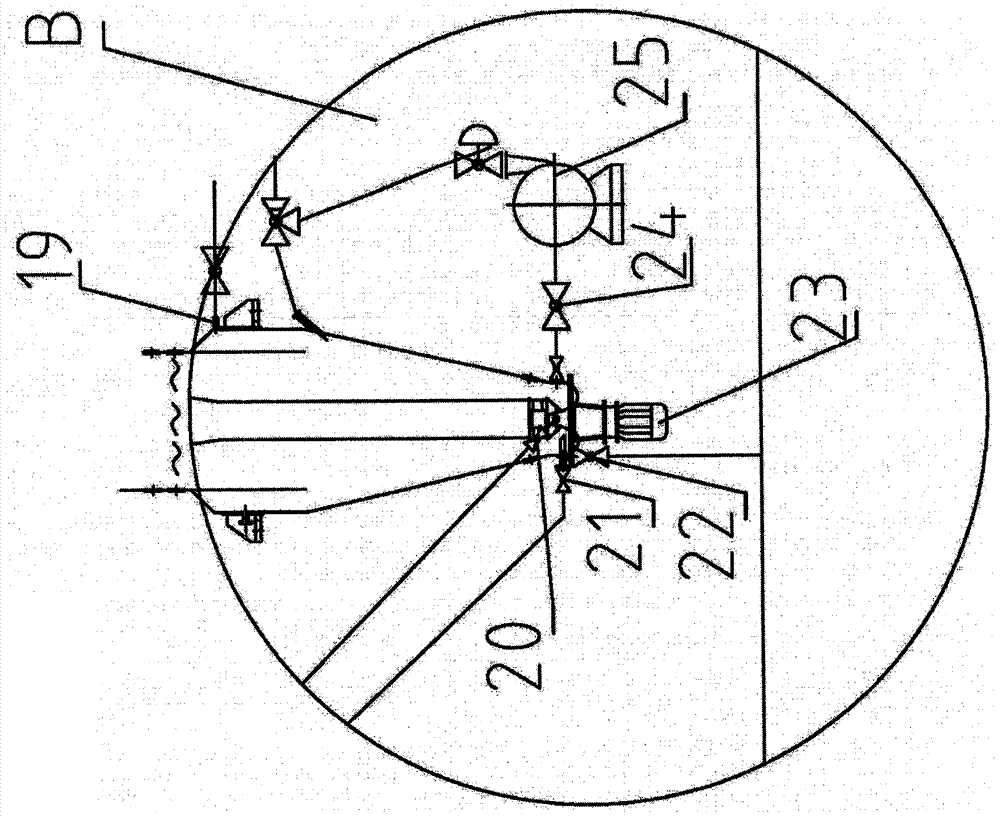

Continuous vacuum crystallization device with flash vaporization and cooling

ActiveCN105879424AReduce energy consumptionUniform crystal sizeEvaporationSolution crystallizationSlurryVacuum pump

The invention provides a continuous vacuum crystallization device with flash vaporization and cooling. The apparatus comprises the following components: a raw material storage tank, a raw material pump, a self-evaporator, a number one vacuum crystallizer, a number two vacuum crystallizer, a number three vacuum crystallizer, a hydrocyclone, a slurry barrel, and a centrifuge. The device is characterized in that: the raw material storage tank is connected to the raw material pump, the self-evaporator, the number one vacuum crystallizer, the number two vacuum crystallizer, the number three vacuum crystallizer, the hydrocyclone, the slurry barrel, and the centrifuge in order; the top part of the self-evaporator is connected to a number one surface cooler by a pipeline, the number one surface cooler is connected to a liquid ring vacuum pump by a pipeline, the liquid ring vacuum pump is connected to a number one steam-water separator by a pipeline, a slurry outlet of the self-evaporator is connected to a slurry inlet of the number one vacuum crystallizer by a pipeline, and the top part of the number one vacuum crystallizer is provided with a number one steam jet vacuum pump. Compared with periodic crystallization, the comprehensive energy consumption is 40% of the comprehensive energy consumption of the periodic crystallization, crystal size is uniform, and equipment structures are simple; the device is suitable for long-term continuous production without fouling and scabbing.

Owner:HAIZHOU E P GRP CO LTD

Electroplating copper cylinder solution suitable for oversize current density and electroplating method

ActiveCN111074306AReduce processing timeImprove reliabilityCellsSemiconductor devicesMeth-Methane sulfonate

The invention discloses an electroplating copper cylinder solution suitable for the oversize current density and an electroplating method. The electroplating copper cylinder solution comprises the following components by concentration: 150-240 g / L of copper methane sulfonate, 40-70 g / L of methanesulfonic acid, 30-50 mg / L of chloridion, 2-5 mg / L of bis-(sodium sulfopropyl)-disulfide, 40-100 mg / L ofpolyethylene glycol, 40-80 mg / L of Janus green, and the balance of DI pure water. The components are evenly mixed to form the electroplating copper cylinder solution suitable for the oversize currentdensity; before electroplating, a wafer needs to be subjected to vacuum treatment through a pretreatment solution; the pretreatment solution is the DI pure water, the wafer is mounted through an electroplating hanger, and then is vacuumized in vacuum equipment for 5-10 min through the DI pure water; and after vacuumizing, electroplating is conducted in the electroplating copper cylinder solution.According to the electroplating copper cylinder solution provided by the invention, the problem is completely solved, especially through adding of the Janus green, an additive is adsorbed on the surface of a seed layer, a copper cylinder is evenly electroplated on the surface of a substrate, and performance indexes that scorch is avoided, and the arch rate is less than or equal to 5% can be met.

Owner:江苏矽智半导体科技有限公司

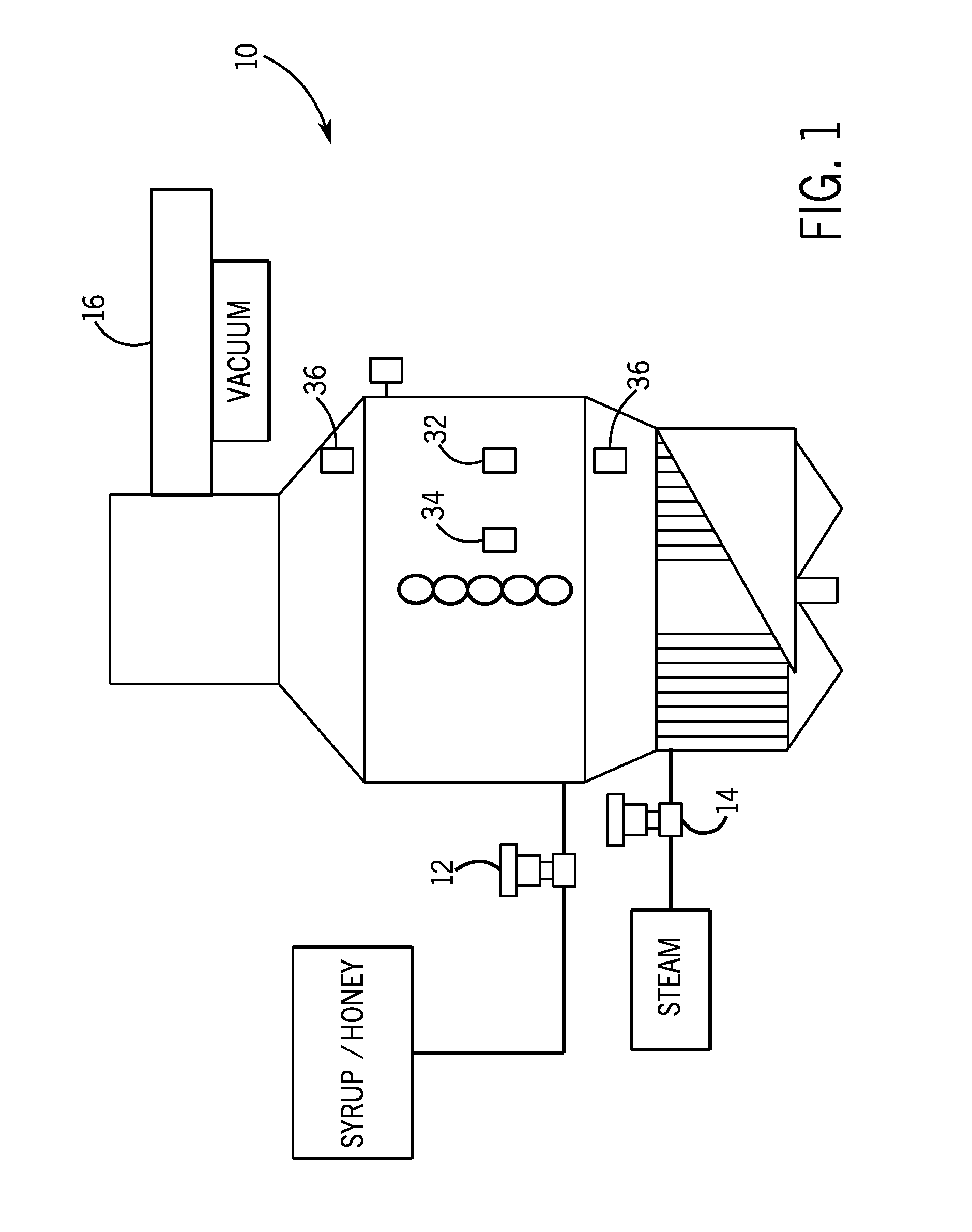

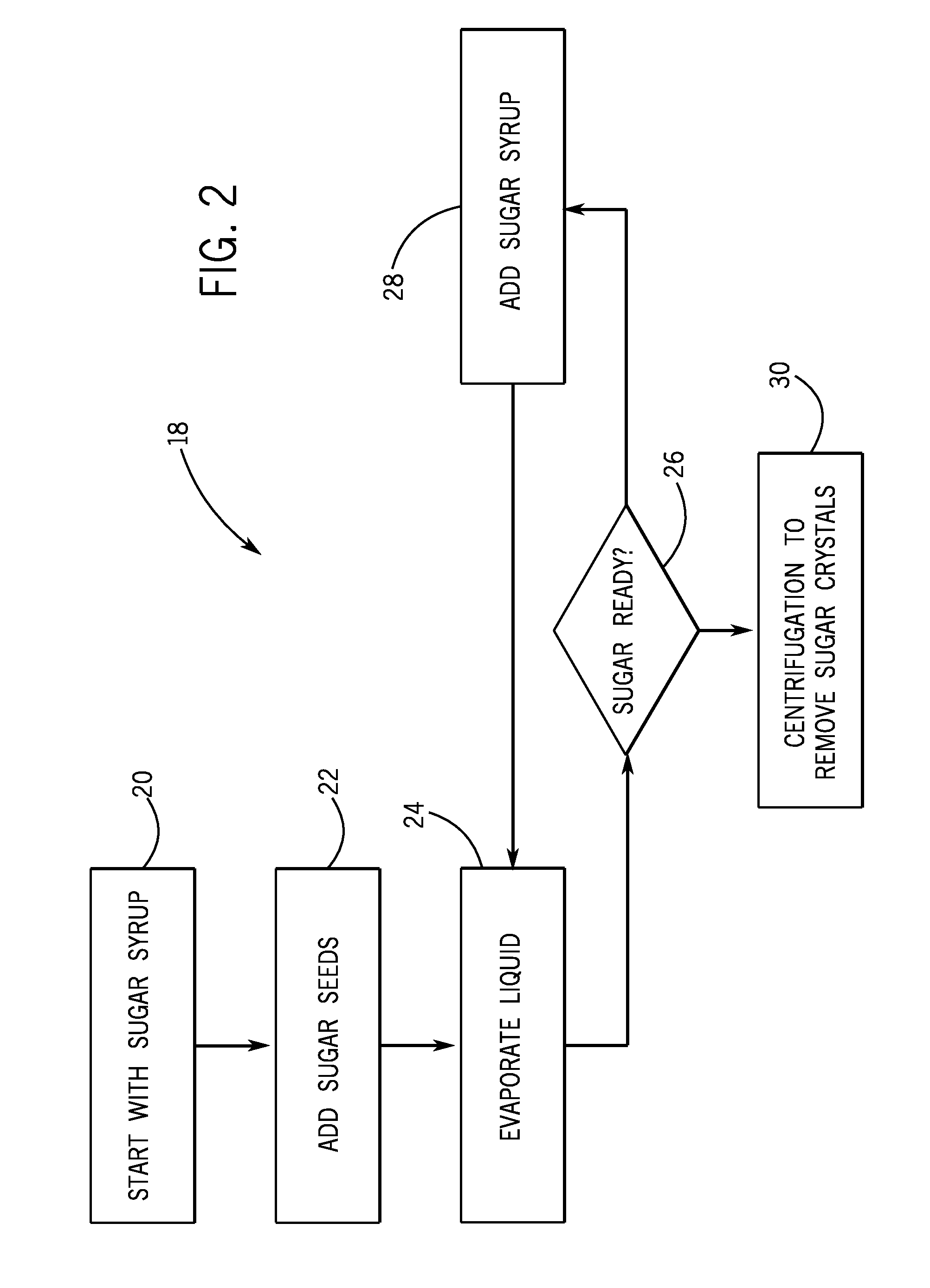

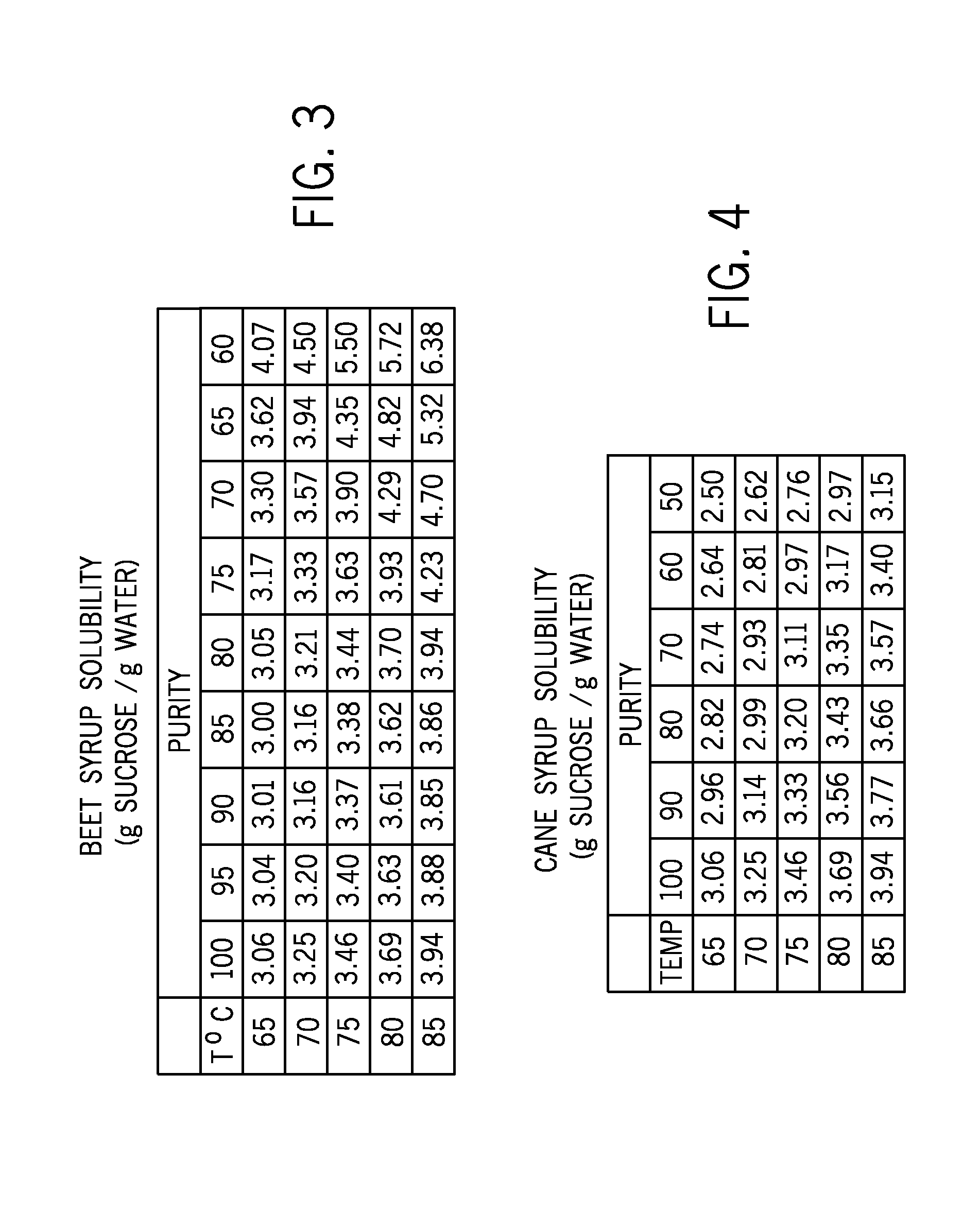

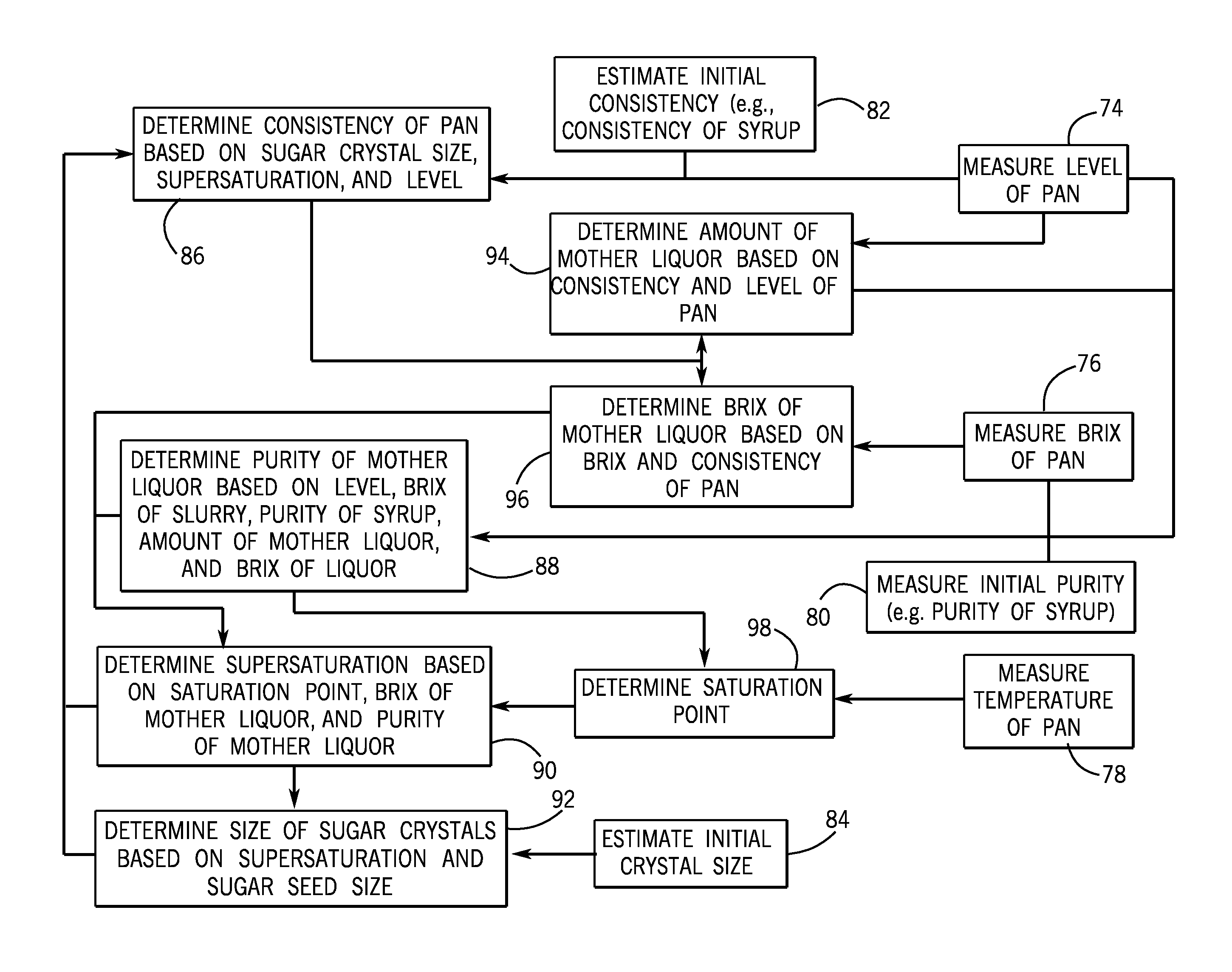

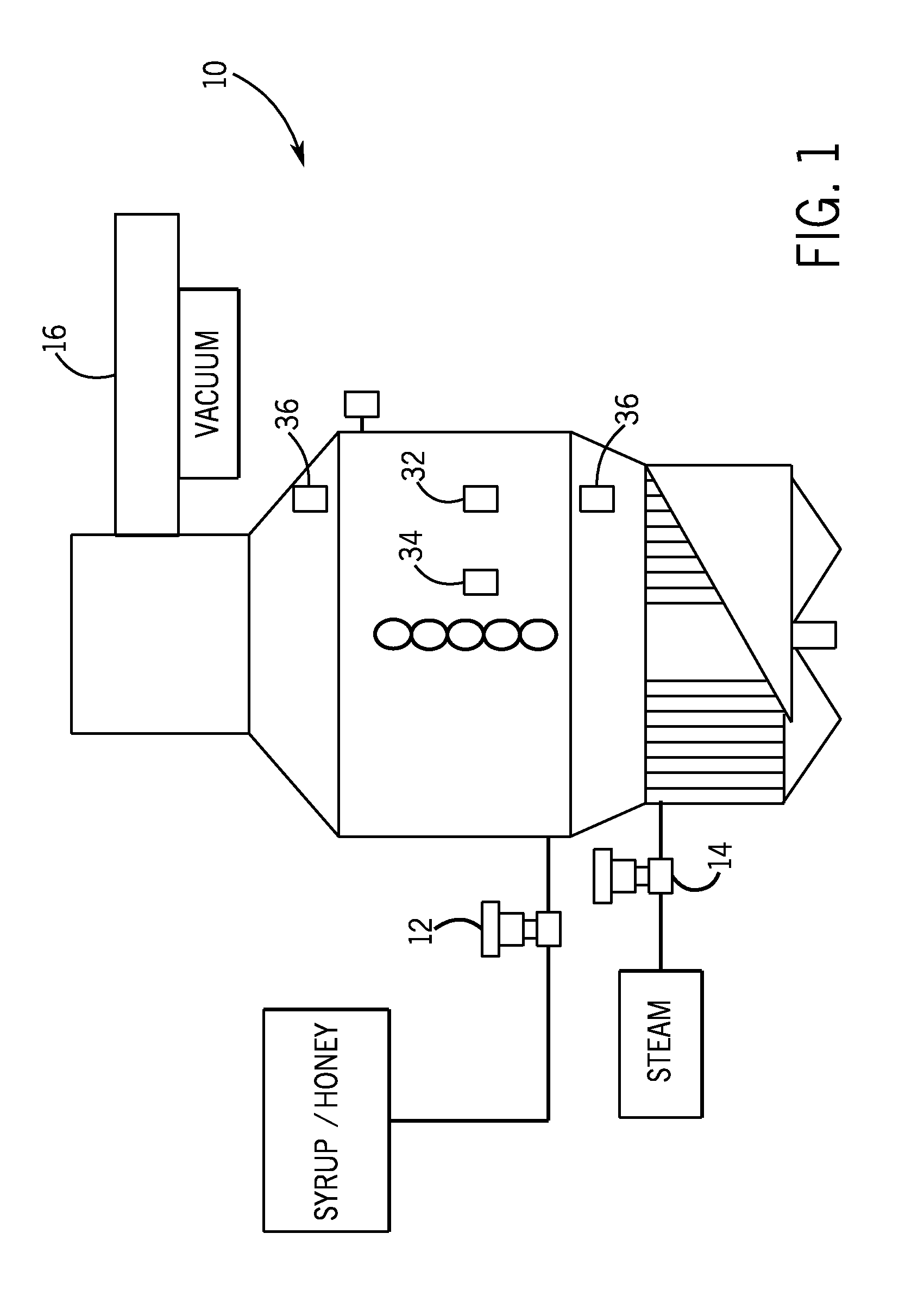

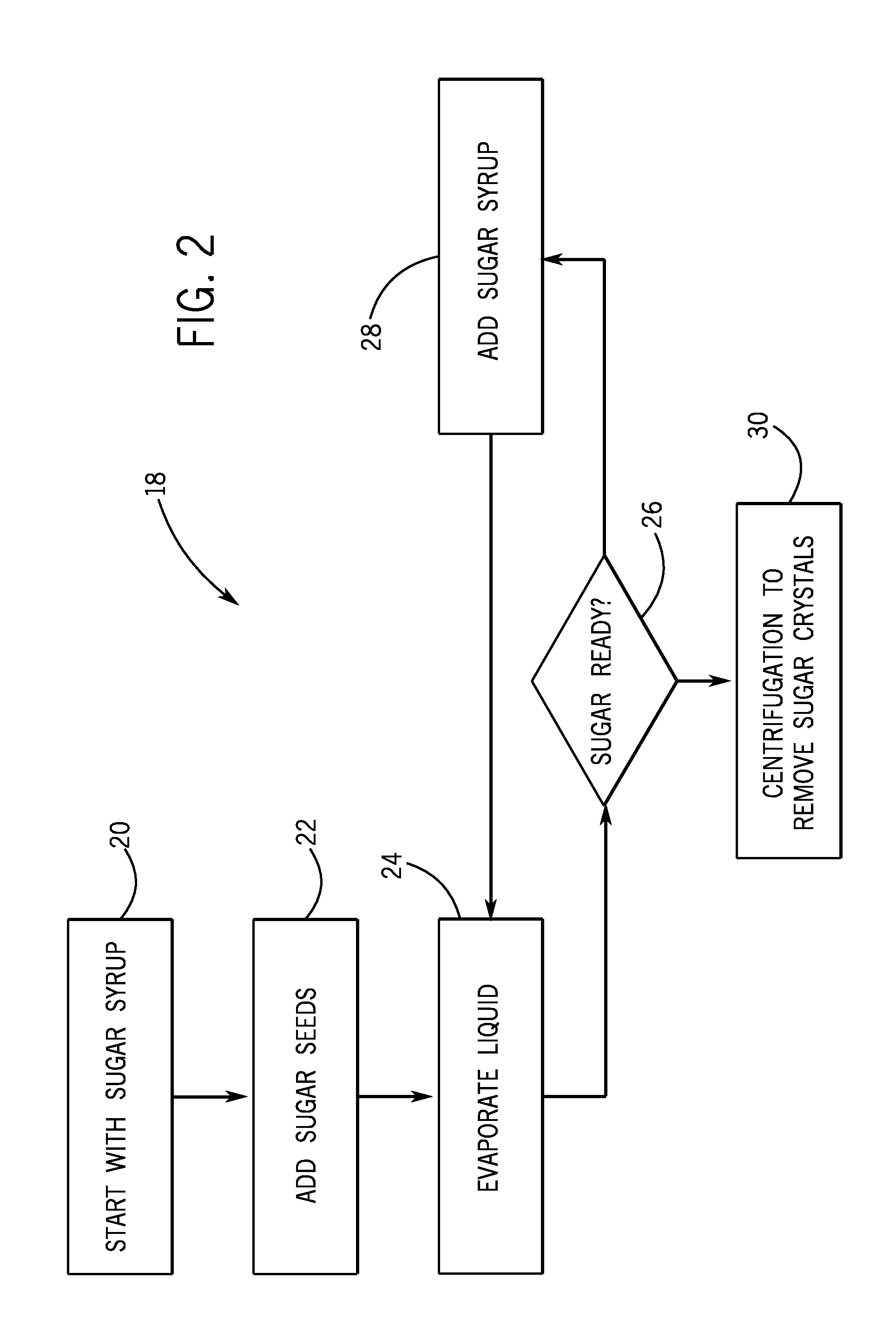

Sugar crystallization control system and method

ActiveUS20140261396A1Increase sugar productionIncreasing crystal size uniformitySugar crystallisationSolution crystallizationControl systemClosed loop

The embodiments described herein include one embodiment that provides a method for controlling sugar crystallization. The method includes, during a crystallization process, determining supersaturation of a sugar slurry of syrup and regulating influx of syrup into the sugar slurry to promote sugar crystallization in a closed-loop manner based upon the determined supersaturation.

Owner:ROCKWELL AUTOMATION TECH

Separation membrane, preparation method and application thereof

ActiveCN110152500ASimple manufacturing methodImprove thermal stabilitySemi-permeable membranesMembranesCarboxylic acidGroup element

Relating to the field of separation membranes, the invention discloses a separation membrane, a preparation method of the separation membrane and application of the separation membrane in the oil-water separation process. The separation membrane comprises a substrate and a separation layer growing on the substrate, wherein the separation layer is formed by an inorganic-organic coordination compound, the inorganic element in the inorganic-organic coordination compound is selected from IVB group elements, and the organic ligand in the inorganic-organic coordination compound is organic carboxylicacid. The separation membrane provided by the invention has good thermal stability, chemical stability and durability, and has excellent oil-water separation performance.

Owner:CHINA PETROLEUM & CHEM CORP +2

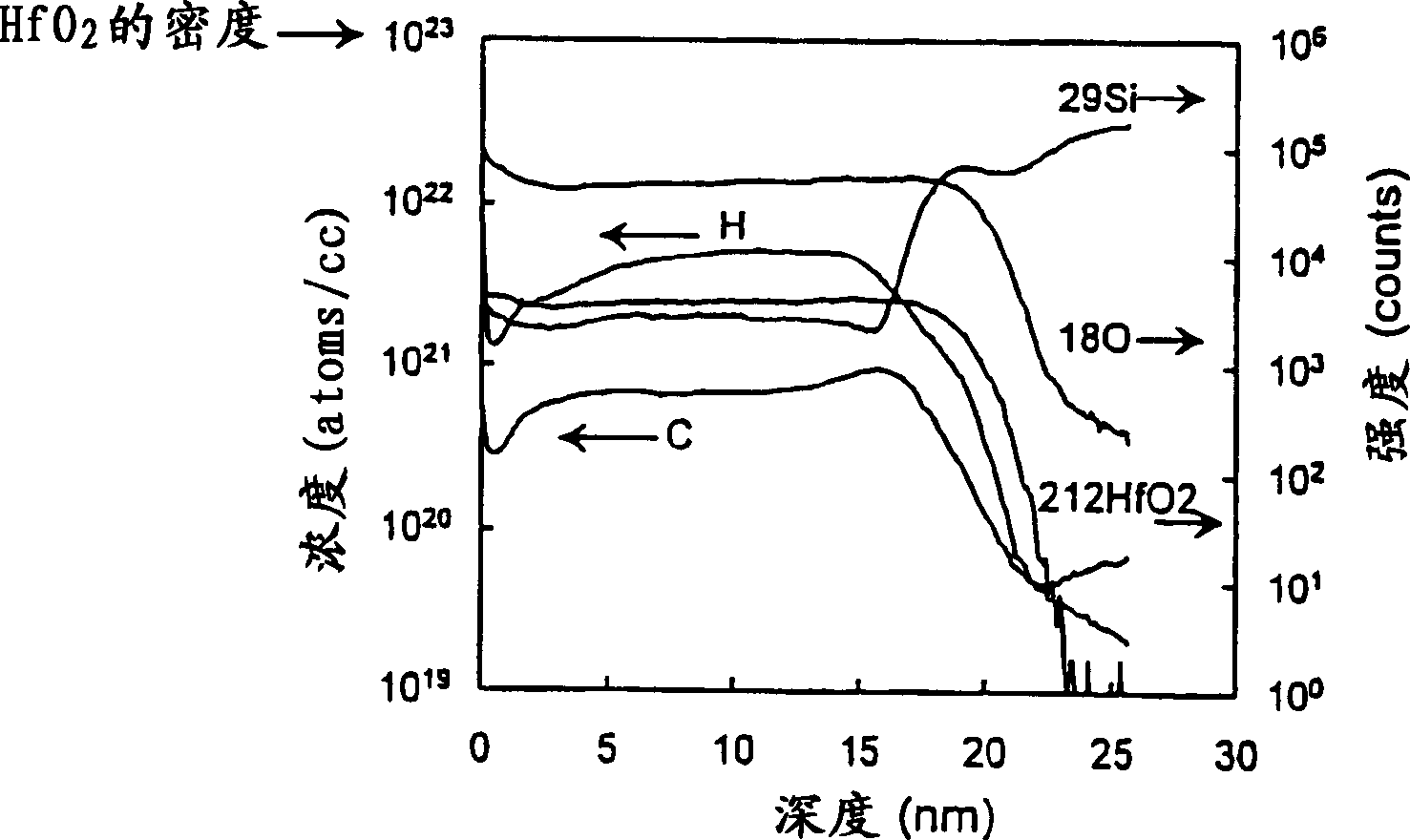

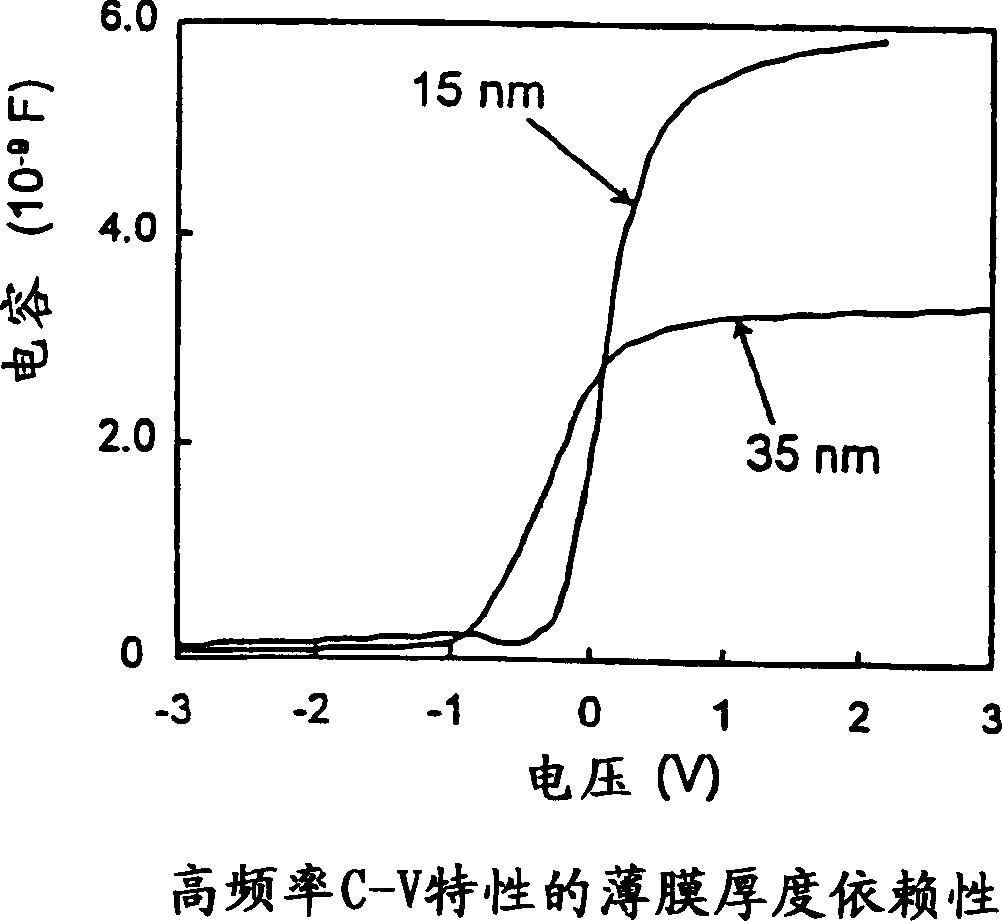

Method for forming metal oxide on surface of substrate

InactiveCN1571124AUniform crystal sizeSimple processSolid-state devicesVacuum evaporation coatingProduct gasOxygen

A film-forming method includes the steps of introducing oxygen radicals and an organic raw material gas containing a metal element into a vacuum container, and reacting the organic raw material gas with the oxygen radicals, thereby forming a metal oxide film on a surface of a substrate disposed in the vacuum container.

Owner:ANELVA CORP

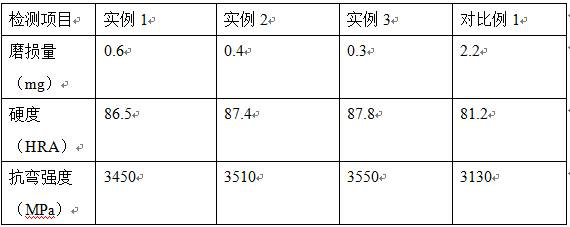

Preparation method of anti-wear tungsten carbide alloy material

ActiveCN111485156AUniform crystal sizeReduce consumptionTungsten/molybdenum carbideAmmonium paratungstateTungstate

The invention relates to a preparation method of an anti-wear tungsten carbide alloy material, and belongs to the technical field of metal metallurgy. The preparation method comprises the following steps of firstly, taking expanded graphite as a template, mixing the expanded graphite with an ammonium tungstate solution and starch, heating and evaporating to crystallize and separate out tungsten inthe form of ammonium paratungstate, and controlling uniform crystal granularity by virtue of polyhydroxy steric hindrance of the starch so as to enable thermally reduced tungsten to be uniformly attached to the surface of the expanded graphite; then generating a tungsten carbide layer on the surface of the expanded graphite, and therefore, obtaining tungsten carbide powder with a graphite interlayer structure; and finally, blending and sintering the tungsten carbide powder and other metal powder, and preparing the wear-resistant tungsten carbide alloy material finally. Due to the fact that the tungsten carbide interlayer structure can slide along the metal powder interlayer and directionally move in the friction direction in the friction state, therefore, consumption of internal energy ofhard alloy material is reduced, abrasion of the hard alloy material is reduced, damage to a hard alloy structure due to repeated volume change can be avoided through the interlayer structure, and theabrasion resistance is further improved.

Owner:HUNAN GOLDEN EAGLE ENERGY TECH CO LTD

Sugar crystallization control system and method

ActiveUS9309576B2Increase sugar productionGood size uniformitySugar crystallisationSolution crystallizationControl systemClosed loop

The embodiments described herein include one embodiment that provides a method for controlling sugar crystallization. The method includes, during a crystallization process, determining supersaturation of a sugar slurry of syrup and regulating influx of syrup into the sugar slurry to promote sugar crystallization in a closed-loop manner based upon the determined supersaturation.

Owner:ROCKWELL AUTOMATION TECH

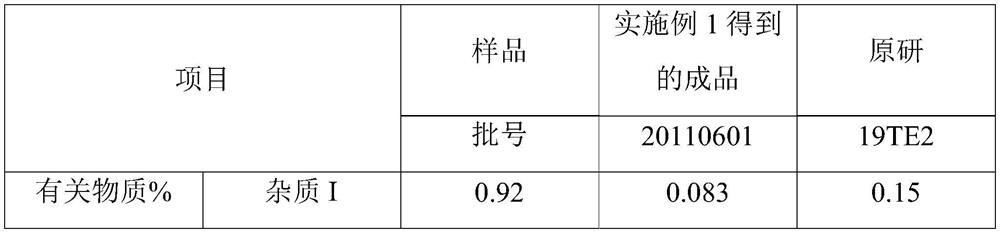

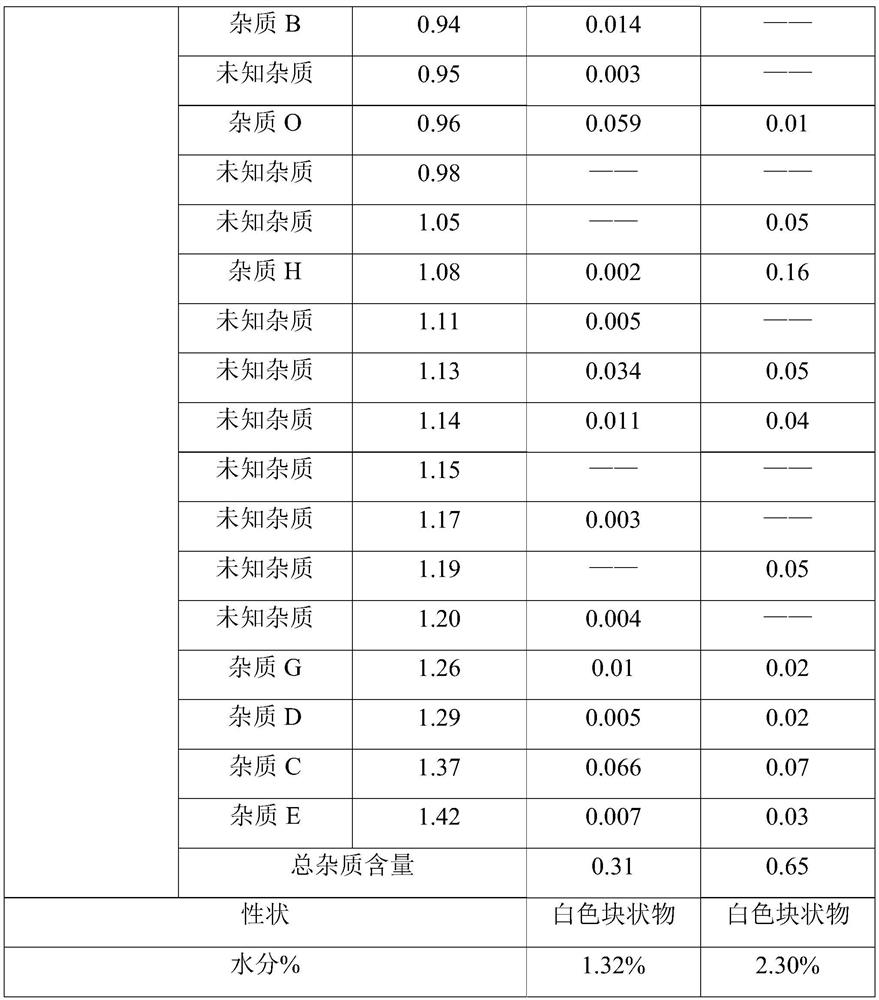

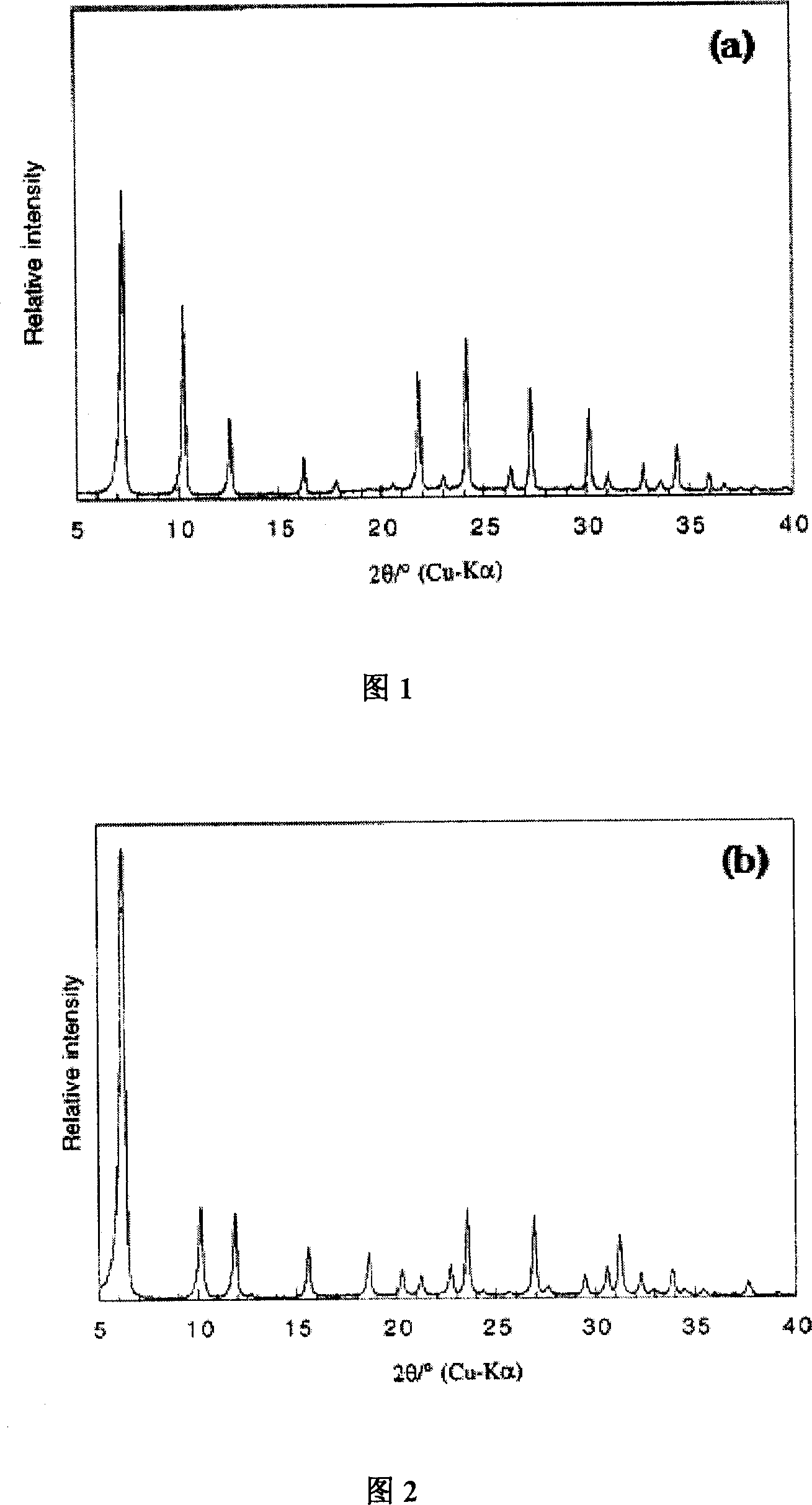

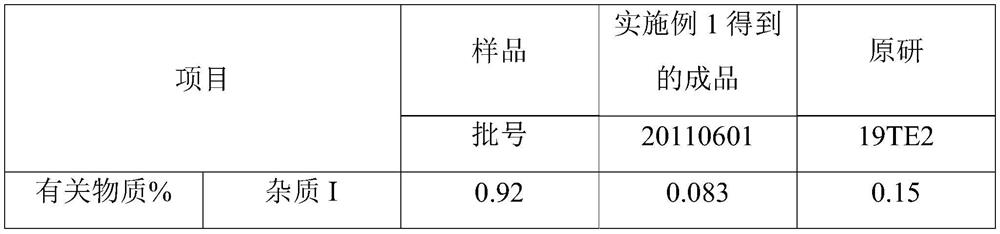

Preparation method of tedizolid phosphate freeze-dried preparation for injection

ActiveCN112826801AUniform crystal sizeEasy to operateAntibacterial agentsPowder deliveryPhosphateDrugs preparations

The invention relates to the technical field of pharmaceutical preparations, and particularly discloses a preparation method of a tedizolid phosphate freeze-dried preparation for injection. The preparation method of the tedizolid phosphate freeze-dried preparation for injection comprises the following steps: a, adding tedizolid phosphate and a freeze-drying protective additive into water for injection to obtain tedizolid phosphate liquid medicine; b, sequentially cooling the liquid medicine to -8 to -10 DEG C and -40 to -50 DEG C, and keeping for a specific time; heating the liquid medicine to -15 DEG C to -10 DEG C, and cooling the liquid medicine to -40 DEG C to -50 DEG C, and keeping the temperature for a certain period to obtain a freeze-dried product; c, under the vacuum condition, heating the freeze-dried product to -30 to -10 DEG C and 40 to 50 DEG C, and keeping the temperature for a certain period, so as to obtain the tedizolid phosphate freeze-dried preparation for injection. The preparation method is simple to operate, the time cost for preparing the tedizolid phosphate freeze-dried preparation for injection is remarkably reduced, and the high-quality tedizolid phosphate freeze-dried preparation for injection, which is low in impurity and moisture content, can be obtained.

Owner:SHIJIAZHUANG NO 4 PHARMA

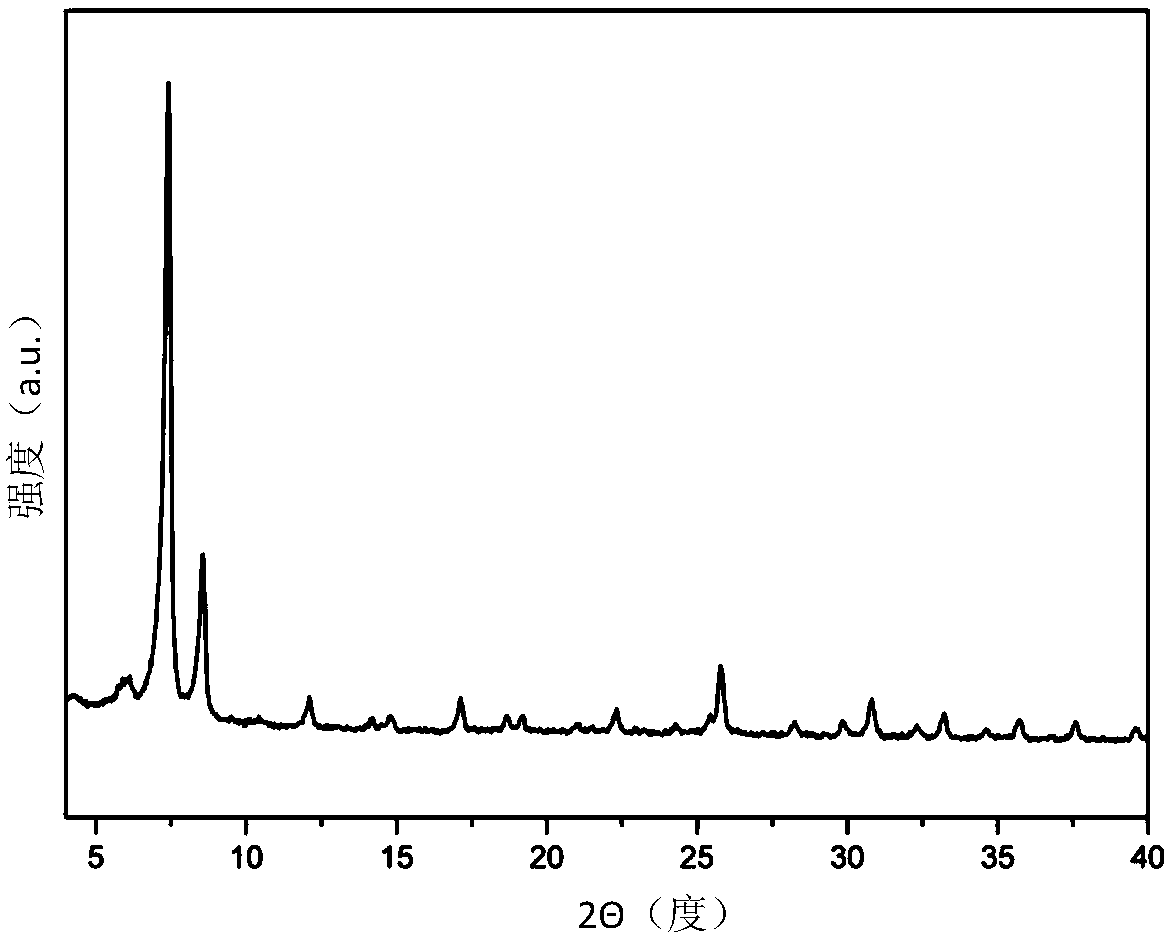

LTA and FAU molecular screen nanocrystalline preparation method

ActiveCN100360405CImprove performanceUniform crystal sizeAluminosilicate zeolite type-ATetramethylammonium hydroxideMolecular sieve

The invention relates a method for preparation of LTA and FAJJ molecular sieve nanometer crystal. The method comprises the following steps: entering the silico-aluminum into mineralization agent and TMAOH to make solution; after intimate mixing, in the condition of agitation or quiescence, making it react for 1-30 days in 100 deg.C; after crystallization, centrifugalizing and filtering it, finally scrubbing and drying and obtaining the LTA and FAJJ molecular sieve nanometer crystal, and synthesizing the LTA molecular sieve nanometer crystal in the range of (0.8-3.0)SiO2: Al2O3: (0-20)(TMA)02: (0-7.5)Na: (50-5000)H2O and FAU molecular sieve nanometer crystal in the range of 3.4SiO2:(0.5-1.8)Al2O3:(0-20)(TMA)O2: (0-7.5)Na:(50-5000)H2O.

Owner:珠海横琴长满欧国际贸易有限公司

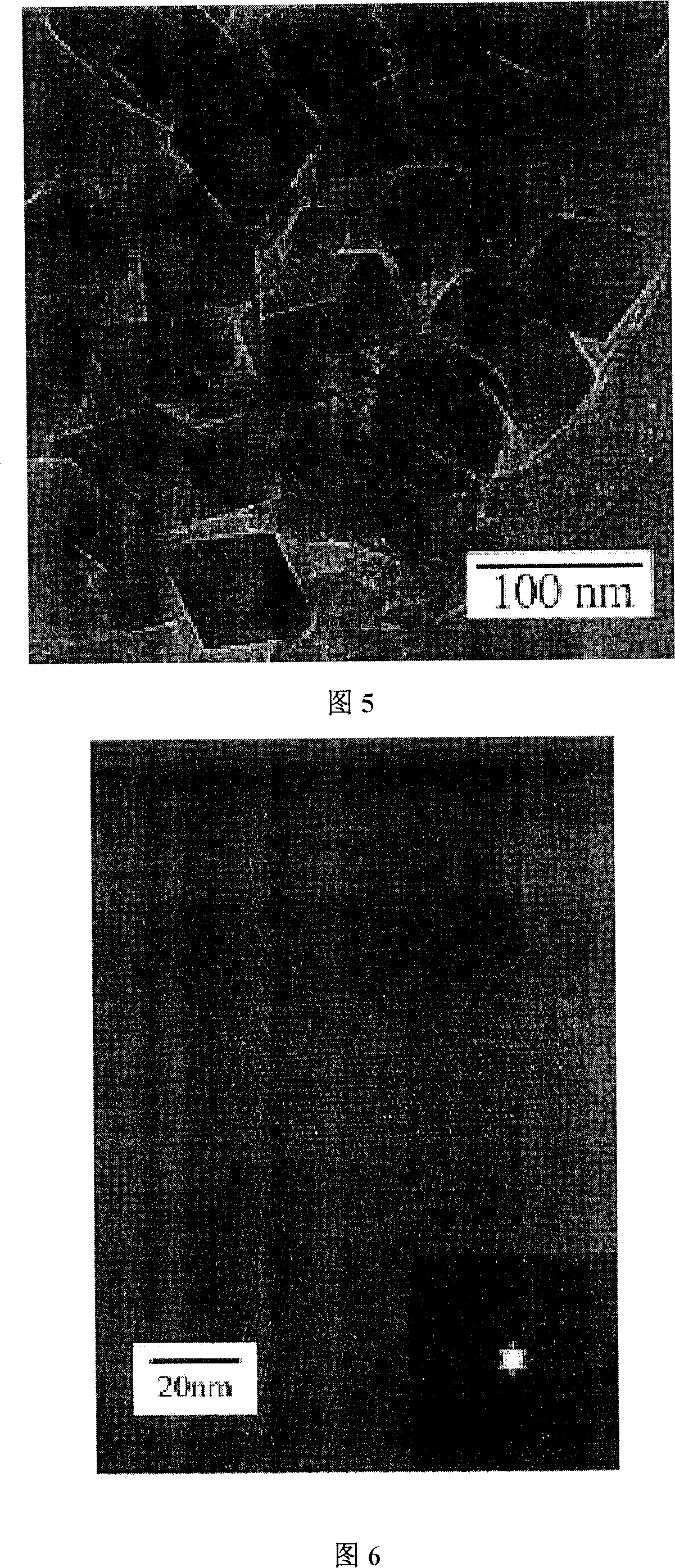

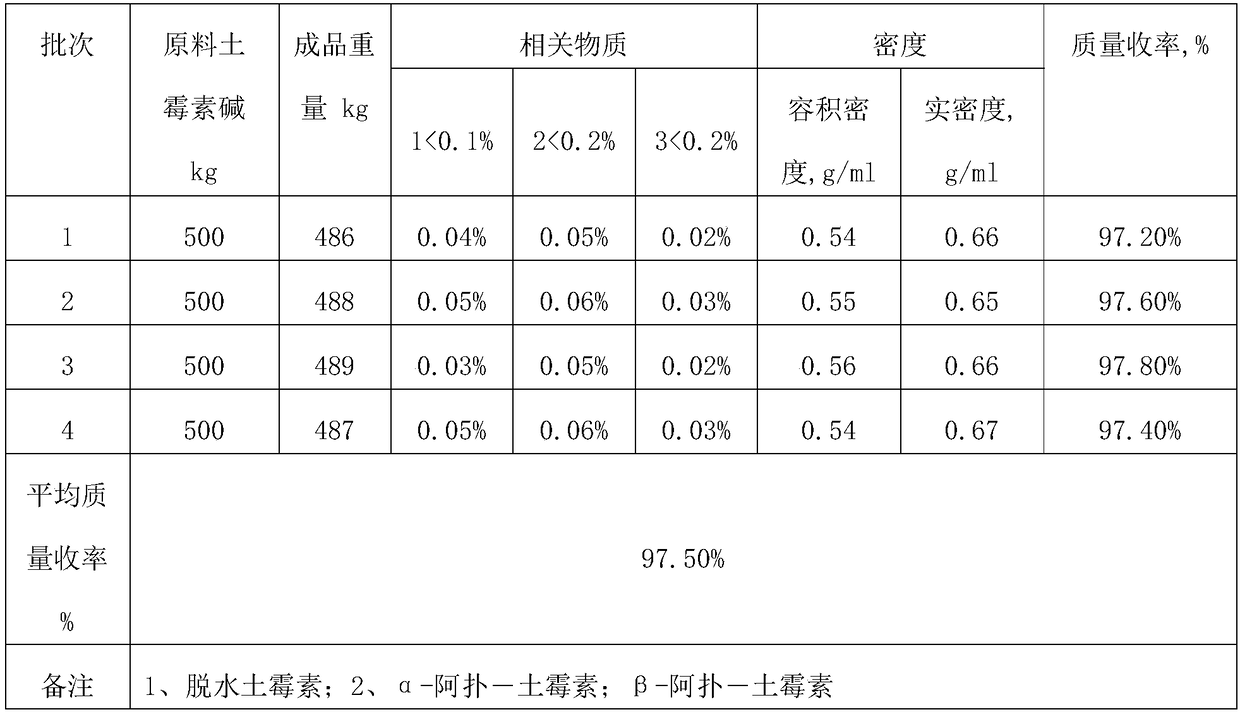

Oxytetracycline hydrochloride preparation method

InactiveCN109438278AUniform crystal sizeCrystallize fastOrganic compound preparationCarboxylic acid amide separation/purificationChlorideOxytetracycline Hydrochloride

The invention discloses an oxytetracycline hydrochloride preparation method which comprises the following steps: 1, adding oxytetracycline and calcium chloride into methanol, uniformly stirring, and filtering to obtain filtrate, wherein oxytetracycline hydrochloride comprise the following raw materials: 1500-2100 L of methanol, 350-500 Kg of oxytetracycline and 35-50 Kg of calcium chloride; 2, controlling the temperature of the filtrate to 20-26 DEG C, adding a hydrochloric acid-methanol solution to obtain a mixed solution, and performing intermittent stirring on the mixed solution to separateout oxytetracycline hydrochloride, wherein the hydrochloric acid-methanol solution contains 26 Kg of hydrogen chloride; and 3, performing centrifugal separation on the mixed solution after the oxytetracycline hydrochloride is separated out, and drying, thereby obtaining the oxytetracycline hydrochloride. The oxytetracycline hydrochloride preparation method disclosed by the invention has the advantages that the mass yield of the oxytetracycline hydrochloride is stabilized at 96% or higher, and the content of impurities such as dehydrated mycin, alpha-apo-oxytetracycline, and beta-apo-oxytetracycline in the product is low.

Owner:盐城市大丰区天生联合药业有限公司

Method for controlling maltitol crystallization granularity

InactiveCN110776539AReduce the ratioAvoid explosive nucleationSugar derivativesOrganic chemistry methodsIcing sugarBrix

The invention relates to a method for controlling the maltitol crystallization granularity. According to the method, firstly, a maltitol solution is evaporated and concentrated into a saturation state; then, seed crystals are added; the maltitol solution is continuously supplemented in a vacuum evaporation state; the brix of massecuite is controlled; the concentrated crystallization is continuously completed; and then, centrifugal drying is performed to obtain maltitol crystals. The crystallization process is controlled by controlling the seed crystal addition quantity and the material supplementing concentration. By the method, the maltitol nucleation can be inhibited; the generation of fine grains can also be reduced, so that the granularity distribution of the finally obtained crystal product is uniform; and the proportion of powdered sugar in the granularity distribution is reduced, so that the agglomeration of the maltitol product is effectively inhabited. The method has the advantages that the crystallization period is shortened; the crystallization efficiency is improved; the granularity of the finally obtained maltitol crystals is uniform and stable; the natural fluidity ofthe product after the drying is good; the agglomeration risk during the storage at a room temperature is reduced; and the method can be used for producing maltitol products with different granularities.

Owner:ZHEJIANG HUAKANG PHARMA

A kind of preparation method of tedizolid phosphate freeze-dried preparation for injection

ActiveCN112826801BUniform crystal sizeEasy to operateAntibacterial agentsPowder deliveryPhosphatePharmaceutical formulation

The invention relates to the technical field of pharmaceutical preparations, and specifically discloses a preparation method of a tedizolid phosphate freeze-dried preparation for injection. The preparation method of the freeze-dried preparation of tedizolid phosphate for injection comprises the following steps: a. adding tedizolid phosphate and a freeze-drying protective agent to water for injection to obtain a tedizolid phosphate liquid; b. cooling the liquid in sequence To ‑8~‑10°C and ‑40~‑50°C, keep for a specific time; then heat up to ‑15~‑10°C, then cool to ‑40~‑50°C, keep for a specific time to obtain a freeze-dried product; c, Under vacuum conditions, the freeze-dried product is heated to -30--10°C and 40-50°C, and kept for a specific time to obtain a freeze-dried formulation of tedizolid phosphate for injection. The preparation method of the invention is simple to operate, significantly reduces the time cost for preparing the tedizolid phosphate lyophilized preparation for injection, and can obtain a high-quality tedizolid phosphate lyophilized preparation for injection with low impurities and moisture content.

Owner:SHIJIAZHUANG NO 4 PHARMA

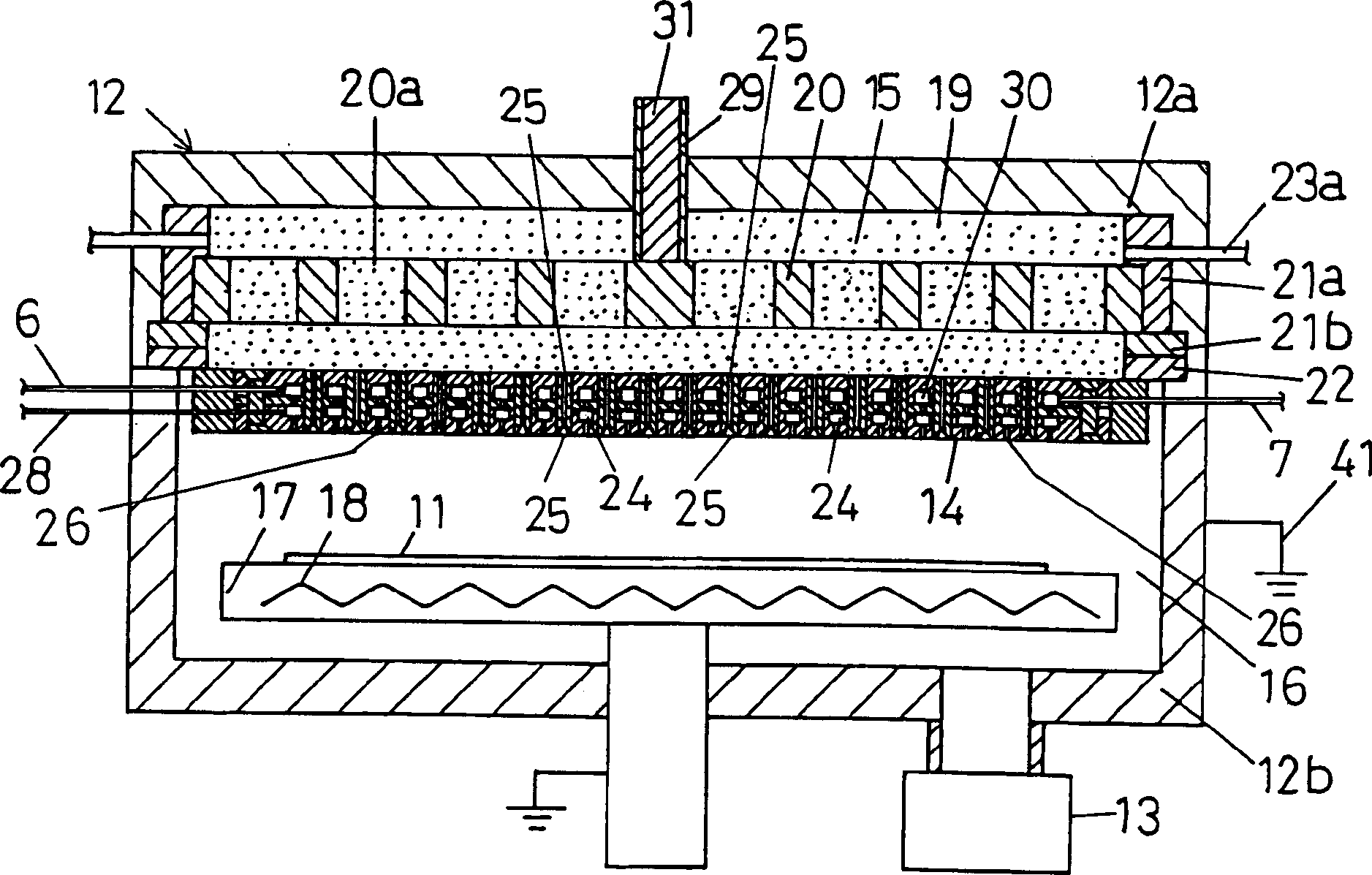

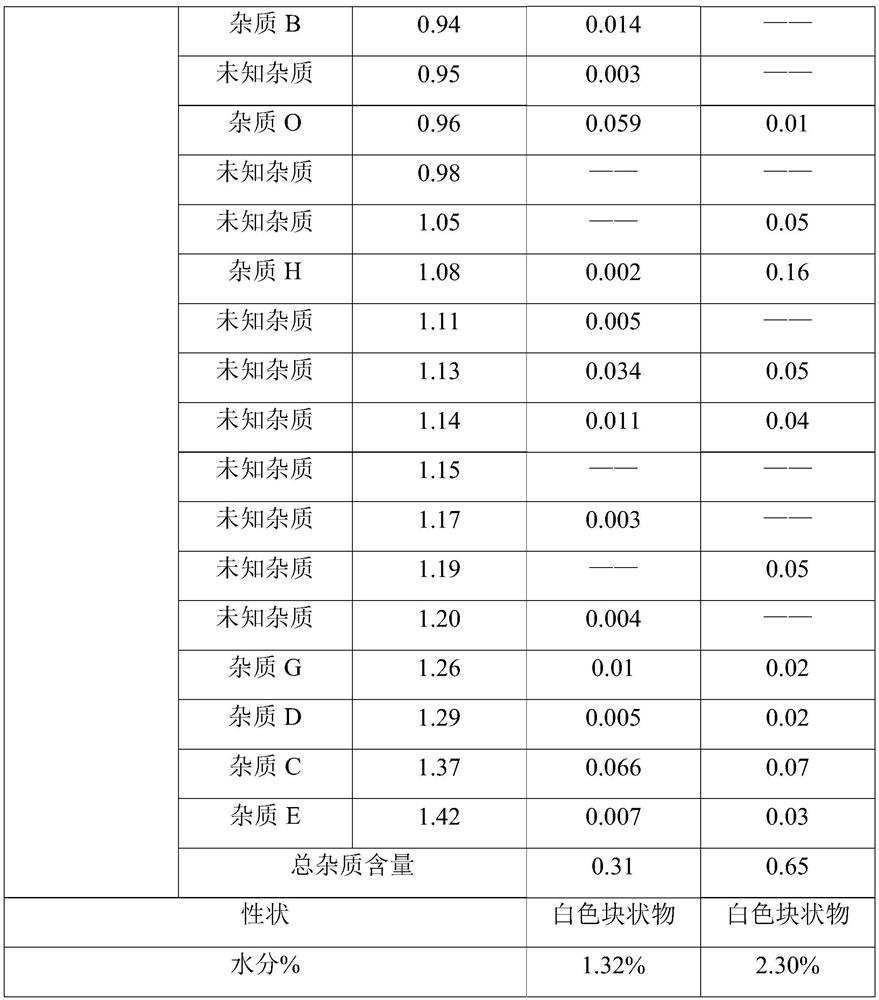

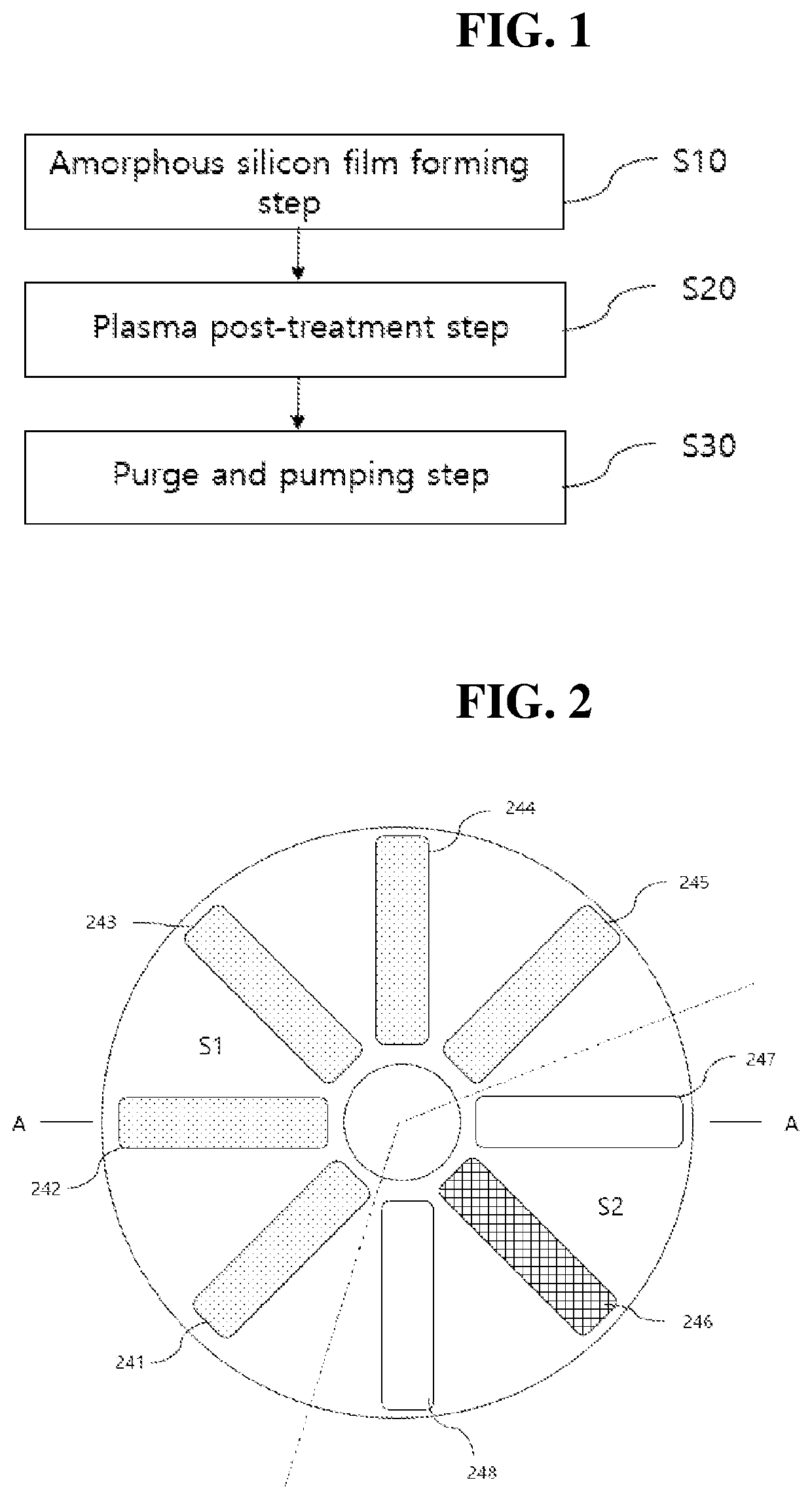

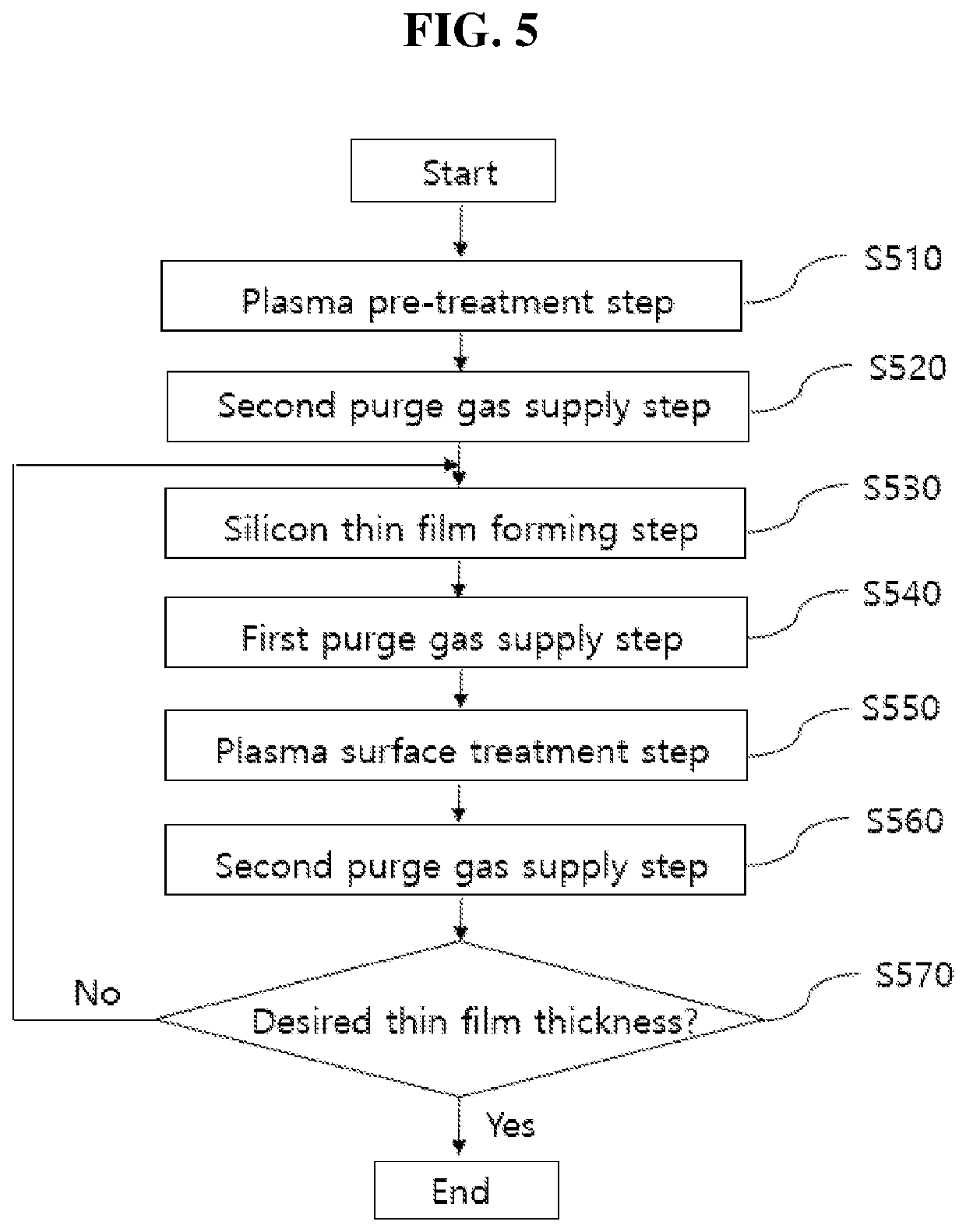

Thin film forming device and thin film forming method using the same

PendingUS20210296114A1Excellent characteristicUniform grain sizeSemiconductor/solid-state device testing/measurementElectric discharge tubesThin membraneComposite material

The disclosure relates to a thin film forming device and a thin film forming method using the same capable of improving the film quality of a silicon thin film by dividing a reaction space in a process chamber of the thin film forming device and thereby forming the silicon thin film on a substrate in a first space and treating a surface of the silicon thin film, formed in the first space, in a second space by using plasma. By the thin film forming device and the thin film forming method using the same according to the disclosure, with a trend that a pattern is complicated and the depth of the pattern increases, impurities in a thin film may be more efficiently removed, a uniform thin film may be formed on a pattern, and the grain size of the crystals of a silicon thin film may be made uniform.

Owner:JUSUNG ENG

Vacuum flash cooling continuous crystallization device

ActiveCN105879424BReduce energy consumptionUniform crystal sizeEvaporationSolution crystallizationEvaporationSlurry

Vacuum flash cooling continuous crystallization device, including raw material storage tank, raw material pump, self-evaporator, No. 1 vacuum crystallizer, No. 2 vacuum crystallizer, No. 3 vacuum crystallizer, hydrocyclone, slurry barrel, centrifuge, etc. It is characterized in that: the raw material storage tank is sequentially connected with a raw material pump, a self-evaporator, a No. 1 vacuum crystallizer, a No. 2 vacuum crystallizer, a No. 3 vacuum crystallizer, a hydrocyclone, a slurry tank, and a centrifuge. The top of the cooler is connected to the No. 1 surface cooler through a pipeline, the No. 1 surface cooler is connected to the No. 1 water ring vacuum pump through a pipeline, the No. No. 1 vacuum crystallizer slurry inlet, No. 1 vacuum crystallizer top is provided with a No. 1 steam jet vacuum pump. Compared with the batch crystallization, the comprehensive energy consumption of the present invention is 40% of that of the batch crystallization. Scar can be produced continuously for a long time.

Owner:HAIZHOU E P GRP CO LTD

A cyanide-free chemical gold plating solution and its gold plating process applied in the field of wafer advanced packaging

ActiveCN113026068BAvoid narrow operating rangesQuickly achieve fillingCellsSemiconductor devicesCyanideActive agent

The invention discloses a cyanide-free chemical gold-plating solution and a gold-plating process applied to the field of advanced packaging of wafers. 10-60g / L; conductive salt 10-60g / L; buffer 30-60g / L; anti-aging agent 5-10g / L; surfactant 15-80mg / L; wetting agent 1-5mg / L; reaction Accelerator 50-80mg / L; Stabilizer 0.2-5mg / L; The reaction accelerator is a compound of 2,6-diaminopyridine and 3-pyridinemethanol, and 2,6-diaminopyridine and 3-pyridine The mass concentration ratio of methanol is 2:1. The solution obtained by the invention not only ensures the stability of the plating solution, but also makes it easy to spread the plated parts on the surface of the electrode to achieve the purpose of uniform plating, and further achieves the effect of filling the micropores of the wafer package without voids and gaps.

Owner:SHENZHEN CHENGGONG CHEM

Inorganic-organic coordination compound separation membrane and production method and application thereof

ActiveCN110141973AUniform crystal sizeImprove thermal stabilityMembranesSemi-permeable membranesOil waterThermal stability

The invention relates to the field of separation membranes, and discloses an inorganic-organic coordination compound separation membrane, a production method of the separation membrane and applicationof the separation membrane in an oil-water separation process. The separation membrane comprises a substrate and a separation layer which grows on the substrate, wherein the separation layer is formed by an inorganic-organic coordination compound, an inorganic element in the inorganic-organic coordination compound is selected from IIB family elements, and an organic ligand in the inorganic-organic coordination compound is an imidazole compound. The provided separation membrane is good in thermal stability, chemical stability and durability and excellent in oil-water separation performance.

Owner:CHINA PETROLEUM & CHEM CORP +2

A kind of preparation method of wear-resistant tungsten carbide alloy material

ActiveCN111485156BUniform crystal sizeReduce consumptionTungsten/molybdenum carbideAmmonium paratungstateTungstate

The invention relates to a preparation method of a wear-resistant tungsten carbide alloy material, which belongs to the technical field of metallurgy. The present invention first uses expanded graphite as a template, mixes it with ammonium tungstate solution and starch, heats and evaporates, and crystallizes tungsten as ammonium paratungstate, and controls the crystallization particle size uniformly by the multi-hydroxyl hindrance of starch, so that thermally reduced tungsten is evenly attached to Expanded graphite surface, followed by sintering reaction to generate tungsten carbide layer on the expanded graphite surface, so as to obtain tungsten carbide powder with graphite interlayer structure, and finally blend and sinter tungsten carbide powder and other metal powders to finally obtain wear-resistant tungsten carbide alloy material , because the interlayer structure of tungsten carbide can slip along the interlayer of metal powder under the friction state, and move directionally along the friction direction, thereby reducing the consumption of internal energy of the cemented carbide material, reducing the wear of the cemented carbide material, and the layer The interstructure can also avoid the damage of the cemented carbide structure caused by repeated volume changes, thereby further improving the wear resistance.

Owner:HUNAN GOLDEN EAGLE ENERGY TECH CO LTD

Cobalt-nickel bimetallic hydroxyl phosphite rod-like crystal array film and preparation method thereof

ActiveCN110482480AReduce energy consumptionIntensified anisotropyPhysical/chemical process catalystsCoupling light guidesIonChemistry

The invention discloses a cobalt-nickel bi-metal hydroxyl phosphite rod-like crystal array film and a preparation method of the cobalt-nickel bi-metal hydroxyl phosphite rod-like crystal array film. The preparation method comprises the following steps: dissolving nickel nitrate hexahydrate, cobalt nitrate hexahydrate and sodium hypophosphite in deionized water, and adding N, N-dimethylacetamide; soaking the pre-cleaned activated carbon fibers into the prepared solution, and carrying out sealed reaction in a reaction kettle at 140-160 DEG C for 10-20 hours; and after the reaction kettle is naturally cooled to normal temperature, taking out the activated carbon fiber, repeatedly cleaning with absolute ethyl alcohol and deionized water, and drying at 60 DEG C for 8 hours to obtain a compact and uniform M11 (HPO3) 8 (OH) 6 (M = Ni + Co) rod-like crystal array film on the surface of the activated carbon fiber. The rod-like crystal array film obtained by the invention is simple and safe in preparation method, and the array crystal is uniform and compact, has stable and uniform surface performance, and can be applied to the fields of novel energy storage, catalysis and sensing.

Owner:ZHEJIANG SCI-TECH UNIV

4A zeolite production technique by bruising process

InactiveCN100467377CUniform crystal sizeLess investmentCrystalline aluminosilicate zeolitesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAlcoholSoluble glass

The invention discloses a bruising method of 4A zeolite, which comprises the following steps: (A) allocating 300-500 wt soda and 600-900 wt alumina cement; mixing evenly; inputting into autoclave with 5000-8000 wt water; reacting 10-30 min; controlling temperature at 70-90 deg.c; getting sodium aluminate solution; (B) allocating 4-6 wt sodium aluminate solution, 1 wt liquid soluble glass with module at 2.9-3.2 and solid content at 20-30%; mixing; adding into crystal tank to crystal; adding 0.004-0.006 wt bruising agent; controlling temperature at 70-90 deg.c; reacting 20-30 min; discharging; allocating bulk factor at 1-3:1:0.001-0.003= (A) sodium aluminate solution : module at 2.9-3.2 and solid content at 20-30% soluble glass solution : anhydrous alcohol; mixing; heating-up to 70-80 deg.c; reacting 1-2 h; getting bruising agent; (C) filtering; discharging zeolite; (D) drying; storing or packing.

Owner:SHANDONG DONGFANG HUALONG IND & TRADE GRP CO LTD

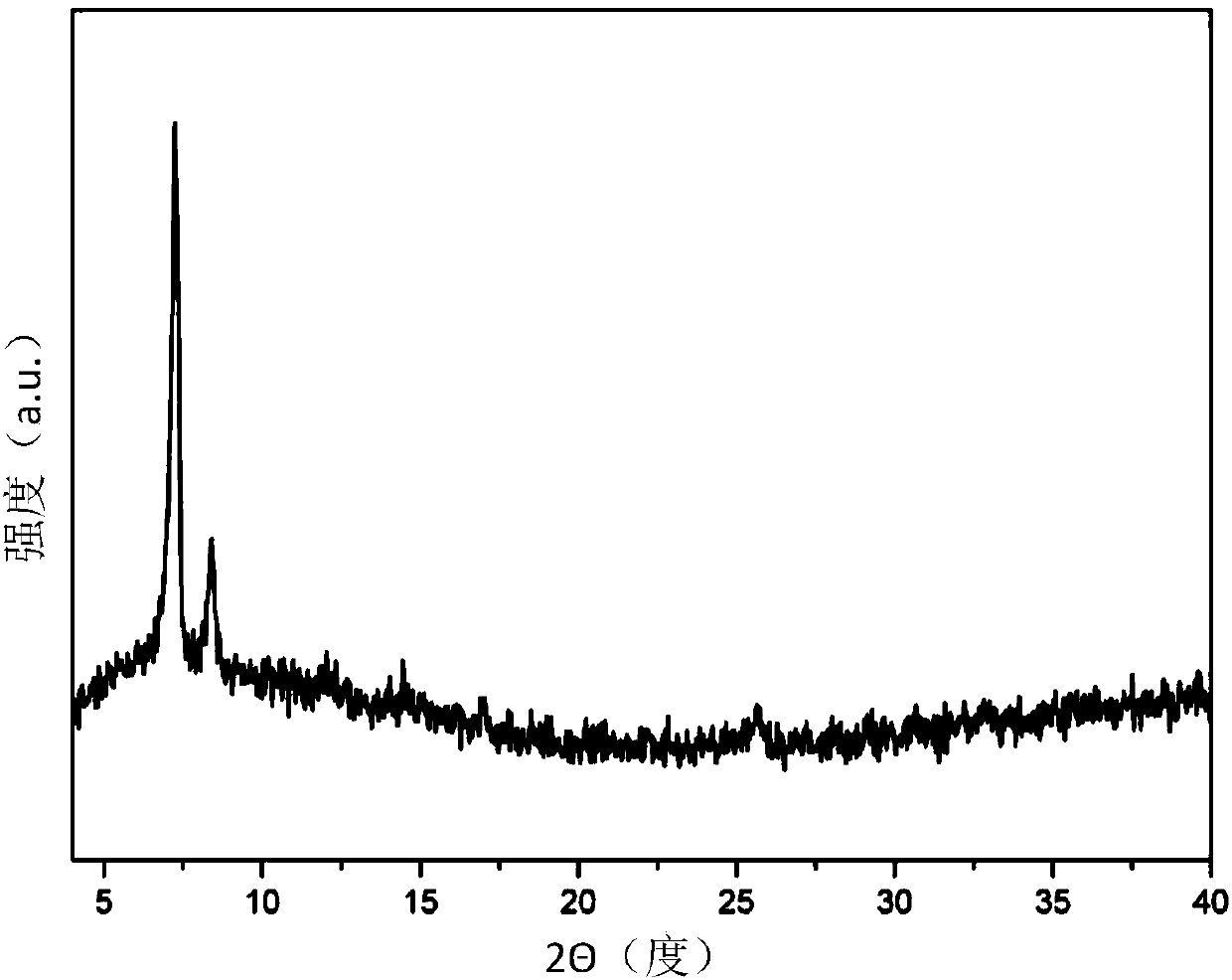

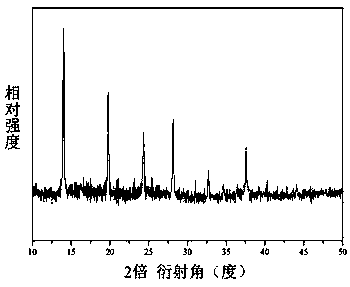

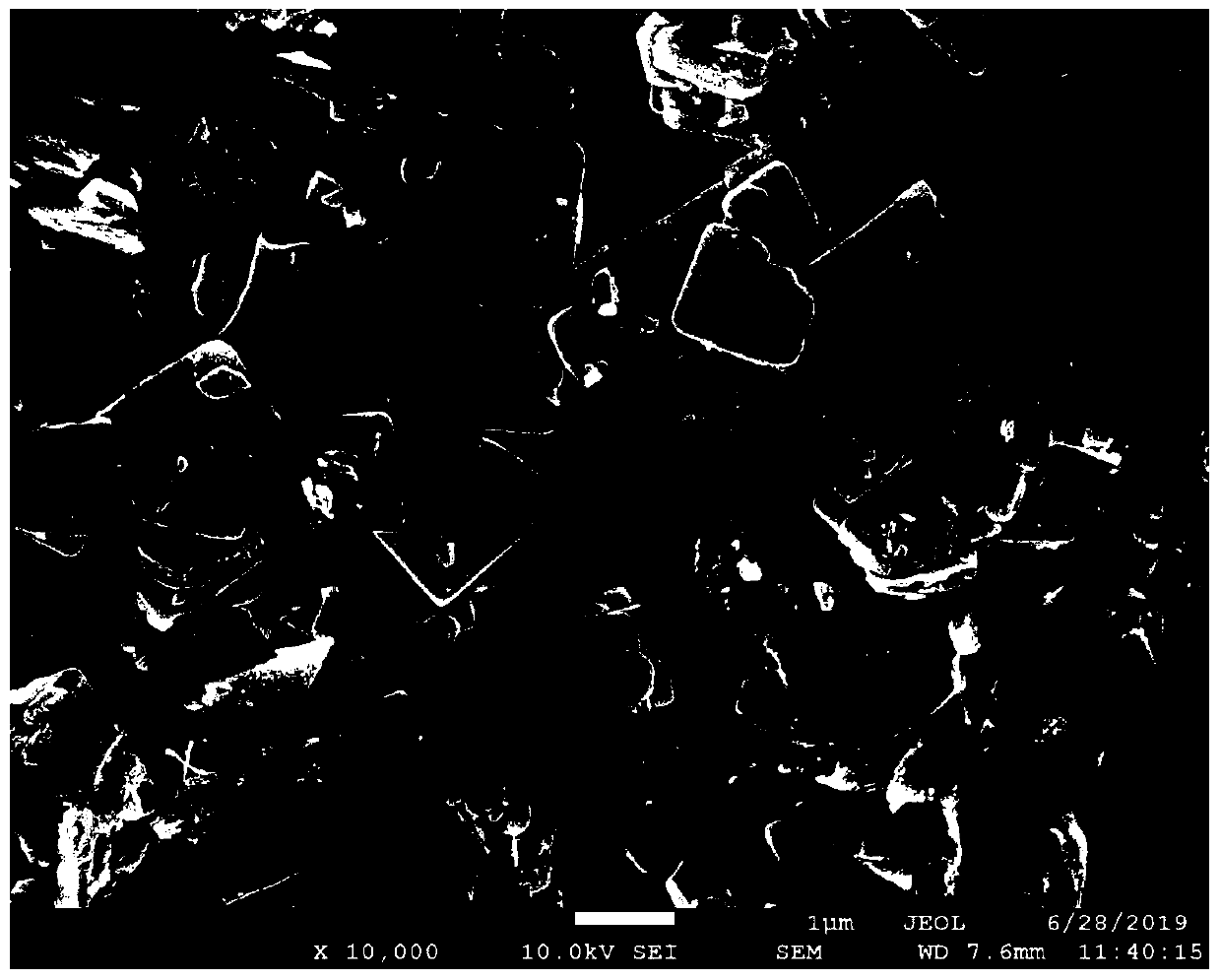

Preparation method of Bi4NbO8Cl

PendingCN110773205AUniform crystal sizeThin facetPhysical/chemical process catalystsWater/sewage treatment by irradiationChloride potassiumPhoto catalysis

The invention relates to the technical field of photocatalytic materials, and particularly discloses a preparation method of Bi4NbO8Cl. The preparation method of the Bi4NbO8Cl comprises the followingsteps: carrying out a hydrothermal reaction on bismuth nitrate pentahydrate and potassium chloride under alkaline conditions, and calcining a hydrothermal reaction product, niobium pentoxide, potassium chloride and sodium chloride to obtain the Bi4NbO8Cl. The preparation method of Bi4NbO8Cl disclosed by the invention is simple to operate, low in preparation cost and low in energy consumption, andthe obtained Bi4NbO8Cl is good in crystal form structure and relatively high in photocatalytic activity.

Owner:河北地质大学

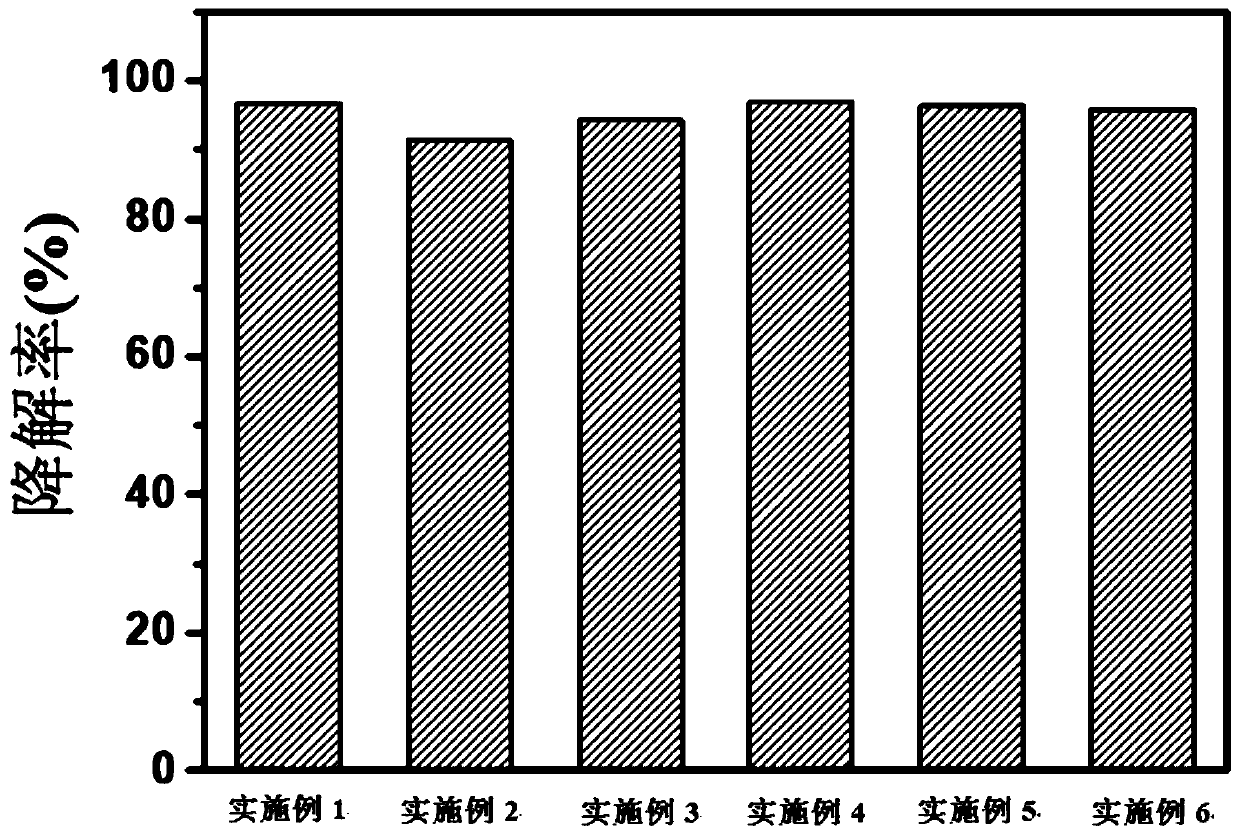

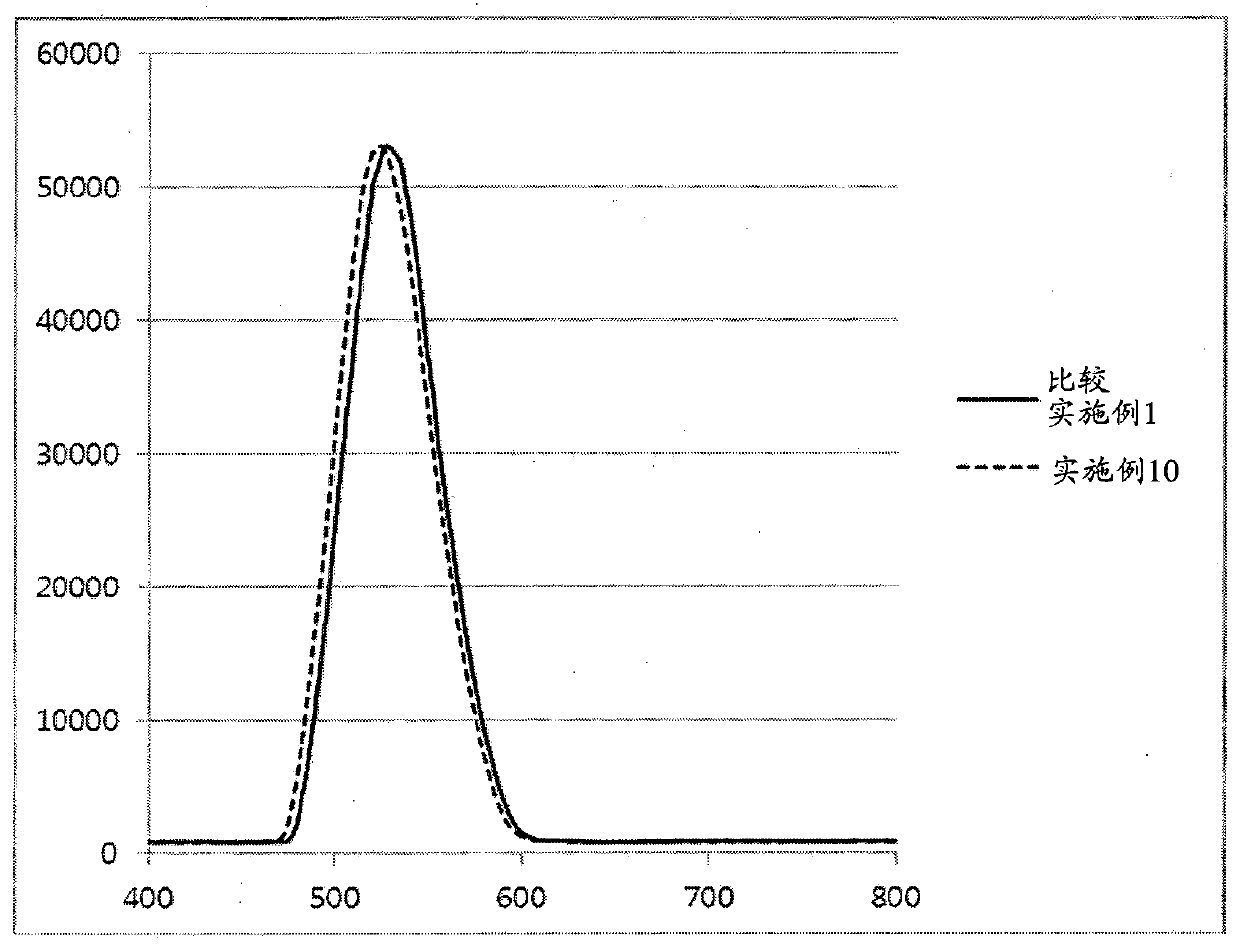

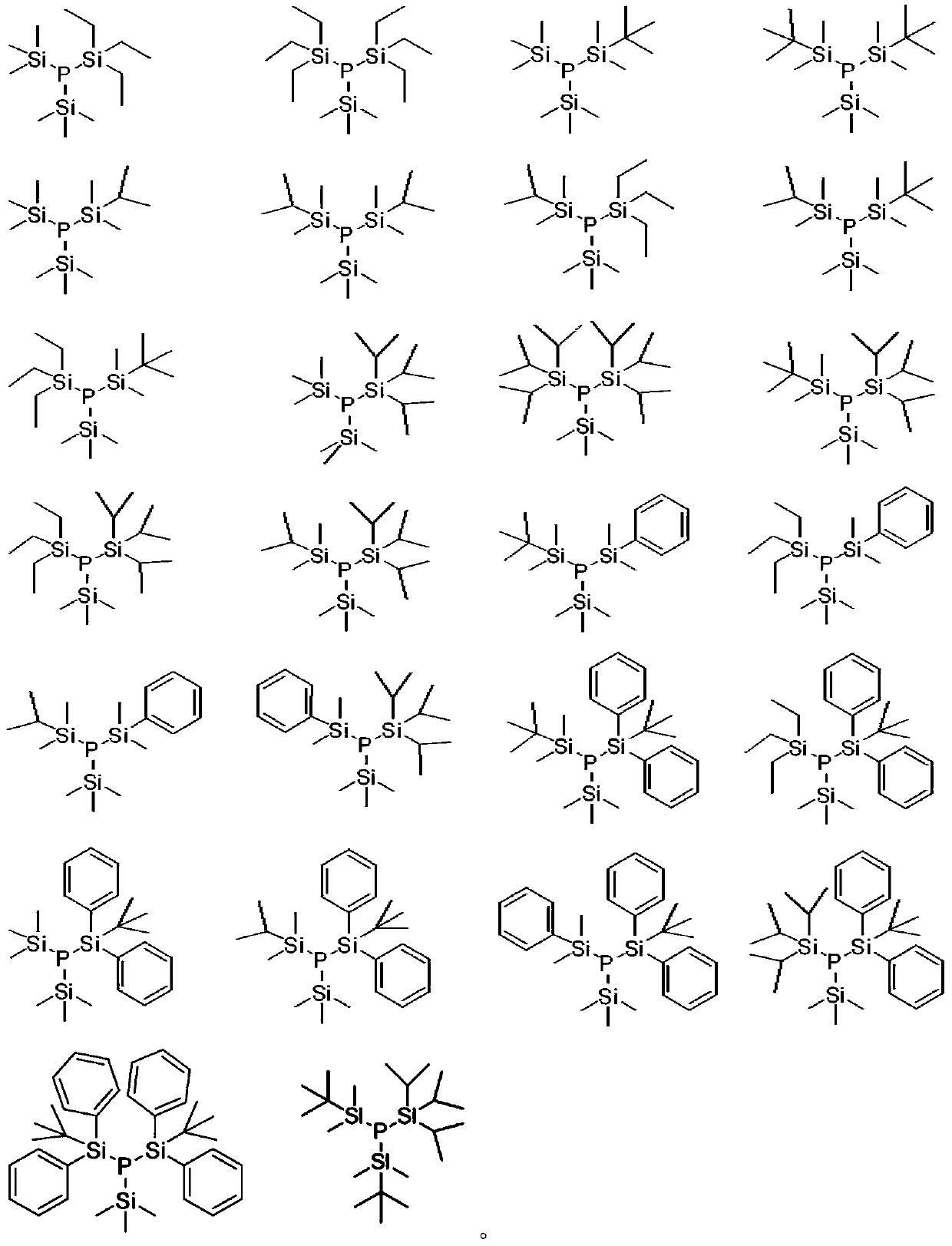

Phosphine precursor for preparing quantum dot and quantum dot prepared therefrom

ActiveCN110612339AUniform crystal sizeImprove luminous efficiencyPhosphorus organic compoundsLuminescent compositionsQuantum dotOrganic chemistry

Owner:SK CHEM CO LTD

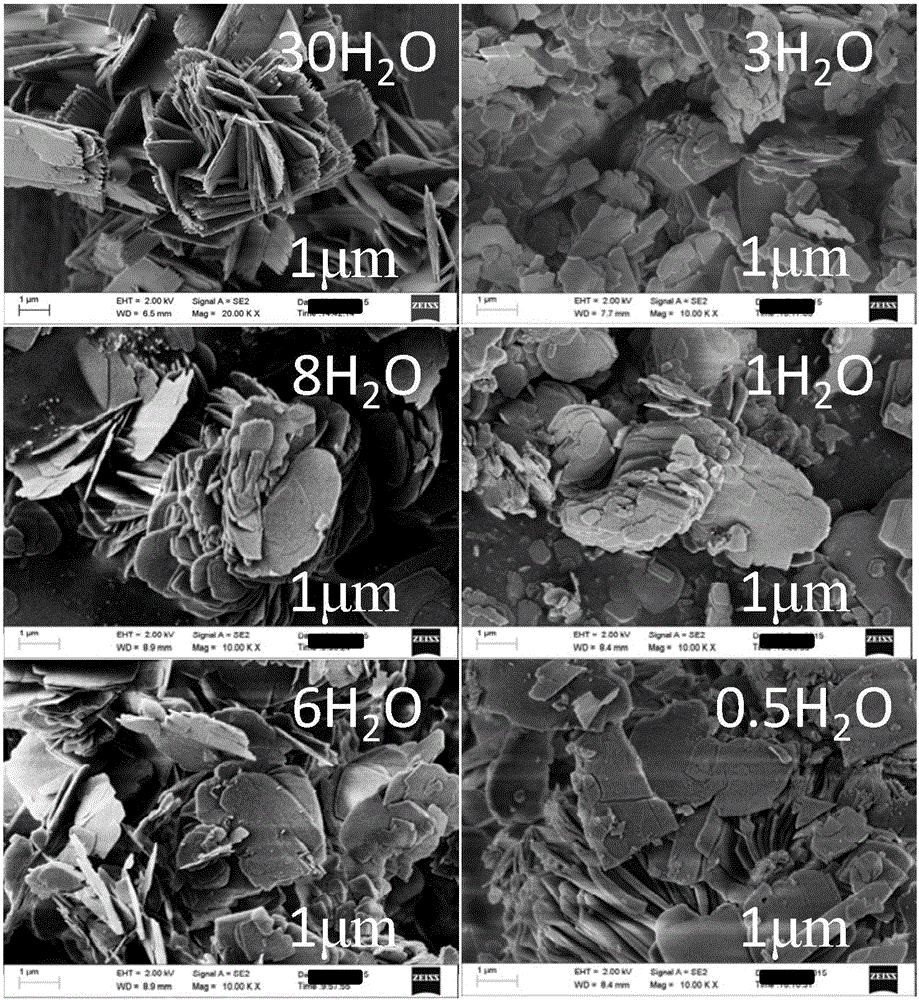

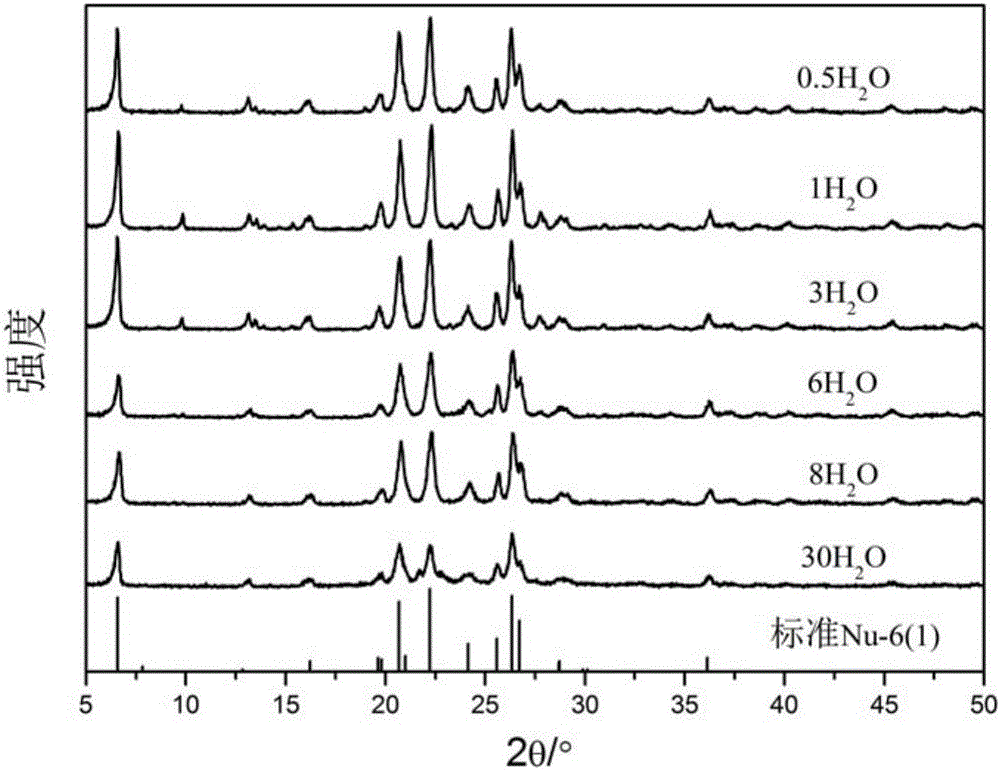

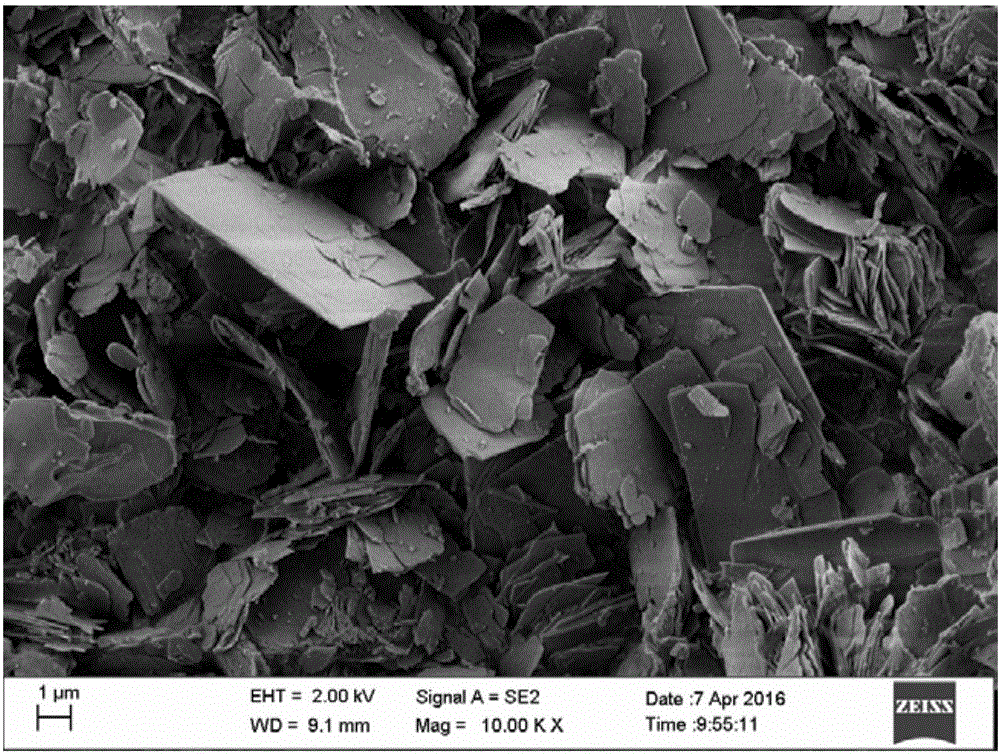

Synthesis method of Nu-6(1) molecular sieve

InactiveCN106082258AReduce contentLow costCrystalline aluminosilicate zeolitesMolecular sieveAlcohol

The invention discloses a method for synthesizing a Nu-6(1) molecular sieve. The method comprises the following steps that 1, a mother solution is prepared, wherein a template agent and ethyl alcohol are mixed to obtain a solution A, a silicon source, an alkali source and water are mixed to obtain a solution B, an aluminum source, water and acid with a pH value regulating effect are mixed to obtain a solution C, the solution B is dropwise added into the solution A, the solution C is dropwise added into the mixed solution of the solution A and the solution B, aging is conducted, and seed crystals are added to obtain the mother solution; 2, the mother solution obtained in the step 1 is dried and ground into powder; 3, the powder and water are mixed, and the Nu-6(1) molecular sieve is synthesized through crystallization. According to the technical scheme, the content of the water and the template agent in the raw materials is greatly decreased, so that raw material cost and environmental pollution are greatly reduced, and the green chemistry requirement is met.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

High-concentration saline wastewater energy-saving crystallization device

ActiveCN105439344BReduce energy consumptionUniform crystal sizeMultistage water/sewage treatmentHigh concentrationSlurry

Owner:HAIZHOU E P GRP CO LTD

A method for preparing a wafer-level graphene micro-nano single crystal array

InactiveCN108441948BScale controllableSimple manufacturing methodPolycrystalline material growthFrom chemically reactive gasesMicro nanoSingle crystal

The invention belongs to the technical field of graphene material synthesis and preparation and more particularly relates to a preparation method of a wafer level graphene micro-nano monocrystal array. The method comprises the steps of performing chemical vapor deposition on the surface of polycrystal copper foil in a mixed atmosphere containing methane and oxygen for growth to form the graphene micro-nano monocrystal array, wherein methane serves as a carbon source for graphene growth; the copper foil serves as a catalytical substrate for the graphene growth; and the oxygen serves as etchinggas in a formation process of the graphene monocrystal array. According to the method, a graphene array structure is directly prepared by a simple one-step chemical vapor deposition method; the disadvantage of complicated steps of complicated micro-nano machining, etching and the like required by a graphene film in a subsequent application is overcome; quick and low-cost preparation of a large area micro-nano graphene monocrystal is achieved; and the application in large-scale device preparation is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com