Cobalt-nickel bimetallic hydroxyl phosphite rod-like crystal array film and preparation method thereof

A metal hydroxy phosphite, crystal array technology, applied in chemical instruments and methods, physical/chemical process catalysts, optical components, etc., can solve problems such as no reports of double transition metal hydroxy phosphite rod-shaped crystal array thin film materials. , to achieve the effect of strengthening the anisotropic growth trend and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

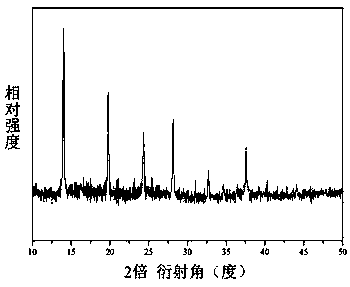

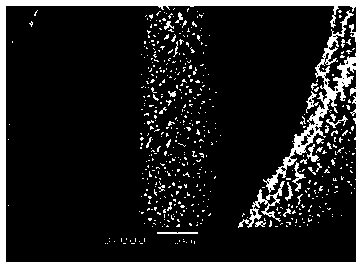

[0023]Dissolve 0.2908 g nickel nitrate hexahydrate, 0.2910 g cobalt nitrate hexahydrate and 0.2120 g sodium hypophosphite in 10 ml deionized water, stir evenly, wherein the molar concentration ratio of nickel nitrate hexahydrate, cobalt nitrate hexahydrate, and sodium hypophosphite is 1:1:2, the total molar concentration of nickel ions and cobalt ions is 0.20 mol / L. 10 ml of N,N-dimethylacetamide was added to the mixed solution, and a homogeneous solution was obtained after magnetic stirring. Activated carbon fibers were obtained by heat-treating natural cotton fibers at 1000 °C for 1 h in a nitrogen atmosphere. Submerge the pre-cleaned activated carbon fibers in the above solution for 5 hours. The mixed solution, together with activated carbon fibers, was reacted at 160 °C for 10 h. After the reaction, the reaction kettle was naturally cooled to normal temperature, and the activated carbon fiber was taken out, washed repeatedly with absolute ethanol and deionized water thre...

Embodiment 2

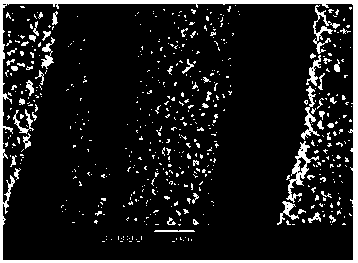

[0026] Dissolve 0.2908 g nickel nitrate hexahydrate, 0.2910 g cobalt nitrate hexahydrate and 0.2120 g sodium hypophosphite in 20 ml deionized water, stir evenly, wherein the molar concentration ratio of nickel nitrate hexahydrate, cobalt nitrate hexahydrate, and sodium hypophosphite is 1:1:2, the total molar concentration of nickel ions and cobalt ions is 0.10 mol / L. 20 ml of N,N-dimethylacetamide was added to the mixed solution, and a homogeneous solution was obtained after magnetic stirring. Activated carbon fibers were obtained by heat-treating natural cotton fibers at 1000 °C for 1 h in a nitrogen atmosphere. Submerge the pre-cleaned activated carbon fibers in the above solution for 5 hours. The mixed solution, together with activated carbon fibers, was reacted at 140 °C for 20 h. After the reaction, the reaction kettle was naturally cooled to normal temperature, and the activated carbon fiber was taken out, washed repeatedly with absolute ethanol and deionized water thr...

Embodiment 3

[0029] Dissolve 0.5816 g nickel nitrate hexahydrate, 0.5820 g cobalt nitrate hexahydrate and 0.4140 g sodium hypophosphite in 30 ml deionized water, stir evenly, wherein the molar concentration ratio of nickel nitrate hexahydrate, cobalt nitrate hexahydrate, and sodium hypophosphite is 1:1:2, the total molar concentration of nickel ions and cobalt ions is 0.13 mol / L. 30 ml of N,N-dimethylacetamide was added to the mixed solution, and a homogeneous solution was obtained after magnetic stirring. Activated carbon fibers were obtained by heat-treating natural cotton fibers at 1000 °C for 1 h in a nitrogen atmosphere. Submerge the pre-cleaned activated carbon fibers in the above solution for 5 hours. The mixed solution, together with activated carbon fibers, was reacted at 150 °C for 12 h. After the reaction, the reaction kettle was naturally cooled to normal temperature, and the activated carbon fiber was taken out, washed repeatedly with absolute ethanol and deionized water thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com