Continuous vacuum crystallization device with flash vaporization and cooling

A vacuum crystallization and crystallization device technology, applied in the direction of solution crystallization, evaporation, chemical instruments and methods, etc., can solve the problems of unguaranteed product quality, low labor productivity, affecting product quality, etc., and achieve the improvement of labor productivity and labor efficiency. Improvement and the effect of fewer operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

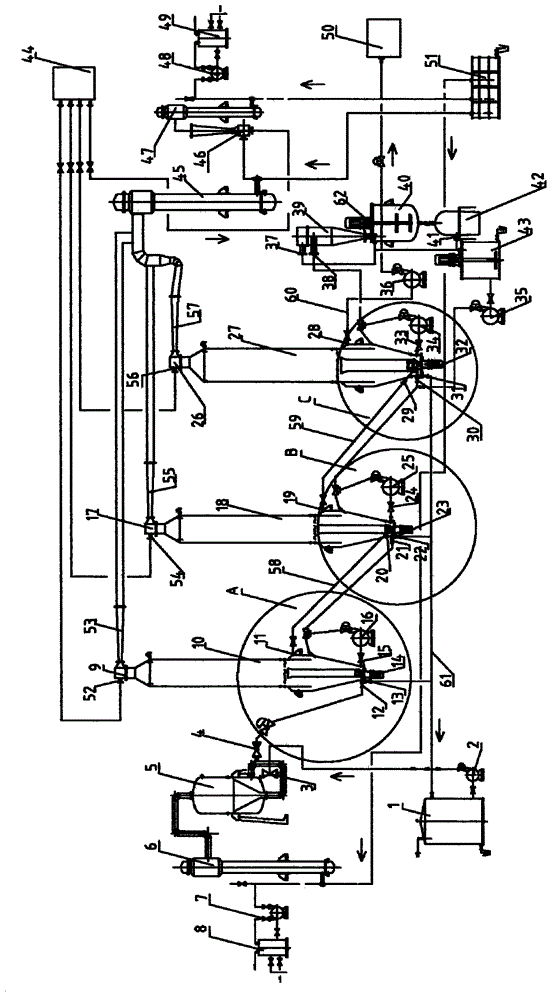

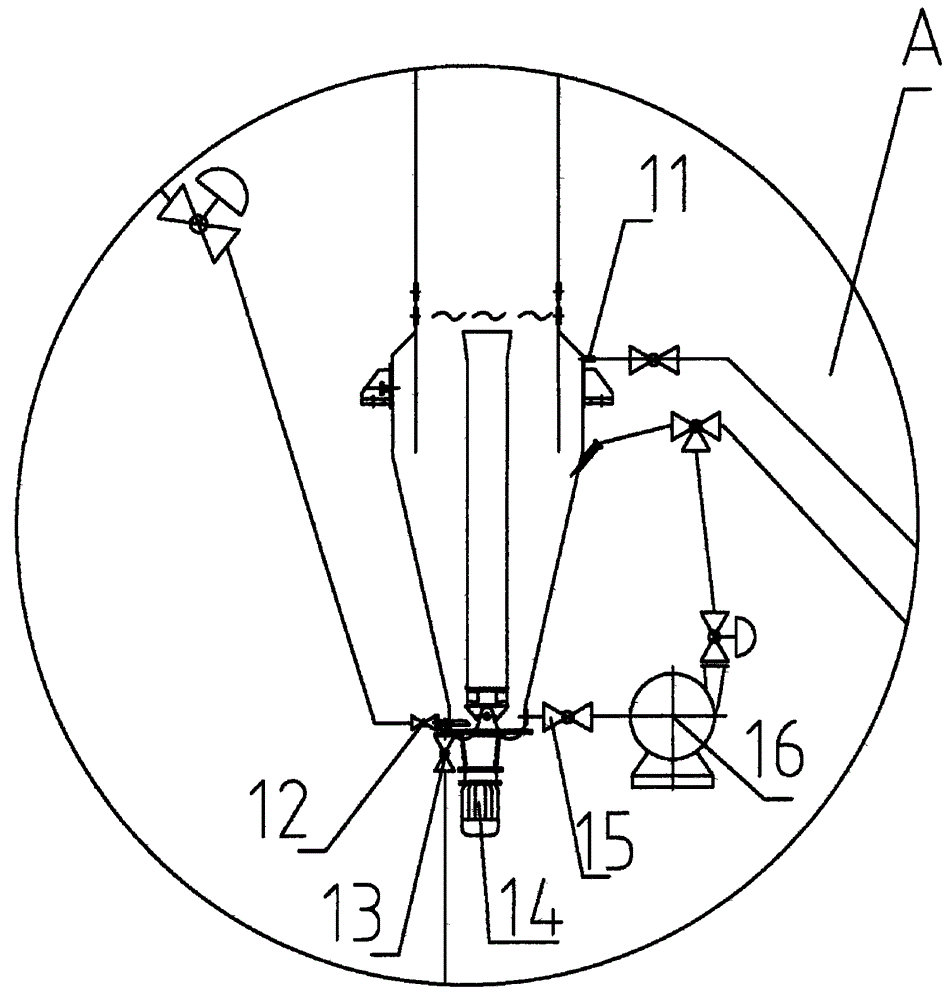

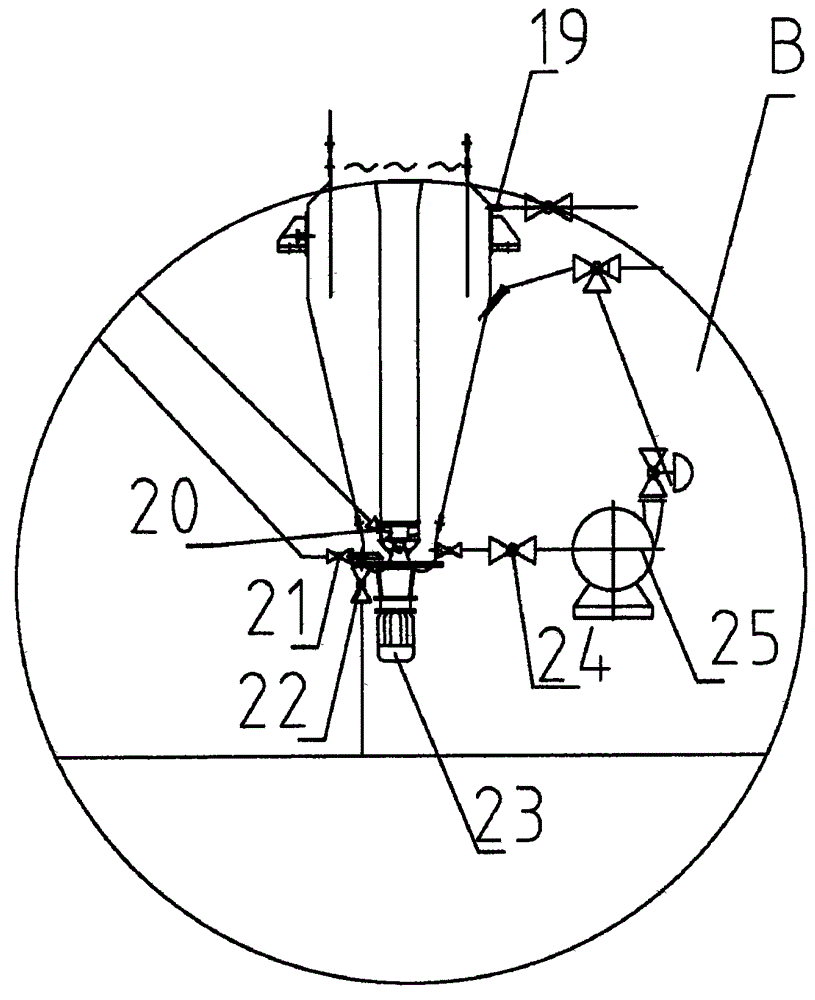

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the present invention is a vacuum flash cooling continuous crystallization device, comprising raw material storage tank 1, raw material pump 2, self-evaporator 5, No. 1 vacuum crystallizer 10, No. 2 vacuum crystallizer 18, No. 3 vacuum crystallizer 27, The hydrocyclone 39, the slurry bucket 40, and the centrifuge 42 are characterized in that: the raw material storage tank 1 is sequentially connected to the raw material pump 2, the self-evaporator 5, the No. 1 vacuum crystallizer 10, the No. 2 vacuum crystallizer 18, and the No. 3 vacuum crystallizer. No. vacuum crystallizer 27, hydrocyclone 39, slurry bucket 40, centrifuge 42, the top of the self-evaporator 5 is connected to No. 1 surface cooler 6 through pipelines, and No. 1 surface cooler 6 is connected to water ring vacuum pump 7 through pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com