Preparation method of wafer level graphene micro-nano monocrystal array

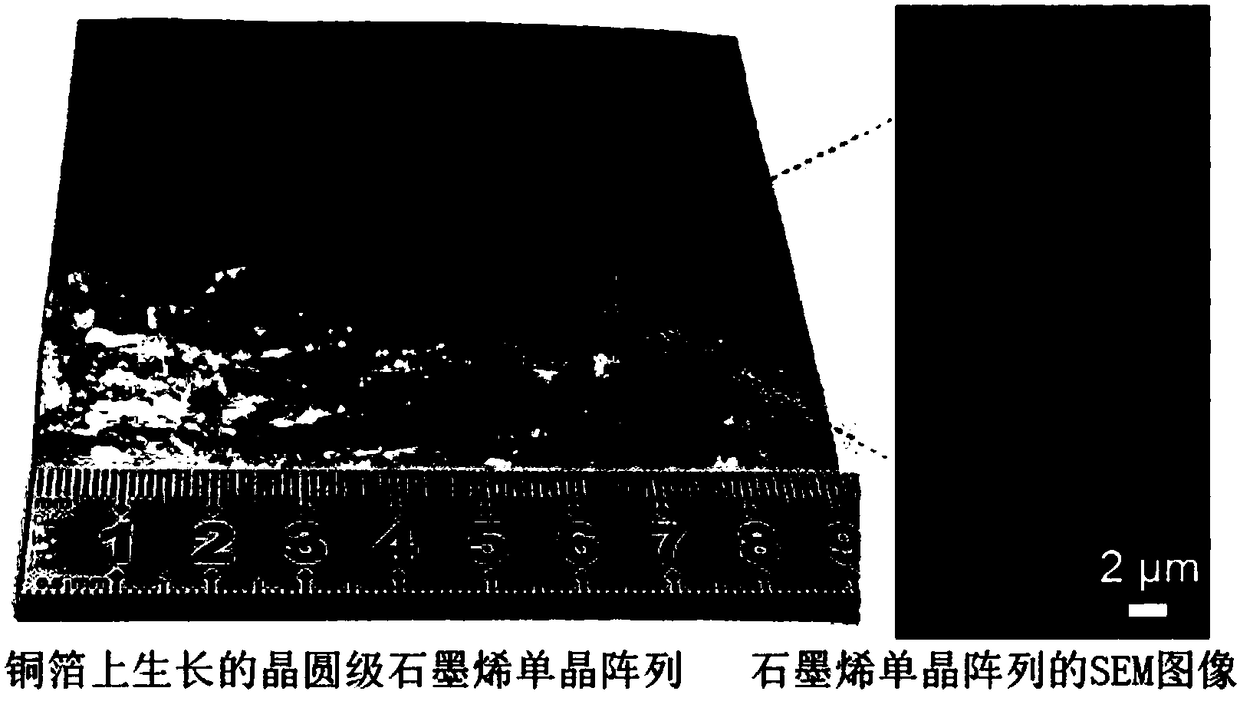

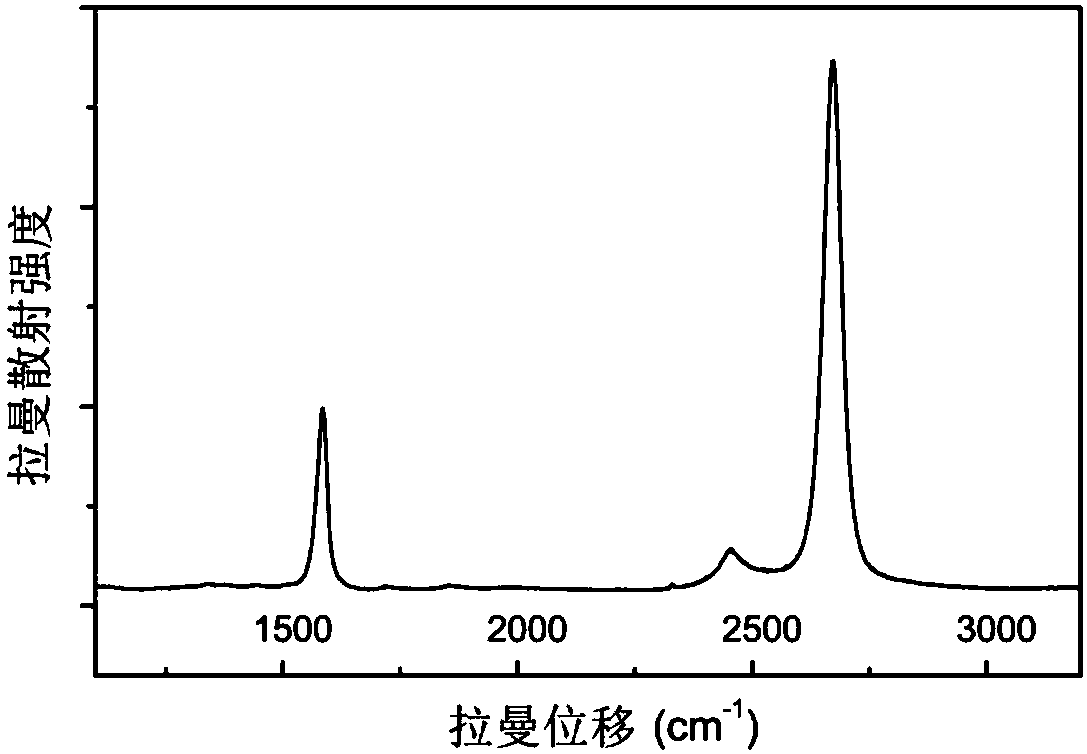

A graphene, micro-nano technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of inability to prepare large areas, complicated steps of graphene micro-nano single crystal array, etc., and achieve good application prospects , the effect of less defects and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

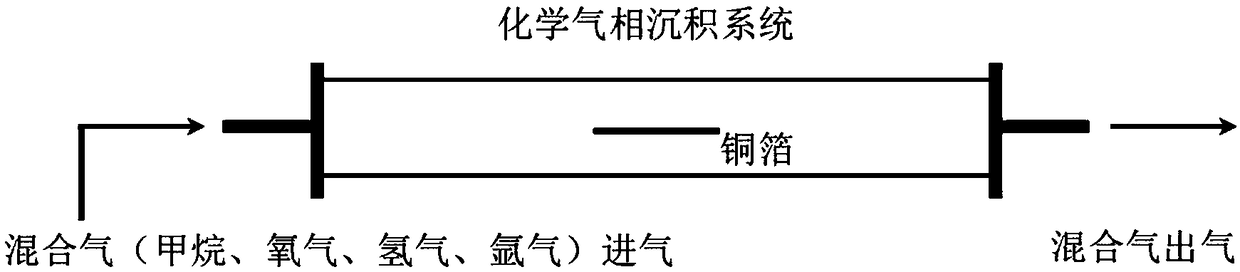

[0030] The method for preparing a graphene micro / nano single crystal array provided by the present invention may specifically include the following steps:

[0031] (1) Pretreatment of copper foil: After immersing the copper foil in a 1:1:1 mixed solution of acetic acid, ethanol and deionized water for 15 minutes, rinse it with deionized water, and then dry it with nitrogen; Commercially available single crystal copper foil or polycrystalline copper foil can be used as the copper foil.

[0032] (2) The temperature rise of the metal copper foil: Put the cleaned and dry copper foil in a chemical vapor deposition system, and pass in argon gas. The temperature will rise to 1000-1030°C within 30-60 minutes, and then pass in hydrogen gas to make hydrogen The volume fraction of the mixed gas in the system is 1.8-2.1%, and the temperature is continued to rise to 1050-1070°C, and the temperature range is maintained for 10-30 minutes.

[0033] (3) Direct growth of graphene single crystal array...

Embodiment 2

[0045] (1) The size of 3 pieces is 9*9cm 2 Copper foil with a size and thickness of 100 microns is soaked in a 1:1:1 mixed solution of acetic acid, ethanol and deionized water for 15 minutes, rinsed with deionized water, and dried with nitrogen.

[0046] (2) Put the cleaned 3 pieces of copper foil into the chemical vapor deposition system, and pass in 500sccm argon to remove the clean air. The temperature will be raised to 1030℃ within 40 minutes, and then the high purity hydrogen at a flow rate of 10sccm will be introduced, and the temperature will continue to rise to 1070°C and keep the temperature constant for 10 minutes.

[0047] (3) Keep the temperature and the flow of argon and hydrogen unchanged, continue to feed 5 sccm of methane with a concentration of 2% into the chemical vapor deposition system, and feed 2-4 sccm of oxygen with a concentration of 0.1% respectively, under normal pressure conditions After 5 hours of growth, the temperature is lowered to room temperature, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com