Preparation method of Bi4NbO8Cl

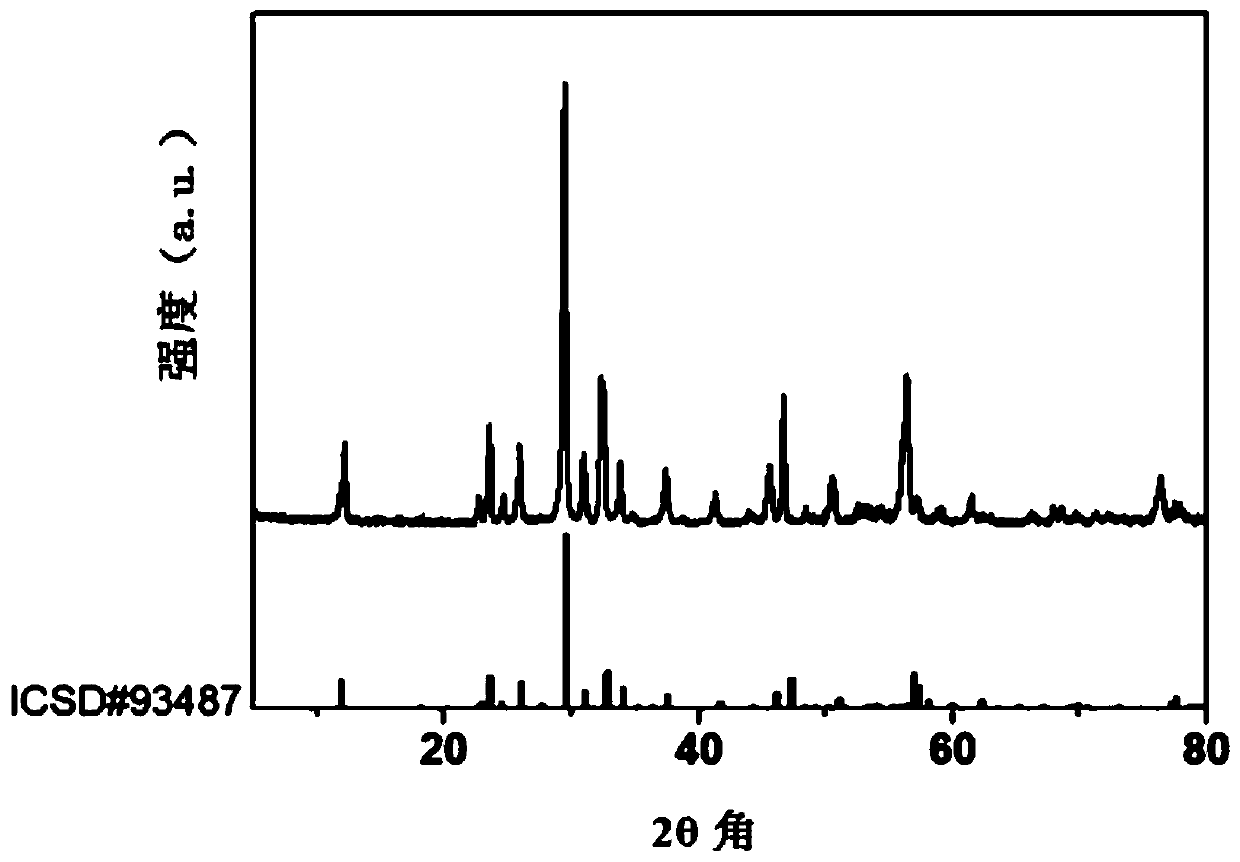

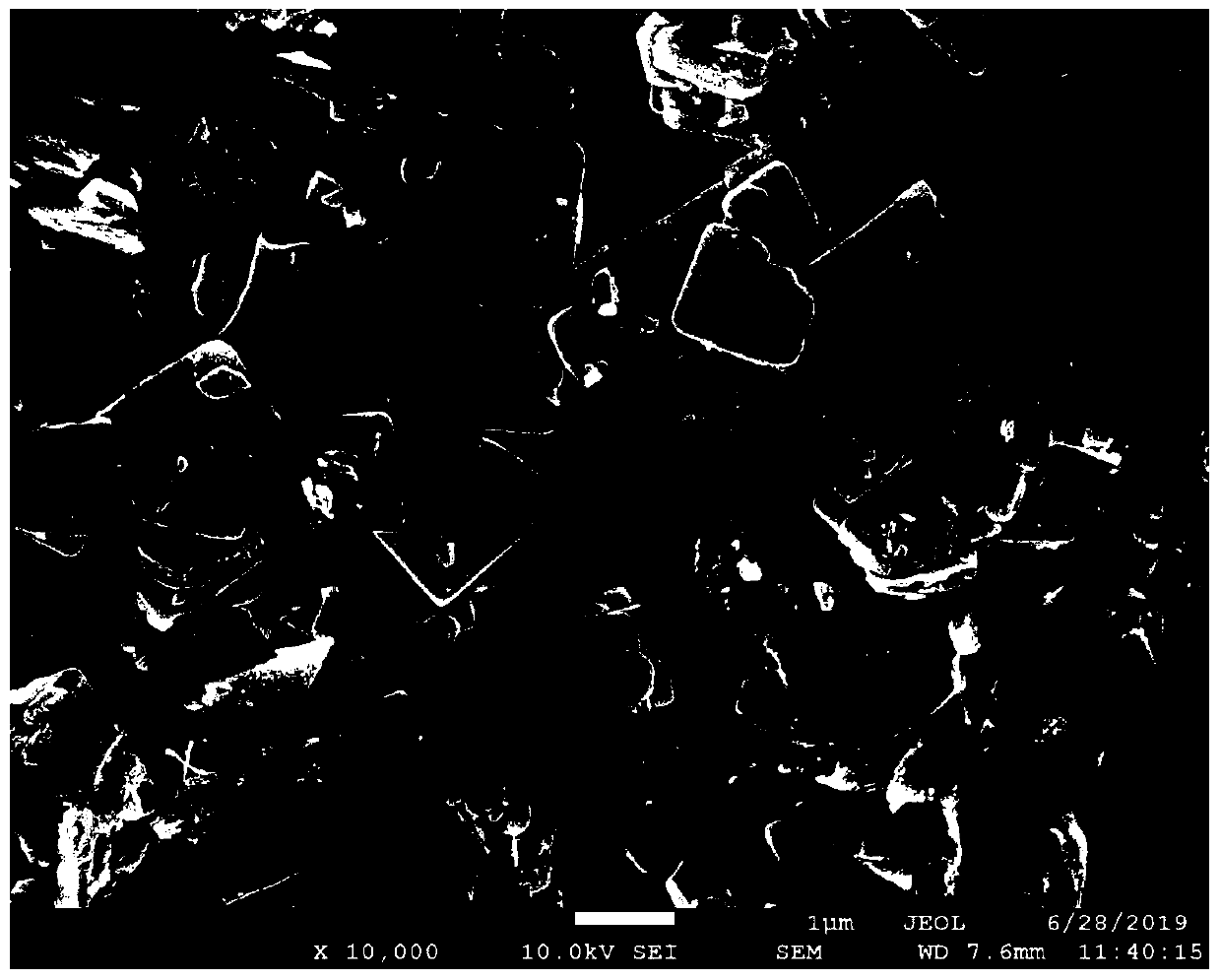

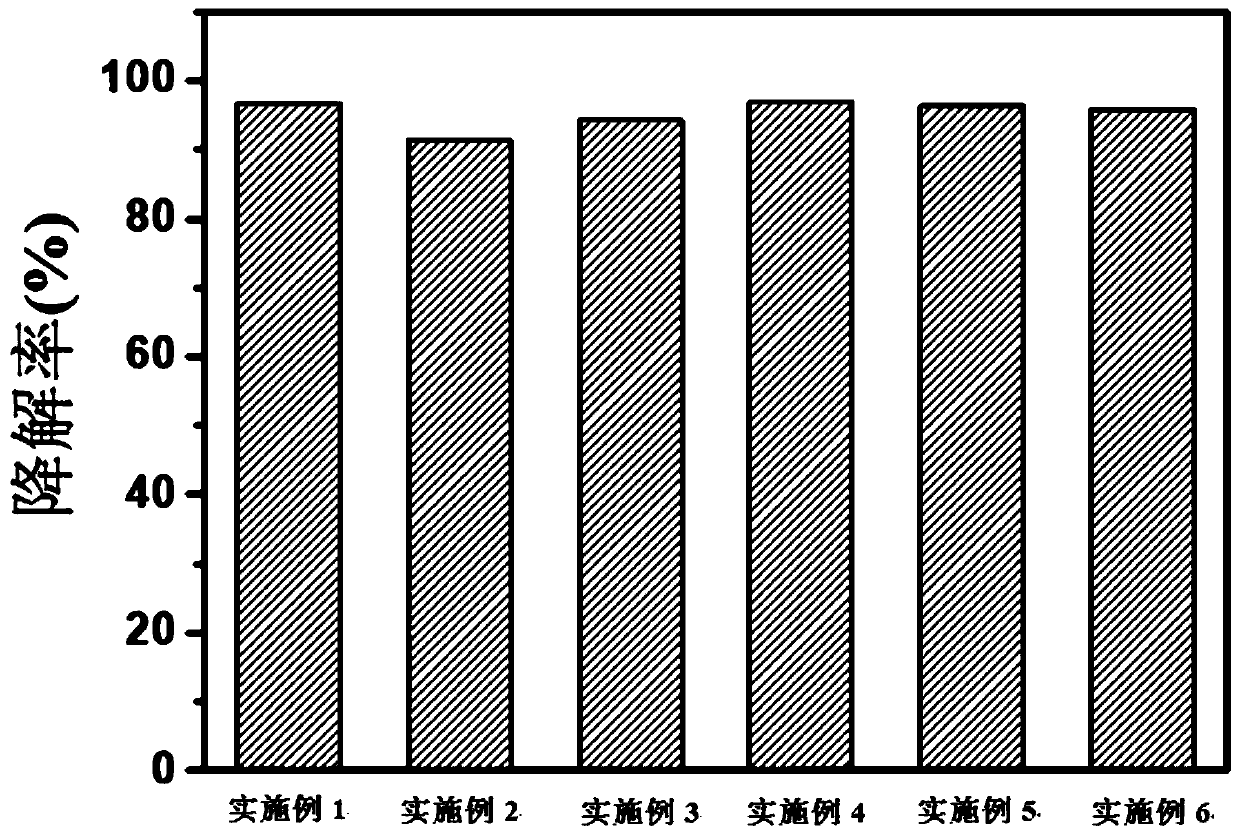

A technology of hydrothermal reaction and potassium chloride, which is applied in the field of photocatalytic materials, can solve the problems of uncontrollable crystal plane growth, long reaction time at high temperature, and low photocatalytic efficiency, and achieve excellent visible light catalytic performance, uniform crystal size, and catalytic highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A Bi 4 NbO 8 The preparation method of Cl comprises the following processing steps:

[0033] a. According to Bi 4 NbO 8 For the stoichiometry of corresponding elements in Cl, add 1.455g of bismuth nitrate pentahydrate and 0.224g of potassium chloride into a beaker filled with 30mL of distilled water, stir at 200r / min for 1h, and obtain a white suspension;

[0034] b. Slowly add 1 mol / L sodium hydroxide aqueous solution to the white suspension, and keep stirring until the pH of the white suspension reaches 12.5, and stir at 200r / min for 0.5h to obtain a suspension;

[0035] c. Transfer the suspension into a polytetrafluoroethylene-lined hydrothermal reaction kettle, tighten the lid, put it in an oven, adjust the temperature of the oven to 160°C, and carry out hydrothermal reaction. The reaction time is 18h; The resulting product was filtered, washed, and dried in an oven at 55°C for 6 hours to obtain a hydrothermal reaction product;

[0036] d. Mix the hydrothermal ...

Embodiment 2

[0039] A Bi 4 NbO 8The preparation method of Cl comprises the following processing steps:

[0040] a. According to Bi 4 NbO 8 For the stoichiometry of corresponding elements in Cl, add 1.455g of bismuth nitrate pentahydrate and 0.224g of potassium chloride into a beaker filled with 30mL of distilled water, stir at 200r / min for 1h, and obtain a white suspension;

[0041] b. Slowly add 1 mol / L sodium hydroxide aqueous solution to the white suspension, and keep stirring until the pH of the white suspension reaches 13, and stir at 200r / min for 0.5h to obtain a suspension;

[0042] c. Transfer the suspension into a polytetrafluoroethylene-lined hydrothermal reaction kettle, tighten the lid, put it in an oven, adjust the temperature of the oven to 170°C, and carry out hydrothermal reaction. The reaction time is 24h; The obtained product was filtered, washed, and dried in an oven at 60°C for 7 hours to obtain a hydrothermal reaction product;

[0043] d. After mixing the hydrothe...

Embodiment 3

[0045] A Bi 4 NbO 8 The preparation method of Cl comprises the following processing steps:

[0046] a. According to Bi 4 NbO 8 For the stoichiometry of corresponding elements in Cl, add 1.455g of bismuth nitrate pentahydrate and 0.224g of potassium chloride into a beaker filled with 32mL of distilled water, stir at 200r / min for 1h, and obtain a white suspension;

[0047] b. Slowly add 1 mol / L sodium hydroxide aqueous solution to the white suspension, and keep stirring until the pH of the white suspension reaches 13.5, and stir at 200r / min for 0.5h to obtain a suspension;

[0048] c. Transfer the suspension into a polytetrafluoroethylene-lined hydrothermal reaction kettle, tighten the lid, put it in an oven, adjust the temperature of the oven to 180°C, and carry out hydrothermal reaction. The reaction time is 36h; The obtained product was filtered, washed, and dried in an oven at 60°C for 8 hours to obtain a hydrothermal reaction product;

[0049] d. After mixing the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com