Inorganic-organic coordination compound separation membrane and production method and application thereof

A coordination compound and compound technology, applied in the field of separation membranes, can solve the problems of difficult preparation, poor membrane separation and durability, and achieve the effects of uniform crystal size, excellent performance, and good thermal and chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method for the above-mentioned inorganic-coordination compound separation membrane, the method comprising the following steps:

[0034] 1) forming a seed film on the surface of the substrate;

[0035] 2) Secondary growth on the seed film to form a separation layer.

[0036] In the preparation method of the present invention, preferably, step 1) includes:

[0037] 1-1) In a polar solvent, a compound containing M element is subjected to a contact reaction with the organic ligand, and the product after the contact reaction is separated from solid to liquid to obtain an inorganic-organic coordination compound seed crystal, wherein the The M is selected from group IIB elements, and the organic ligand is an imidazole compound;

[0038] 1-2) dispersing the inorganic-organic coordination compound seed crystals obtained in step 1-1) in water to obtain an aqueous dispersion;

[0039] 1-3) Put the substrate into the aqueous disp...

Embodiment 1

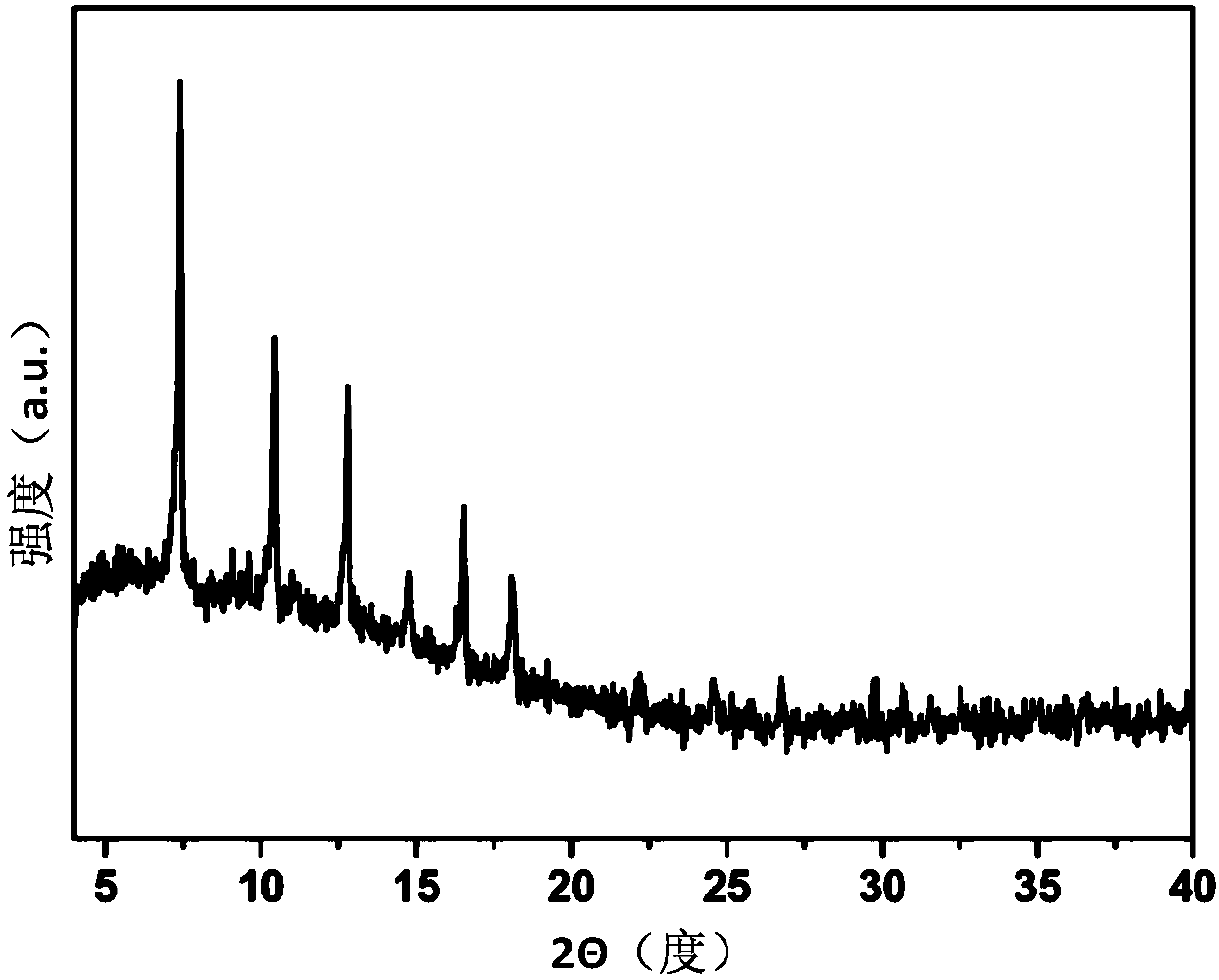

[0075] (1) Preparation of Zn(mim) 2 seed crystal

[0076] Add 1.5g of zinc nitrate hexahydrate and 20g of 2-methylimidazole into 90ml of deionized water to disperse evenly, and stir and react at 25°C for 30min. The product was centrifuged, washed three times with deionized water, and dried at 60°C to obtain a white seed crystal powder.

[0077] (2) Preparation of Zn(mim) 2 Seed solution

[0078] 0.2 g of the obtained seed crystal powder was added into 10 ml of deionized water, and was ultrasonicated for 30 min at a frequency of 40 kHz to uniformly form a seed crystal dispersion.

[0079] (3) Preparation of Zn(mim) 2 Seed film

[0080] Immerse the treated stainless steel mesh (800 mesh in pore size and 2 μm in thickness) in the dispersed seed crystal dispersion liquid, ultrasonically treat it at a frequency of 30 kHz for 10 min, and dry it at 120 ° C for 2 h, repeat the above dipping and ultrasonic 1. The drying step is performed twice to obtain a continuous and uniform s...

Embodiment 2

[0093] Step (1) prepares Zn(mim) 2 Seed and step (2) prepare Zn(mim) 2 The seed solution was carried out according to the method of Example 1.

[0094] (3) Preparation of Zn(mim) 2 Seed film

[0095] Immerse the treated stainless steel mesh (400 mesh in pore size and 2 μm in thickness) in the dispersed seed crystal dispersion liquid, ultrasonically treat it for 10 min at a frequency of 30 kHz, and dry it at 120 °C for 2 h, repeat the above dipping and ultrasonic 1. The drying step is performed twice to obtain a continuous and uniform seed crystal film formed on the stainless steel mesh.

[0096] (4) Preparation of Zn(mim) 2 Coordination Compound Separation Membrane

[0097] Dissolve 0.11g of zinc acetate dihydrate in 2ml of deionized water, dissolve 1.150g of 2-methylimidazole in 18ml of deionized water, mix the above two solutions and put the stainless steel mesh coated with the seed crystal film vertically into the mixed solution In the reaction at 25°C for 24h, Zn(mim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com