Separation membrane, preparation method and application thereof

A separation membrane and separation layer technology, which is applied in the field of separation membranes, can solve the problems of difficult preparation, poor durability of membrane separation membranes, etc., and achieve the effects of uniform crystal size, excellent performance, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides the preparation method of above-mentioned separation membrane, and this method comprises the following steps:

[0034] 1) forming a seed film on the surface of the substrate;

[0035] 2) Secondary growth on the seed film to form a separation layer.

[0036] In the preparation method of the present invention, preferably, step 1) includes:

[0037] 1-1) In the presence of an organic solvent, the compound containing the M element is subjected to a contact reaction with the organic carboxylic acid, and the product after the contact reaction is separated from solid to liquid to obtain an inorganic-organic coordination compound seed crystal, wherein the Said M is an element of group IVB;

[0038] 1-2) dispersing the inorganic-organic coordination compound seed crystals obtained in step 1-1) in water to obtain an aqueous dispersion;

[0039] 1-3) Put the substrate into the aqueous dispersion prepared in step 1-2) and perform ultrasonic tr...

Embodiment 1

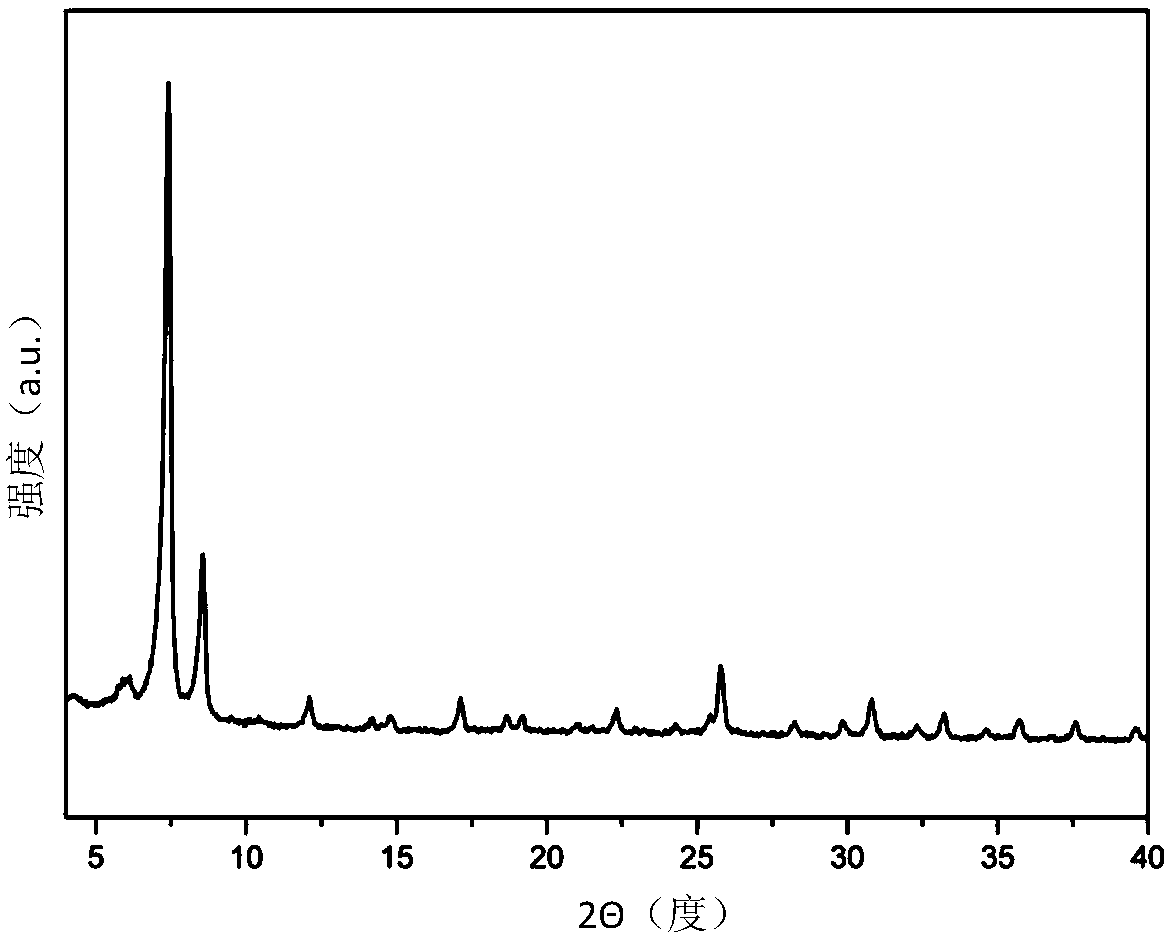

[0079] (1) Preparation of Zr-H 2 BDC Seed

[0080] 0.08g ZrCl 4 Add to 20ml DMF to disperse evenly, then add 0.057g terephthalic acid and 0.043g benzoic acid, and mix well under stirring. Then place it at 120°C for 24h. After cooling, the product was centrifuged, washed three times with DMF and deionized water, and then dried in an oven at 80°C to obtain a white seed crystal powder.

[0081] (2) Preparation of Zr-H 2 BDC seed solution

[0082] Add 25 mg of the obtained seed crystal powder into 50 ml of deionized water in a beaker, and disperse it uniformly by ultrasonication for 30 min at a frequency of 40 kHz to form a seed crystal dispersion.

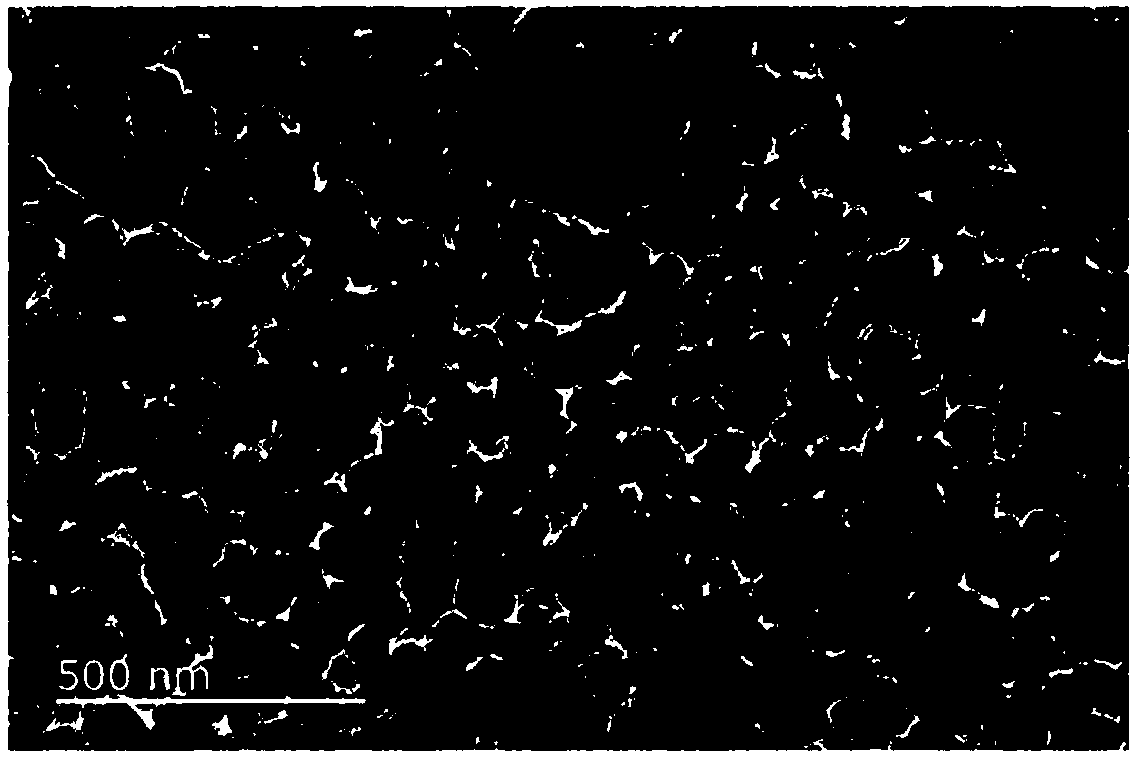

[0083] (3) Preparation of Zr-H 2BDC seed film

[0084] Put the treated stainless steel mesh carrier (pore size 500 mesh, thickness 2 μm) in a beaker containing 25ml of seed dispersion, ultrasonicate for 30min at a frequency of 40kHz, and bake in an oven at 120°C for 2h, repeat this step 3 times, A continuous, uniform seed film...

Embodiment 2

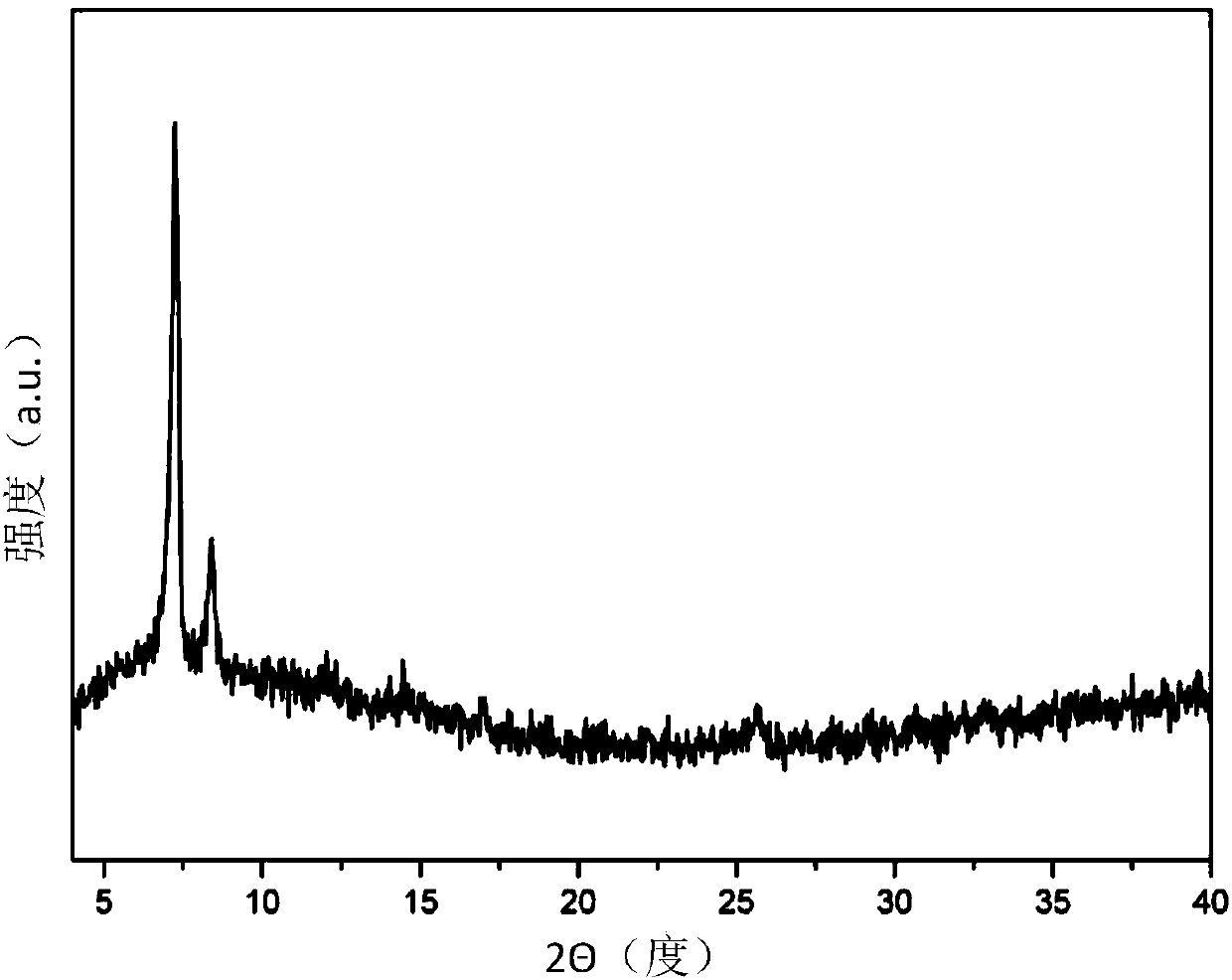

[0097] (1) Preparation of Zr-H 2 BDC Seed

[0098] 0.08g ZrCl 4 Add to 20ml DMF to disperse evenly, then add 0.057g terephthalic acid and 0.043g benzoic acid, and mix well under stirring. Then place it at 120°C for 24h. After cooling, the product was centrifuged, washed three times with DMF and deionized water, and then dried in an oven at 80°C to obtain a white seed crystal powder.

[0099] (2) Preparation of Zr-H 2 BDC seed solution

[0100] Add 25 mg of the obtained seed crystal powder into 50 ml of deionized water in a beaker, and disperse it uniformly by ultrasonication for 30 min at a frequency of 40 kHz to form the seed crystal solution.

[0101] (3) Preparation of Zr-H 2 BDC seed film

[0102] Put the treated stainless steel mesh carrier (500 mesh in pore size and 2 μm in thickness) in a beaker containing 25ml of seed solution, ultrasonicate for 30min at a frequency of 40kHz, and put in an oven at 120°C for 2h. Repeat this step 3 times to obtain A continuous, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com