Oxytetracycline hydrochloride preparation method

The technology of oxytetracycline hydrochloride and oxytetracycline base is applied in the field of preparation of oxytetracycline hydrochloride, which can solve the problems of low product quality and yield, long cooling crystallization time, and increase the impurity content of dehydrated oxytetracycline, so as to reduce impurities. The effect of generation, uniform crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

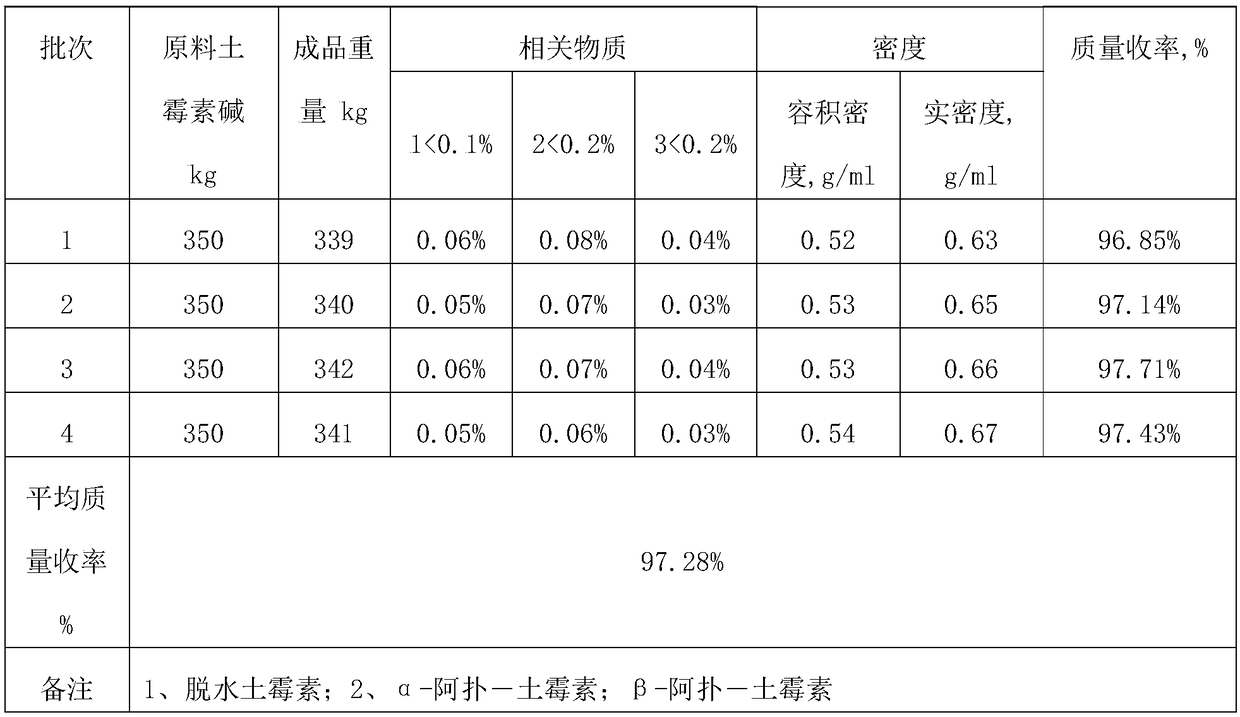

Embodiment 1

[0016] Take 1500L of methanol, 350Kg of oxytetracycline base, and 35Kg of calcium chloride, add oxytetracycline base and calcium chloride into methanol and adjust the temperature to about 30°C, stir evenly and filter to obtain the filtrate.

[0017] Then, the temperature of the filtrate was controlled within the range of 24-26° C., and a methanol solution of hydrochloric acid equivalent to 26 Kg of hydrogen chloride was added into the filtrate to obtain a mixed solution. The mixed solution was stirred intermittently to precipitate oxytetracycline hydrochloride. The intermittent stirring was specifically: the total stirring time was 4 hours, the stirring was carried out for 5 minutes every 30 minutes, and the stirring speed was 15-20 r / min.

[0018] After the intermittent stirring was finished, the temperature of the mixed solution was lowered to 0° C., and oxytetracycline hydrochloride was fully separated out. At this point, the mixed solution is centrifuged to obtain a wet pr...

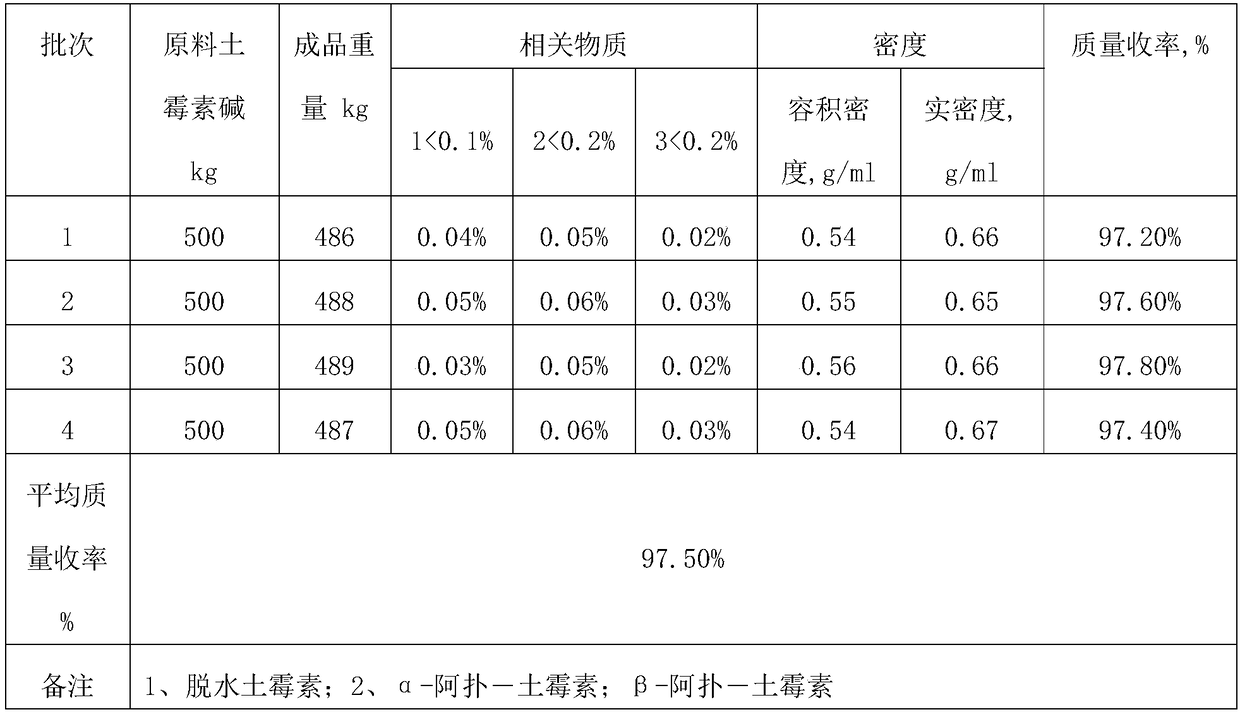

Embodiment 2

[0023] Take 2100L of methanol, 500Kg of oxytetracycline base, and 50Kg of calcium chloride, add oxytetracycline base and calcium chloride into methanol and adjust the temperature to about 30°C, stir evenly and filter to obtain the filtrate.

[0024] Then, the temperature of the filtrate was controlled within the range of 21-23° C., and a methanol solution of hydrochloric acid equivalent to 26 Kg of hydrogen chloride was added to the filtrate to obtain a mixed solution. The mixed solution was stirred intermittently to precipitate oxytetracycline hydrochloride. The intermittent stirring was specifically: the total stirring time was 4 hours, the stirring was carried out for 5 minutes every 30 minutes, and the stirring speed was 10-15 r / min.

[0025] After the intermittent stirring was finished, the temperature of the mixed solution was lowered to 0° C., and oxytetracycline hydrochloride was fully separated out. At this point, the mixed solution is centrifuged to obtain a wet prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com