A kind of preparation method of wear-resistant tungsten carbide alloy material

A tungsten carbide alloy, tungsten carbide technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of low mechanical strength, poor wear resistance, etc., to improve wear resistance, reduce wear, and uniform crystal grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

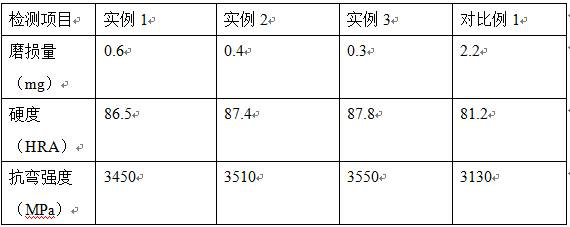

Examples

preparation example Construction

[0048] Preparation of expanded graphite:

[0049] Weigh the expandable graphite and put it into an oven, dry it at 120-130°C for 12-14 hours, put the dried expandable graphite into a microwave reactor, process it with a power of 1-2kW for 1-2min and then naturally cool to room temperature , and continue to repeat microwave treatment for 3 to 5 times of heating and expansion to obtain expanded graphite;

[0050] Preparation of layered tungsten carbide powder:

[0051] Mix the above-mentioned expanded graphite with 1 mol / L ammonium tungstate solution and starch according to the mass ratio of 10:50:1, put them in an evaporating dish, heat up to 100-110 °C, heat preservation, evaporation and crystallization until the solution The water evaporates completely;

[0052] Preparation of Nanotubular Particles:

[0053] Grind the above-mentioned evaporative crystallized product into 500-600 mesh particles, mix it with ammonium bicarbonate and polyvinyl alcohol in a mass ratio of 1:1:10,...

example 1

[0060] Preparation of expanded graphite:

[0061] Weigh the expandable graphite and put it in an oven, dry it at 120°C for 12 hours, put the dried expandable graphite into a microwave reactor, treat it with a power of 1kW for 1min, then naturally cool to room temperature, and continue to repeat microwave treatment for heating and expansion for 3 times, to obtain expanded graphite;

[0062] Preparation of layered tungsten carbide powder:

[0063] According to the mass ratio of 10:50:1, the above-mentioned expanded graphite, ammonium tungstate solution with a concentration of 1mol / L and starch are mixed and placed in an evaporating dish, heated to 100 ° C, and thermally evaporated and crystallized until the water in the solution is completely Evaporation ends;

[0064] Preparation of Nanotubular Particles:

[0065] Grind the above-mentioned evaporative crystallization process into 500 mesh particles, mix it with ammonium bicarbonate and polyvinyl alcohol in a mass ratio of 1:...

example 2

[0072] Preparation of expanded graphite:

[0073] Weigh the expandable graphite and put it into an oven, dry it at 120-130°C for 13 hours, put the dried expandable graphite into a microwave reactor, treat it with a power of 1kW for 2 minutes, and then naturally cool to room temperature, and continue to repeat microwave treatment for heating. Expand 4 times to obtain expanded graphite;

[0074] Preparation of layered tungsten carbide powder:

[0075] According to the mass ratio of 10:50:1, the above-mentioned expanded graphite, ammonium tungstate solution with a concentration of 1 mol / L and starch were mixed and put into an evaporating dish, heated to 105 ° C, and heat preservation, evaporation and crystallization treatment until the water in the solution was completely Evaporation ends;

[0076] Preparation of Nanotubular Particles:

[0077] Grind the above-mentioned evaporative crystallization process into 550 mesh particles, mix it with ammonium bicarbonate and polyvinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com