Electroplating copper cylinder solution suitable for oversize current density and electroplating method

A technology of current density and electroplating copper, applied in the field of materials, can solve the problems of voids, long time consumption of electroplating copper pillars, unstable signal transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

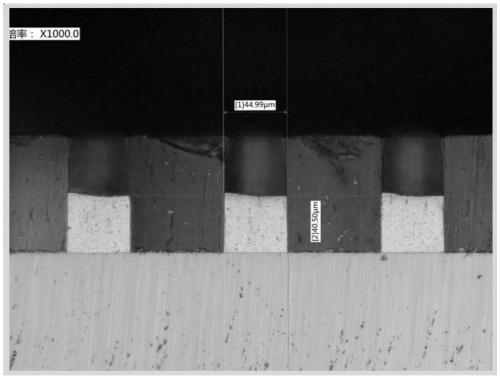

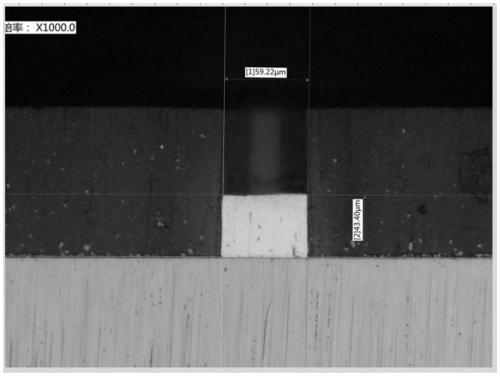

Image

Examples

Embodiment 1

[0064] The formula consists of the following:

[0065] Copper methanesulfonate: 200g / L;

[0066] Methanesulfonic acid: 50g / L;

[0067] Chloride ion: 50mg / L, mainly provided by one or more in copper chloride dihydrate, sodium chloride or hydrochloric acid;

[0068] Sodium polydisulfide dipropane sulfonate: 4mg / L;

[0069] Polyethylene glycol: 60mg / L;

[0070] Tobacco green: 80mg / L;

[0071] Solution preparation process: Take 1L solution as an example, take 300ml of water, add copper methanesulfonate: 200g; methanesulfonic acid: 50g, copper chloride dihydrate: 0.114g, sodium polydithiodipropanesulfonate: 0.004g ; Polyethylene glycol: 0.06g; Yanlu green: 0.08g, stir to dissolve, and then add water to the liquid level to 1L.

[0072] Process parameters for electroplating using the copper electroplating solution prepared in this example: pre-treatment vacuuming: 5min, solution exchange time: 5min, temperature: 35±2°C, current density: 30A / dm 2 , the stirring rate is 200r / min,...

Embodiment 2

[0075] The formula consists of the following:

[0076] Copper methanesulfonate: 220g / L;

[0077] Methanesulfonic acid: 60g / L;

[0078] Chloride ion: 50mg / L, mainly provided by one or more in copper chloride dihydrate, sodium chloride or hydrochloric acid;

[0079] Sodium polydisulfide dipropane sulfonate: 2mg / L;

[0080] Polyethylene glycol: 60mg / L;

[0081] Diphenylmethane dye: 60mg / L;

[0082] Solution preparation process: Take 1L solution as an example, take 300ml of water, add copper methanesulfonate: 220g; methanesulfonic acid: 60g, copper chloride dihydrate: 0.114g, sodium polydithiodipropanesulfonate: 0.002g ; Polyethylene glycol: 0.06g; Diphenylmethane dye: 0.06g, stir to dissolve, and then add water to the liquid level to 1L.

[0083] Process parameters for electroplating using the copper electroplating solution prepared in this example: pretreatment vacuuming: 5min, solution exchange time: 10min, temperature: 25±2°C, current density: 30A / dm 2 , the stirring rat...

Embodiment 3

[0086] The formula consists of the following:

[0087] Copper methanesulfonate: 240g / L;

[0088] Methanesulfonic acid: 50g / L;

[0089] Chloride ion: 40mg / L, mainly provided by one or more in copper chloride dihydrate, sodium chloride or hydrochloric acid;

[0090] Sodium polydisulfide dipropane sulfonate: 4mg / L;

[0091] Polyethylene glycol: 60mg / L;

[0092] Tobacco green: 70mg / L;

[0093]Solution preparation process: Take 1L solution as an example, take 300ml of water, add copper methanesulfonate: 240g; methanesulfonic acid: 50g, copper chloride dihydrate: 0.091g, sodium polydisulfide dipropanesulfonate: 0.004g ; Polyethylene glycol: 0.06g; Yanlu green: 0.07g, stir to dissolve, and then add water to the liquid level to 1L.

[0094] Process parameters for electroplating using the copper electroplating solution prepared in this example: pre-treatment vacuuming: 10 min, solution exchange time: 10 min, temperature: 30±2°C, current density: 25A / dm 2 , stirring rate 200r / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com