Method for forming metal oxide on surface of substrate

A technology of oxide film and thin film, which is applied in metal material coating process, gaseous chemical plating, ion implantation plating, etc., can solve problems such as the deterioration of dielectric constant and electrical characteristics, and achieve shortened process time, good interface, and crystal size consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

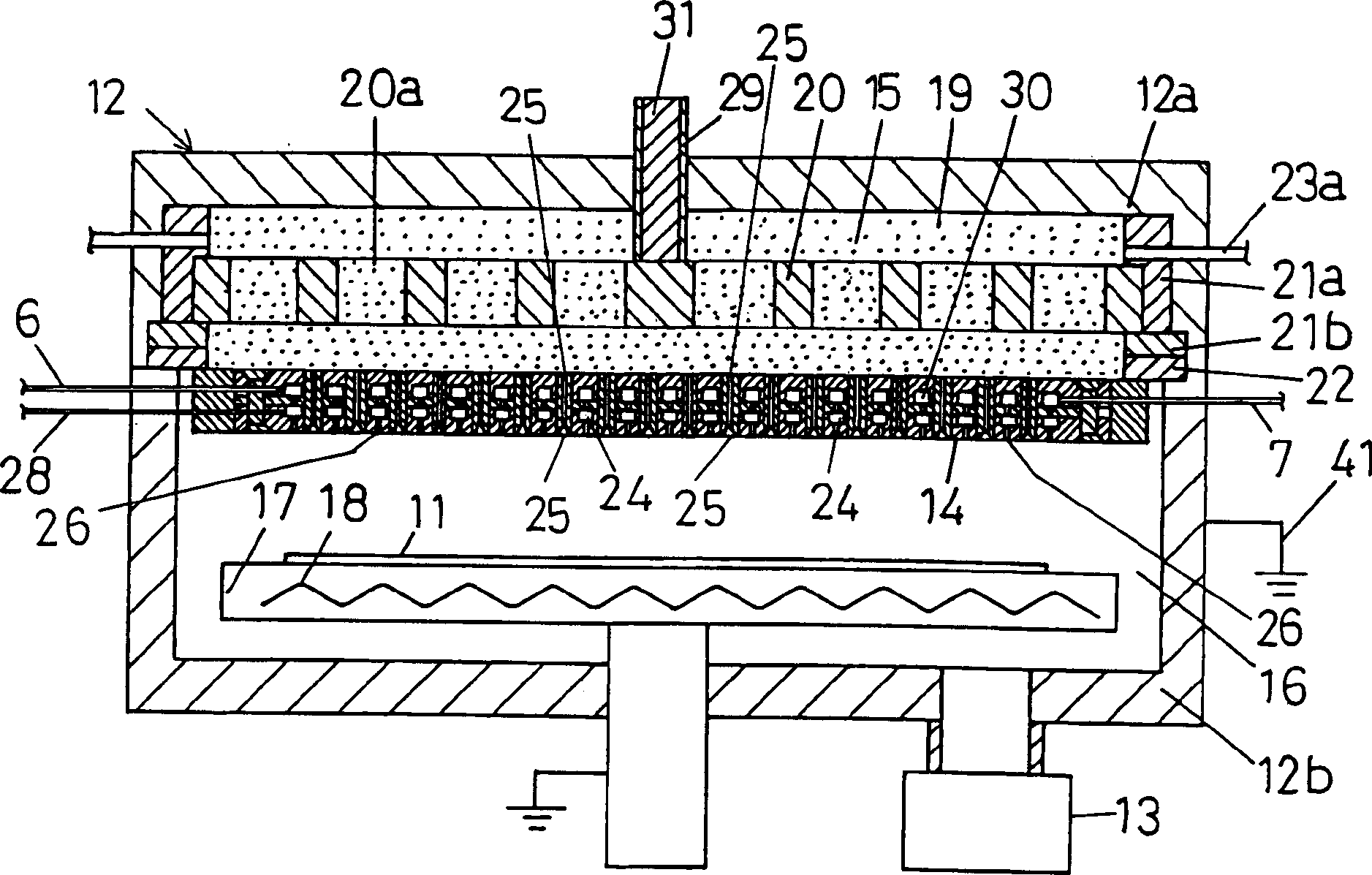

[0053] figure 1 The inside of the vacuum chamber of the thin film forming apparatus used for the thin film forming method of this invention is shown.

[0054] Such as figure 1 As shown, the inside of the vacuum container 12 is divided into a plasma generation space 15 and a film formation processing space 16 by a partition plate 14 . The plasma generation space 15 and the film formation processing space 16 communicate only through a plurality of through holes 25 formed in the partition plate 14 .

[0055] exist figure 1 In the illustrated embodiment, the vacuum container 12 is composed of an upper container 12a forming the plasma generation space 15 and a lower container 12b forming the film formation processing space 16 from the viewpoint of good assembly. When the vacuum container 12 is produced by closing the upper container 12a and the lower container 12b, a partition plate 14 is provided at a position therebetween. The plasma generation space 15 is formed by the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com