Multi-size nanoparticle hybrid metal film and preparation method thereof

A technology of nano-particles and mixed metals, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. It can solve problems such as development limitations, high silver material prices, and increased process complexity and cost, and reduce operational complexity. degree, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The concrete implementation of the present invention is described in detail below, it is necessary to point out here that the following implementation is only used for further description of the present invention, and can not be interpreted as limiting the protection scope of the present invention. Some non-essential improvements and adjustments still belong to the protection scope of the present invention.

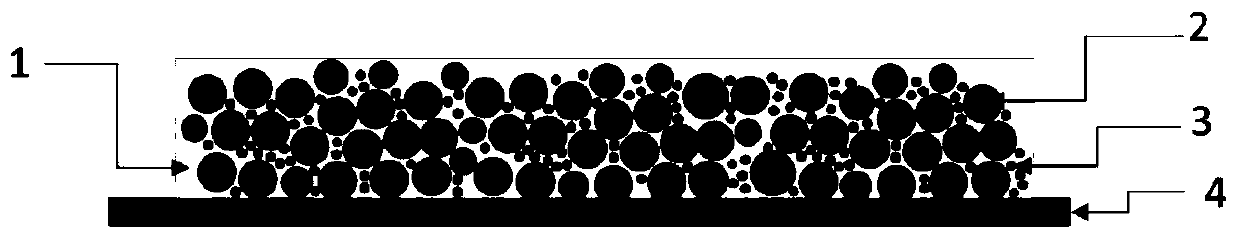

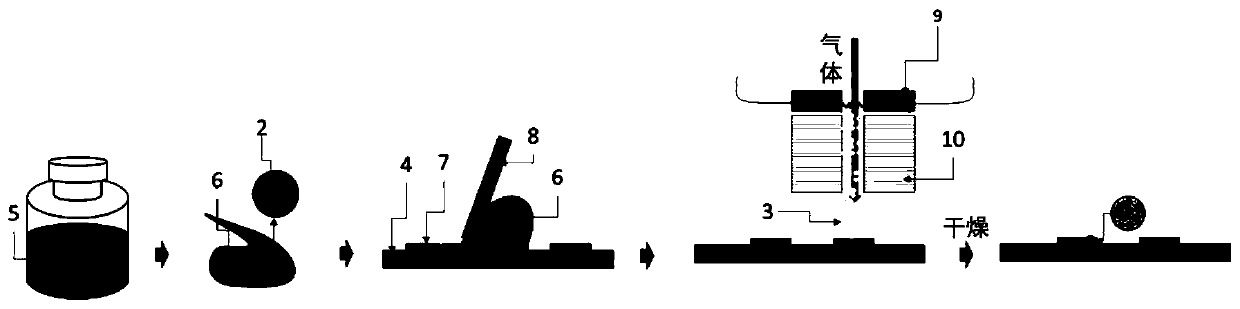

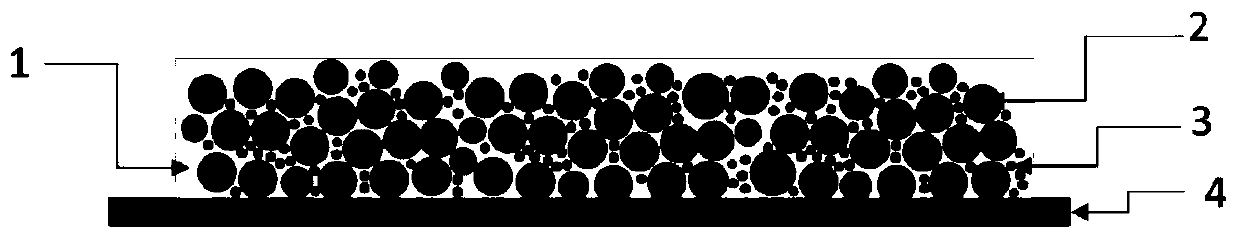

[0045] The invention provides a single-layer multi-size nano-particle mixed metal film and a preparation method thereof, wherein the multi-size nano-particle mixed metal film of the present invention is as figure 1 shown, including:

[0046] The organic dielectric material 1 forms an organic coating layer;

[0047] Nano-metal mixtures of at least two sizes are configured in the organic medium material; gap filling is realized by inserting small-sized nano-metal particles 3 into gaps between large-sized nano-metal particles 2, and the large-size nano-metal particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com