Method for preparing titanium dioxide/bamboo charcoal composite material

A composite material and titanium dioxide technology, which is applied in chemical instruments and methods, oxidized water/sewage treatment, chemical/physical processes, etc., can solve the problems of reduced photocatalytic efficiency, low utilization rate of light energy, and difficulty in recycling, etc. Catalytic performance, reduced production cost, uniform size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

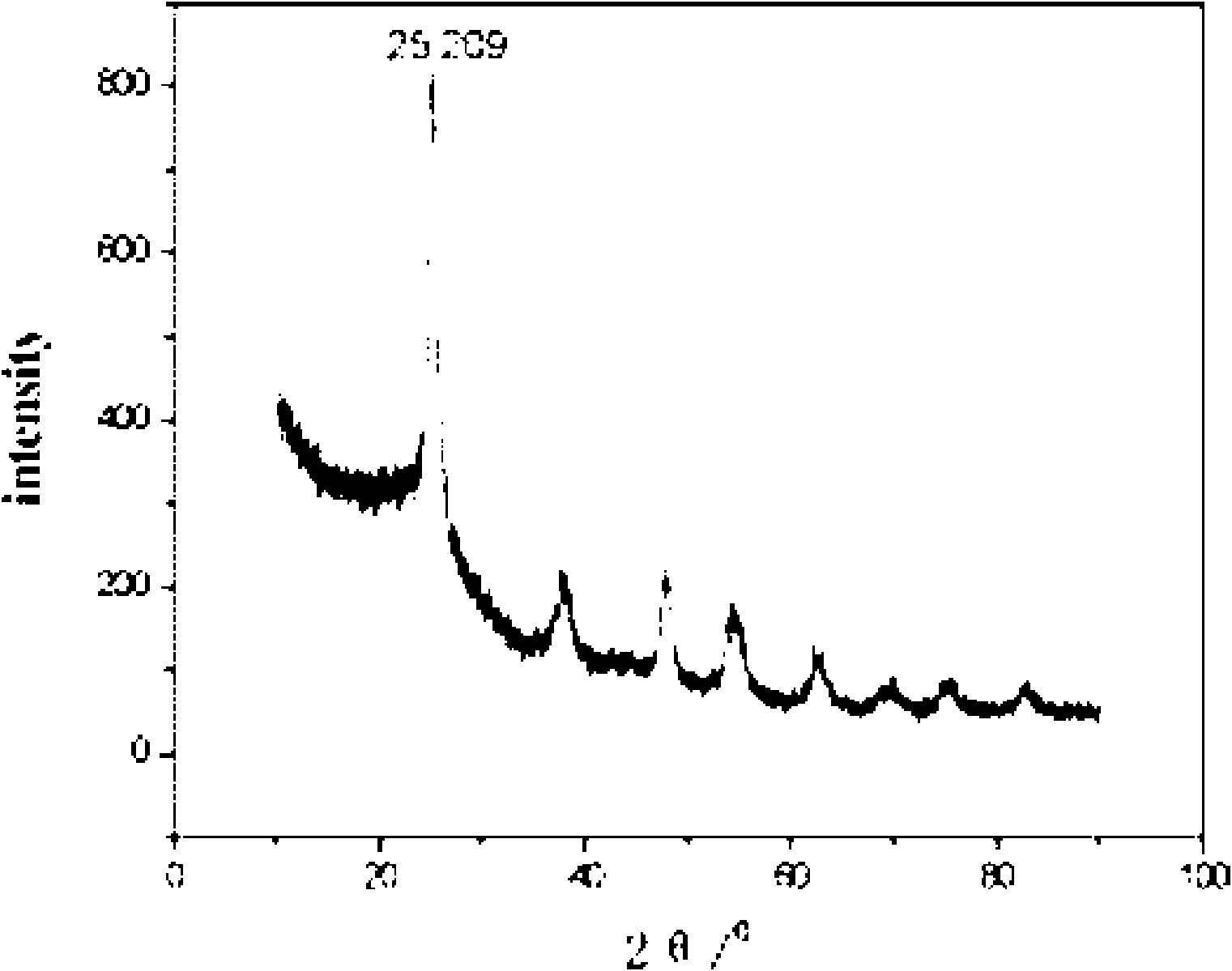

Image

Examples

Embodiment 1

[0013] Using bamboo charcoal and tetra-n-butyl titanate as raw materials, titanium dioxide / bamboo charcoal composites were prepared by microwave-assisted method. The specific implementation steps are:

[0014] 40-mesh bamboo charcoal was selected by the 8411A electric vibrating sieve machine, soaked in dilute acid for 24 hours, washed repeatedly with distilled water until neutral, and dried in an oven for later use.

[0015] Mix absolute ethanol, tetra-n-butyl titanate, and glacial acetic acid at a volume percentage of 56%:34%:10%, and stir for 10 minutes to obtain solution A; weigh 5 g of bamboo charcoal and mix it with 58 mL of solution A, and continue stirring for 30 minutes to obtain Mixture B; measure 90% ethanol by volume, and adjust the pH of the solution to 2.5 with dilute nitric acid to obtain solution C; pour 20mL of solution C into the pear-shaped dropping funnel, adjust the plunger of the dropping funnel to make the solution C was added dropwise to the mixture B s...

Embodiment 2

[0019] The 60-mesh bamboo charcoal was selected by the 8411A electric vibrating sieve machine, soaked in dilute acid for 24 hours, washed repeatedly with distilled water until neutral, and dried in an oven for later use.

[0020] Mix absolute ethanol, tetra-n-butyl titanate, and glacial acetic acid by volume percentage at 60%:32%:8%, and stir for 10 minutes to obtain solution A; weigh 5 g of bamboo charcoal and mix it with 60 mL of solution A, and continue stirring for 30 minutes to obtain Mixture B; measure 90% ethanol by volume, and adjust the pH=2.7 of the solution with dilute nitric acid to obtain solution C; pour 22mL of solution C into the pear-shaped dropping funnel, adjust the plunger of the dropping funnel to make the solution C was added dropwise to the mixture B stirred at a constant speed at a rate of 1 drop / s-2 drops / s, and the entire dropping process was controlled within 40 minutes.

[0021] Pour the mixture into three equal parts into dry polytetrafluoroethylen...

Embodiment 3

[0024] 100-mesh bamboo charcoal was selected by the 8411A electric vibrating sieve machine, soaked in dilute acid for 24 hours, washed repeatedly with distilled water until neutral, and dried in an oven for later use.

[0025] Anhydrous ethanol, tetra-n-butyl titanate, and glacial acetic acid were mixed at a ratio of 58%:33%:9% by volume, and stirred for 10 minutes to obtain a solution A. Weigh 5g of bamboo charcoal and mix it with 58mL solution A, continue to stir for 30min to obtain mixture B; measure ethanol with a volume percentage of 90%, and adjust the pH of the solution to 2.7 with dilute nitric acid to obtain solution C; pour 22mL of solution C into pears In the shaped dropping funnel, adjust the plunger of the dropping funnel so that the solution C is added dropwise to the mixture B stirred at a constant speed at a rate of 1 drop / s to 2 drops / s, and the entire dropping process is controlled within 30 minutes.

[0026] Pour the mixture into three equal parts into dry p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com