Vanadium-phosphorus-oxygen catalyst, and preparation method thereof

A technology of vanadium phosphorus oxide and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of increasing catalyst manufacturing cost, uneven grain size distribution, and insufficient concentration of particle size distribution, etc. Achieve the effects of promoting micro-mixing, concentrating grain size distribution, and uniform distribution of active centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] (2) Preparation of vanadium phosphorus oxygen catalyst

[0046] Step (1) The obtained vanadium phosphorus oxide is first formed to obtain a vanadium phosphorus oxygen catalyst intermediate, and then activated; or the obtained vanadium phosphorus oxide is first activated to obtain a vanadium phosphorus oxygen catalyst intermediate, and then formed to obtain vanadium phosphorus oxygen catalyst.

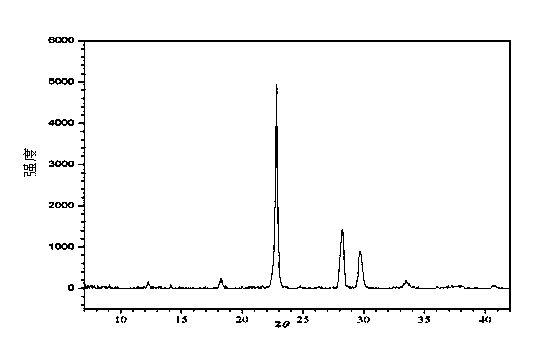

[0047] The shape of the obtained vanadium-phosphorus-oxygen catalyst can be shapes such as pressed sheet, sphere, extruded bar, and the phase of matter of the catalyst is mainly vanadyl pyrophosphate ((VO 2 ) 2 P 2 o 7 )Mutually.

[0048] The above-mentioned molding process generally includes: adding vanadium phosphorus oxide powder (or activated vanadium phosphorus catalyst intermediate) to graphite powder with a mass fraction of 3% to 5%, after mixing thoroughly, using a rotary tablet press, Properly adjust the impact strength, extrude into a certain shape, such as columna...

Embodiment 1

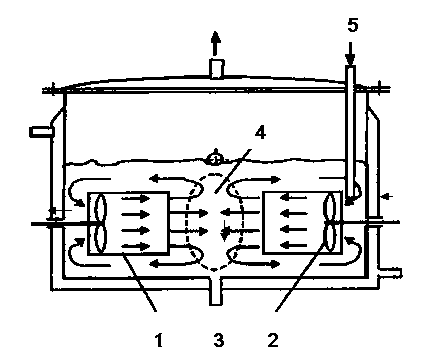

[0055] exist figure 1 In the impingement flow reactor shown, add isobutanol and benzyl alcohol mixed solution 649mL, isobutanol / benzyl alcohol volume ratio 10:1, vanadium pentoxide 29.53g, start the impingement flow reactor, make the stirring blade rotate When it reaches 1500r / min, the reaction liquid passes through the guide tube to form an impingement flow. Raise the reaction temperature and keep it at 110±2°C, carry out the reflux reaction, keep the reflux time for 4 hours, then add 44.7g of phosphoric acid with a concentration of 85%, continue to reflux for 4 hours, and the reaction ends. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed three times with a small amount of isobutanol, and then the filter cake was placed in an enamel tray and dried naturally at room temperature, dried in an oven at 105°C for 8 hours, and finally placed in a muffle furnace. Calcined at 250°C for 5 hours to obtain dark brown van...

Embodiment 2

[0059] exist figure 1 In the impingement flow reactor shown, add 649mL of isobutanol and benzyl alcohol mixture, the volume ratio of isobutanol / benzyl alcohol is 15:1, 29.53g of vanadium pentoxide, 0.3g of ferric nitrate hexahydrate, and 0.5 g of zirconium nitrate, start the impingement flow reactor, make the rotation speed of the stirring blade reach 2500r / min, and the reaction liquid passes through the guide tube to form an impingement flow. Raise the reaction temperature and keep it at 100±2°C, carry out the reflux reaction, keep the reflux time for 4 hours, then add 34.98g of phosphoric acid with a concentration of 100%, the phosphorus / vanadium molar ratio is 1.1, continue to reflux for 4 hours, and the reaction ends. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed with a small amount of isobutanol three times, then the filter cake was placed in an enamel tray and dried naturally at room temperature, dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com