Method for preparing porous covalent organic material by using ultra-gravity method

A technology of covalent organic and high gravity method, which is applied in the field of preparation of porous covalent organic materials and production of porous covalent organic materials, can solve the shortage of mass production technology of porous covalent organic materials, the difficulty of industrialization of porous covalent organic materials, The problem of low material mixing rate can achieve the effect of strengthening micro mass transfer and micro mixing process, shortening reaction time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

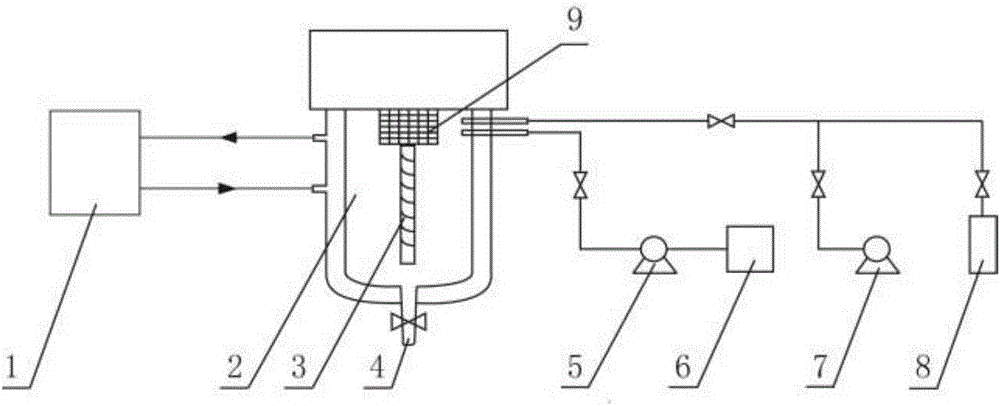

Method used

Image

Examples

Embodiment 1

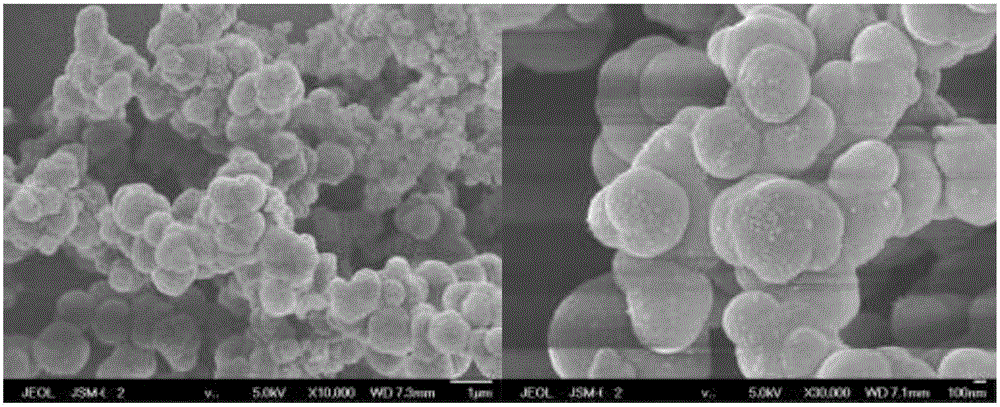

[0035] Carry out the disposition of reaction material in the glove box, add catalyst 11.25g bis(1,5-cyclooctadiene) nickel and 6.4g2,2'-bipyridine in 800mlN,N'-dimethylformamide, then add 5mL of 1,5-cyclooctadiene was stirred for at least 30 minutes to dissolve it completely. Subsequently, 2.47 g of 1,3,5-tribromobenzene was added to the solution to obtain a purple solution. The reaction kettle is pumped and nitrogen reciprocated four times to ensure that the reaction kettle maintains an anhydrous and oxygen-free environment. The reactor was heated with a water bath circulation device and kept at 85°C. Connect the material bottle to the feed pipe, repeat the pumping and venting operations again to ensure that the connection pipeline reaches anhydrous and oxygen-free conditions, and use a peristaltic pump to pump all the materials into the cavity of the supergravity rotating bed. The rotation speed of the high-gravity rotating bed is set to 2000r / min, and the timing starts wh...

Embodiment 2

[0049] Except following change, all the other are the same as embodiment 1.

[0050] Use a peristaltic pump to feed into the reactor, 100ml each time

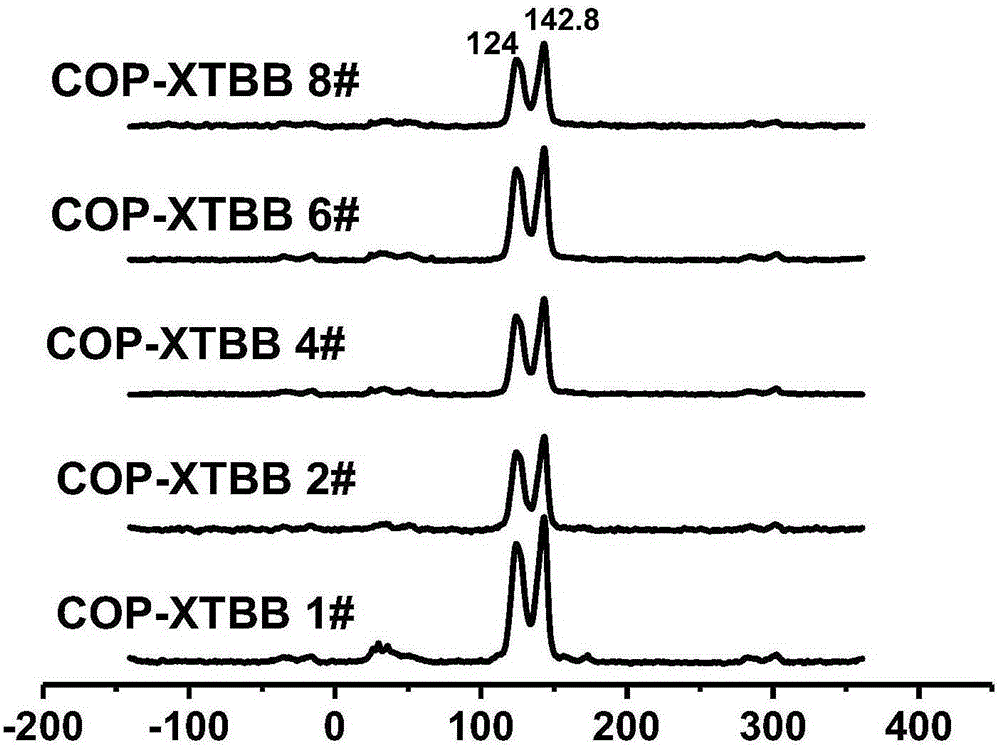

[0051] Set the rotation speed of the high-gravity rotary bed to 400r / min, 800r / min, 1200r / min, 1600r / min, 2000r / min, 2400r / min, 2800r / min, and start the high-gravity rotary bed equipment. Start the timing from the pump, and take the material from the feed port after 1 hour.

Embodiment 3

[0053] Except following change, all the other are the same as embodiment 1.

[0054] Add 11.25 g of catalyst bis(1,5-cyclooctadiene) nickel and 6.4 g of 2,2'-bipyridine into 800 ml of N,N'-dimethylformamide, then add 5 ml of 1,5-cyclooctadiene, Stir for at least 30 minutes to completely dissolve. Subsequently, 4.83 g of 1,3,5-tris((4-bromophenyl)ethynyl)benzene was added to the solution to obtain a purple solution.

[0055] The reactor was heated with an oil bath circulation device and kept at 105°C. The rotating speed of the high-gravity rotating bed is set at 2000r / min, and the running time is 1h.

[0056] After drying in vacuum, the material was soaked in ethanol for 24 h, and then washed with supercritical CO 2 Drying removes solvent molecules to ensure the integrity of the material skeleton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com