Production process of 5-hydroxymethyl furfural

A technology of hydroxymethylfurfural and formic acid, which is applied in the preparation of organic compounds, the separation/purification of carboxylic acid compounds, and the preparation of carboxylate salts. It can solve problems such as environmental pollution and resource waste, reduce side reactions, and increase yields. rate, the effect of increasing the mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

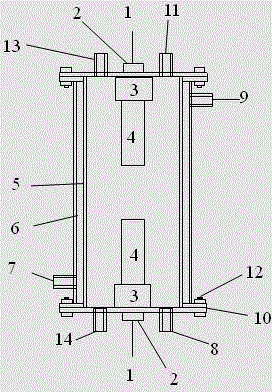

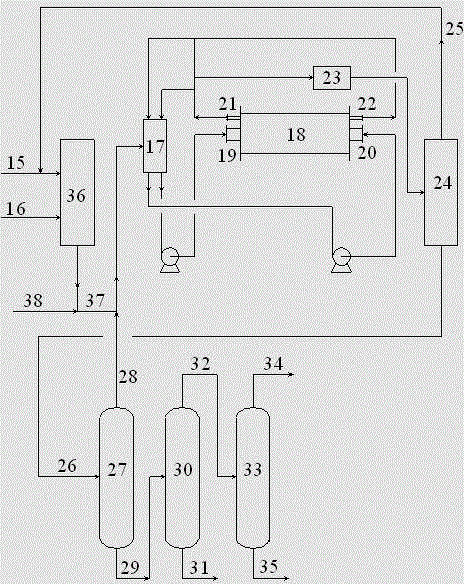

Image

Examples

Embodiment 1

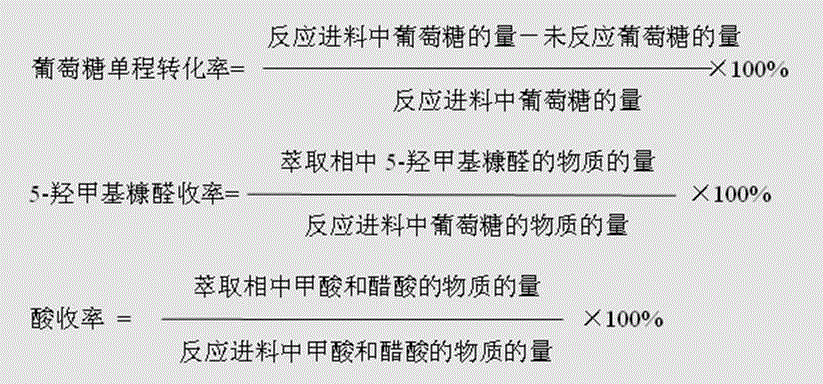

[0039] The crushed corn stalks and water were injected into the hydrolysis tank according to the mass ratio of 1:1. The pre-hydrolysis temperature was 240°C and the pre-hydrolysis time was 20 min. %.

[0040] Add sodium sulfate in gained solution, control concentration is 3wt%.

[0041] The composite extractant used is a mixed solvent of benzene, ethyl acetate and 1,1,1-trichloroethane, wherein benzene accounts for 40wt%, ethyl acetate accounts for 20wt%, and 1,1,1-trichloroethane accounts for 40wt% %.

[0042] The feed ratio of extractant and glucose solution is 3:1 (volume ratio), and the feed rate of extractant and glucose solution is equal to the ultrasonic reactor volume (that is, the feed volume space velocity is 1 h -1 , that is, the reaction time is 1 h), pump the extractant and glucose solution into the ultrasonic reactor respectively, and quickly mix with the circulating material in the ultrasonic reactor to react-extraction process, the rate of the circulating mat...

Embodiment 2

[0045] According to the method of Example 1, the difference is that the feed rate is twice the volume of the ultrasonic reactor, that is, the reaction time is 0.5 h.

[0046] The experimental results showed that the conversion rate of glucose was 77wt%, the yield of 5-hydroxymethylfurfural was 60.4wt%, the recovery rate of acetic acid was 93.6wt%, and the recovery rate of formic acid was 90.2wt%.

Embodiment 3

[0048] According to the method of Example 1, the difference is that the feed rate is 0.67 times the volume of the ultrasonic reactor, that is, the reaction time is 1.5 h.

[0049] The experimental results showed that the conversion rate of glucose was 99%, the yield of 5-hydroxymethylfurfural was 81.9%, the recovery rate of acetic acid was 93.6%, and the recovery rate of formic acid was 90.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com