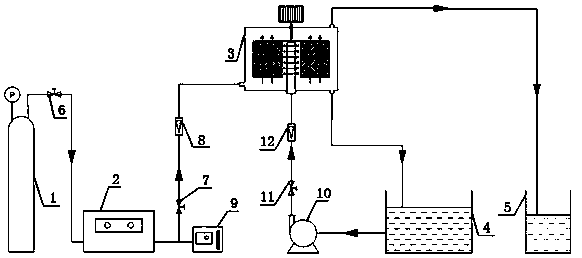

Supergravity reaction device and application thereof

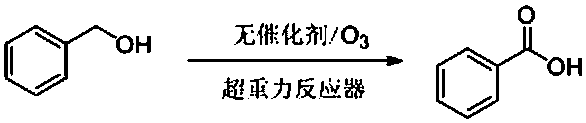

A reaction device and super-gravity technology, which can be used in feeding devices, chemical/physical/physical-chemical stationary reactors, and ozone oxidation to prepare carboxylic acids, etc. The catalyst can be regenerated to use benzoic acid, which is difficult to separate and purify, and achieve the effects of broad industrial application prospects, short reaction time, and high atom utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

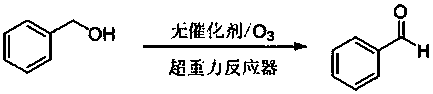

Embodiment 1

[0031]Weigh 3 g of benzyl alcohol and dissolve it in 500 mL of ethyl acetate and place it in the storage tank, set the liquid flow meter to 100 L / h, the gas flow meter to 50 L / h, the gas phase ozone concentration to 30 mg / L, and the supergravity The reactor rotation speed was 800 rpm. After reacting for 30min, after removing the reaction solvent with a rotary evaporator, through silica gel column chromatography (eluent is V 石油醚 / V 乙酸乙酯 =5:1) to obtain 2.37g of benzaldehyde with a yield of 80.5%.

[0032] 1 H NMR (600 MHz, CDCl 3 ) δ 10.02 (s, 1H), 7.88 (d, J = 12 Hz, 2H), 7.63 (t, J = 6 Hz, 1H), 7.53 (t, J = 6 Hz, 2H).

Embodiment 2

[0034] Weigh 3 g of benzyl alcohol and dissolve it in 500 mL of methanol and place it in the liquid storage tank. Set the liquid flow meter to 100 L / h, the gas flow meter to 70 L / h, and the gas phase ozone concentration to 80 mg / L. The speed is 800 rpm. After reacting for 15min, after removing the reaction solvent with a rotary evaporator, through silica gel column chromatography (eluent is V 石油醚 / V 乙酸乙酯 =5:1) to obtain 1.79 g of benzaldehyde with a yield of 61%.

[0035] 1 H NMR (600 MHz, CDCl 3 ) δ 10.02 (s, 1H), 7.88 (d, J = 12 Hz, 2H), 7.63 (t, J = 6 Hz, 1H), 7.53 (t, J = 6 Hz, 2H).

Embodiment 3

[0037] Weigh 3 g of benzyl alcohol and dissolve it in 500 mL of ethyl acetate and place it in the storage tank, set the liquid flow meter to 100 L / h, the gas flow meter to 100 L / h, and the gas phase ozone concentration to 50 mg / L, and the hypergravity reaction The engine speed is 500 rpm. After reacting for 30 min, remove the reaction solvent with a rotary evaporator, and perform silica gel column chromatography (eluent is V 石油醚 / V 乙酸乙酯 =5:1) to obtain 0.44g of benzaldehyde with a yield of 15%.

[0038] 1 H NMR (600 MHz, CDCl 3 ) δ 10.02 (s, 1H), 7.88 (d, J = 12 Hz, 2H), 7.63(t, J = 6 Hz, 1H), 7.53 (t, J = 6 Hz, 2H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com