Method for preparing transparent magnesium hydroxide liquid phase dispersion

A magnesium hydroxide, liquid phase dispersion technology, applied in the direction of magnesium hydroxide, etc., can solve the problems of poor dispersion performance and compatibility, and achieve the effects of good stability, easy scale-up, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

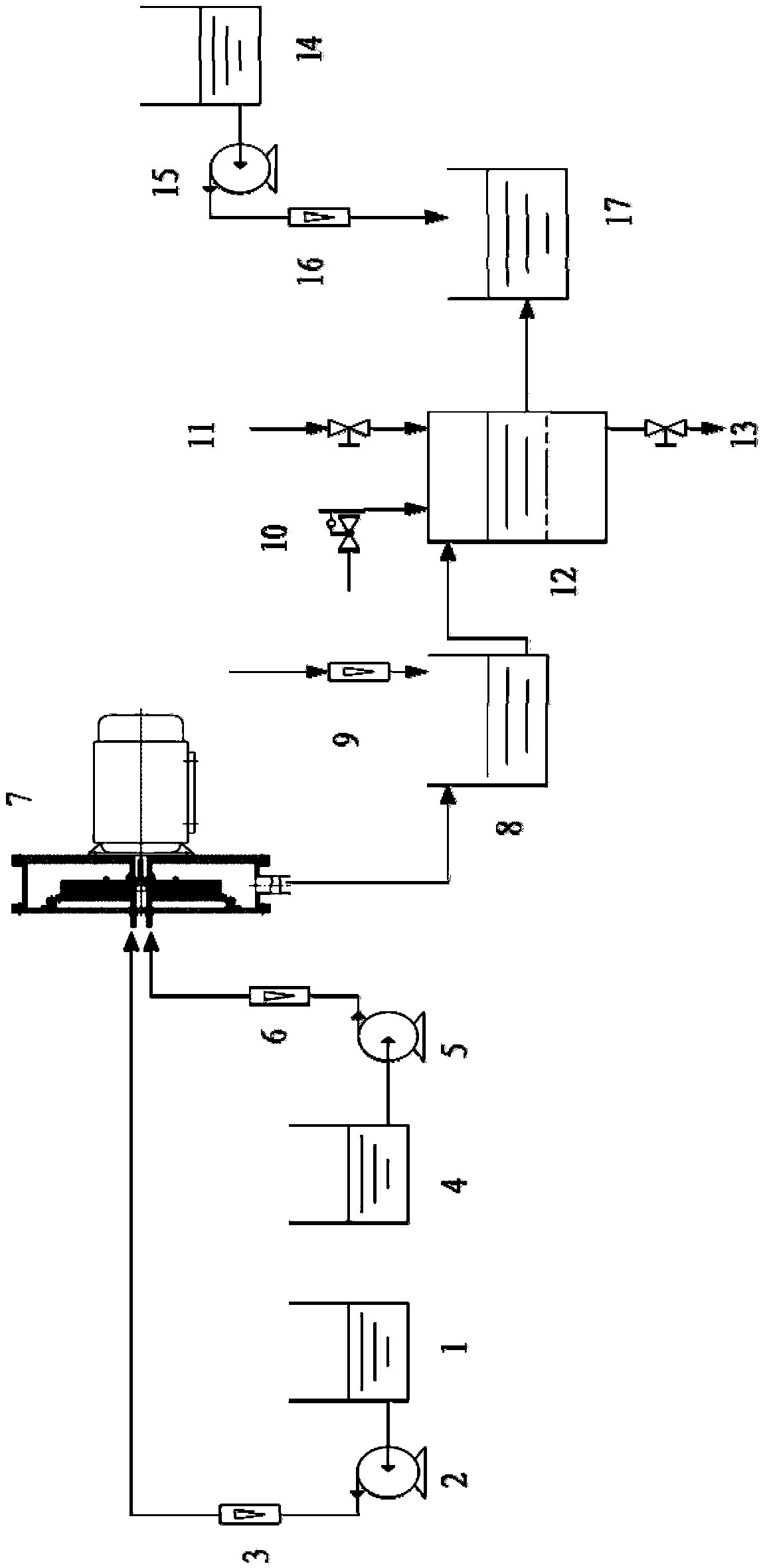

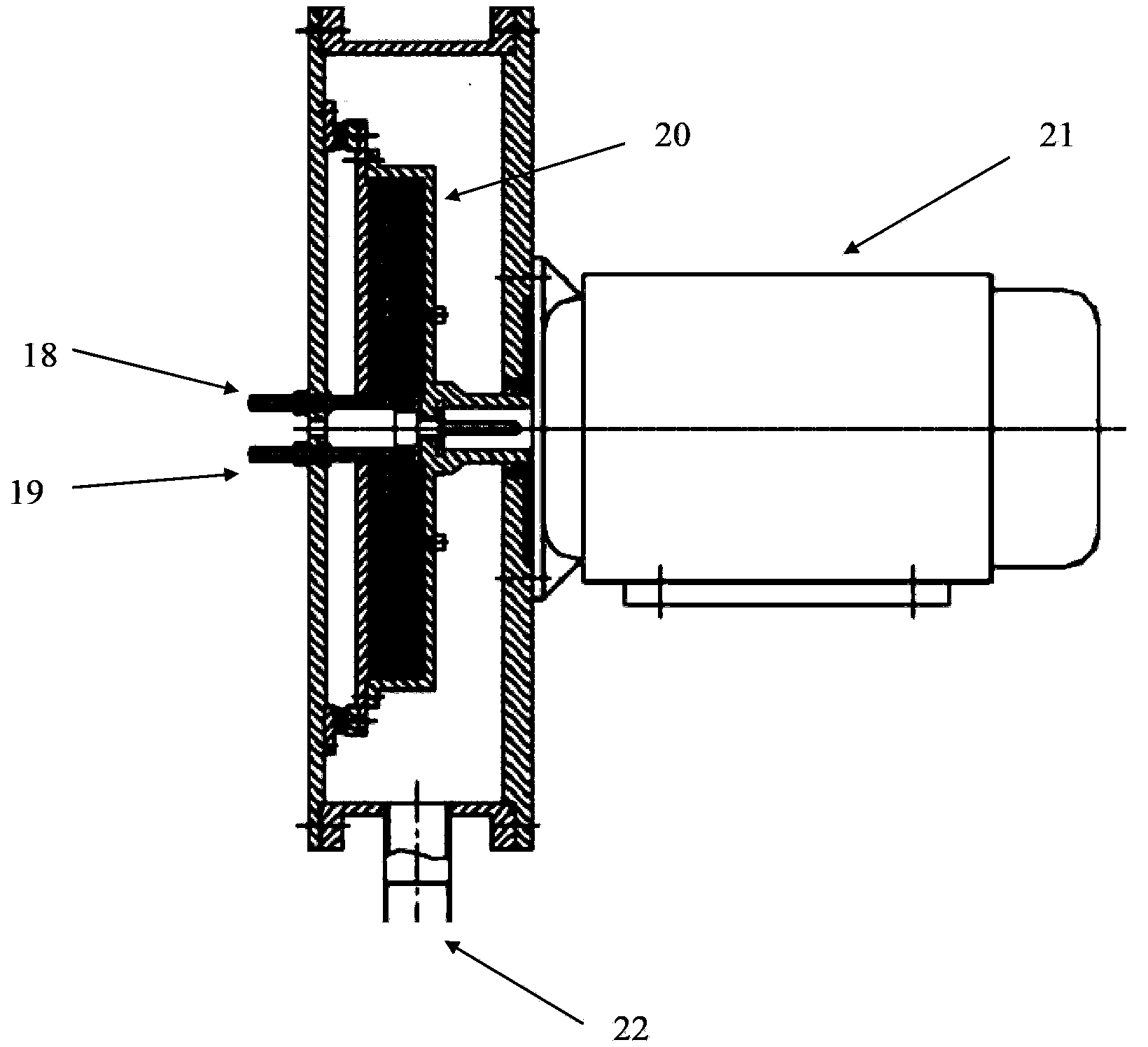

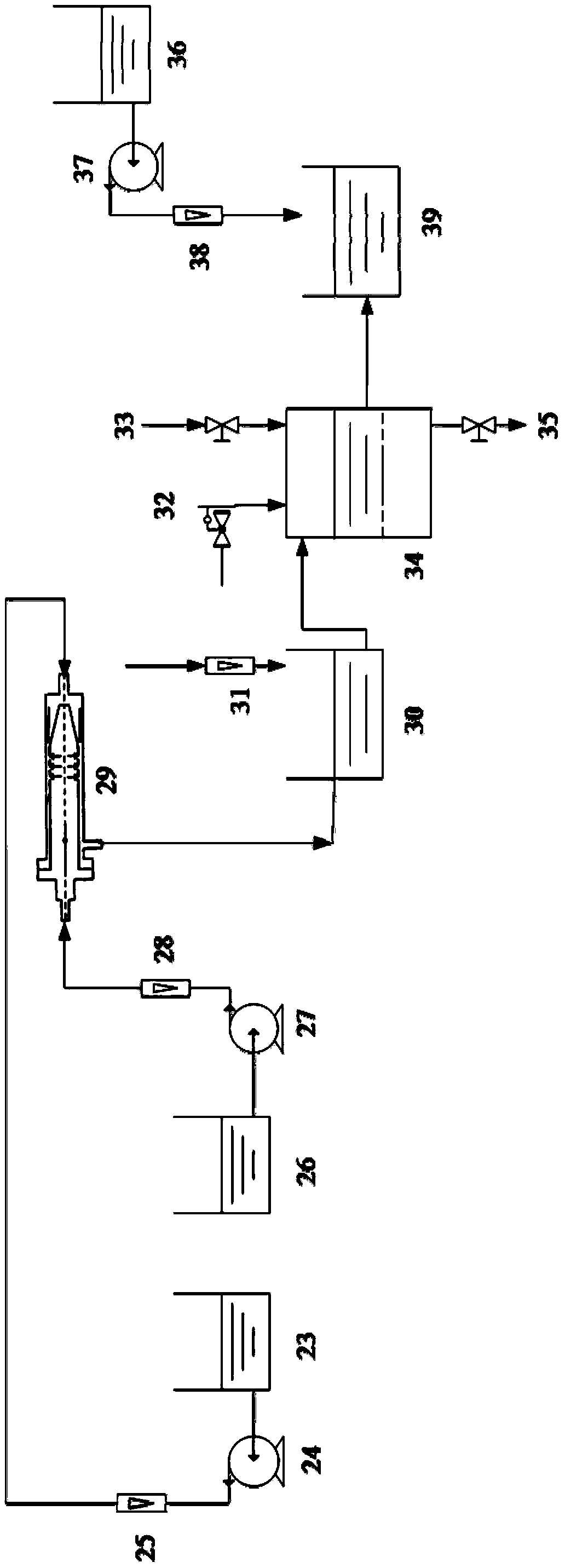

[0063] 1. The high-gravity rotating packed-bed reactor used in the present invention is prior art, such as published patent (ZL95215430.7); the reaction flow diagram of an embodiment of the high-gravity rotating packed-bed reactor used in the present invention is as follows figure 1 As shown, the schematic diagram of the high-gravity rotating packed bed reactor is shown in figure 2 shown. The implementation is as follows:

[0064] Open the supergravity rotating device 7, and adjust the rotating speed to make the rotating speed in the supergravity device rotor reach a predetermined value. The magnesium salt solution in the magnesium salt solution storage tank 1 adopts the pump 2 and enters the magnesium salt solution feed port 18 in the supergravity rotating device after being metered by the flowmeter 3; the lye in the lye storage tank 4 adopts the pump 5 and After being measured by the flow meter 6, it is poured into the lye feed port 19 in the supergravity rotating device...

Embodiment 1

[0069] Add 1000 g of an ethanol solution with a mass concentration of magnesium chloride of 3.5% into the magnesium salt solution storage tank; add 1000 g of an ethanol solution with a mass concentration of sodium hydroxide of 1.23% into the lye storage tank; turn on the supergravity rotating device and adjust the speed to 1000 rpm; Turn on the feed pump, transport the magnesium salt solution and lye to the rotating bed at the same time for precipitation and crystallization reaction, and control the feed line speed of the magnesium salt solution and lye to be 5m / s, and control the temperature of the reaction system to 20°C ; After the magnesium salt solution and lye are fed, and the suspension obtained from the reaction flows out of the supergravity rotating device, close the supergravity rotating device, and gradually add 890mg N-β-(aminoethyl)- γ-Aminopropylmethyldimethoxysilane, the temperature of the modification tank is controlled at 60°C, and the modification time is 2 ho...

Embodiment 2

[0071]Add 1000 g of ethanol solution with a mass concentration of magnesium chloride of 10% in the magnesium salt solution storage tank; add 1800 g of ethanol solution with a mass concentration of potassium hydroxide of 5% in the lye storage tank; open the supergravity rotating device and adjust the rotating speed to 1800rpm; Turn on the feed pump, transport the magnesium salt solution and lye to the rotating bed at the same time for precipitation and crystallization reaction, and control the feed linear velocity of the magnesium salt solution to 2m / s, and the feed linear velocity of the lye to 3.6m / s , control the temperature of the reaction system to be 40°C; after the magnesium salt solution and alkali solution are fed, and the suspension obtained from the reaction flows out of the supergravity rotating device, close the supergravity rotating device, and gradually add 2.5g N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane, the temperature of the modification tank is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com