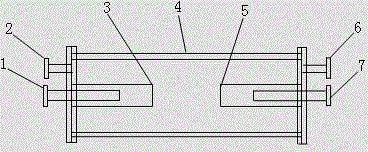

Method for producing furfuraldehyde from pentose solution by adopting impinging stream reactor

A technology of impinging flow reactor and pentose sugar, applied in the direction of organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

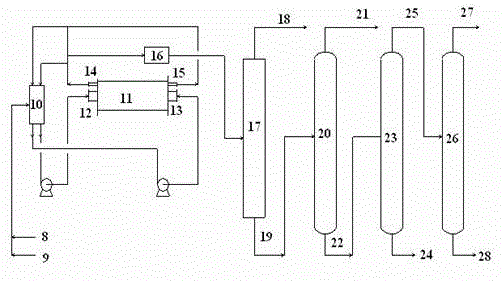

Method used

Image

Examples

Embodiment 1

[0039] The extractant is a mixed solvent of benzene, ethyl acetate and 1,1,1-trichloroethane, wherein benzene accounts for 40 wt%, ethyl acetate accounts for 20 wt%, and 1,1,1-trichloroethane accounts for 40 wt%.

[0040] The feed ratio of extractant and pentose solution is 3:1 (volume ratio), and the feed rate of extractant and pentose solution is equal to the impinging flow reactor volume (that is, the feed volume space velocity is 1h -1 , that is, the reaction time is 1 h), pump the extractant and the pentose solution into the impinging flow reactor respectively, and quickly mix with the circulating material in the impinging flow reactor to react—extraction process, the circulating material rate is 200% of the amount of material. Control the reaction temperature at 200 °C and the reaction pressure at 3 MPa.

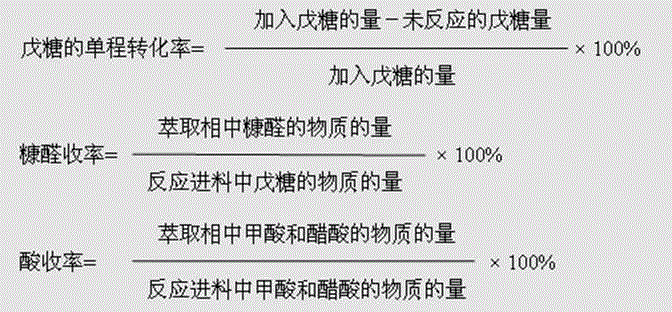

[0041] The experimental results showed that the conversion rate of pentose sugar was 97.4%, the yield of furfural was 82.1%, the recovery rate of acetic acid was 90.9...

Embodiment 2

[0044] The experimental results showed that the conversion rate of pentose sugar was 78.1%, the yield of furfural was 61.4%, the recovery rate of acetic acid was 93.8%, and the recovery rate of formic acid was 90.8%.

[0045] Example 3

Embodiment 3

[0047] The experimental results showed that the conversion rate of pentose sugar was 99%, the yield of furfural was 82.5%, the recovery rate of acetic acid was 93.9%, and the recovery rate of formic acid was 90.9%.

[0048] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com