Reservoir protection agent composition, drilling fluid containing reservoir protection agent composition and application thereof

A technology of reservoir protection agent and composition, which is applied in the field of oil drilling, can solve problems such as unsatisfactory protection effect of fractured reservoirs, difficult to accurately grasp the characteristics of reservoir fractures, unsatisfactory temporary plugging effect, etc., to achieve reservoir protection Excellent performance, improved reservoir protection ability, good elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In the reservoir protective agent composition of the present invention, the preparation method of the intermediate product may comprise: mixing acrylamide, cationic monomer, crosslinking agent, toughening material and water, adding an initiator to the resulting mixture for reaction, and then The reaction product is dried and pulverized.

[0044] Preferably, the method of mixing acrylamide, cationic monomer, crosslinking agent, toughening material and water includes: (1) adding acrylamide, cationic monomer and crosslinking agent into water to dissolve and stirring evenly; (2) ) Add the toughening material to the mixture in step (1), and stir evenly; (3) Stir the mixture in step (2) under a protective atmosphere. Wherein, the protective atmosphere may be nitrogen and / or inert gas, and the stirring time in step (3) may be 20-30 min.

[0045] Preferably, the conditions of the reaction include: the temperature is 30-60°C, and the time is 3-5h. The protective atmosphere and...

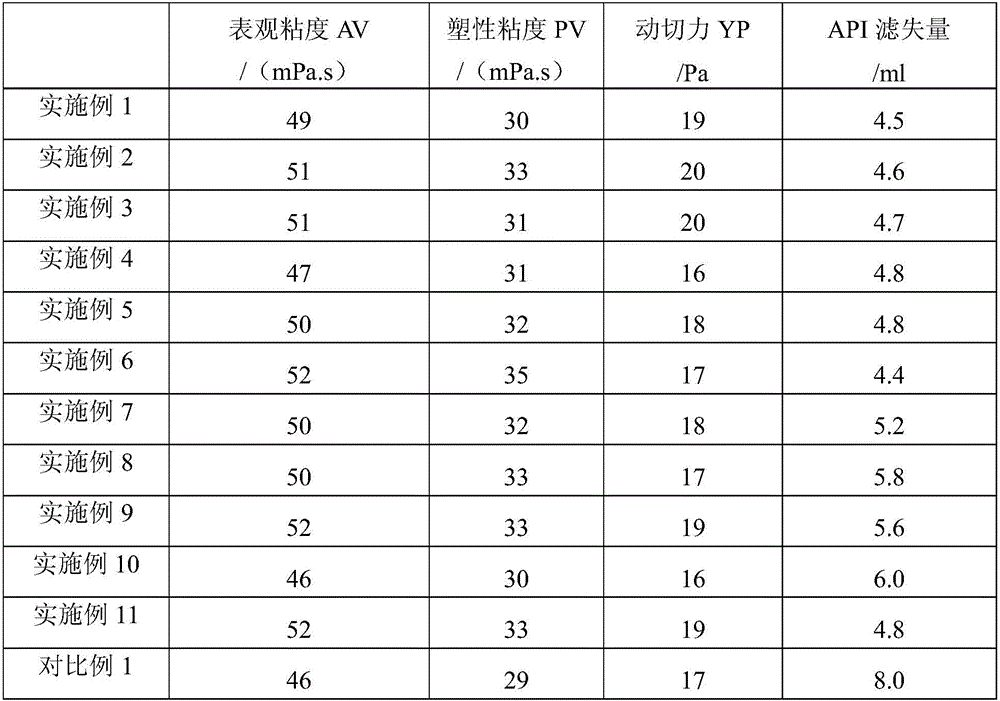

Embodiment

[0060] The present invention will be described in detail through examples below, but the present invention is not limited thereby. In the following, preparation examples, examples and comparative examples, unless otherwise specified, the materials used are all commercially available, and the methods used are all conventional methods in the art.

[0061] Polyester fiber was purchased from Shenzhen Tianzhitu Technology Co., Ltd., the brand name is TZT-PET-6.

[0062]Polyacrylonitrile fiber was purchased from Shenzhen Tianzhitu Technology Co., Ltd., the brand name is TZT-PAN-6.

[0063] The zero-permeability drilling fluid treatment agent was purchased from Hebei Huayun Hongye Chemical Co., Ltd., with the brand name HY-3000.

[0064] The ultra-low permeability drilling fluid treatment agent was purchased from Shijiazhuang Hualai Dingsheng Technology Co., Ltd., and the brand is YP-4.

preparation example 1

[0066] This preparation example is used to illustrate the preparation method of polymer elastic particles.

[0067] Add 20kg of acrylamide, 4kg of dimethyl diallyl ammonium chloride and 0.01kg of N,N'-methylenebisacrylamide into 67.96kg of water, fully dissolve, then add 8kg of bentonite, and stir evenly. Add the above-mentioned reaction solution into the reactor equipped with a stirrer, a condenser, and a thermometer, pass through nitrogen protection, stir for 20 minutes, then adjust the temperature to 60°C, add 0.03kg of ammonium persulfate, stop nitrogen and stirring, and react 3h; the reaction product was taken out, dried at 105°C for 15h, and pulverized to obtain an intermediate product of granular reservoir protection agent.

[0068] Take 10kg of intermediate product and 5kg of sodium carbonate, add 79.95kg of water and continuously stir for 10h, then add 5kg of sodium chloride and 0.05kg of octadecyltrimethylammonium chloride, and continue stirring for 0.5h to obtain po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com