Chemical agent for treating and recycling paper sludge and treating method thereof

A papermaking sludge and sludge technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of air pollution, waste of resources, waste of raw materials, etc., and achieve The effect of protecting the environment, reducing enterprise costs, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

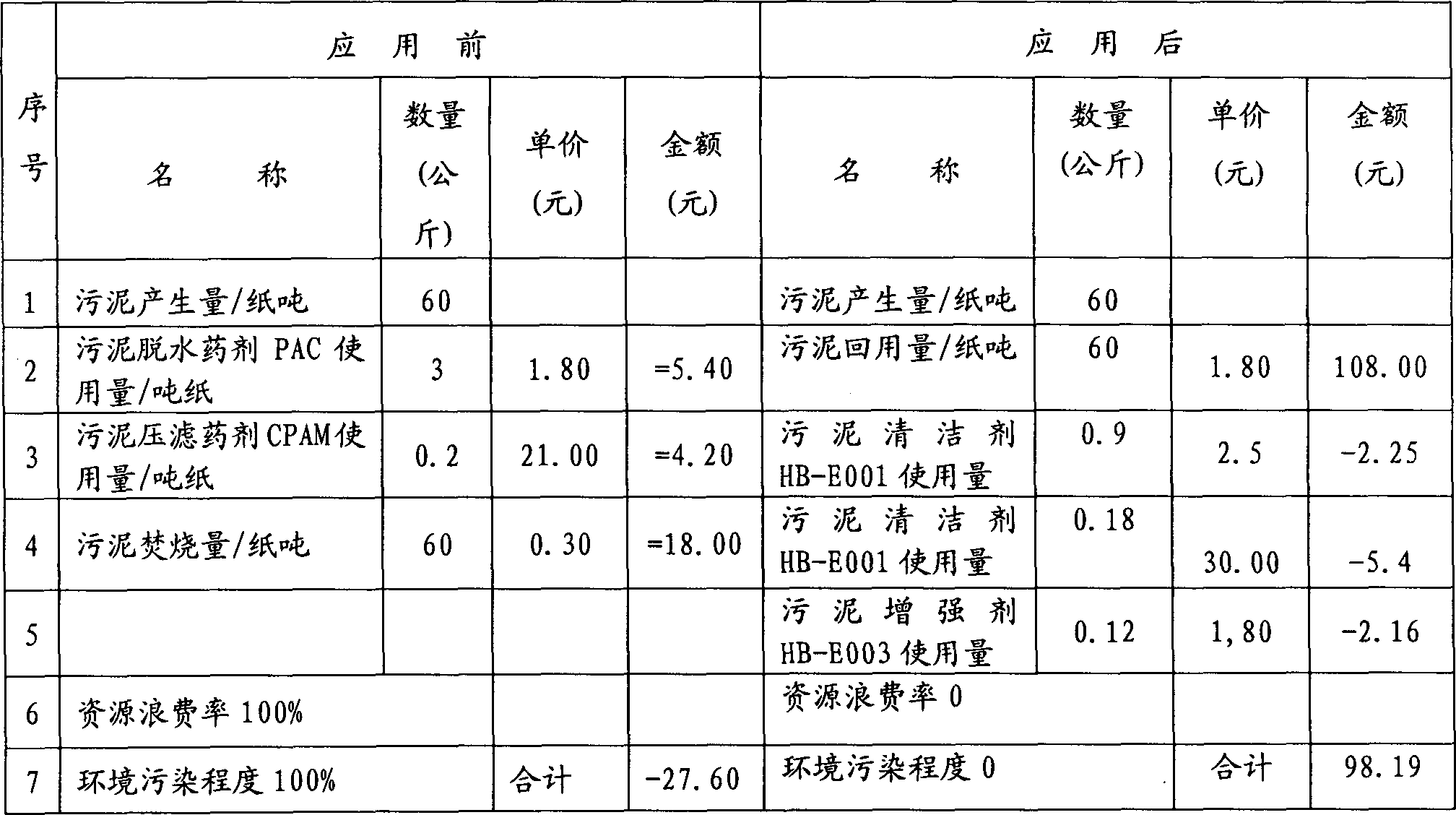

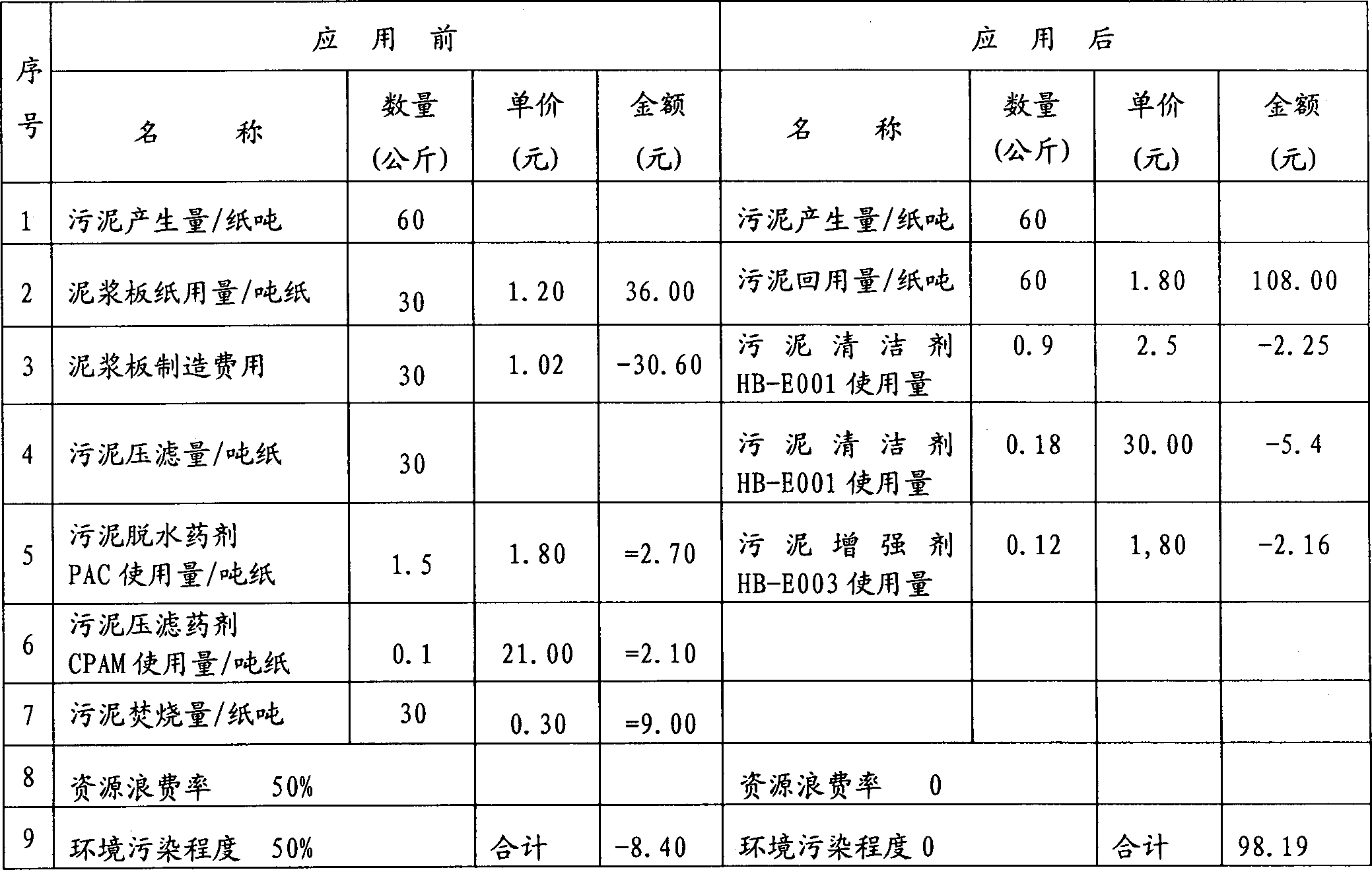

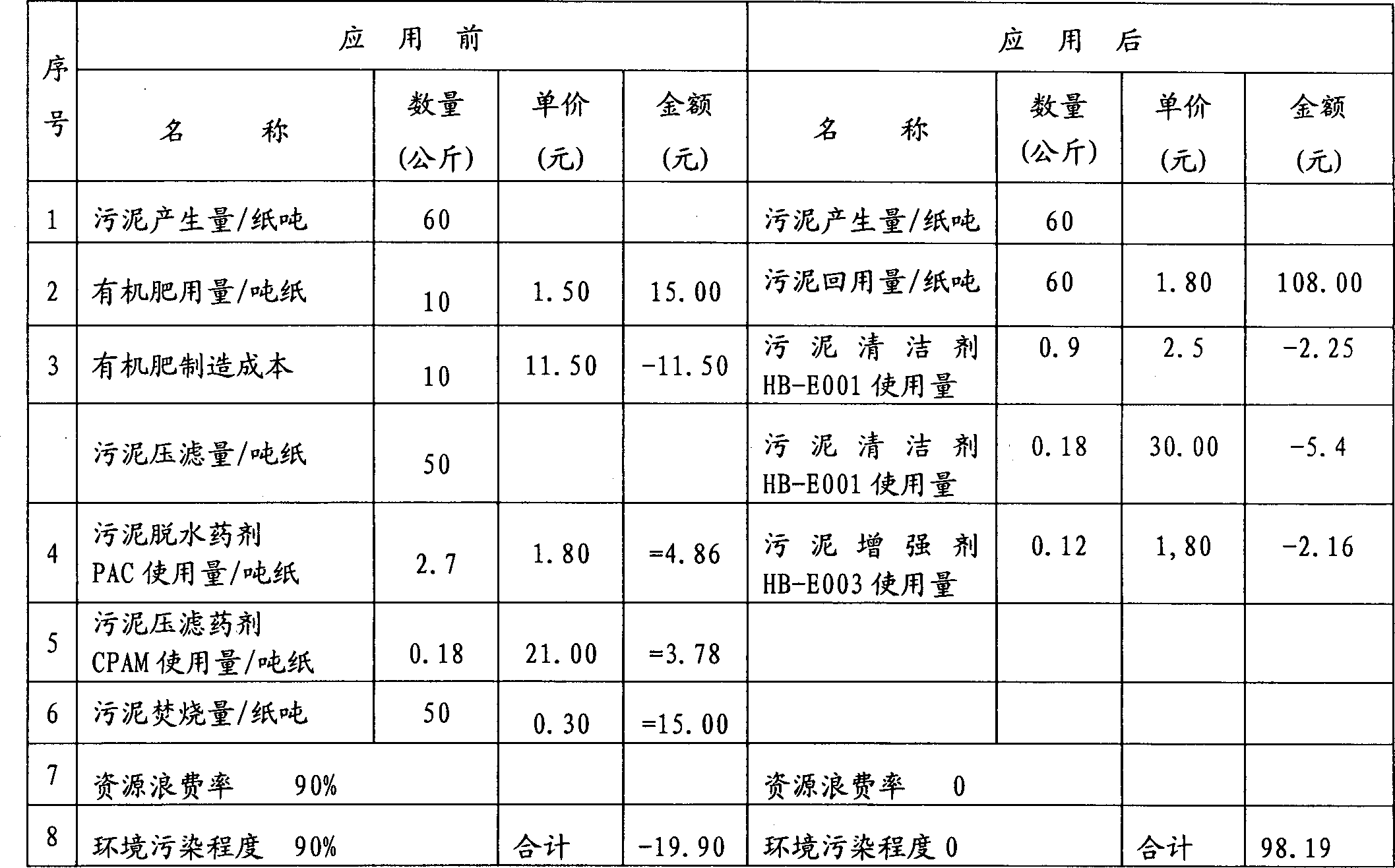

[0022] Technical thinking of the present invention is:

[0023] Provide application process, sludge cleaner HB-E001, sludge activator HB-E002, sludge enhancer HB-E003, sludge treatment machine HB-H001; first process sludge (fine fibers) into finished slurry, According to different paper types, according to the proportion of long, medium and small fiber requirements, make paper after reasonable matching; mainly to overcome the existing sludge transported to landfill and incineration; to overcome the low added value of manufacturing mud boards and the small market Excess sludge is still transported or incinerated by press filtration; it overcomes the high cost of processing sludge into farmland organic fertilizers, and excess sludge is still transported or incinerated by press filtration; it overcomes the need to reuse sludge into paper by polymer organic polyacrylamide A large amount of pages is lost, causing a vicious cycle in the system, and the excess sludge is still transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com