Horizontal well sand prevention and water control pipe string and oil production increasing method

A technology for horizontal wells and water control pipes, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of rapid water cut rise, high oil production water cut, and high implementation costs, reducing processing costs, The effect of improving oil recovery and improving water control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 provides a sand control and water control pipe string for a horizontal well, and its structure will be described in detail below.

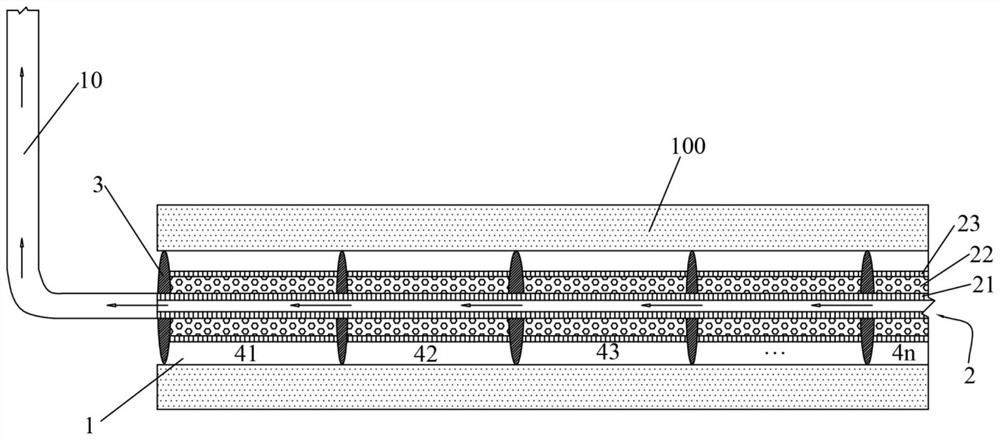

[0032] refer to figure 1 , the horizontal well sand control and water control pipe string includes a reservoir 100, a horizontal well, a sand control pipe assembly 2, and several packers 3.

[0033] Petroleum is stored in the reservoir 100 , and the horizontal well includes a horizontal part and a wellhead part. The wellhead part and the horizontal part are connected together from outside to inside and extend to the horizontal part of the horizontal well to penetrate into the reservoir 100 .

[0034] A number of sequentially connected water plugging test sections 1 are selected in the horizontal part of the horizontal well and the surrounding reservoir 100 .

[0035] The wellhead of the horizontal well is provided with an oil pipeline 10 , and the inlet end of the oil pipeline 10 is docked with the oil outlet end of the inner ...

Embodiment 2

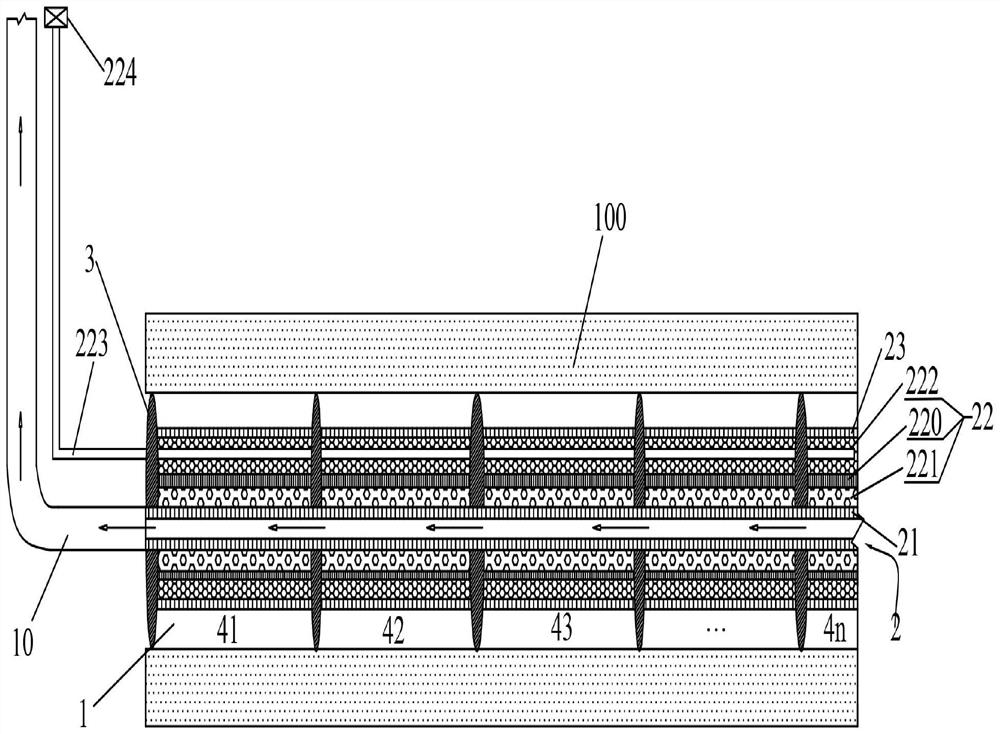

[0049] In order to drain more and more water in the support particle layer 22, on the basis of embodiment 1, embodiment 2 is improved for the support particle layer 22, and the support particle layer 22 of embodiment 2 is improved to a drainage type, The specific structure is as follows:

[0050] refer to figure 2 , the support particle layer 22 is provided with an annular filter 220, and the annular filter 220 separates the support particle layer 22 with an annular part 221 with more oil and less water and an annular part with less oil and water 222, wherein the annular part with more oil and less water 221 is close to the inner pipe 21, and the less-oil-more-water annular portion 222 is closer to the outer pipe 23. A drain blind pipe 223 is horizontally arranged in the less-oil-more-water annular portion 222, and the outlet of the drain blind pipe 223 is provided with Water blocking valve 224.

[0051] When the oil-water mixture is exported to the later stage, since the o...

Embodiment 3

[0053] Embodiment 3 provides a method for increasing oil in a horizontal well, using the sand control and water control pipe string of the horizontal well provided in Embodiment 1, the method includes the following steps:

[0054] Step A: selecting the water plugging experiment section 1 in the horizontal part of the horizontal well and the surrounding reservoir 100;

[0055] Step B: preparing the sand control pipe assembly 2, which specifically includes the following steps:

[0056] Step B1: dividing the water blocking experiment section 1 into multiple water blocking sections;

[0057] According to the principle that well sections with similar permeability are divided into one section, the water plugging test section 1 is divided into the first experimental section, the second experimental section, ..., the nth experimental section, wherein n is a natural number greater than 1;

[0058] Step B2: divide the pipe wall of the outer pipe 23 into a plurality of partitions accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com