Heating ring die system for straw biomass granulator

A biomass pellet and heating ring technology, which is applied in the fields of biofuels, heating devices, lighting and heating equipment, etc., can solve the problem of 10-20 minutes for machine preparation, and the same time required for shutdown, increasing production costs and pelletizing time. It can improve the adaptability of raw materials, improve work efficiency, and prevent production accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

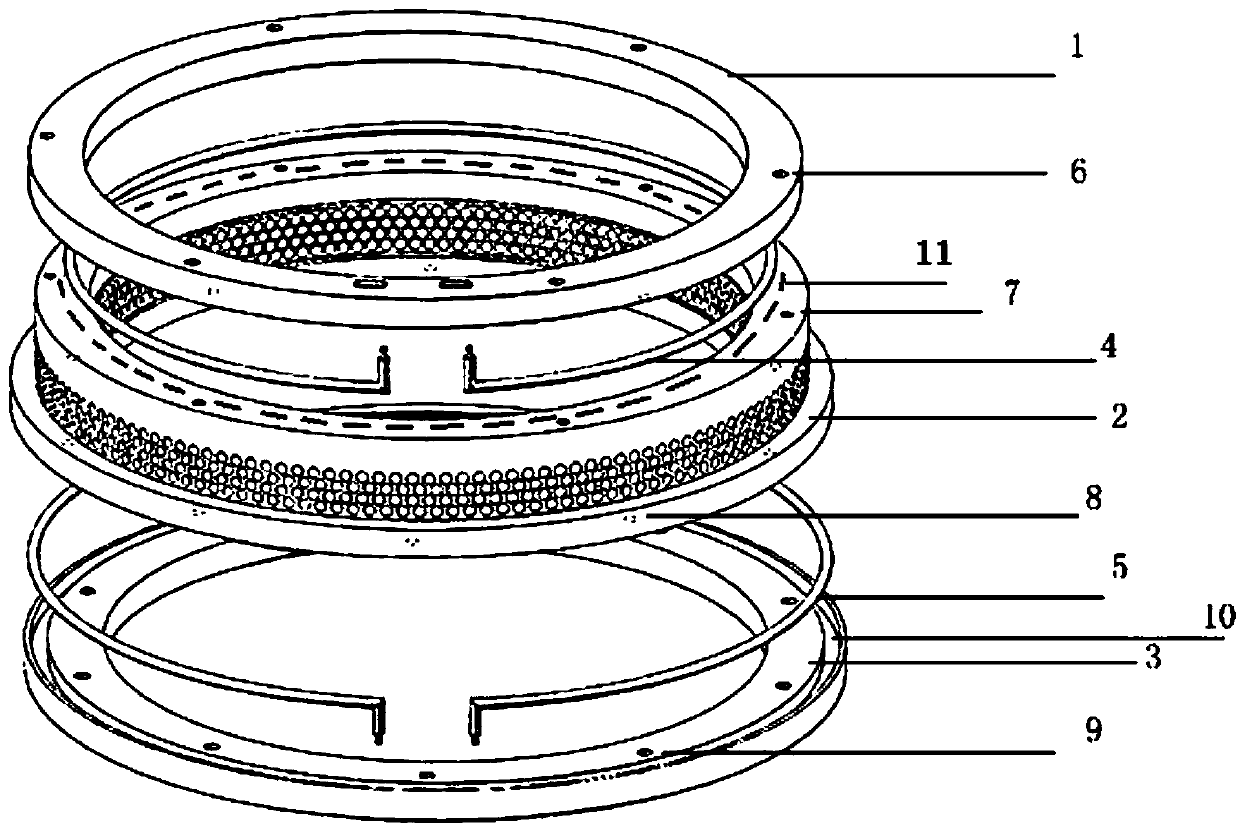

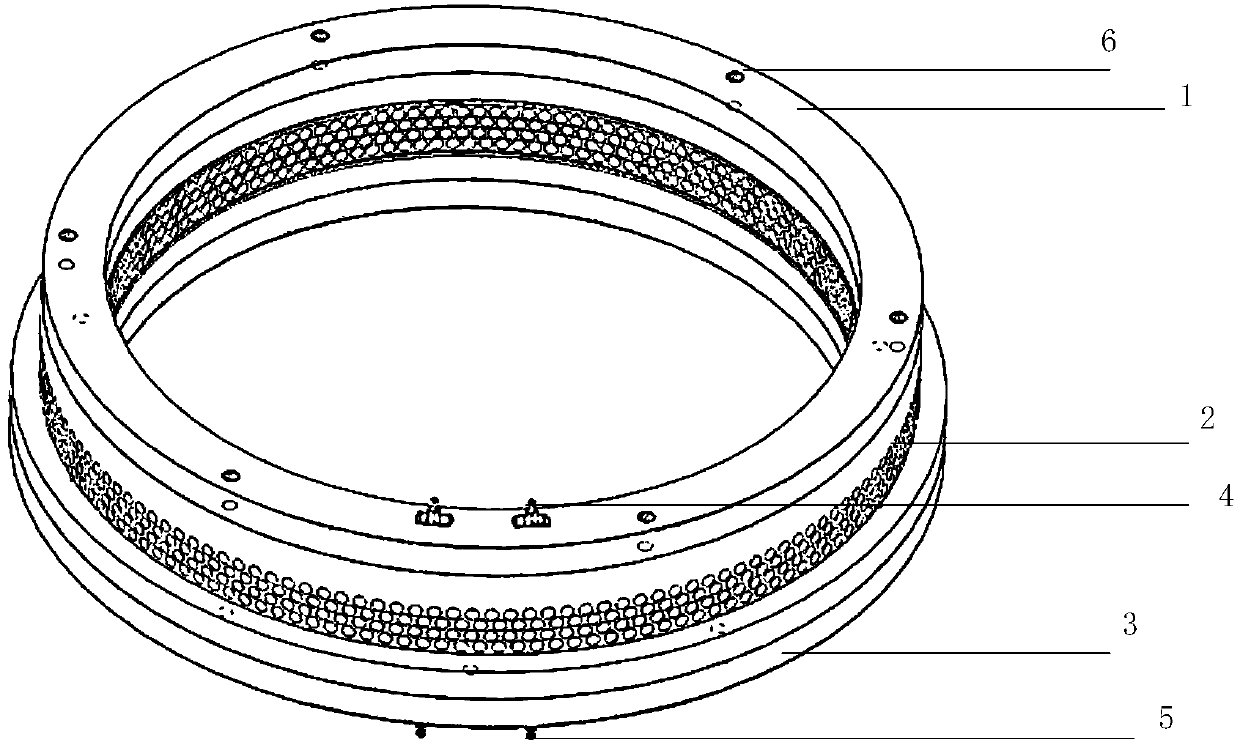

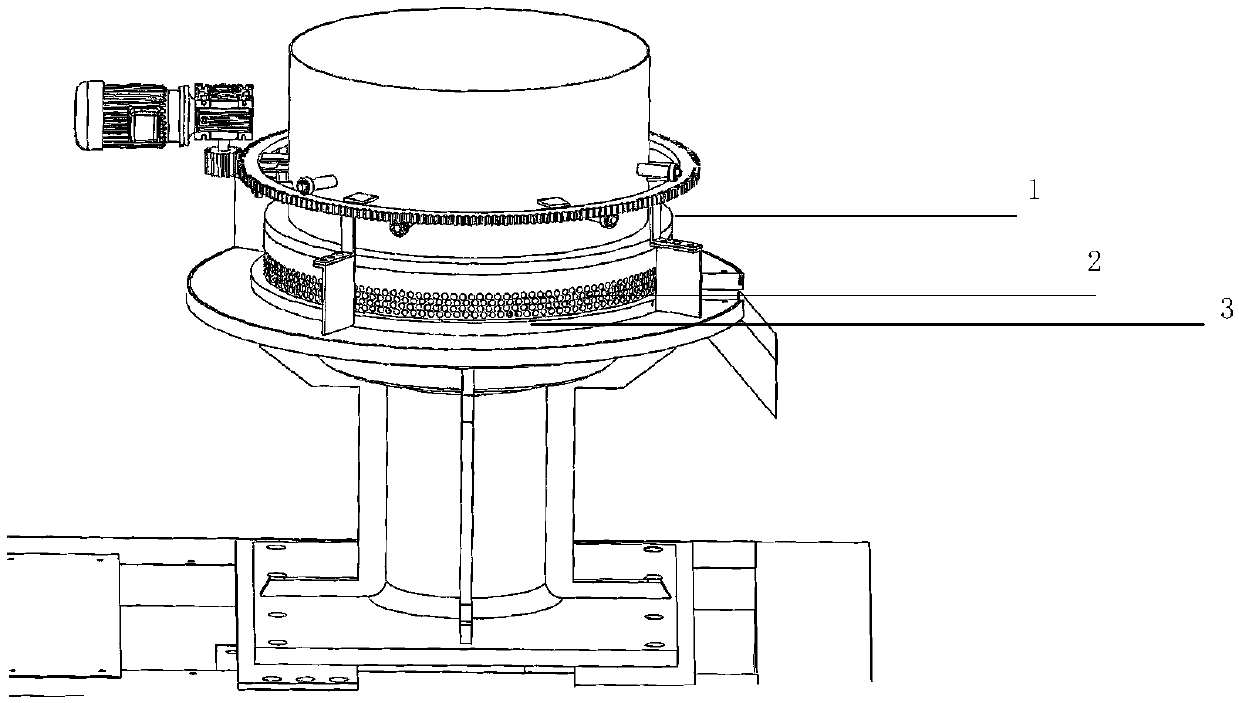

[0019] In order to make the technical solution and advantages of the device of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings through specific implementation methods. It should be particularly pointed out that the specific implementations described in this specification are only used to explain the device of the present invention, rather than to limit the present invention. see figure 1 , figure 2 , this embodiment 1 discloses a heating device for the ring die of a straw biomass pellet machine, including a compression flange 1, a ring die 2, a bottom plate 3 of the ring die, an upper heating element 4 located on the upper part of the ring die, and an upper heating element 4 located on the ring die 2 The lower heating element 5 below, the ring die 2 and the ring die bottom plate 3 are respectively provided with an upper groove 11 accommodating the upper heating element and a lower gr...

Embodiment 2

[0022] Similar to Embodiment 1, the difference lies in the number and position of the heating elements. In this embodiment, the heating ring mold system device only has the upper heating element 4, and the upper part of the ring mold 2 is provided with a groove for accommodating the upper heating element 4 11,6 is the through hole of the upper fastening bolt, and 7 is the corresponding upper fixing hole with internal thread. Fastening bolts tightly seal the upper heating element 4 in the upper groove 11 through a plurality of through holes 6 evenly distributed on the compression flange and correspondingly distributed on the ring die 2 with internal thread fixing holes 7, leaving only the electrode It is electrically connected with the power supply for heating. In this embodiment, the upper heating element 4 adopts a ring-shaped electric heating rod, and the ring-shaped electric heating rod coincides with the axes of the compression flange 1 , the ring die 2 , and the bottom pl...

Embodiment 3

[0041] Similar to Embodiment 1, the difference lies in the number and position of the heating elements. In this embodiment, there is only the lower heating element 5, and a groove 10 for accommodating the lower heating element 5 is arranged above the bottom plate of the ring die, and 8 is the lower heating element 5. The fastening bolt through hole, 9 is the corresponding lower fixing hole with internal thread. The fastening bolts seal the lower heating element 5 tightly in the groove 10 through a plurality of through holes 8 evenly distributed on the ring die 2 and correspondingly distributed on the ring die bottom plate 3 with internal thread fixing holes 9, leaving only the electrodes and The heating is electrically connected to a power supply. In this embodiment, the lower heating element 5 adopts a ring-shaped electric heating rod, and the ring-shaped electric heating rod coincides with the axes of the compression flange 1 , the ring die 2 , and the bottom plate 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com