Attaching control method of object, attaching machine and storage medium

A technology of control method and storage medium, applied in chemical instruments and methods, lamination devices, optics, etc., can solve problems such as time-consuming influence, error-prone, error-prone attachment accuracy, etc., to avoid error-prone and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

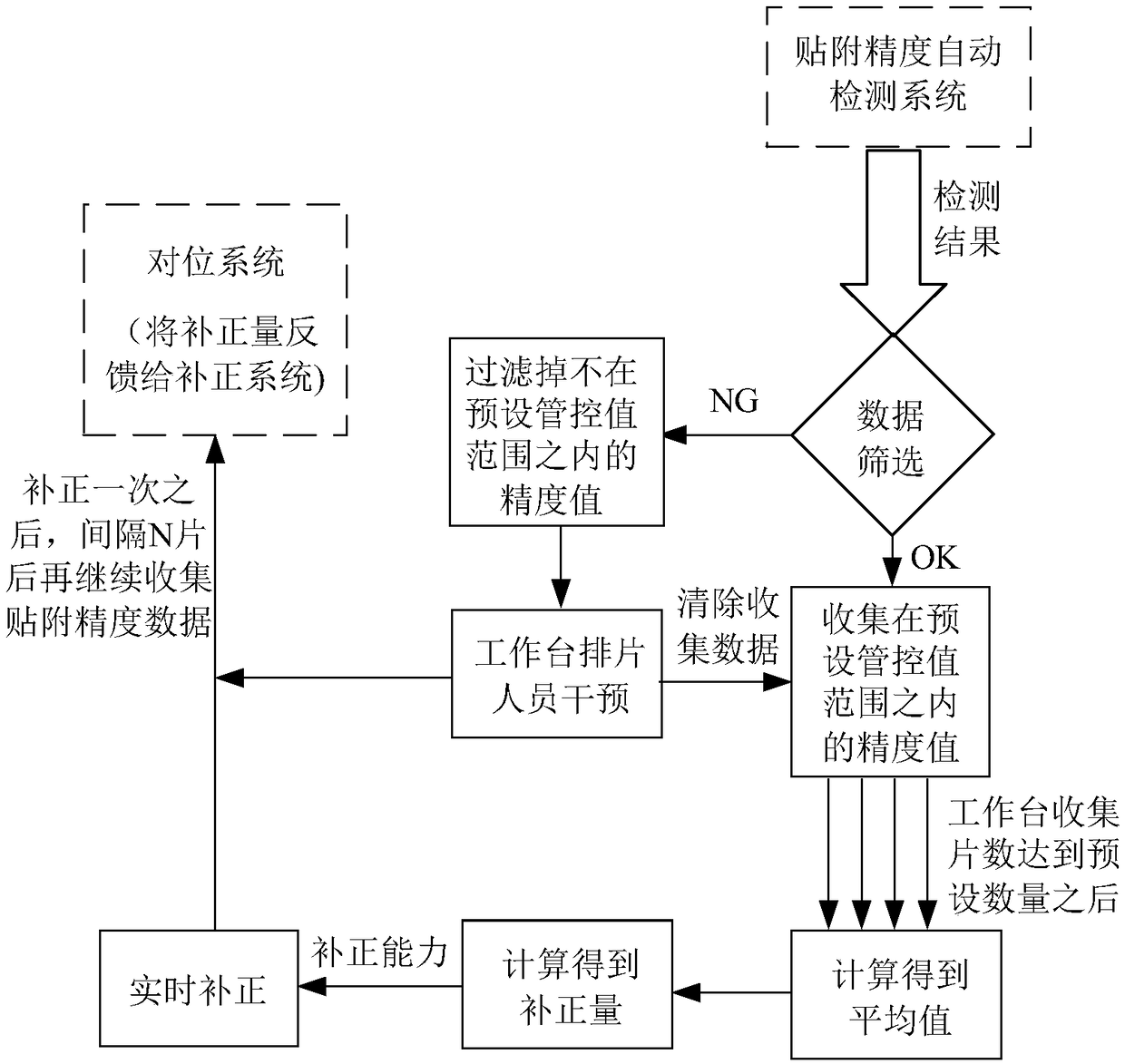

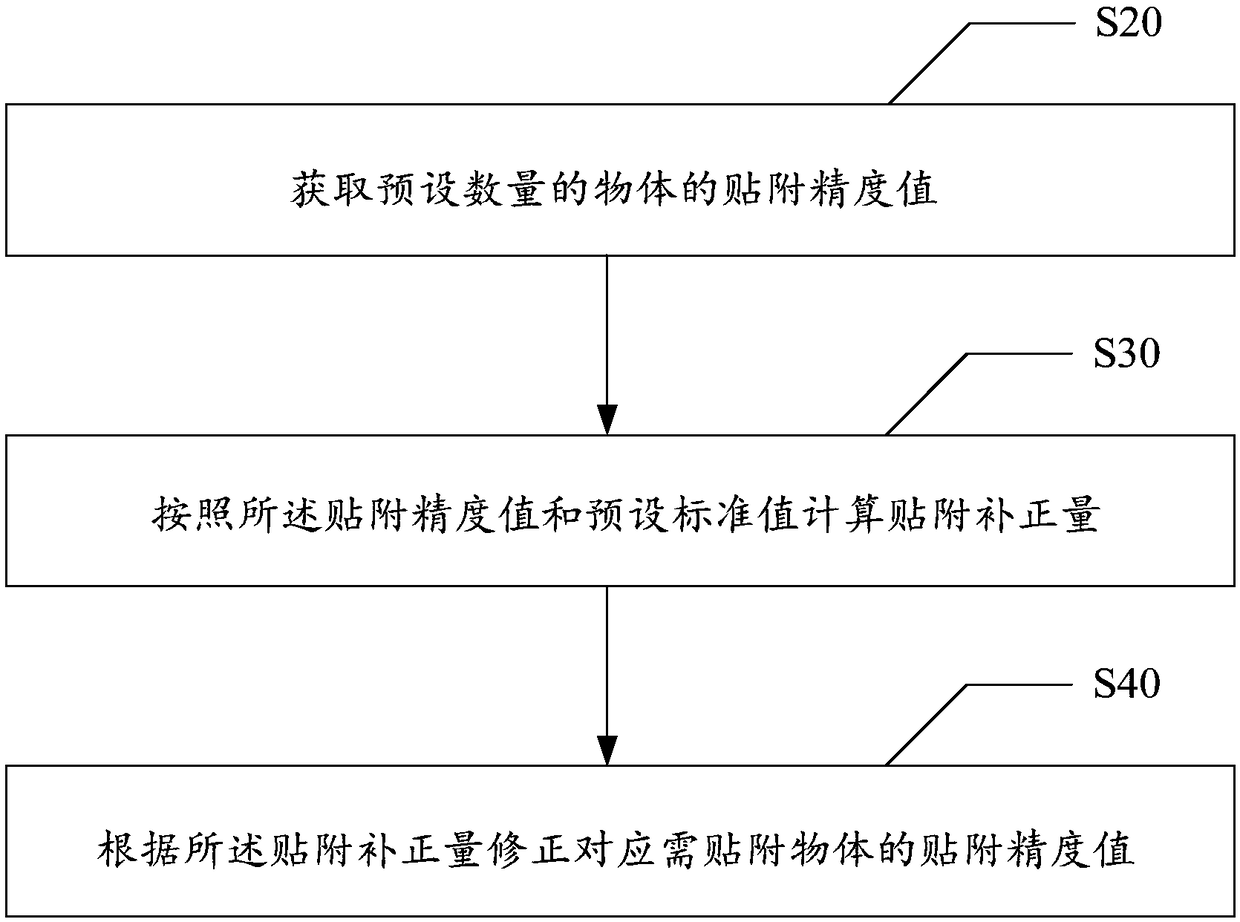

Method used

Image

Examples

Embodiment Construction

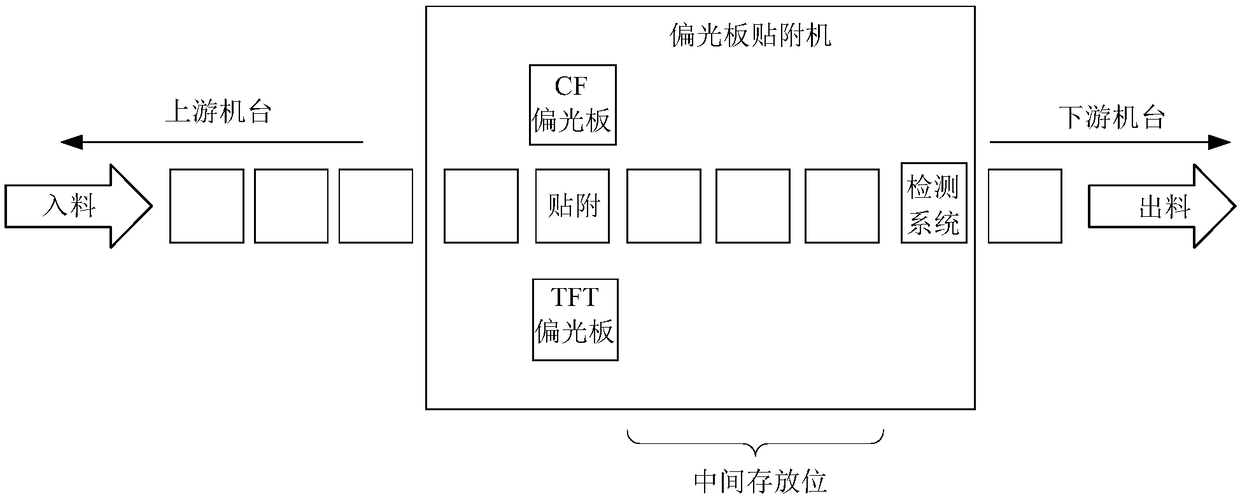

[0038] The object referred to in this application can be a polarizer, it can also be the installation and attachment of a color filter, a thin film transistor, etc. a liquid crystal panel, or it can be other objects such as the attachment of paper or film, etc. can be.

[0039] Hereinafter, the present application takes setting the object as a polarizing plate and applying the attachment of the polarizing plate as a preferred embodiment of the present application to make the following description:

[0040] Polarizing plates are used in liquid crystal displays. The imaging of liquid crystal displays must rely on polarized light. All liquid crystals have two polarizing plates at the front and back attached to the liquid crystal glass to form a liquid crystal sheet. If any polarizing plate is missing, the liquid crystal sheet cannot display image. Therefore, the polarizer is a particularly important component of the liquid crystal display panel.

[0041] Control terminals may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com