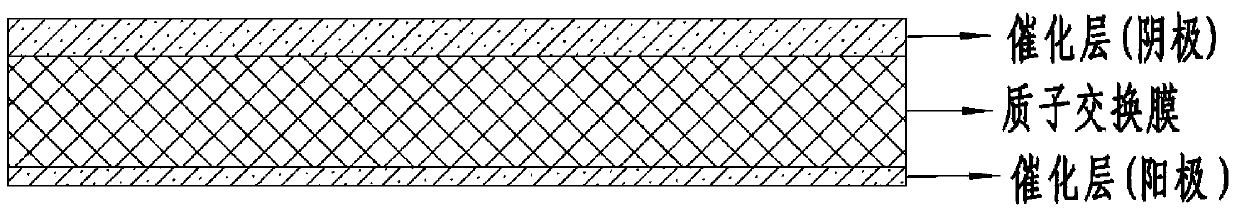

Preparation method of membrane electrode assembly of proton exchange membrane fuel cell

A proton exchange membrane, fuel cell membrane technology, applied in fuel cells, battery electrodes, electrical components, etc., can solve problems such as swelling, membrane shrinkage, and unfavorable scale-up production, and achieve the effect of being suitable for mass production and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.5g of carbon-supported platinum catalyst (Johnson Matthey Catalyst Hispec9100, UK), then weigh 5g of perfluorosulfonic acid resin solution (DuPont’s perfluorosulfonic acid resin solution DE520), 5g of isopropyl Alcohol, 2.5 g deionized water for ultrasonic dispersion for 30 min.

[0028] (2) Stir at 10,000 rpm for 90 min with a high-speed disperser (Germany IKA Company, T25 digital display type) to obtain catalyst slurry.

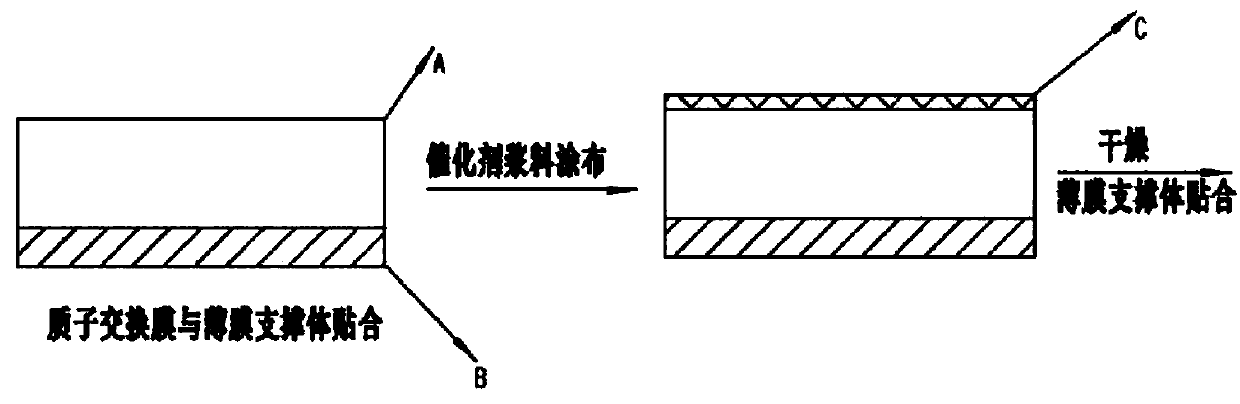

[0029] (3) Proton exchange membrane (DuPont NR 212, USA, thickness of proton exchange membrane is about 50μm) placed at the bottom of side a

[0030] One layer of film support body 1 (the thickness of the PET film is 100 μm, and the surface tension coefficient is 45 mN / m), so that the film support body 1 and the side a of the proton exchange membrane are closely attached.

[0031] (4) Coat the catalyst slurry on side b of the proton exchange membrane by screen printing, and dry at 80° C. for about 5 minutes.

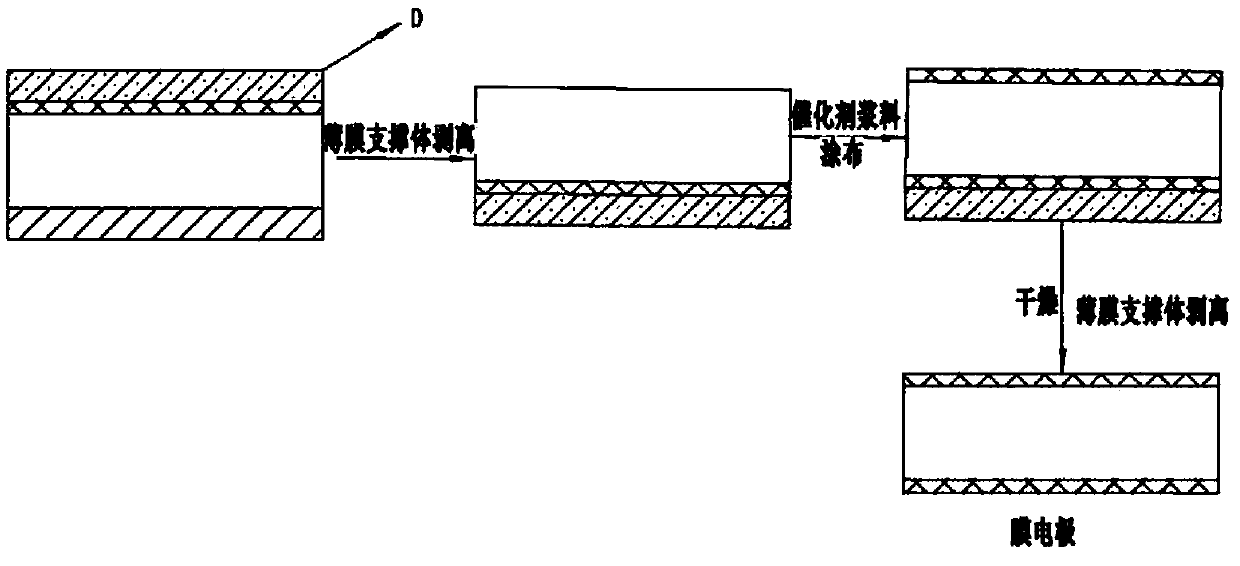

[0032] (5) Lay the membran...

Embodiment 2

[0035] (1) Weigh 2g of carbon-supported platinum ruthenium catalyst (Johnson Matthey Catalyst Hispec5000, UK), and then weigh 8g of perfluorosulfonic acid resin solution (perfluorosulfonic acid resin solution DE520 from DuPont, USA), 8 g of methanol, 5 g deionized water was used for ultrasonic dispersion for 30 min.

[0036] (2) Stir at 10,000 rpm for 90 min with a high-speed disperser (Germany IKA Company, T25 digital display type) to obtain catalyst slurry.

[0037] (3) Proton exchange membrane (proton exchange membrane thickness of American Gore company is about 18 μm) a layer of film support 1 (polytetrafluoroethylene film thickness of 200 μm, surface tension coefficient of 18 mN / m) is placed on the bottom of side a, so that the film support 1 and side a of the proton exchange membrane are closely attached.

[0038] (4) Coat the catalyst slurry on side b of the proton exchange membrane with a slot die coater, and dry it at 25° C. for about 30 minutes.

[0039] (5) Lay th...

Embodiment 3

[0042] (1) Weigh 2g of carbon-supported platinum-cobalt alloy catalyst (Pt-Co / C, 46wt% Pt, 6 wt% Co)), and then weigh 8g of perfluorosulfonic acid resin solution (perfluorosulfonic Acid resin solution DE520), 8 g glycerol, 5 g deionized water for ultrasonic dispersion for 30 min.

[0043] (2) Stir at 10,000 rpm for 90 min with a high-speed disperser (Germany IKA Company, T25 digital display type) to obtain catalyst slurry.

[0044] (3) Proton exchange membrane (NR 115 from DuPont, USA, thickness of proton exchange membrane is about 120μm) A layer of film support 1 (polyvinyl chloride film thickness 50μm, surface tension coefficient 40mN / m) is placed on the bottom of side a to make the membrane support Body 1 and side a of the proton exchange membrane are closely attached.

[0045] (4) Coat the catalyst slurry on side b of the proton exchange membrane with a sprayer, and dry it at 95°C for about 5 minutes.

[0046] (5) Lay the membrane support 2 and the side b of the proton e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com