Liquid fuel additive

A liquid fuel and additive technology, applied in the field of fuel additives, can solve the problems of not improving diesel combustion efficiency, reducing the normal operation of internal combustion engines, and complicated manufacturing processes, so as to achieve the effects of saving diesel, improving power, and protecting the fuel system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

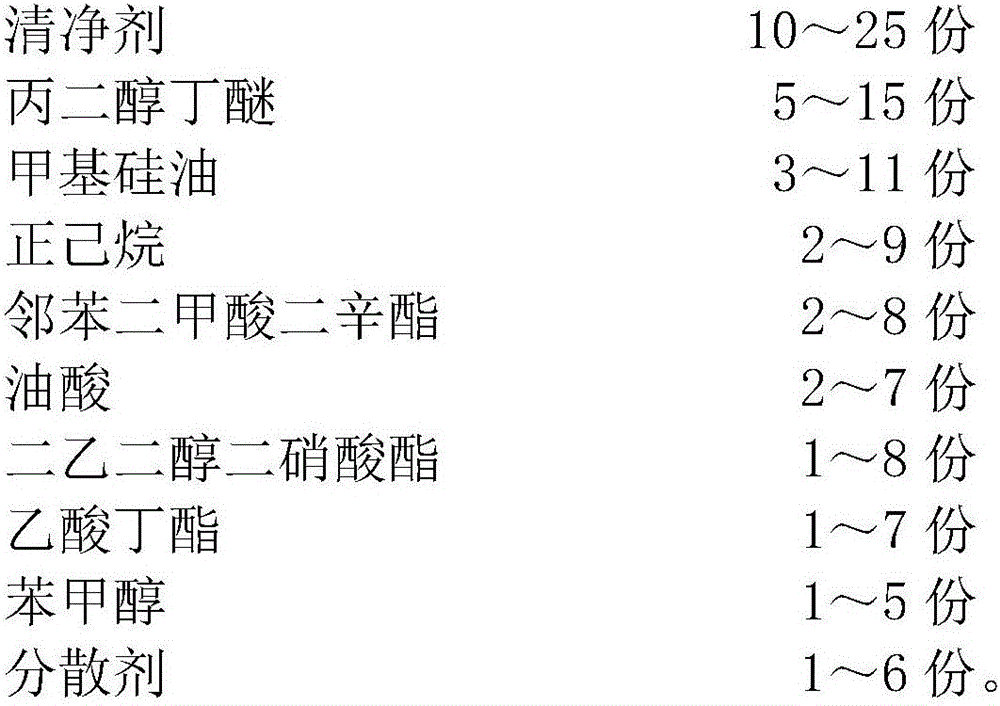

[0028] The liquid fuel additive is made from the following raw materials in parts by weight (mixed uniformly at room temperature):

[0029]

[0030]

[0031] The above detergent is a mixture of 5 parts by weight of dimethylacetamide, 5 parts by weight of diethanol monoisopropanolamine and 30 parts by weight of 1-formyl imidazole.

[0032] The above-mentioned dispersant is a mixture of 10 parts by weight of isobutanol, 25 parts by weight of propanol and 5 parts by weight of monoglyceride stearate.

[0033] When preparing diesel fuel, the additive is added in an amount of 0.2% of the diesel quality.

Embodiment 2

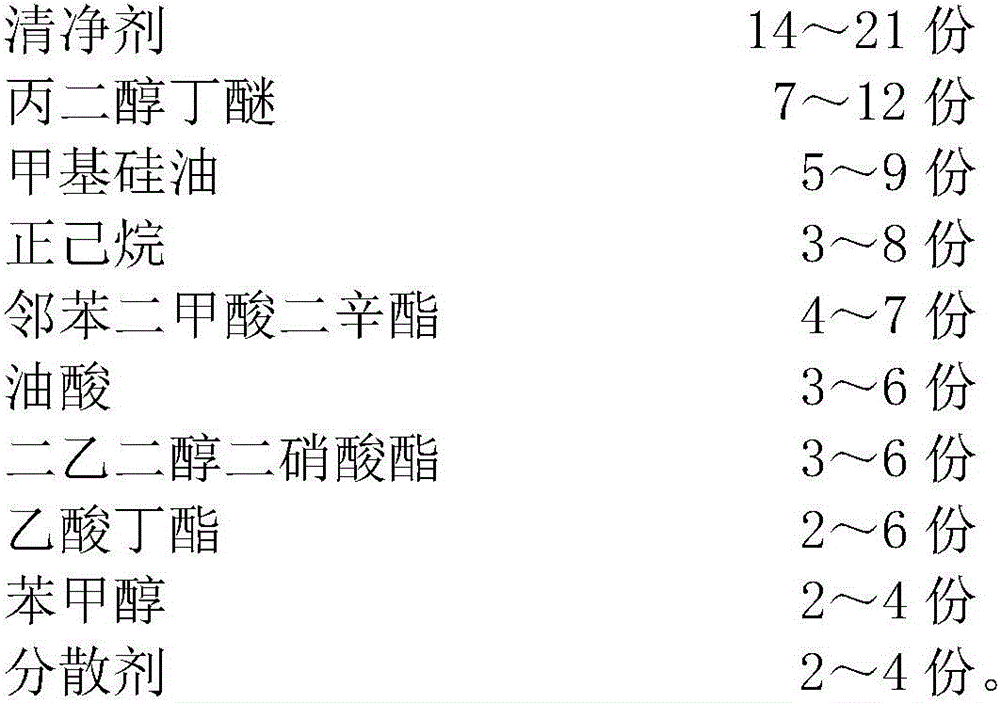

[0035] The liquid fuel additive is made from the following raw materials in parts by weight (mixed uniformly at room temperature):

[0036]

[0037] The above detergent is a mixture of 8 parts by weight of dimethylacetamide, 7 parts by weight of diethanol monoisopropanolamine and 27 parts by weight of 1-formyl imidazole.

[0038] The above-mentioned dispersant is a mixture of 12 parts by weight of isobutanol, 23 parts by weight of propanol and 8 parts by weight of monoglyceride stearate.

[0039] When preparing diesel fuel, the additive is added in an amount of 0.3% of the diesel quality.

Embodiment 3

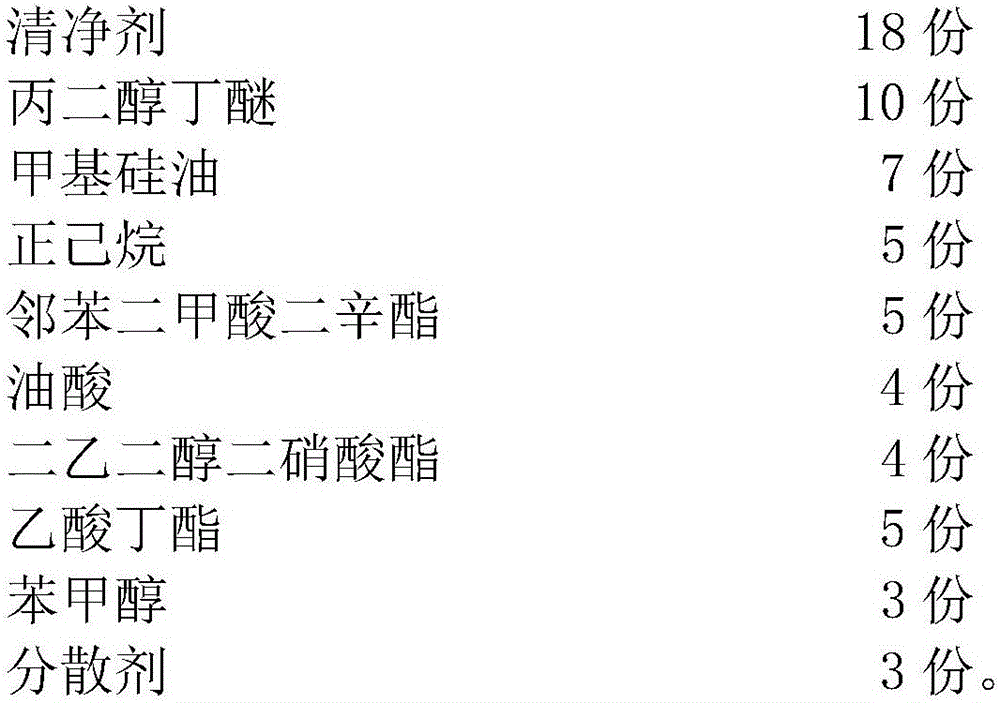

[0041] The liquid fuel additive is made from the following raw materials in parts by weight (mixed uniformly at room temperature):

[0042]

[0043]

[0044] The above detergent is a mixture of 10 parts by weight of dimethylacetamide, 10 parts by weight of diethanol monoisopropanolamine and 25 parts by weight of 1-formyl imidazole.

[0045] The above-mentioned dispersant is a mixture of 15 parts by weight of isobutanol, 20 parts by weight of propanol and 10 parts by weight of monoglyceride stearate.

[0046] When preparing diesel fuel, the additive is added in an amount of 0.4% of the diesel quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com