Diaphragm, preparation method thereof and secondary battery

A diaphragm and ceramic slurry technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of high electrostatic force of the diaphragm, difficult NMP treatment, and limited effect improvement, so as to improve wettability and heat resistance Performance, effect of solving swelling problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

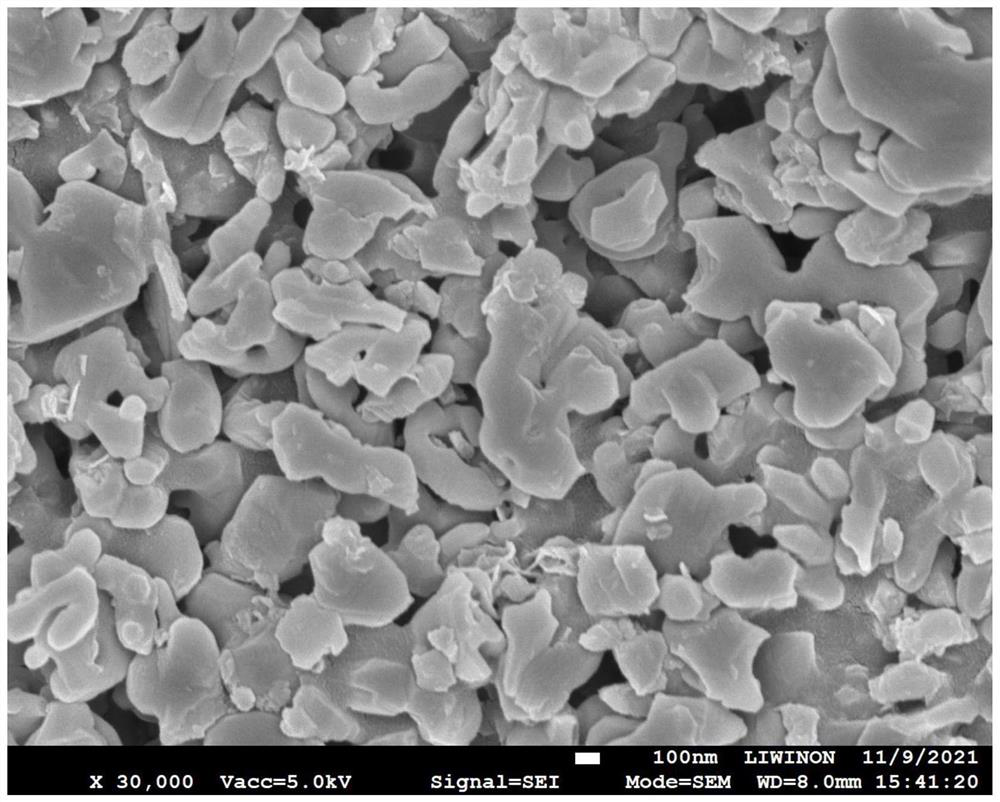

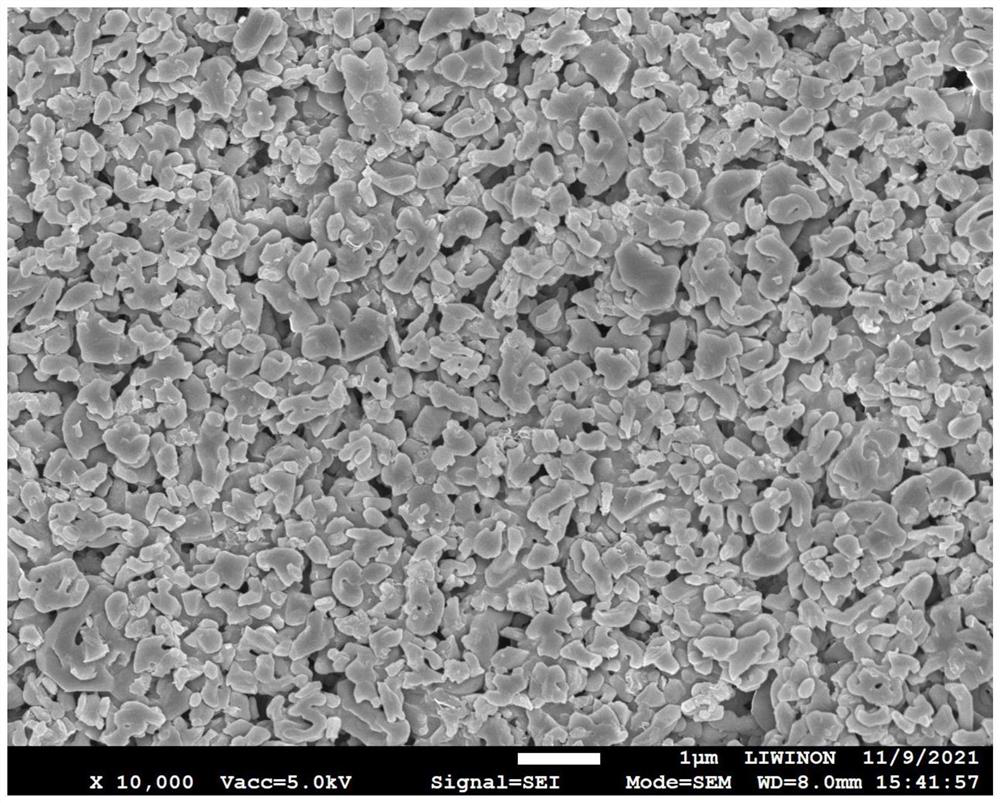

[0047] A method for preparing a lithium-ion battery diaphragm, first preparing a ceramic slurry, denoted as A, and then configuring an initiator and an active dilute monomer solution, denoted as B, wherein: ceramic slurry configuration: according to the ratio of aluminum oxide / Dispersant / wetting agent / modified urethane acrylate / crosslinking agent = 9:0.4:0.1:0.4:0.1 configuration, disperse at 1000r / min for 8min, then defoam at 500r / min for 20min to obtain ceramic slurry a. Initiator and modified urethane acrylate solution configuration, initiator TPO and initiator 184 are mixed at a ratio of 3:1 by weight, and 110 parts of modified urethane acrylate are added for mixing. The total quality of the initiator used is modified urethane acrylate 3% by mass, mixed and stirred until TPO and 184 were completely dissolved to obtain mixed solution B of initiator and reactive diluent monomer. Mix the initiator and active diluted monomer mixture B with the ceramic slurry A at a weight ra...

Embodiment 2

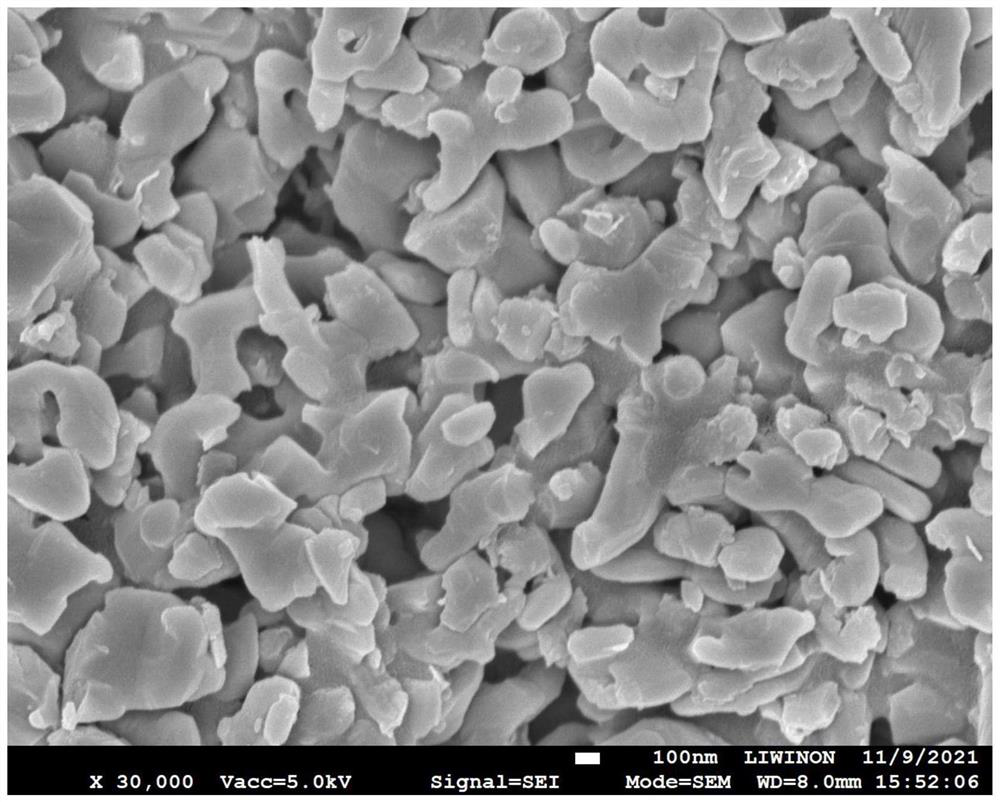

[0049] The difference from Example 1 is that the weight-number ratio of the initiator and the remaining active diluent monomer in the step S2 is 3:110.

[0050] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0052] The difference from Example 1 is that the ratio of parts by weight between the initiator and the remaining reactive diluent monomer in the step S2 is 3:120.

[0053] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com