Membrane electrode of fuel cell and preparation method and application of membrane electrode

A fuel cell membrane and electrode technology, used in fuel cells, battery electrodes, circuits, etc., can solve the problems of proton exchange membrane swelling and deposition time, low catalyst active surface, etc., and achieve easy large-scale production, large electrochemical active area, Environmental pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

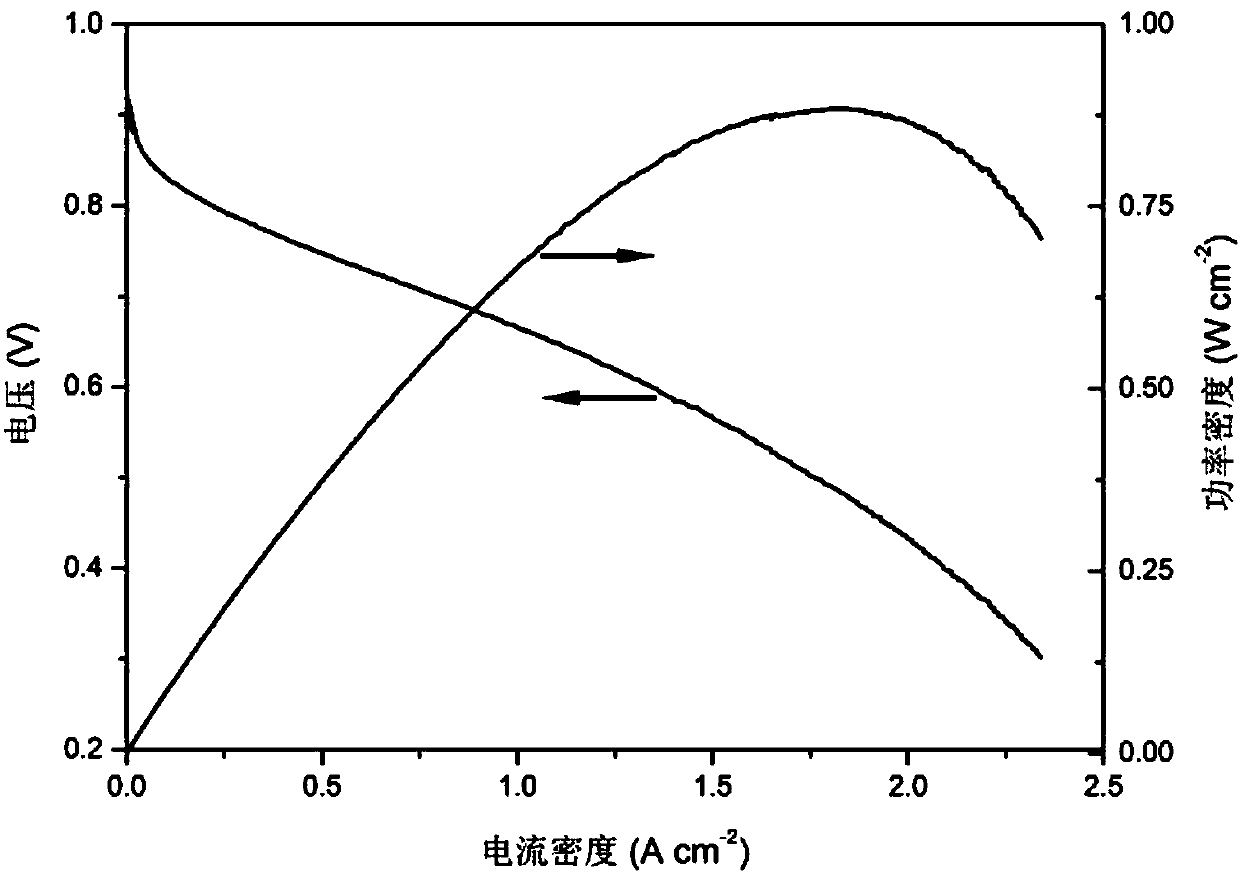

Embodiment 1

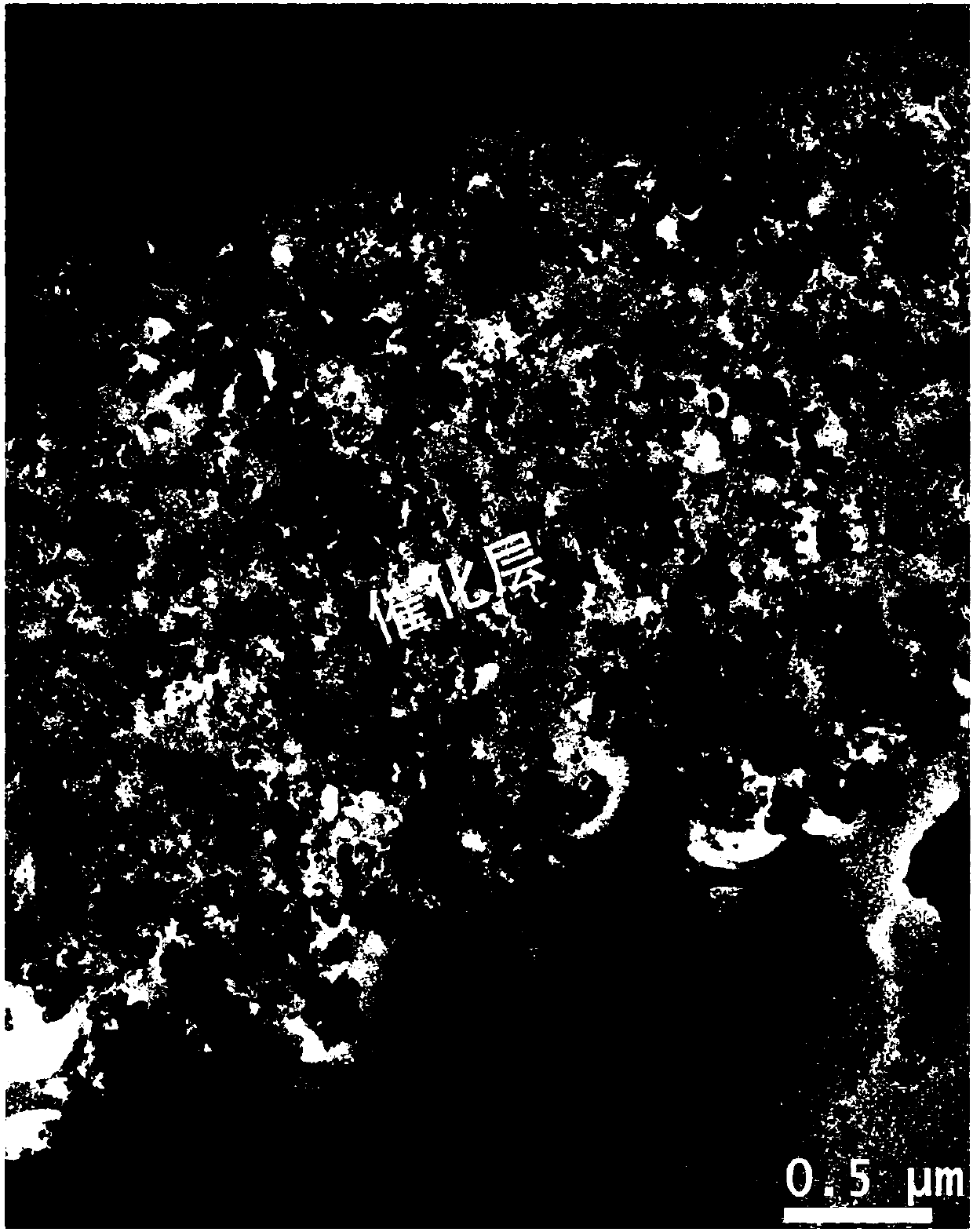

[0029](1) Add 1 mg of carbon powder, 1.25 mg of carbon powder loaded with platinum nanoparticles (commercial carbon-supported platinum catalyst, 20 wt% Pt) and 2.5 mg of Nafion solution (10% Nafion alcohol solution by mass fraction) to 2 mL of isopropyl In the alcohol solution, ultrasonic treatment makes the solution evenly dispersed, and then it is evenly sprayed on the polytetrafluoroethylene (PTFE) transfer medium, so that a layer of uniform matrix is formed on the PTFE transfer medium (area 3.3×3.3cm 2 ), and finally dried at 50°C for 1 hour.

[0030] (2) The PTFE transfer medium with the matrix is fixed in an aqueous solution containing chloroplatinic acid and formic acid, wherein the aqueous solution contains chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) 5.34mg, 1mL of formic acid (mass fraction 88%) and 80mL of water. It was then left to stand at room temperature for 10 hours to deposit 0.2 mg / cm 2 platinum. Afterwards, the above solution was replaced, the transfer ...

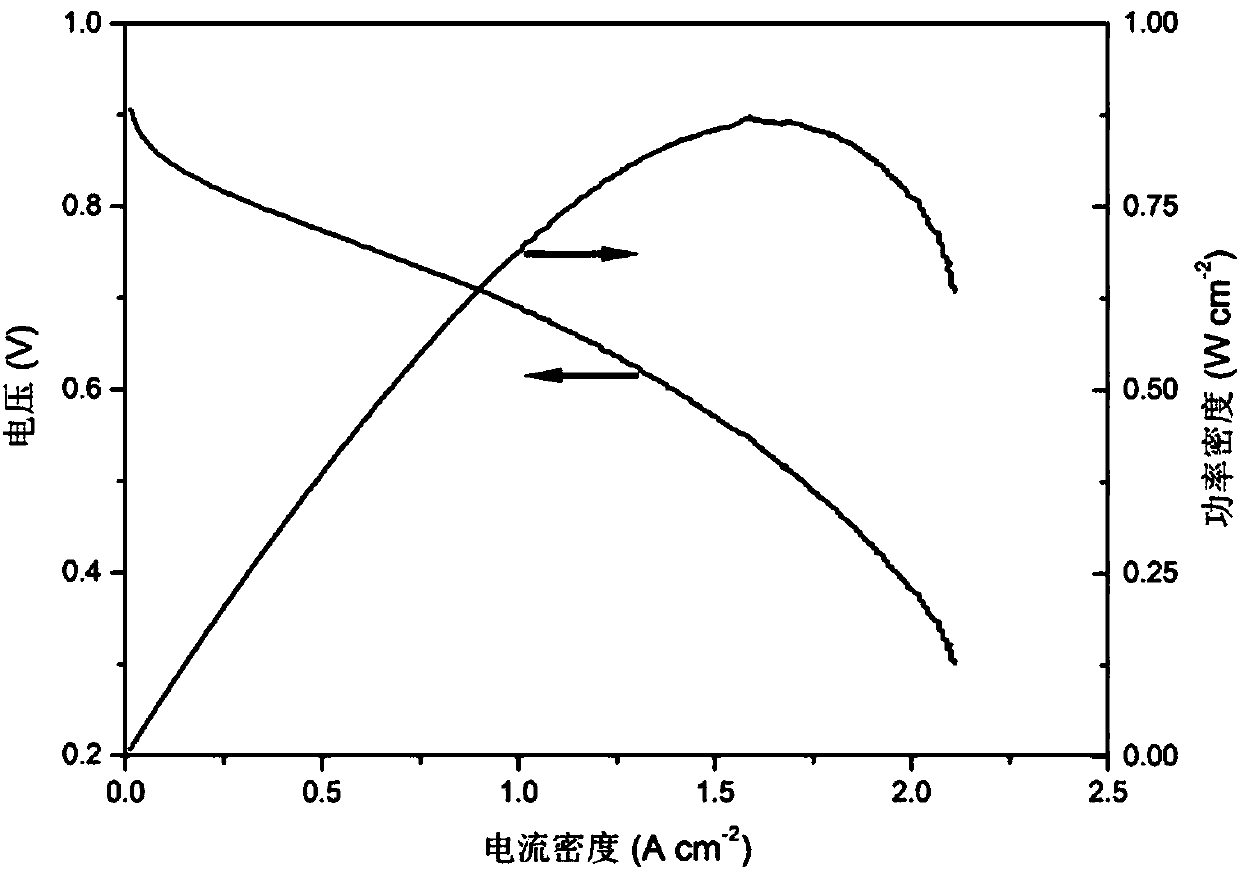

Embodiment 2

[0037] (1) Add 1 mg of carbon powder, 1.5 mg of carbon powder loaded with platinum nanoparticles (self-made, 33 wt% Pt) and 2.8 mg of Nafion solution (Nafion alcohol solution with a mass fraction of 10%) to 2 mL of isopropanol, and ultrasonically Process to disperse the mixed solution evenly, and then spray it evenly on the polytetrafluoroethylene (PTFE) transfer medium to form a uniform matrix on the PTFE transfer medium (area 3.3×3.3cm 2 ), and finally dried at 50°C for 1 hour.

[0038] (2) The PTFE transfer medium with the matrix is fixed in an aqueous solution containing chloroplatinic acid and formic acid, wherein the aqueous solution contains chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) 5.34mg, 1mL of formic acid (mass fraction 88%) and 80mL of water. It was then left to stand at room temperature for 10 hours to deposit 0.2 mg / cm 2 platinum. Afterwards, the above solution was replaced, the transfer medium was repeatedly soaked and rinsed with deionized water, and fina...

Embodiment 3

[0043] (1) Add 1 mg of carbon powder, 1.25 mg of carbon powder loaded with platinum nanoparticles (commercial carbon-supported platinum catalyst, 20 wt% Pt) and 2.5 mg of Nafion solution (10% Nafion alcohol solution by mass fraction) to 2 mL of isopropyl In the alcohol solution, ultrasonic treatment makes the solution evenly dispersed, and then it is evenly sprayed on the polytetrafluoroethylene (PTFE) transfer medium, so that a layer of uniform matrix is formed on the PTFE transfer medium (area 3.3×3.3cm 2 ), and finally dried at 50°C for 1 hour.

[0044] (2) The PTFE transfer medium with substrate is fixed in the aqueous solution containing chloroplatinic acid and formic acid, wherein the aqueous solution contains potassium chloroplatinite (K 2 PtCl 4 ) 5 mg, 1 mL of ascorbic acid (0.4 mol / L) and 80 mL of water. It was then left to stand at room temperature for 10 hours to deposit 0.2 mg / cm 2 platinum. Afterwards, the above solution was replaced, the transfer medium wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com