Crosslinked polybenzimidazoles thin film containing sulfonic group and preparation thereof

A polybenzimidazole and sulfonic acid group-containing technology, applied in the field of polybenzimidazole films and their preparation, can solve the problems of difficult processing, difficult monomer synthesis, poor film-forming properties and mechanical properties, etc., and achieve good transparency , the effect of excellent solubility, high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

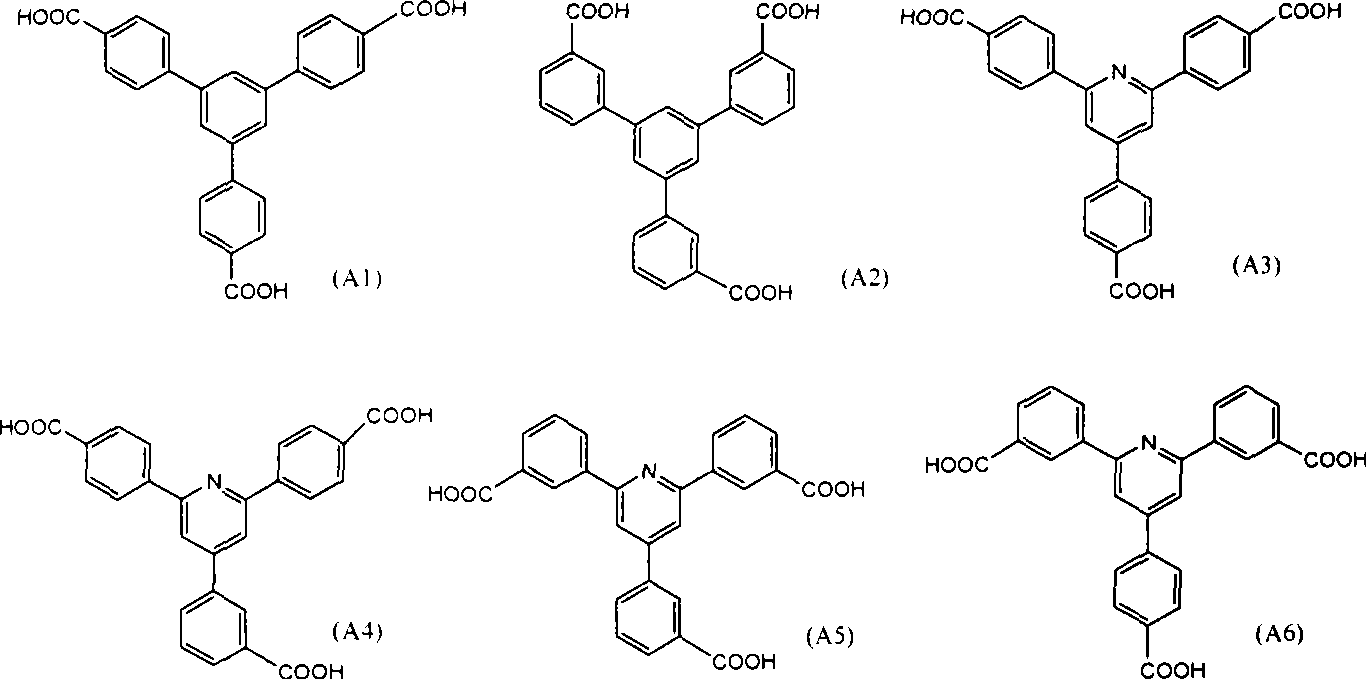

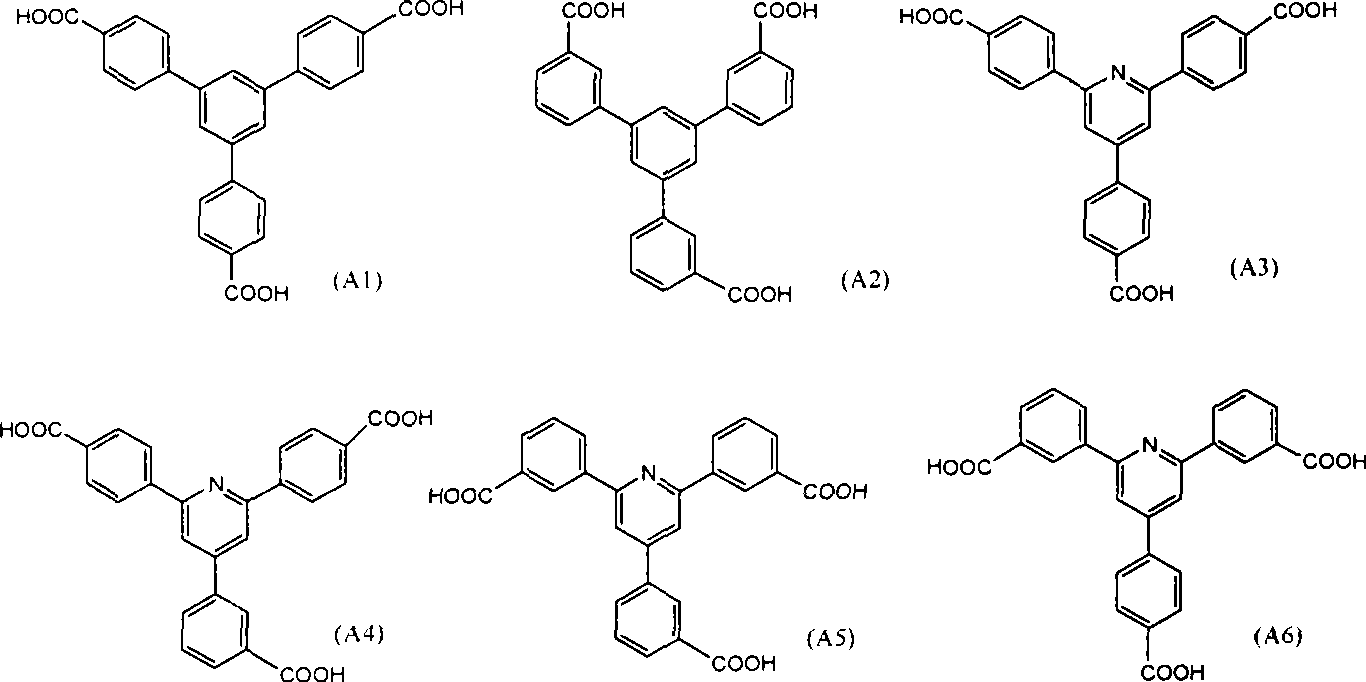

[0044] Dissolve 4.60g of 3,3',4,4'-tetraaminodiphenyl ether and 4.60g of aromatic triacid A1 (see page 4 for the structure) in 138g of polyphosphoric acid (content: 83%) , a transparent homogeneous solution was obtained. Under nitrogen protection, the above solution was heated at 160° C. for 5 h, and then heated to 180° C. for 3 h to obtain a viscous solution. Cool to room temperature and pour into 500ml of water. The precipitate was collected and washed with 5% by weight NaOH aqueous solution, then hot distilled water until neutral to obtain a beige solid. The light brown solid was dried under vacuum at 60° C. for 10 hours to obtain 7.60 g of branched polybenzimidazole (HPBI-1) with a yield of 94%. Intrinsic viscosity 0.46dL / g (0.5g / dL NMP solution, 25°C).

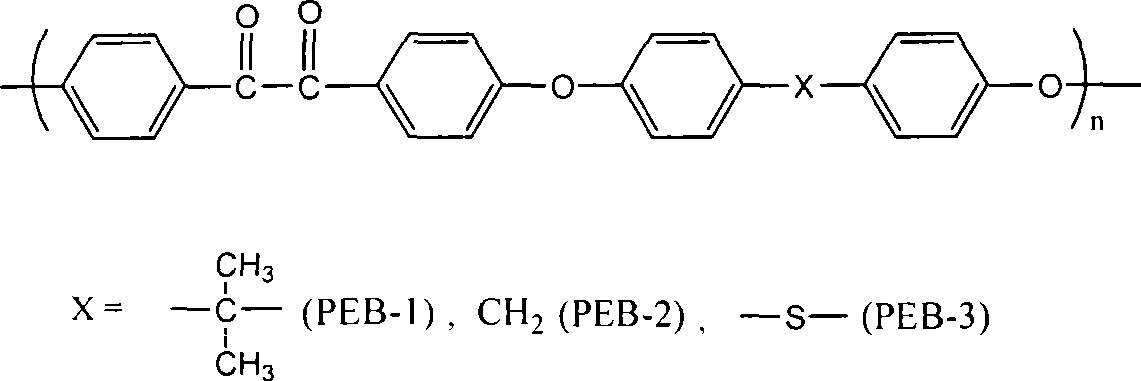

[0045] 7.60 g of HPBI-1, 0.92 g of 1,2-naphthoquinone-4-ammonium sulfonate and 0.92 g of polyether benzil PEB-1 (see page 5 for the structure; number average molecular weight 11,723; repeating unit The molecular weigh...

Embodiment 2

[0047] Dissolve 4.60g of 3,3',4,4'-tetraaminodiphenyl ether and 2.3g of aromatic triacid A2 (see page 4 for the structure) in 92g of polyphosphoric acid (content: 83%) , a transparent homogeneous solution was obtained. Under nitrogen protection, the above solution was heated at 160° C. for 5 h, and then heated to 180° C. for 11 h to obtain a viscous solution. Cool to room temperature and pour into 500ml of water. The precipitate was collected and washed with 5% by weight NaOH aqueous solution, then hot distilled water until neutral to obtain a beige solid. The light brown solid was dried under vacuum at 60° C. for 10 hours to obtain 6.32 g of branched polybenzimidazole (HPBI-2) with a yield of 95%. Intrinsic viscosity 0.40dL / g (0.5g / dL NMP solution, 25°C).

[0048] 6.32 g of HPBI-2, 1.38 g of 1,2-naphthoquinone-4-ammonium sulfonate and 0.23 g of polyether benzil PEB-1 (number average molecular weight 11,723; repeating unit molecular weight is 434.5) were dissolved in 46 g ...

Embodiment 3

[0050] 4.60g of 3,3',4,4'-tetraaminodiphenyl ether and 2.12g of aromatic triacid A1 and 2.13g of aromatic triacid A2 are dissolved in 120g of polyphosphoric acid (content is 83%) to obtain Transparent homogeneous solution. Under nitrogen protection, the above solution was heated at 160° C. for 3 h, and then heated to 180° C. for 3 h to obtain a viscous solution. Cool to room temperature and pour into 500ml of water. The precipitate was collected and washed with 5% by weight NaOH aqueous solution, then hot distilled water until neutral to obtain a beige solid. The light brown solid was dried under vacuum at 60° C. for 10 hours to obtain 7.28 g of branched polybenzimidazole (HPBI-3) with a yield of 94%. Intrinsic viscosity 0.44dL / g (0.5g / dL NMP solution, 25°C).

[0051]7.28 g of HPBI-3, 1.25 g of 1,2-naphthoquinone-4-ammonium sulfonate and 0.55 g of polyether benzil PEB-2 (see page 5 for the structure; number average molecular weight 11,516; repeating unit The molecular weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com