Method for preparing membrane electrode by direct coating method, and membrane electrode prepared by method

A technology of membrane electrode and coating method, which is applied in the direction of circuits, fuel cells, electrical components, etc., to achieve the effect of smooth surface, solve the problem of membrane swelling, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for preparing a membrane electrode comprises the steps of:

[0073] (1) Get a volume of perfluorosulfonic acid proton exchange membrane that is 34cm wide and 1.5 meters long, and slit-coats cathode catalyst slurry on the side without protective film, and the viscosity of said cathode catalyst slurry is 200mpa. s, the solid content is 35%, the dry coating thickness is 9 μm, the coating size is 33 cm wide and 1.45 meters long, and the Pt loading is 0.40 mg / cm after vacuum drying. 2 The cathode side (the first active material catalyst layer);

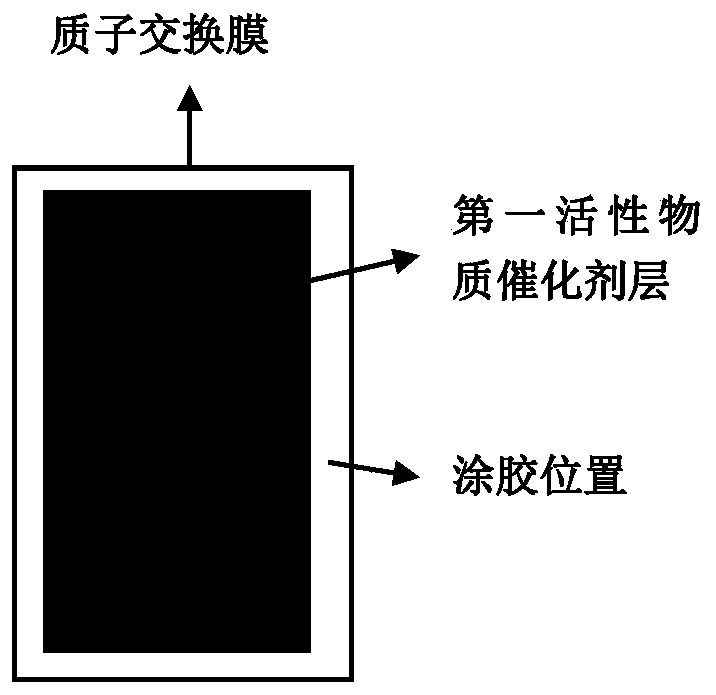

[0074] (2) The automatic glue applicator is loaded with UV glue, and glue is applied at a distance of 1.2mm from the edge of the cathode surface, the glue application amount is 0.2mL / min, and then a protective film with the same size as the proton exchange membrane is pasted on the cathode surface, and the UV ultraviolet rays Irradiation curing, the position of the glue is as figure 1 As shown, it can be seen from the fig...

Embodiment 2

[0078] A method for preparing a membrane electrode comprises the steps of:

[0079] (1) get a volume of perfluorosulfonic acid proton exchange membranes that are 34cm wide and 1.5 meters long, gravure-coated PtM / C cathode catalyst slurry on the side without protective film, and the viscosity of the cathode catalyst slurry is 50mpa.s, solid content of 20%, coating dry thickness of 8μm, coating size of 30cm in width and 1.45m in length, and vacuum drying to obtain a Pt loading of 0.20mg / cm 2 the cathode side;

[0080] (2) The automatic glue applicator is loaded with UV glue, and the glue is dispensed at a distance of 2.0mm from the edge of the cathode surface, the amount of glue applied is 1.0mL / min, and then a protective film of the same size as the proton exchange membrane is pasted on the cathode surface, and UV is cured ;

[0081] (3) adopting a vacuum pump to vacuumize the interlayer gap between the cathode surface and the protective film in step (2), so that the vacuum d...

Embodiment 3

[0084] The difference from Example 1 is that the amount of glue applied in step (2) is 0.05mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com