Preparation method of anti-fouling anion-exchange membrane

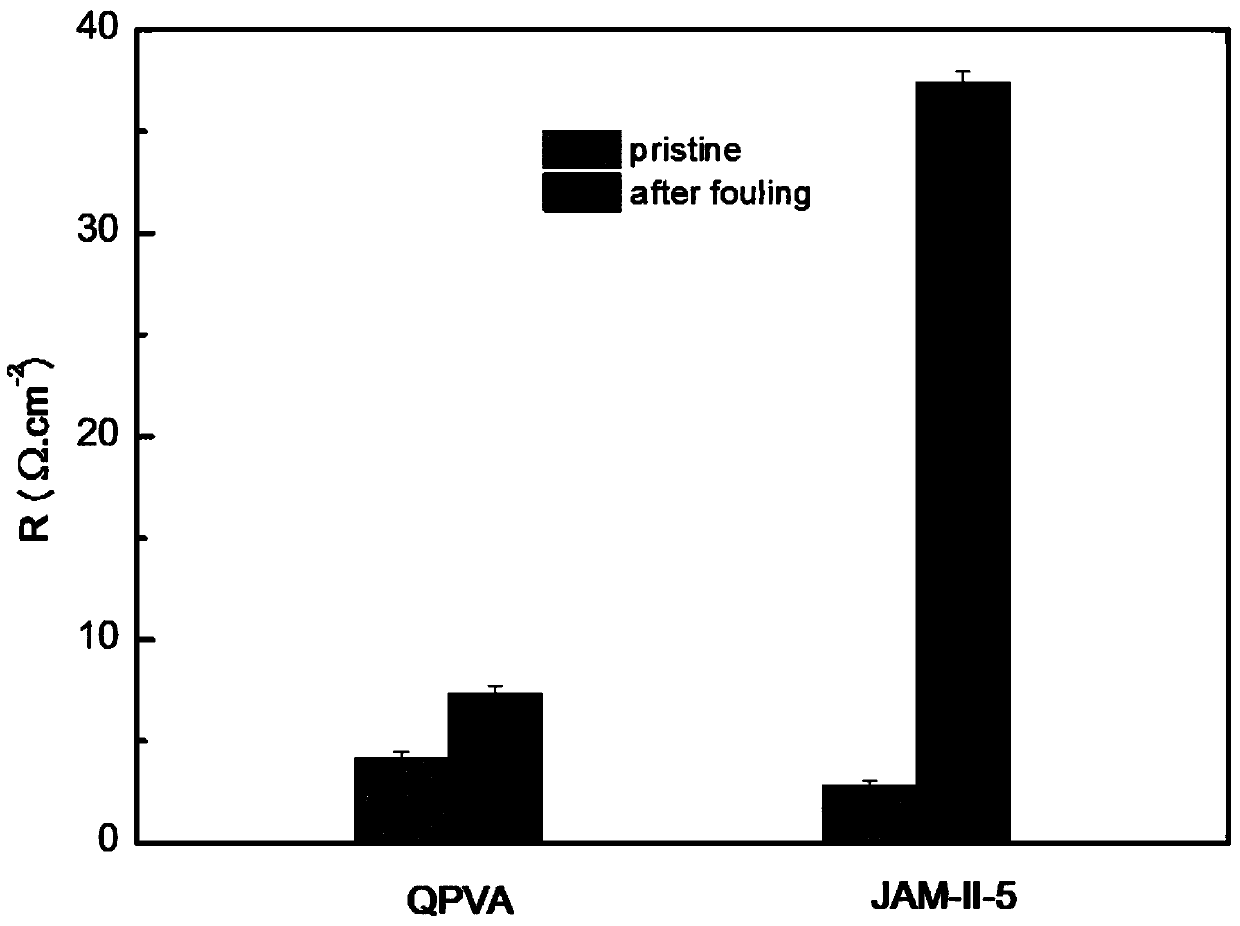

An anion exchange membrane and antifouling technology, applied in the field of separation membranes, can solve problems such as unfavorable long-term use, poor stability of the surface modification layer, increased membrane resistance, etc., and achieve the effects of avoiding easy shedding, simple preparation process, and excellent antifouling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

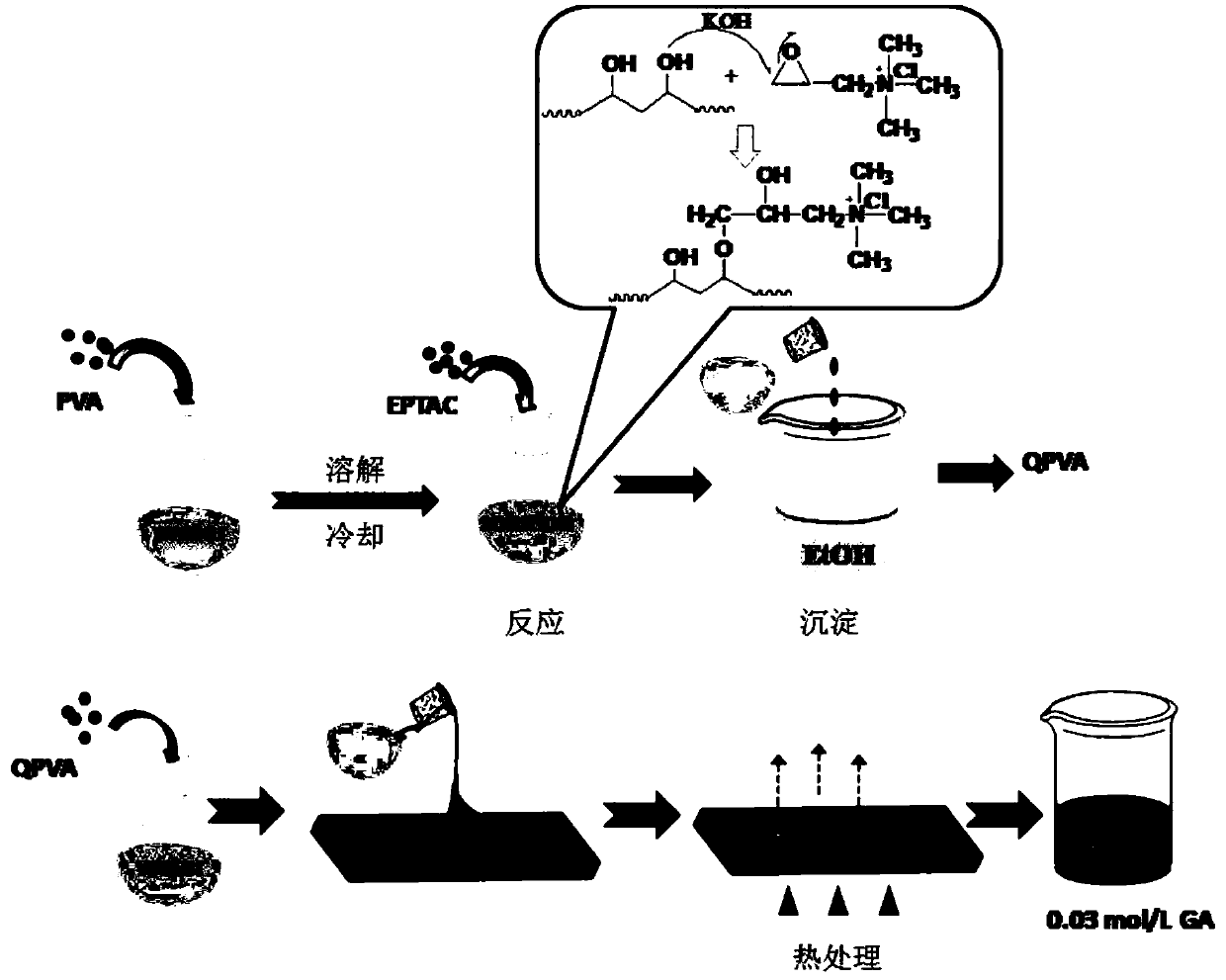

[0038] Add 5g of PVA powder into a small beaker, add 100g of water, then raise the temperature to 90°C, stir magnetically until the PVA is completely dissolved to obtain a transparent solution, cool down to 60°C, add 15g of EPTAC to the solution, stir magnetically for 4.5h, and the reaction is over Finally, slowly drop the reaction solution into a beaker containing 300 mL of absolute ethanol for precipitation, filter, wash with absolute ethanol until neutral, and dry to constant weight to obtain QPVA.

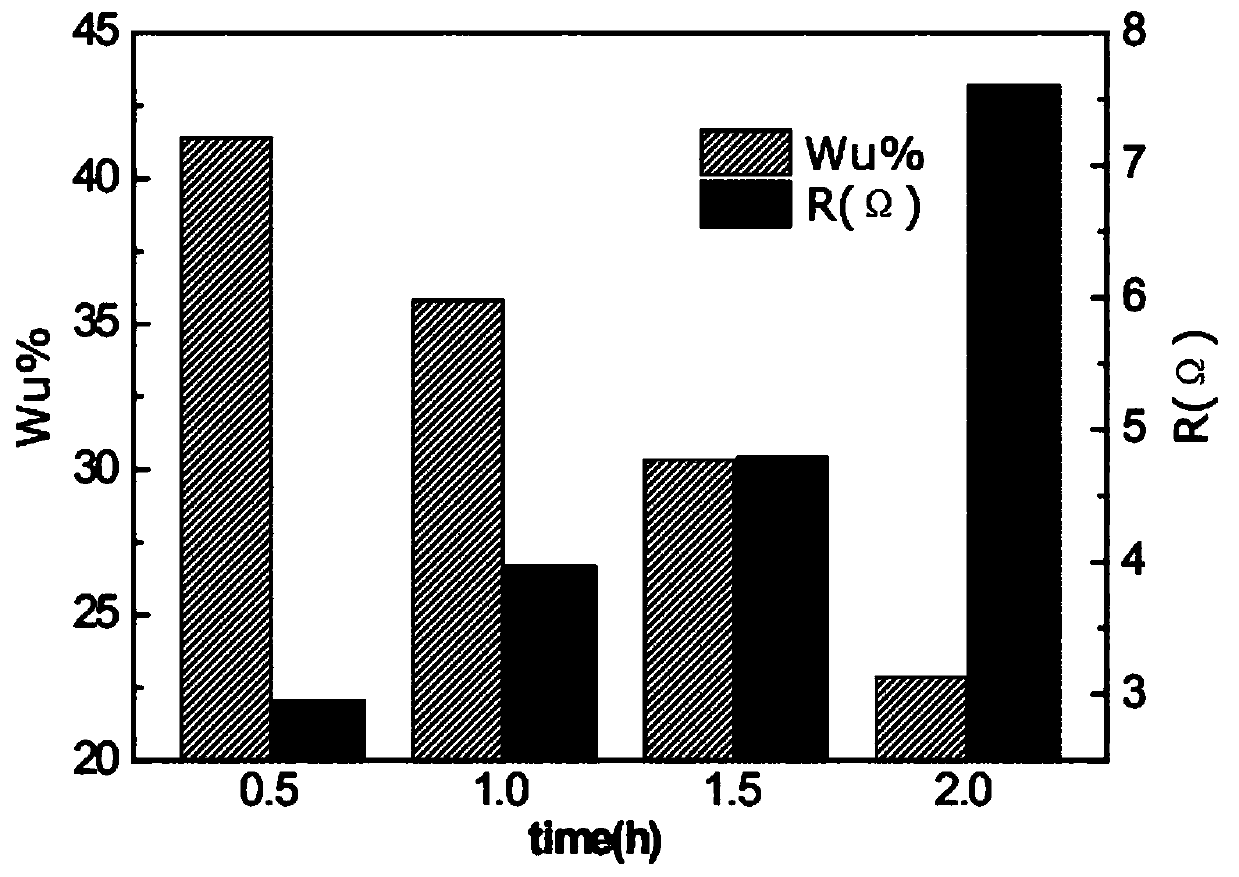

[0039]The prepared QPVA was dissolved in deionized water at 60° C. to prepare a 10% QPVA transparent solution, and after cooling down to room temperature, defoaming was performed. Pour the defoamed solution onto a clean plastic plate, scrape the film with a scraper with a thickness of 100 μm, place it on a flat heater, set the temperature at 60°C, and heat it for 6 hours, then place it in a vacuum oven, set Set the temperature at 190°C, vacuumize, and keep warm for 0.5h. After ...

Embodiment 2

[0042] The EPTAC addition in the above-mentioned example 1 is changed into 3g, and other steps are unchanged.

Embodiment 3

[0044] The EPTAC addition in the above-mentioned example 1 is changed into 6g, and other steps are unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com