Slack coal pressure gasification wastewater resourceful treatment method and treatment system as well as application

A technology of pressurized gasification and treatment of crushed coal, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. To avoid problems such as long process, to achieve the effects of inhibiting sludge bulking, shortening sludge settling time, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is used to illustrate the waste water resource treatment method and treatment system of the crushed coal pressurized gasification of the present invention.

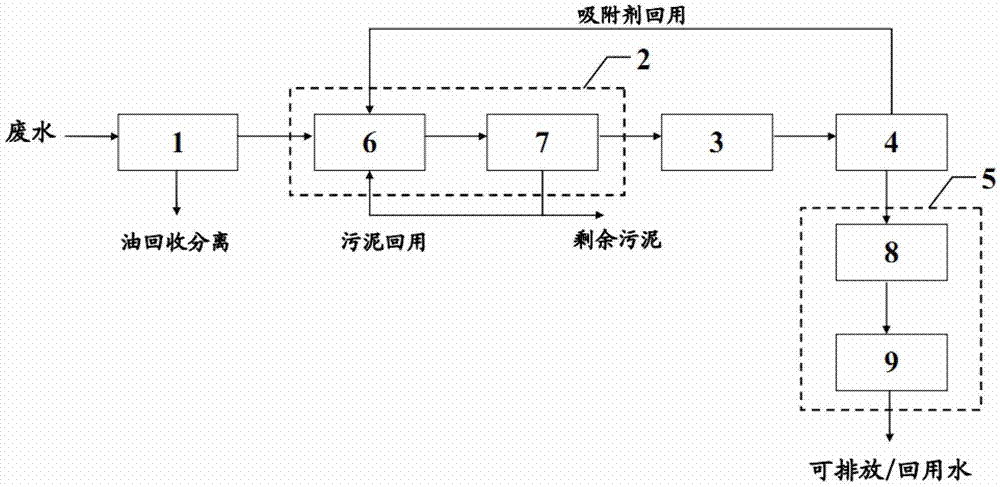

[0041] Such as figure 1 The shown crushed coal pressurized gasification waste water resource treatment system includes sequentially connected oil-water separation unit, activated sludge unit, adsorption separation unit, coagulation clarification unit and biological filtration unit. In actual construction, existing equipment and technologies with the above functions can be selected. For example, the oil-water separation unit can include inclined tube grease traps and vortex-concave air flotation systems, and the activated sludge unit can include biological sedimentation tanks. (such as advection sedimentation tank, vertical flow sedimentation tank, radial flow sedimentation tank, inclined plate sedimentation tank and inclined tube sedimentation tank, etc.), the coagulation clarification unit can incl...

Embodiment 2

[0081] This embodiment is used to illustrate the waste water resource treatment method and treatment system of the crushed coal pressurized gasification of the present invention.

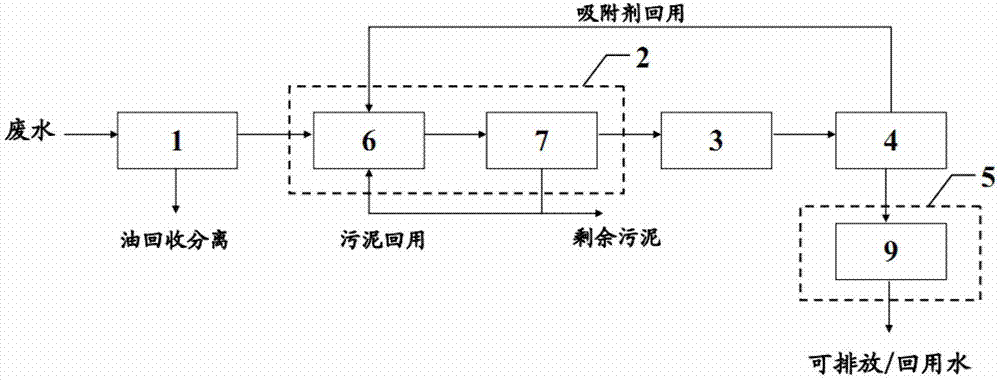

[0082] Such as figure 2 The shown crushed coal pressurized gasification waste water resource treatment system includes sequentially connected oil-water separation unit, activated sludge unit, adsorption separation unit, coagulation clarification unit and biological filtration unit. In actual construction, existing equipment and technologies with the above functions can be selected. For example, the oil-water separation unit can include inclined tube grease traps and vortex-concave air flotation systems, and the activated sludge unit can include biological sedimentation tanks. (such as advection sedimentation tank, vertical flow sedimentation tank, radial flow sedimentation tank, inclined plate sedimentation tank and inclined tube sedimentation tank, etc.), the coagulation clarification unit can inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com