Solvent-resistant polydimethylsiloxane polymer having oil repellency, and production method thereof

A technology of dimethyl siloxane and polymer, applied in the direction of coating, etc., can solve problems such as difficult molding and duplication of basic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] Example 1. Preparation of crosslinked polydimethylsiloxane polymers from bis-triethoxypolydimethylsiloxane oligomers

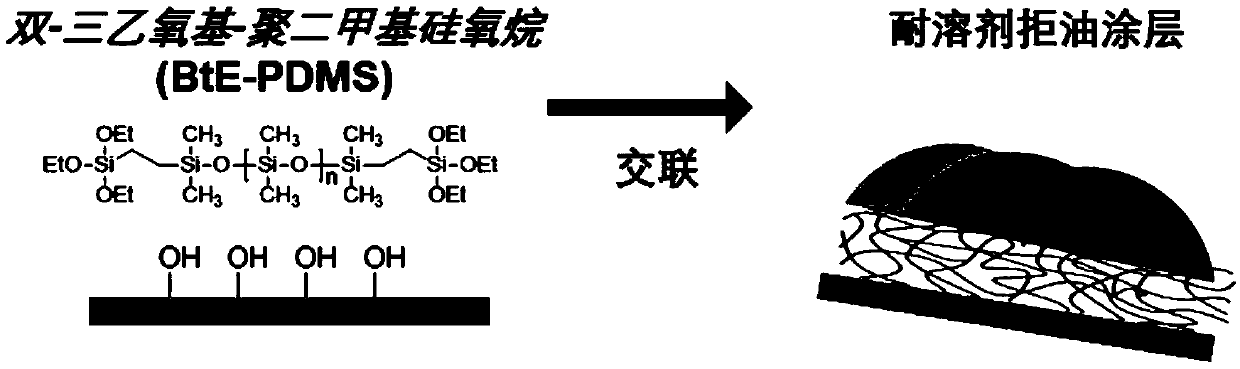

[0108] Such as figure 1 As shown, polydimethylsiloxane with high crosslink density was prepared by polycondensation of bis-triethoxypolydimethylsiloxane oligomer (100% by weight BtE-PDMS oligomer) following the aforementioned procedure. oxane. figure 1 showed the preparation of oil-repellent polydimethylsiloxane coatings by polycondensation of BtE-PDMS oligomers.

Embodiment 2

[0109] Example 2. Adjustment of crosslink density and its effect on mechanical strength, swelling rate and surface oil repellency of polymer

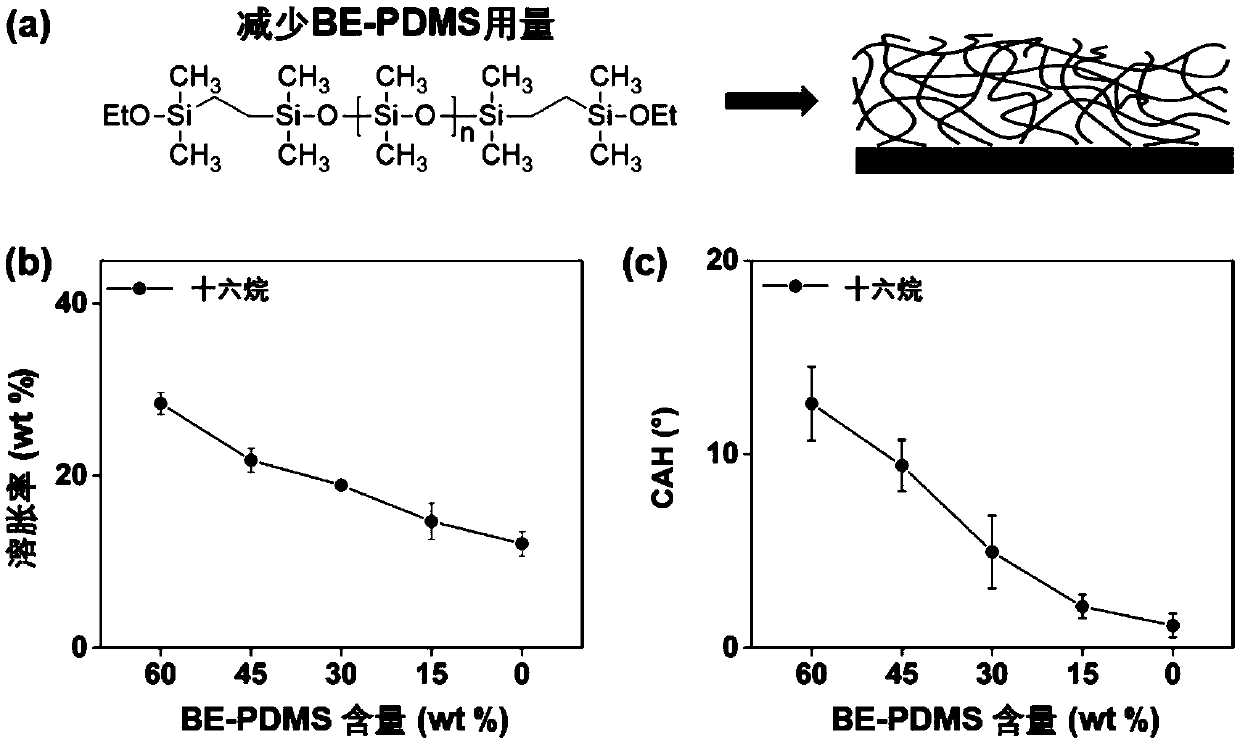

[0110] The crosslink density of polydimethylsiloxane polymers from BtE-PDMS oligomers can be adjusted by selecting (1) (SiMe 2 -O) repeating units (to generate PDMS backbones of different molecular weights), (2) addition of BtE-PDMS oligomers to PDMS oligomers with less reactive moieties for modulation.

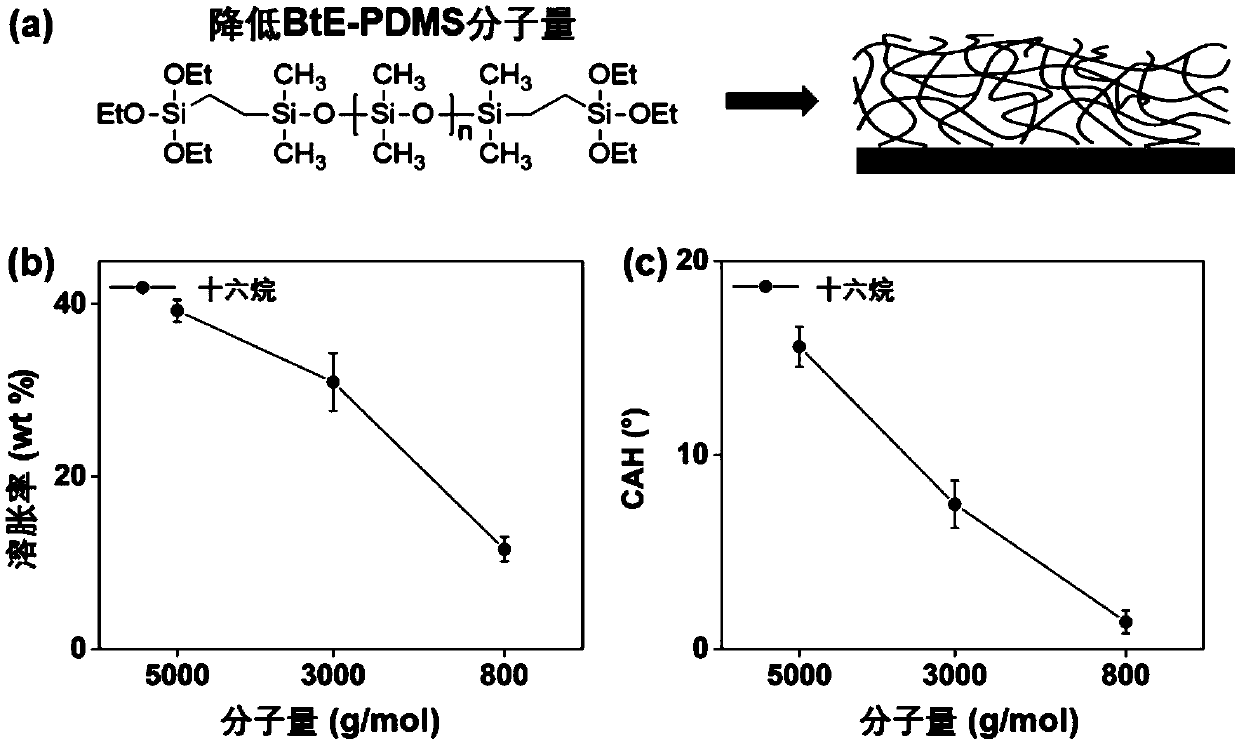

[0111] (1) if figure 2 As shown in (a), cross-linked polydimethylsiloxane polymers were fabricated using BtE-PDMS oligomers with PDMS backbones with molecular weights of 800, 3000, and 5000 following the aforementioned procedure.

[0112] As a proof of concept, the figure 2 The effect of the molecular weight of the PDMS backbone on the mechanical strength, swelling ratio and surface oil repellency of polydimethylsiloxane polymers made from BtE-PDMS is shown in . BtE-PDMS oligomers with PDMS backbones with molecular weights of 800,...

Embodiment 3

[0116] Example 3. Solvent Resistance of Crosslinked Dimethicone Polymers

[0117] The solvent resistance of cross-linked polydimethylsiloxane polymers can be visualized by dropping droplets of dyed solvent onto polymer films and then imaging the droplet contours after a period of time.

[0118] The crosslinked polydimethylsiloxane polymer prepared in Example 2 was used. Figure 4 A comparison of the toluene resistance of polymers with different degrees of crosslinking is shown. Confocal micrograph showing a longitudinal scan of a stained drop of toluene on a polymer surface. The upper left picture shows a cross-linked polydimethylsiloxane polymer made of pure BtE-PDMS (0 wt% BE-PDMS), the fluorescently dyed toluene droplets are completely outside the polymer and cannot enter the polymer bulk phase, Exhibits good solvent resistance properties; top right, cross-linked polydimethylsiloxane polymer fabricated from BtE-PDMS and BE-PDMS oligomers with 60 wt% BE-PDMS, fluorescently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com