Patents

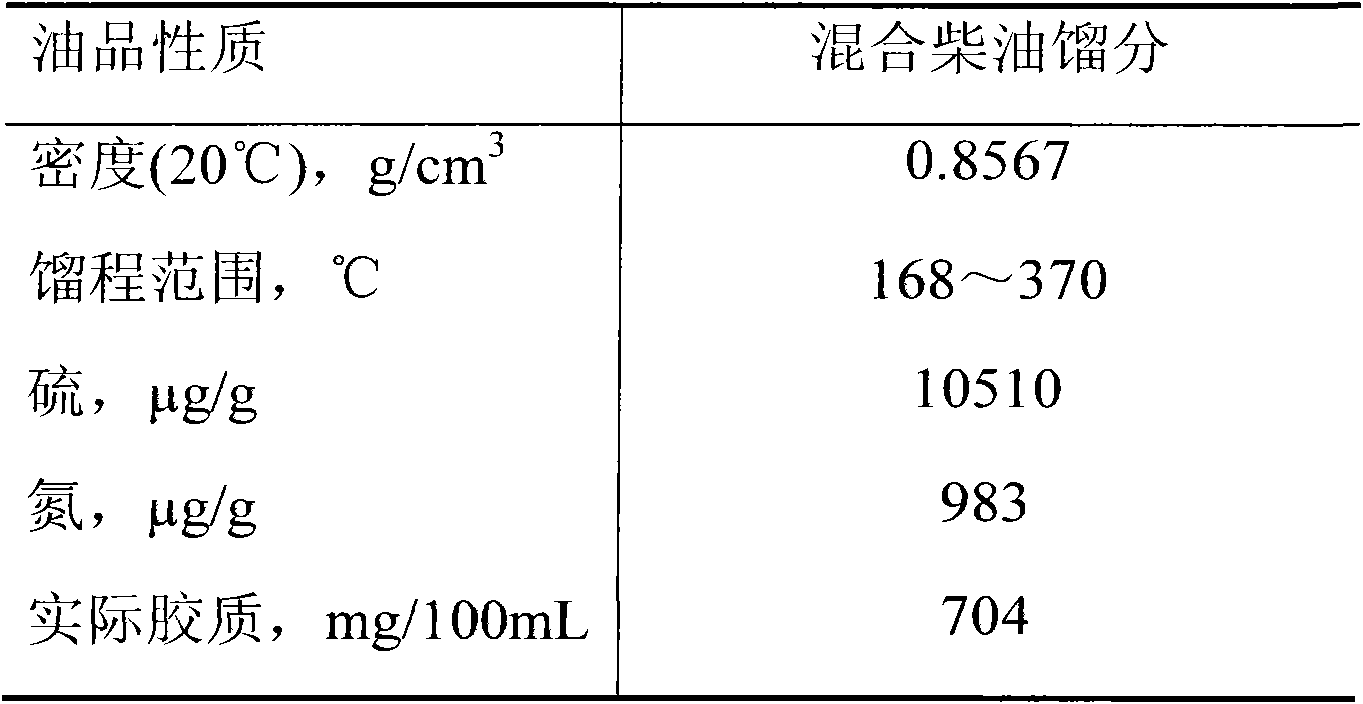

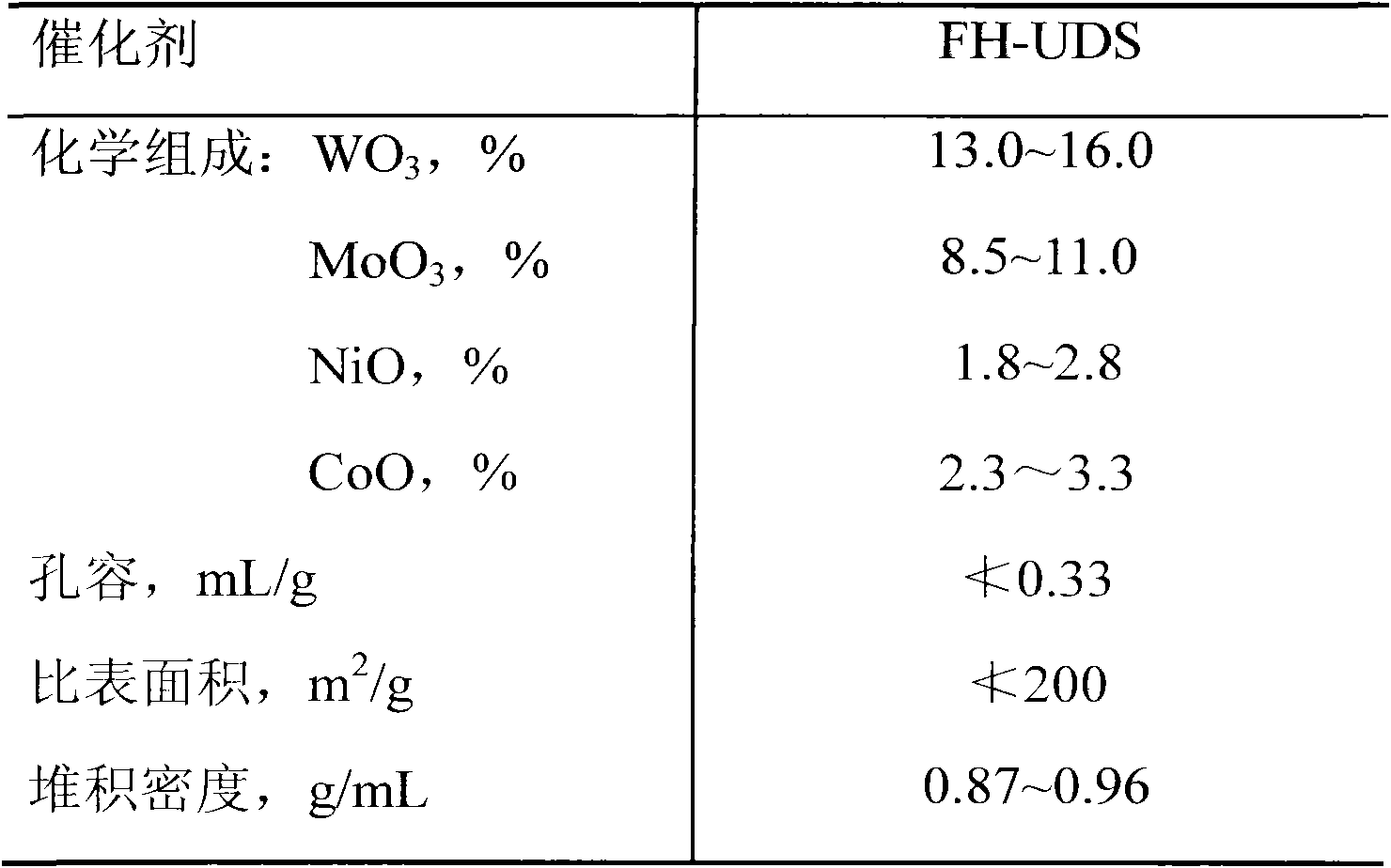

Literature

57results about How to "High Hydrodesulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of hydrogenation catalyst

InactiveCN101298047AEvenly dispersedSmall sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHigh activationReaction temperature

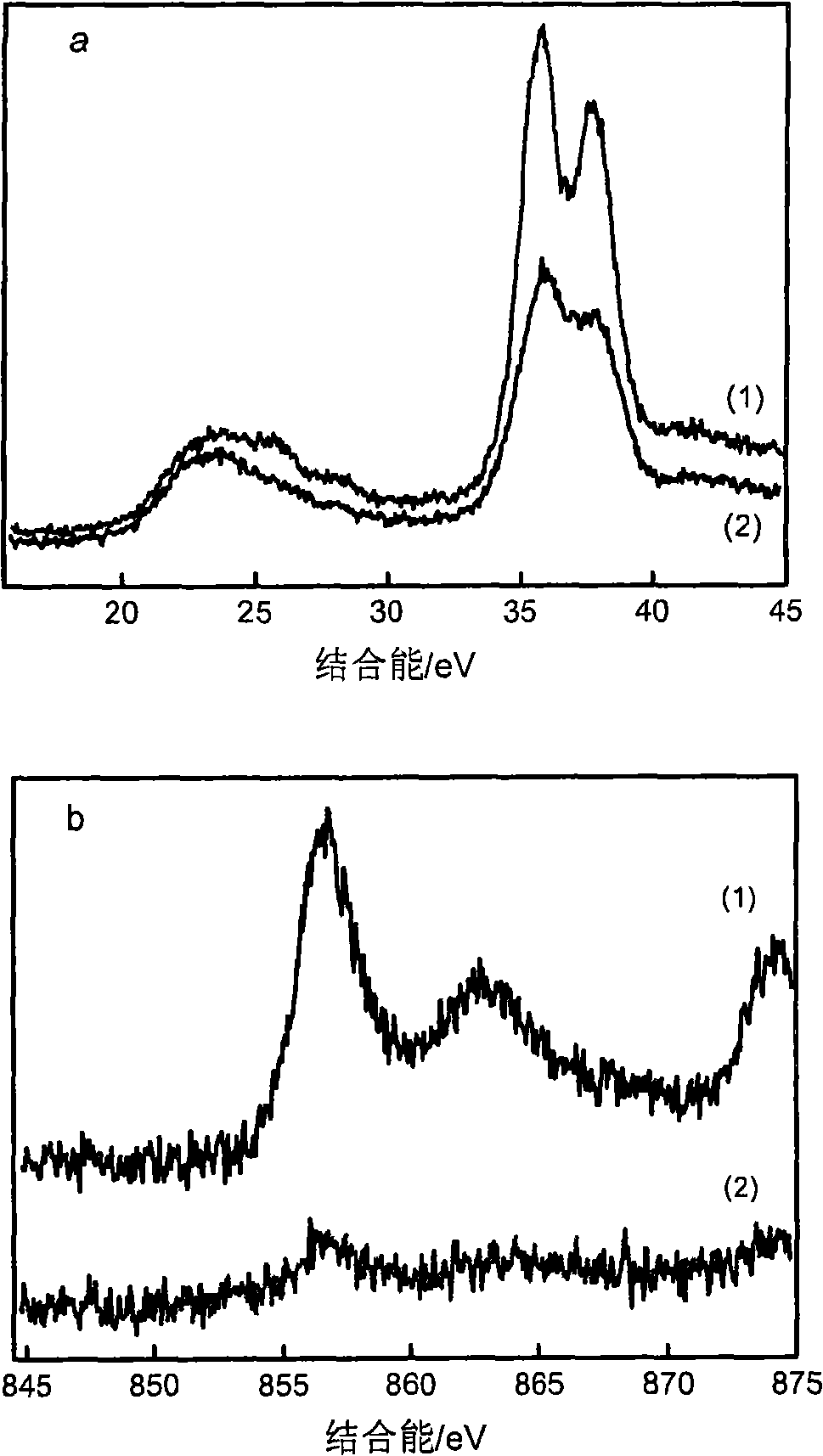

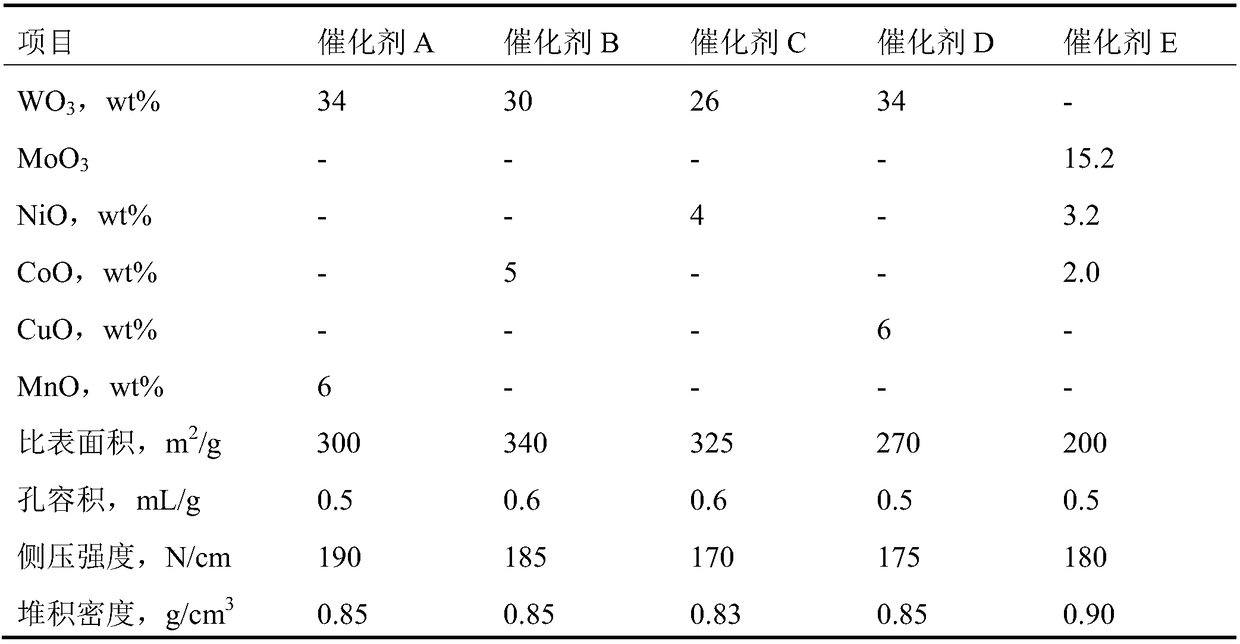

The invention provides a method for preparing a hydrogenation catalyst with high activation. A disposition method is adopted to carry out step-by-step loading to the active components of the metals of VIB and VIII families; the VIB metal comprises tungsten or molybdenum, while the VIII metal comprises nickel or cobalt; a carrier is alumina. The loading of VIB metal takes a corresponding soluble salt as raw material, an acid solution as a precipitator and a cationic surface active agent as a dispersant. In a hydrothermal condition, the corresponding soluble salt, the acid solution and the cationic surface active agent produce metallic oxide particles by a liquid deposition reaction; the loading of VIII metal also takes a corresponding soluble salt as raw material and carbamide as a precipitator; the adding of the precipitator and the generation of precipitation are separated by controlling reaction temperature in sections and even precipitation is realized to disperse the particles of the active components on the carrier evenly. The hydrogenation catalyst prepared shows good effects in the respects of desulfurization and denitrification activation and can greatly reduce the usage of the active components.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

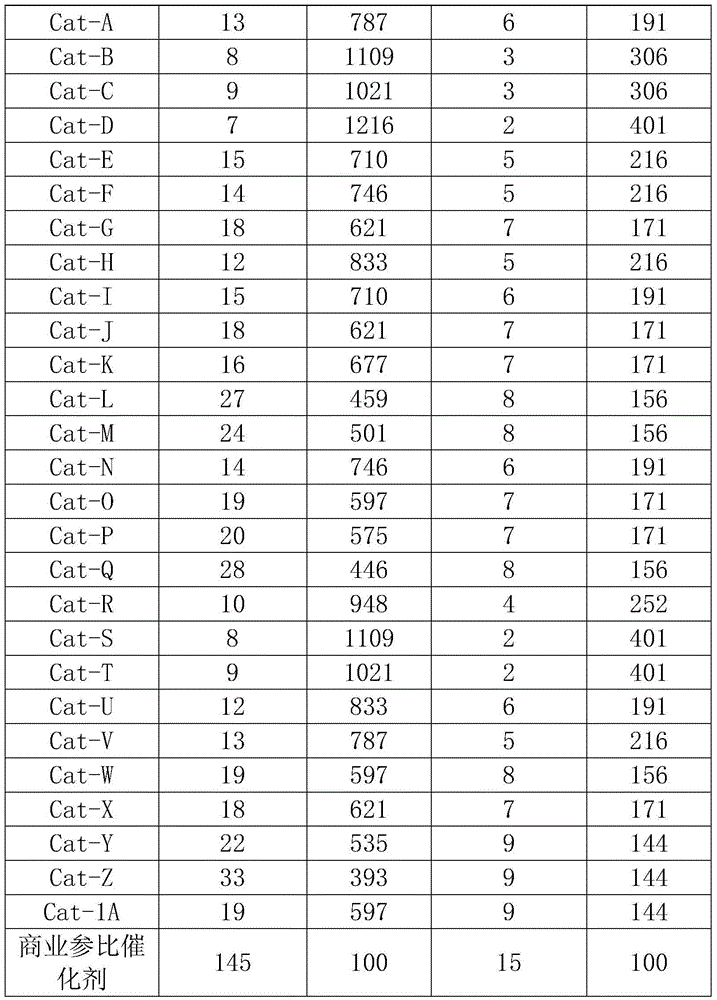

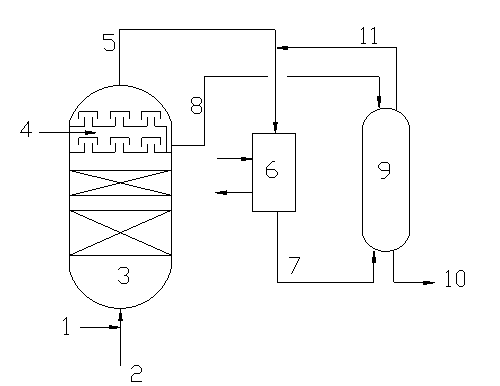

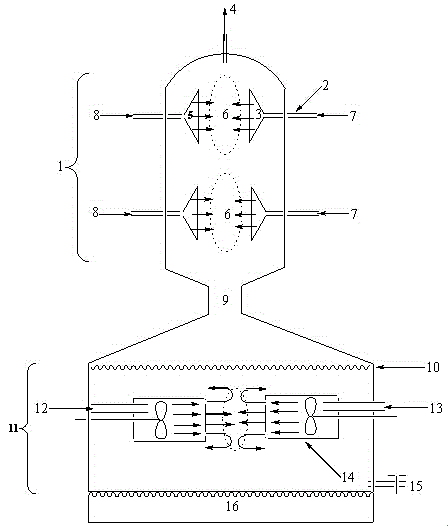

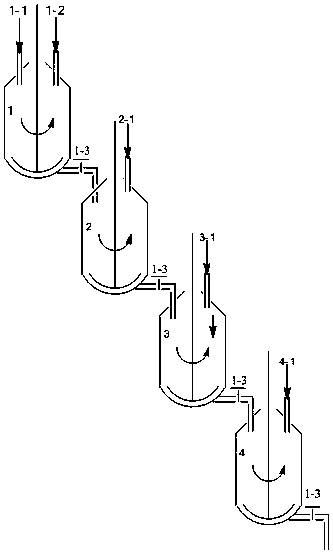

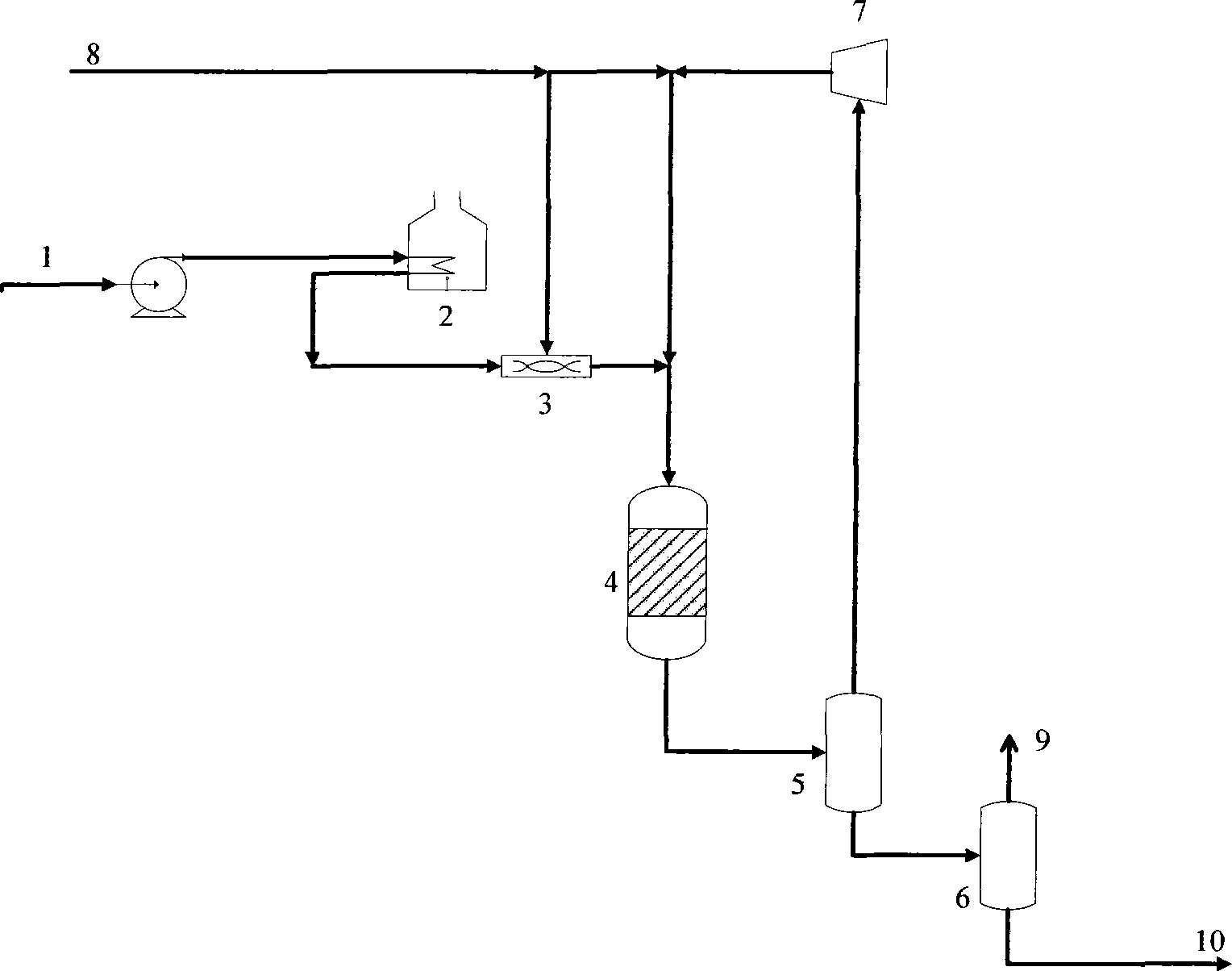

Liquid phase circular hydrogenation treatment method capable of improving mixed amount of hydrogen

ActiveCN102311790AImprove efficiencyEasy to operateTreatment with hydrotreatment processesHydrocarbon oils refiningGas phaseHydrodesulfurization

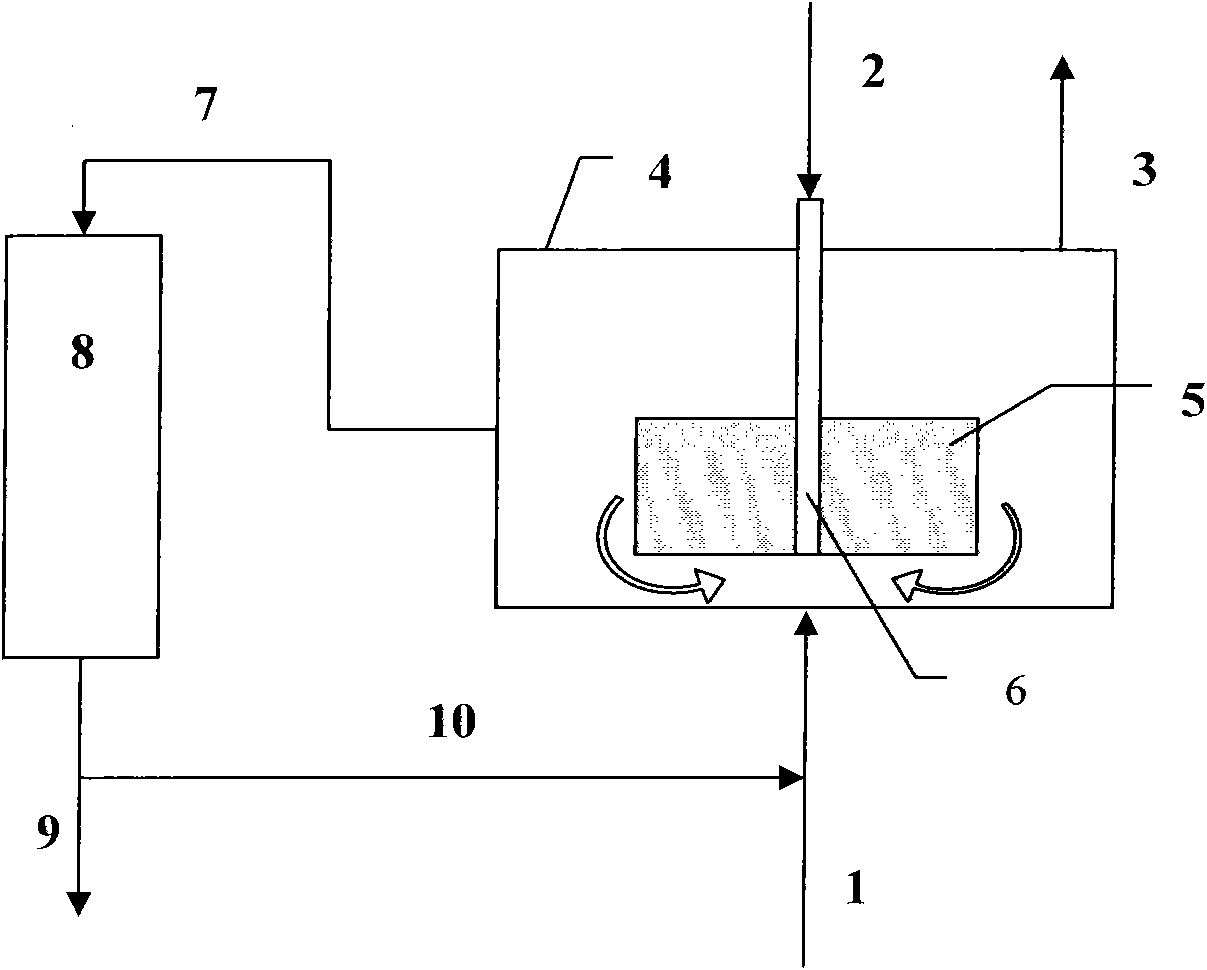

The invention discloses a liquid phase circular hydrogenation treatment method capable of improving mixed amount of hydrogen. The process flow adopted by the method comprises that: a liquid-phase material ( including fresh raw material oil, after-reaction circulating oil and circulating oil in a supergravity hydrogen mixing equipment) and hydrogen are filled into the supergravity hydrogen mixing equipment at the same time; and the hydrogen is torn and cut into lots of micro air bubbles through the high-speed rotation of a gas-liquid mixing impeller, a gas-liquid mass transfer efficiency is increased greatly, hydrogen is dissolved in the liquid-phase material in a saturated state, and the lots of micro air bubbles are dispersed in the liquid-phase material in an emulsified state so as to be brought into a reactor to undergo a hydrogenation reaction. In the method disclosed by the invention, the adoption of the supergravity hydrogen mixing equipment greatly promotes the dissolution of hydrogen and more effectively removes gas-phase impurities such as hydrogen sulfide and ammonia, so as to promote reactions such as hydrodesulfurization, denitrification, aromatic saturation and cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment method of deep vacuum distillation wax oil

ActiveCN101987967AAdaptablePromote depolymerizationRefining to eliminate hetero atomsWaxProtective Agents

The invention relates to a hydrotreatment method of deep vacuum distillation wax oil. The mixture of raw oil and hydrogen passes through two hydrogenation reaction zones in sequence, wherein a hydrogenation protective agent and a hydrogenation demetalization deasphaltenizing agent are filled in the first hydrogenation reaction zone, and a hydrogenation desulfurizing agent and a hydrogenation denitrification desulfurizing agent are filled in the second hydrogenation reaction zone. Reaction products are cooled and separated to obtain refined heavy fraction oil, and the refined heavy fraction oil is a high quality raw material for catalytic cracking. In the invention, the raw oil has strong adaptability and can be used for processing deep vacuum distillation wax oil with high sulphur content, high nitrogen content, high metal and high asphaltene content and mixed oil thereof, and moreover, the device has long running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroprocessing catalyst for heavy oil and preparing method thereof

InactiveCN1488718AReduce dosageAvoid damageRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The present invention relates to a preparation method of hydrogenation treatment catalyst. Said catalyst is prepared by loading molybdenum, nickel and phosphorus on a phosphorus and silicon contained alumina carrier prepared by adopting a special method, and said carrier prepared by special method is prepared by adding phosphorus adjuvant in the course of precipitation and ageing process and adding nano silicon-containing compound in the course of carrier forming process, for example, adding silicon dioxide. As compared with existent catalyst it has higher activity for hydro-desulfurization and hydro-denitrification of heavy oil, specially heavy fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Prevulcanizing method for hydrogenating catalyst

InactiveCN1268433CImprove retentionSuitable for hydrogenation reactionCatalyst activation/preparationRefining by aromatic hydrocarbon hydrogenationHigh rateAdditive ingredient

This invention opens one prevulcanization method of hydrogenated catalyst, which contains mixing one component of alkene, organic polysulfide and accessory ingredient, immersing hydrogenated catalyst in oxidation state after being heated; then immersing by hydrocarbon oil, after re-evaporation to dryness, hydrogenated catalyst being vulcanized can be produced. The method is simple and convenient and thus this invention can be easily carried out. By this method, the hydrogenated catalyst after prevulcanization can maintain higher rate of remaining sulphur, and possesses higher catalytical activity at the same time; it is especially applicable in backflow reactor, for it can solve the practical problem that the catalyst decreases its activity because of losing sulphur.

Owner:CHINA PETROLEUM & CHEM CORP +1

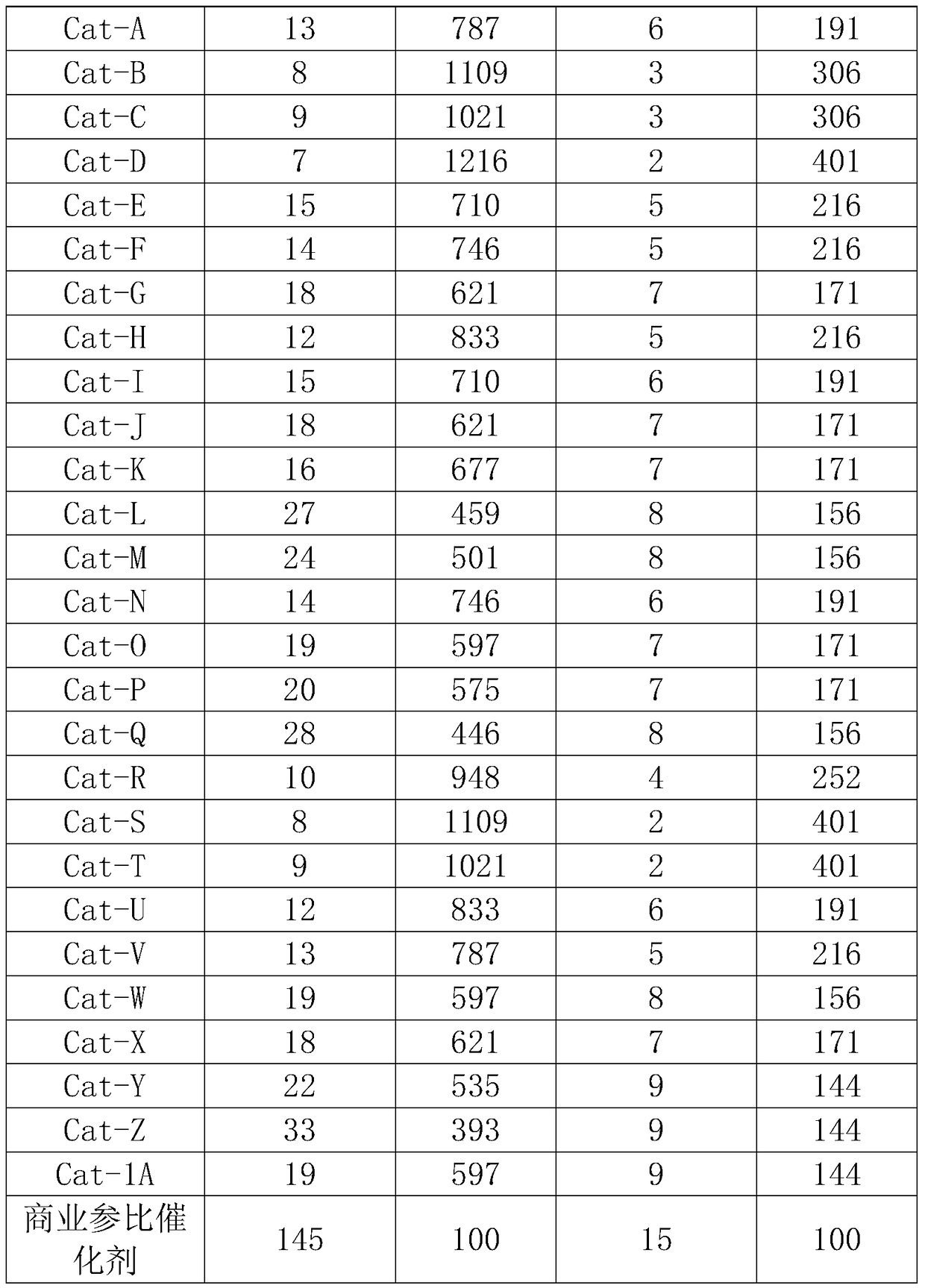

Multi-metal non-supported hydrofining catalyst, preparation method and applications thereof

ActiveCN111215094AEasy to synthesizeEasy to operateHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystHydrogen pressure

The invention relates to a multi-metal non-supported hydrofining catalyst and a preparation method thereof. The hydrofining catalyst is composed of at least one +3 valent metal oxide, at least one VIII group metal oxide, at least one IVB group metal oxide and two VIB group metal oxides, wherein based on metal oxide, the catalyst contains 10-50 wt% of VIII group metal, 1-30 wt% of IVB group metal,1-50 wt% of + 3 valent metal and 5-80 wt% of two VIB group metals. According to the invention, the catalyst can remove sulfur and nitrogen in model diesel oil to less than 10 ppm under the conditionsthat the temperature is 280-440 DEG C, the hydrogen pressure is 1-20 MPa, the volume ratio of hydrogen to diesel oil fraction is 50-1000 V / V, and the volume space velocity of the diesel oil fraction is 0.1-10 h<-1>.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multi-metal body catalyst for ultra-deep desulphurization and denitrogenation as well as hydrofining and preparation method thereof

ActiveCN106268850AThe synthesis process is simpleEasy to operateMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsFuel oilNitrogen

The invention relates to a multi-metal body catalyst for ultra-deep desulphurization and denitrogenation as well as hydrofining and a preparation method thereof. The multi-metal body catalyst is a mixed metal oxide which comprises VIII group metal, IVB group metal and two VIB metals; wherein the catalyst is calculated according to oxides and the catalyst is used as a reference, and the catalyst comprises 1-60 wt.% of VIII group metal, 1-50 wt.% of IVB group metal, and 5-60 wt.% of VIB metal. The invention also discloses a preparation method and an application of the catalyst. The catalyst is applied to a hydrofining reaction of fuel oil containing sulfur and nitrogen; the reaction condition is as follows: the temperature is 280-400 DEG C, the hydrogen pressure is 1-20 MPa, the volume ratio between hydrogen and the fuel oil containing sulfur and nitrogen is 50-1000, and the volume space velocity of the material is 0.1-10h<-1>; the catalyst can be used for respectively eliminating sulfur and nitrogen in diesel oil fractions from 500ppm to 10ppm in the reaction, and ultra-deep hydrodesulfurization and ultra-deep hydrodenitrogenation of diesel oil is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

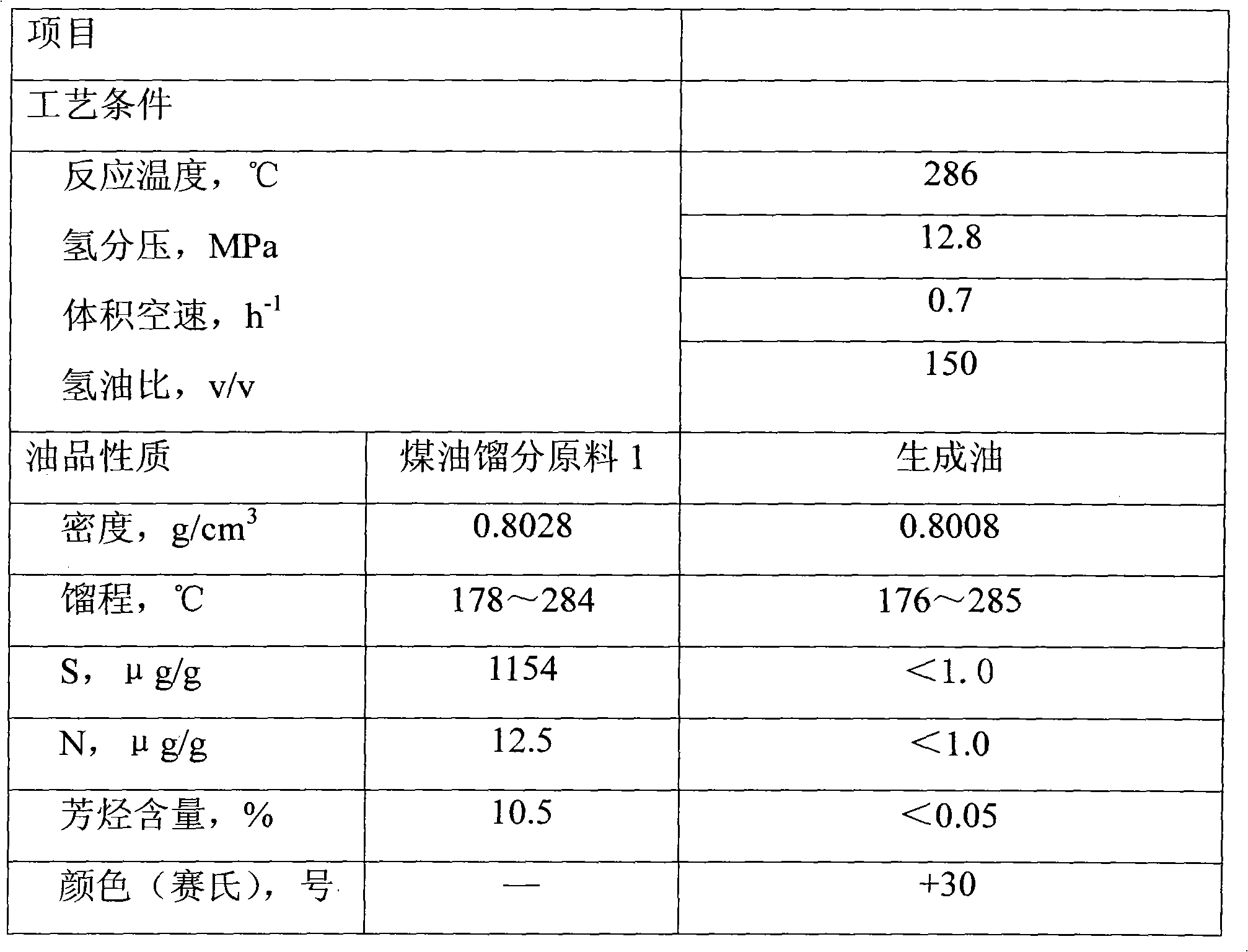

Method for producing low-aromatics solvent oil by hydrogenation

The invention relates to a method for producing low-aromatics solvent oil by hydrogenation. The method comprises the following steps of: passing raw material oil through a heating furnace, then fully mixing the raw material oil and hydrogen gas in an oil-gas mixer, and contacting with a hydrogenation catalyst in a lower hydrogen-oil volume ratio and under milder process conditions to undergo the common hydrogenated purification reaction. Compared with the conventional hydrogenated purification process, the method can achieve the same effect as the conventional purification process under milder process conditions. By the method, the low-sulfur and low-aromatics solvent oil products can be produced. In addition, the method also has the advantages of simple process flow, stable operation, high product properties and low energy consumption, and the new establishment of a hydrogenation device and the modification of the original device are both ok.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment method

ActiveCN102876364AExtended service lifeAchieve refinementTreatment with hydrotreatment processesHydrogenSulfur

The invention discloses a heavy distillate oil hydrotreatment method, which comprises the following steps of: mixing an inferior heavy distillate oil raw material and hydrogen, passing through an upflow reactor, and carrying out demetallization and partial desulphurization and denitrification; allowing the obtained reaction effluent to enter a gas-liquid separation apparatus arranged on the upper portion of the upflow reactor; purifying the obtained gas, allowing the gas and the obtained liquid to pass through a hydrotreatment reactor in the way of gas-liquid countercurrent so as to carry out deep desulphurization and denitrification reactions. By series connection of specially-structured upflow reactor and countercurrent reactor, refining and conversion of high-sulfur, high-nitrogen and high-metal raw materials are realized so as to obviously raise the comprehensive impurity removal effect. Therefore, it is ensured that the activity of the hydrogenation catalyst is fully performed, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified gamma-alumina and hydrogenation catalyst, and preparation method and application of hydrogenation catalyst

ActiveCN107519888AGood dispersionImprove structural stabilityCatalyst carriersCatalyst activation/preparationNitrogenWater soluble

The invention relates to a catalyst carrier and a hydrogenation catalyst, and a preparation method of the hydrogenation catalyst. The method comprises the following steps: (1) making a gamma-alumina carrier contact with a mixture containing urea, a water-soluble salt of a group VIII metal element and water, carrying out heat treatment, drying the solid after heat treatment and then roasting, and thus obtaining a solid after roasting; (2) impregnating the solid obtained in the step (1) in an aqueous solution containing fluorine, drying, and roasting to obtain a modified gamma-alumina carrier; and (3) impregnating the modified gamma-alumina carrier obtained in the step (2) with a solution containing water-soluble salts of a group VIB metal and a group VIII metal. The invention also provides the hydrogenation catalyst prepared by the method and an application of the hydrogenation catalyst in hydrodesulfurization and / or hydrodenitrogenation. Compared with the prior art, the hydrogenation refined catalyst provided by the invention not only has the activity improved obviously, but also has the service life of the catalyst improved obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for reversible hydrogen storing and releasing by organic liquid hydride and its preparation

ActiveCN1583263AHigh activityThe research value of big theoryPhysical/chemical process catalystsCycloalkaneChemistry

A catalyst for the reversable accumulation and release of H2 in liquid-phase organic hydride contains M chosen from Ni, Fe, Co, Mo and W, P, Ti and O. It is prepared through immersing TiO2 in the mixture containing the soluble salt of active elements, drying, calcining, reducing in the mixture of H2 and N2, and passivating by N2.

Owner:NANJING UNIV OF TECH

Method for preparing hydrogenation catalyst

ActiveCN103007949ASimple processSave raw materialsMolecular sieve catalystsCatalyst activation/preparationHydrogenHydrodesulfurization

The invention relates to a method for preparing a hydrogenation catalyst. The preparation method comprises the following steps of: dissolving salts of group VIB metals and group VIII metals in a hydrogen peroxide solution to obtain an impregnation liquid; impregnating the carrier by utilizing the impregnation liquid; and drying and roasting the impregnation product, thus obtaining the hydrogenation catalyst with double metal components. The method for preparing the load type hydrogenation refined catalyst has the advantages that the traditional impregnation method is improved, so that the interaction between active ingredients and the carrier is effectively weakened and the dispersion degree of the components on the carrier is improved. The hydrogen desulfurization and dearomatization activity of the catalyst prepared by the method is higher than that of the catalyst prepared by the traditional impregnation method and having the same active metal content.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydrogenation catalyst composition and its prepn. method

ActiveCN1861259AImprove vulcanization effectHigh reactivityCatalyst activation/preparationRefining to eliminate hetero atomsThioureaSulfur

A composite hydrocatalyst for the hydroprocessing, hydrorefining or hydrocracking of hydrocarbon oil contains thiourea compound, sulfurizing and solvent. It is prepared by introducing the thiourea to the hydrocatalyst before or after or while the sulfurizer is introduced to it. It has high content of sulfur, low released heat in activating and high activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

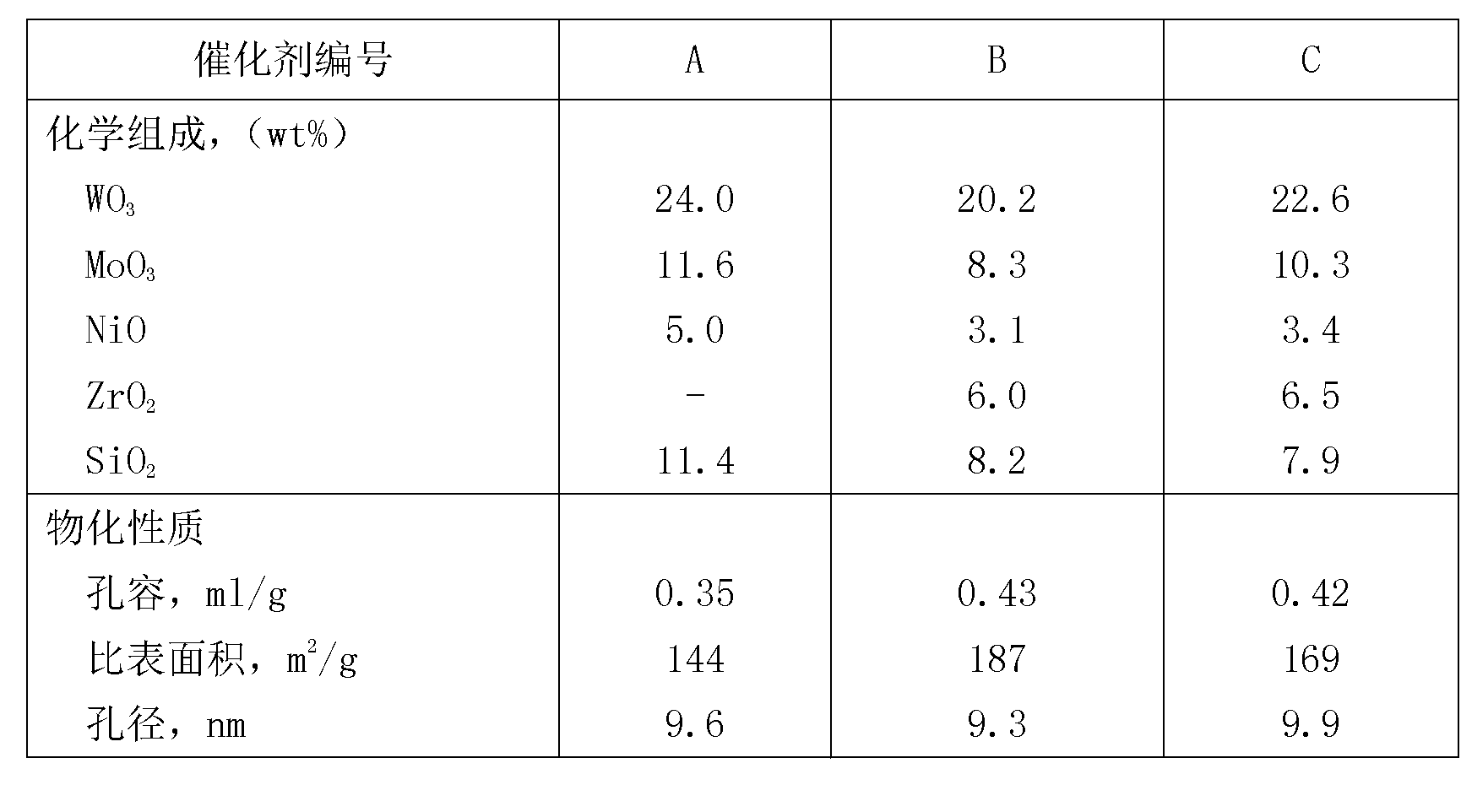

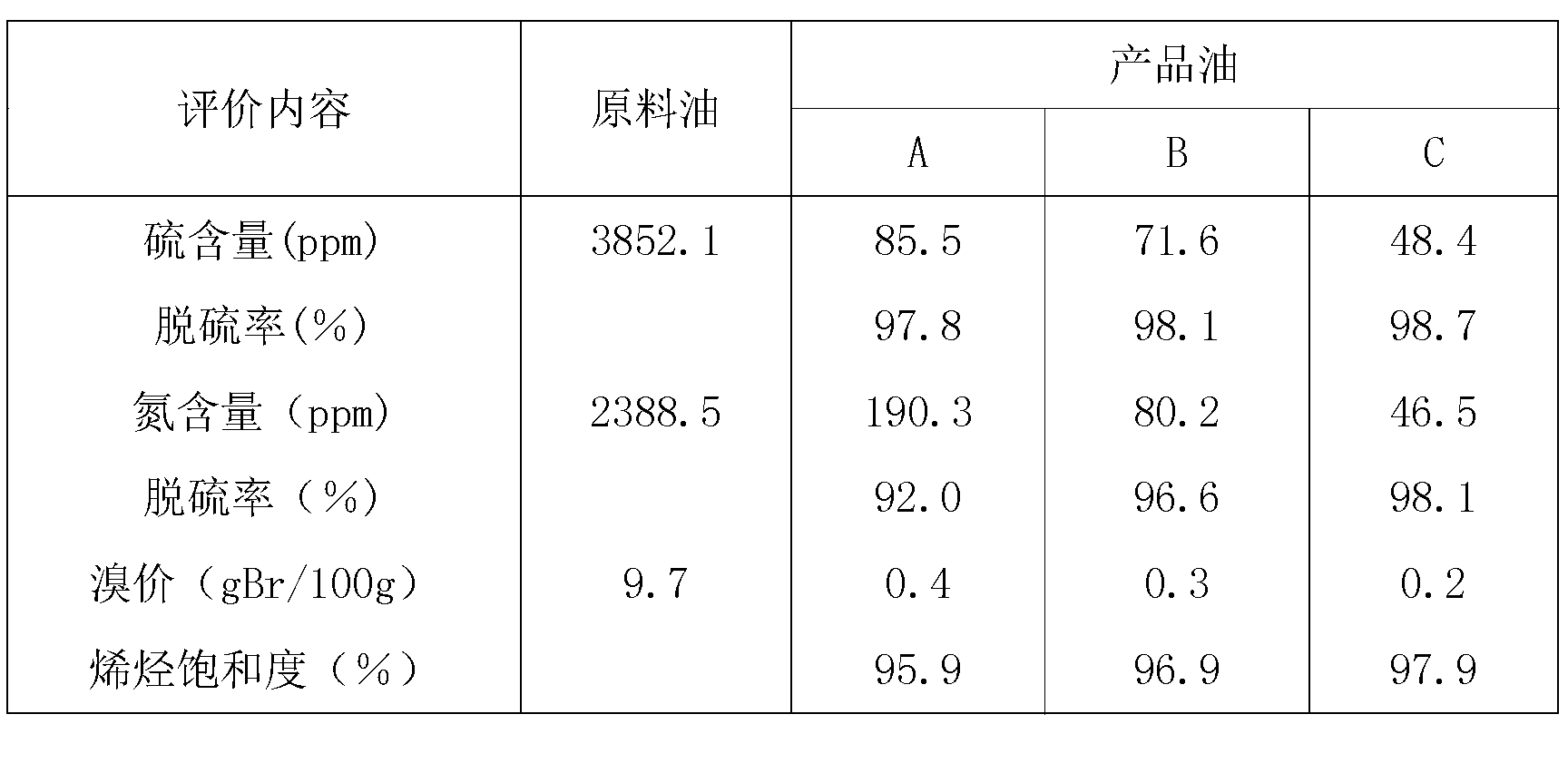

Preparation method of wax oil hydrogenation pretreatment refining agent

InactiveCN103240106AIncrease profitIncrease medium to strong acidityPhysical/chemical process catalystsRefining to eliminate hetero atomsSilica gelCobalt

The invention relates to a preparation method of a wax oil hydrogenation pretreatment refining agent; and the preparation method is characterized by comprising the steps of: adding zirconium hydroxide and silica sol into macroporous aluminum hydroxide dry gel powder; drying and carrying out high-temperature roasting to obtain silicon-zirconium modified aluminum oxide gamma-Al2O3 as carrier; and loading active hydrogenated metal oxide components such as tungsten, molybdenum, cobalt and nickel as well as auxiliary agents containing components such as phosphorus and fluorine by using an impregnation method.

Owner:CHINA NAT OFFSHORE OIL CORP +2

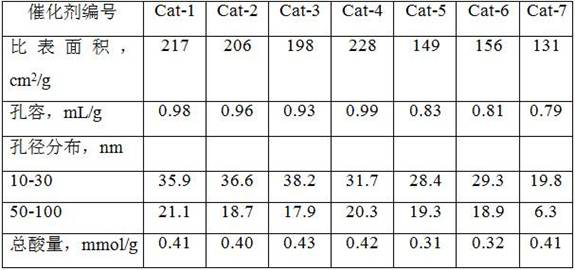

Preparation method of hydrofining catalyst composition

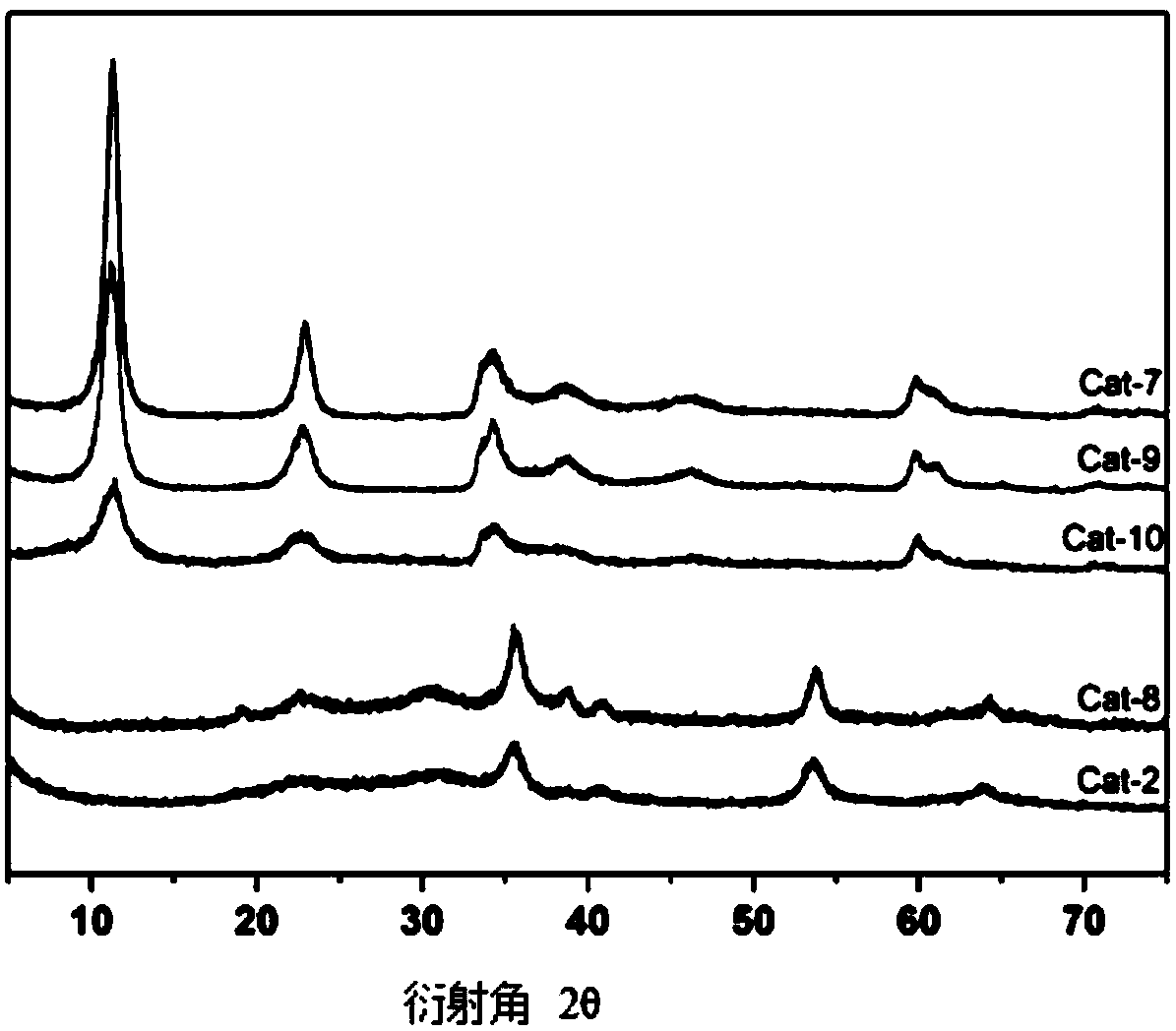

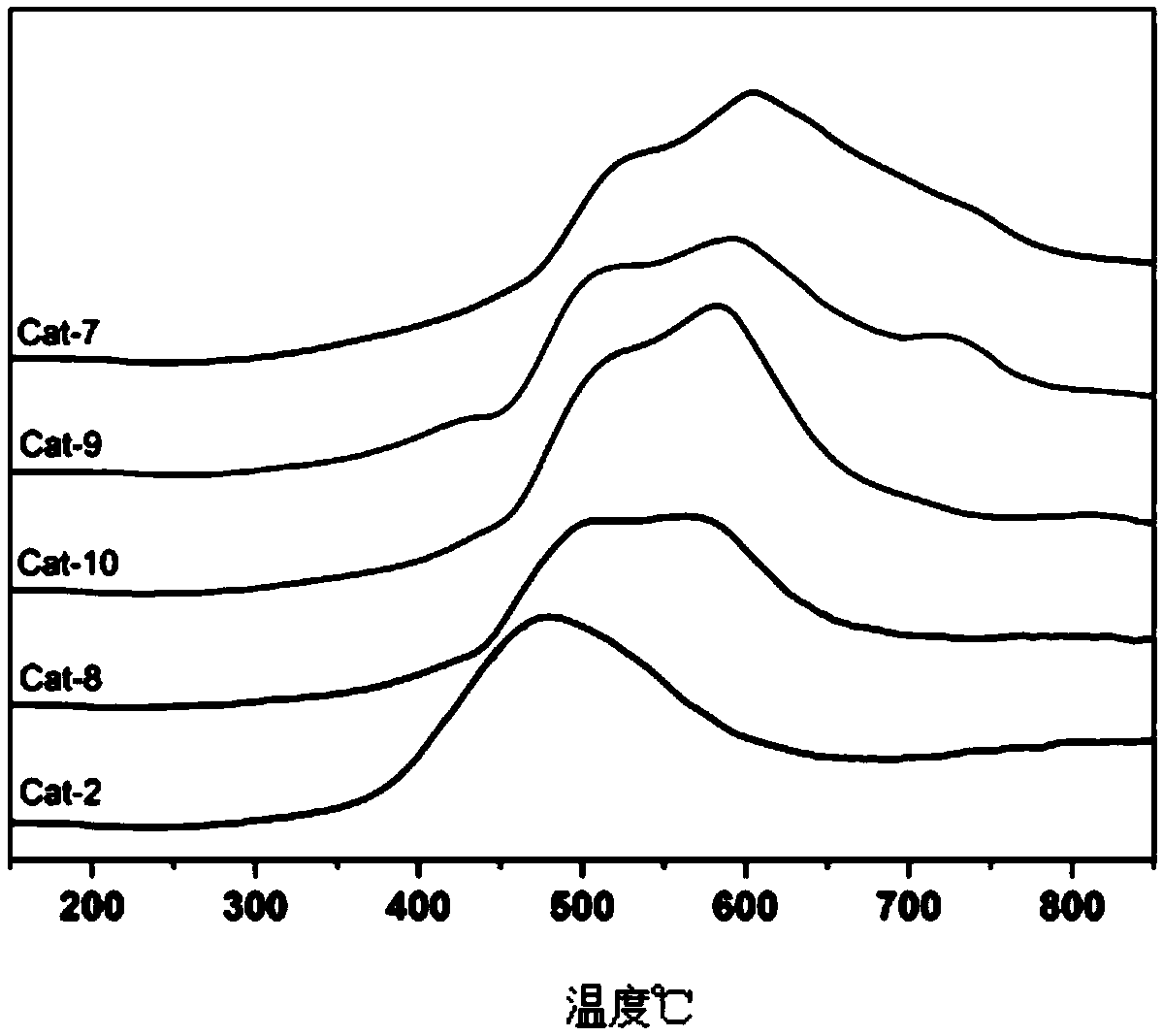

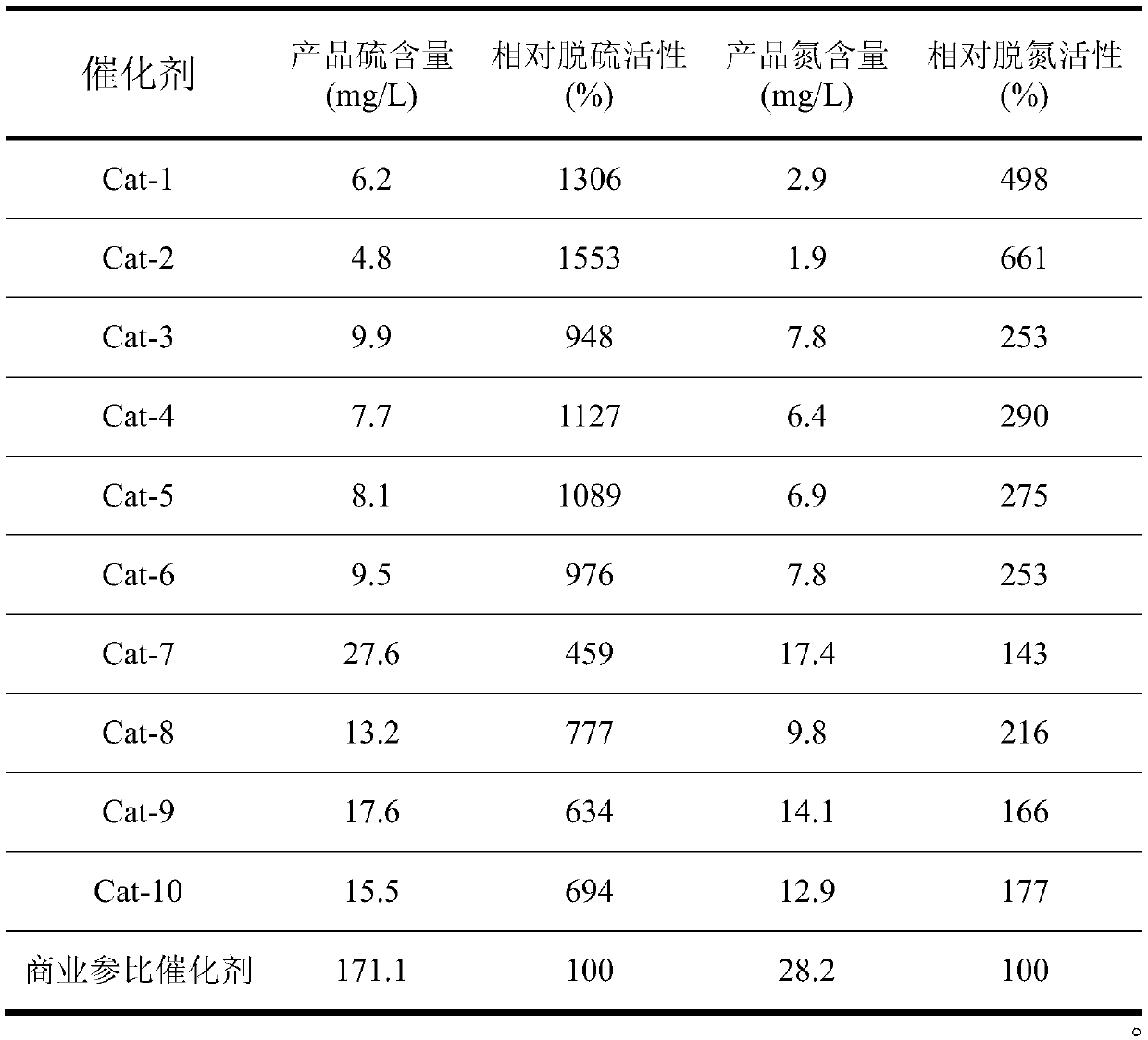

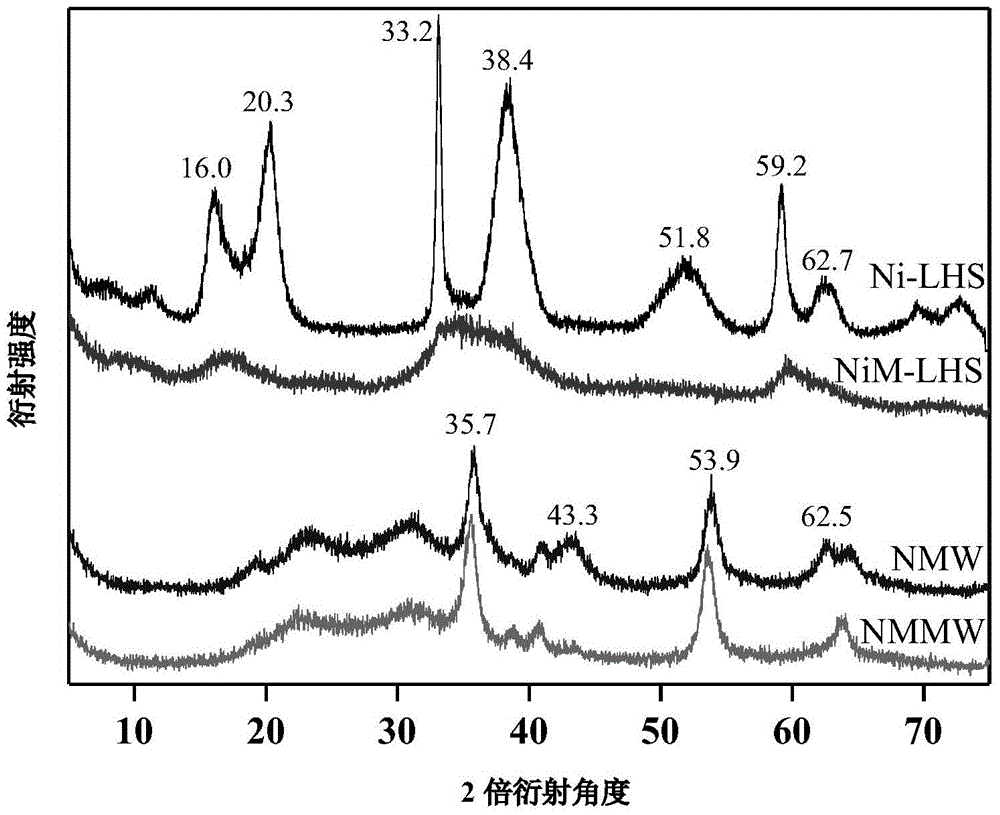

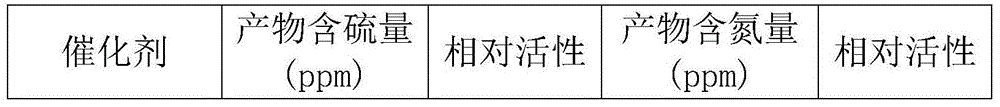

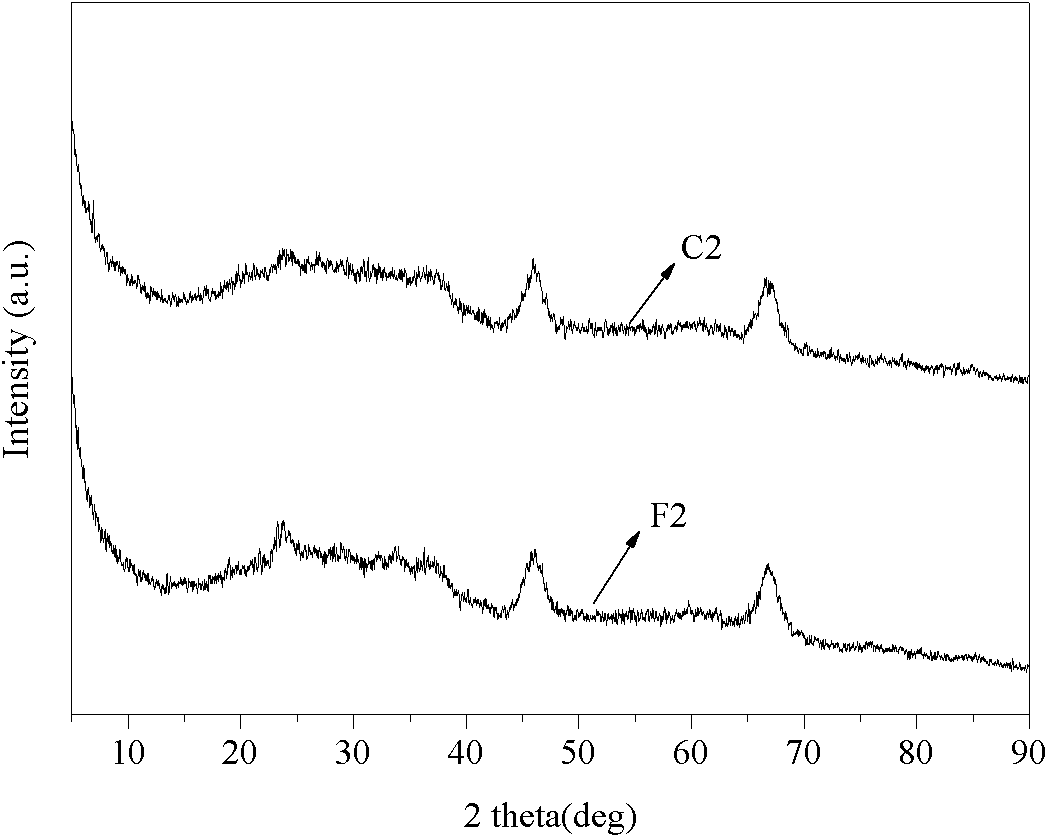

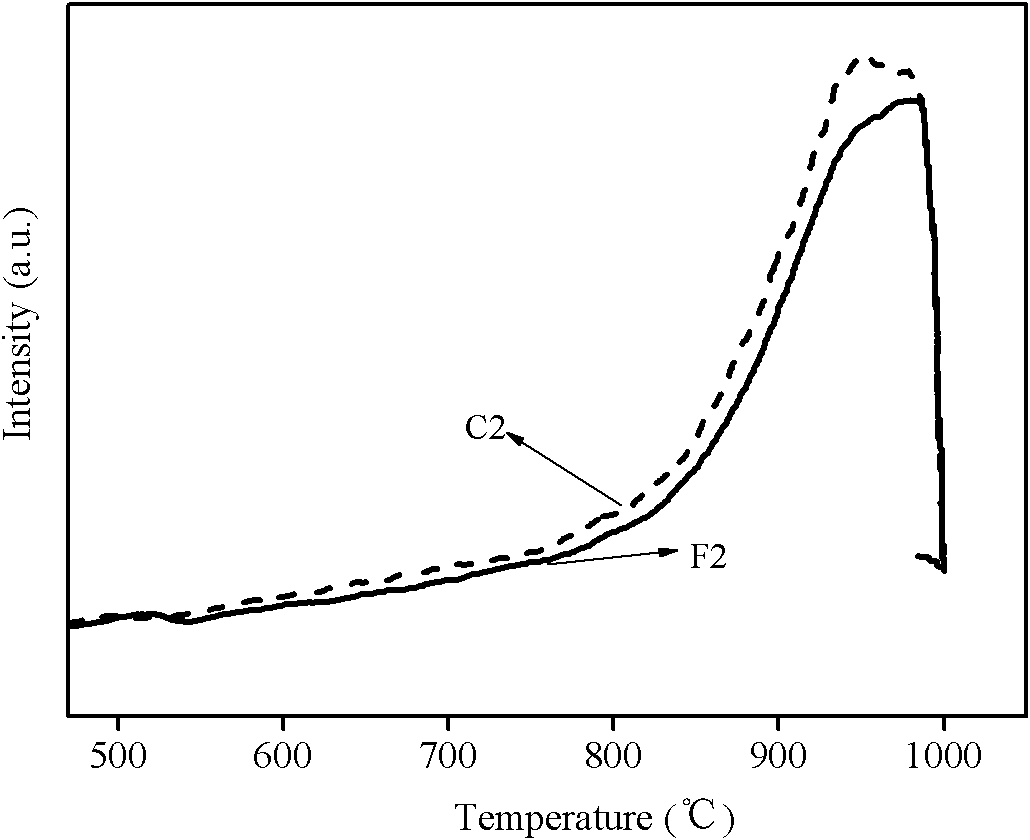

ActiveCN106179377AEvenly dispersedImprove coordinationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsDistillationPrecipitation

The invention discloses a preparation method of a hydrofining catalyst composition. The catalyst composition is a bulk phase hydrofining catalyst composition, and comprises hydrogenation active metal components W, Ni and MO, and alumina. The preparation method of the catalyst composition comprises the following steps: preparing a nickel and aluminum mixed precipitate through an ammonia distillation and precipitation technology in the presence of an organic compound, preparing a tungsten, molybdenum and aluminum mixed precipitate through a parallel flow precipitation technology, mixing the nickel and aluminum mixed precipitate with the tungsten, molybdenum and aluminum mixed precipitate, ageing the obtained mixture, carrying out hydrothermal treatment and adding urea, and molding the finally obtained mixture to prepare the catalyst composition. The catalyst composition prepared through the method is especially suitable for being applied to ultra deep hydrodesulfurization and nitrogen removal reactions of diesel oil fractions, and has high hydrodesulfurization and hydrodenitrogenation reaction performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-activity inferior diesel oil hydrorefining catalyst

ActiveCN102423712ALow viscosityIncrease the diffusion coefficientCatalyst activation/preparationRefining to eliminate hetero atomsSolventSolvothermal reaction

The invention relates to a preparation method of a high-activity inferior diesel oil hydrorefining catalyst. The method comprises steps that: a molding carrier and a salt solution of VIB metals are added into an autoclave; an inorganic acid is adopted as a precipitating agent; a zwitterionic surfactant and a fluorine-containing compound are adopted as a composite dispersant; an alcohol solvent and water are added into the autoclave, and a solvent thermal reaction is carried out for 12-36h under a temperature of 100-200 DEG C; a suspension obtained through the reaction is filtered; a filter cake is washed, dried, and baked, such that a fluorine-containing bimetallic catalyst is obtained; the bimetallic catalyst and a salt solution containing VIII metals are placed in the autoclave; an anionic surfactant is adopted as a dispersant, a certain amount of an alcohol solvent and water are added into the autoclave, and the mixture is subject to solvent thermal reaction for 12-36h under a temperature of 100-200 DEG C; the reaction product is filtered, washed, dried, and baked, such that the inferior diesel oil hydrorefining catalyst is obtained. With the method provided by the invention, the obtained catalyst has relatively high hydrodesulfurization activity and hydrodenitrogenation activity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

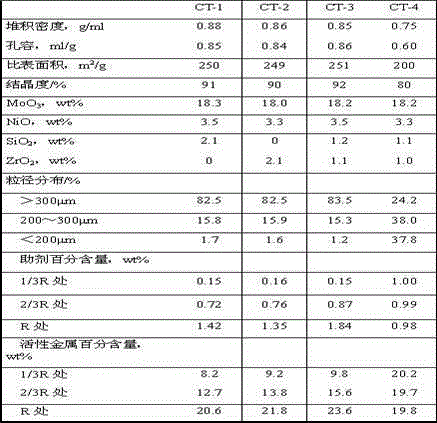

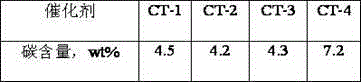

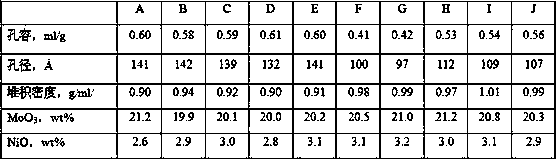

Hydrogenation catalyst composition and preparation method thereof

ActiveCN105618071AAdequate responseQuick buildMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsOxidePrecipitation

The invention discloses a hydrogenation catalyst composition and a preparation method thereof. The hydrogenation catalyst composition comprises an aluminum oxide carrier, an active metal and an auxiliary agent, wherein the active metal is selected from one or more of VIII family and / or VIB family metallic elements, and the auxiliary agent is selected from one or two of silicon or zirconium; the concentration of silicon and / or zirconium in the catalyst, in the form of oxides, are gradually increased from centers to outer surfaces of catalyst particles, wherein the concentration of silicon and / or zirconium at a position of 1 / 3R of particles is 0.1-0.5wt%, the concentration of silicon and / or zirconium at a position of 2 / 3R is 0.5-1.0wt%, the concentration of silicon and / or zirconium at a position of R is 1.0-3.0wt%, and R is the semi-diameter of the catalyst particles by taking the center of the catalyst as an initial point. The catalyst prepared by adopting an impinging stream co-precipitation gel forming mode in the invention is centralized in particle size distribution, and has an ideal pore structure, and the auxiliary agent and the active metal are distributed in the catalyst in a gradient increase mode, so that the deactivation rate of the catalyst can be effectively reduced, and the desulfurization and denitrification capacities of the catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

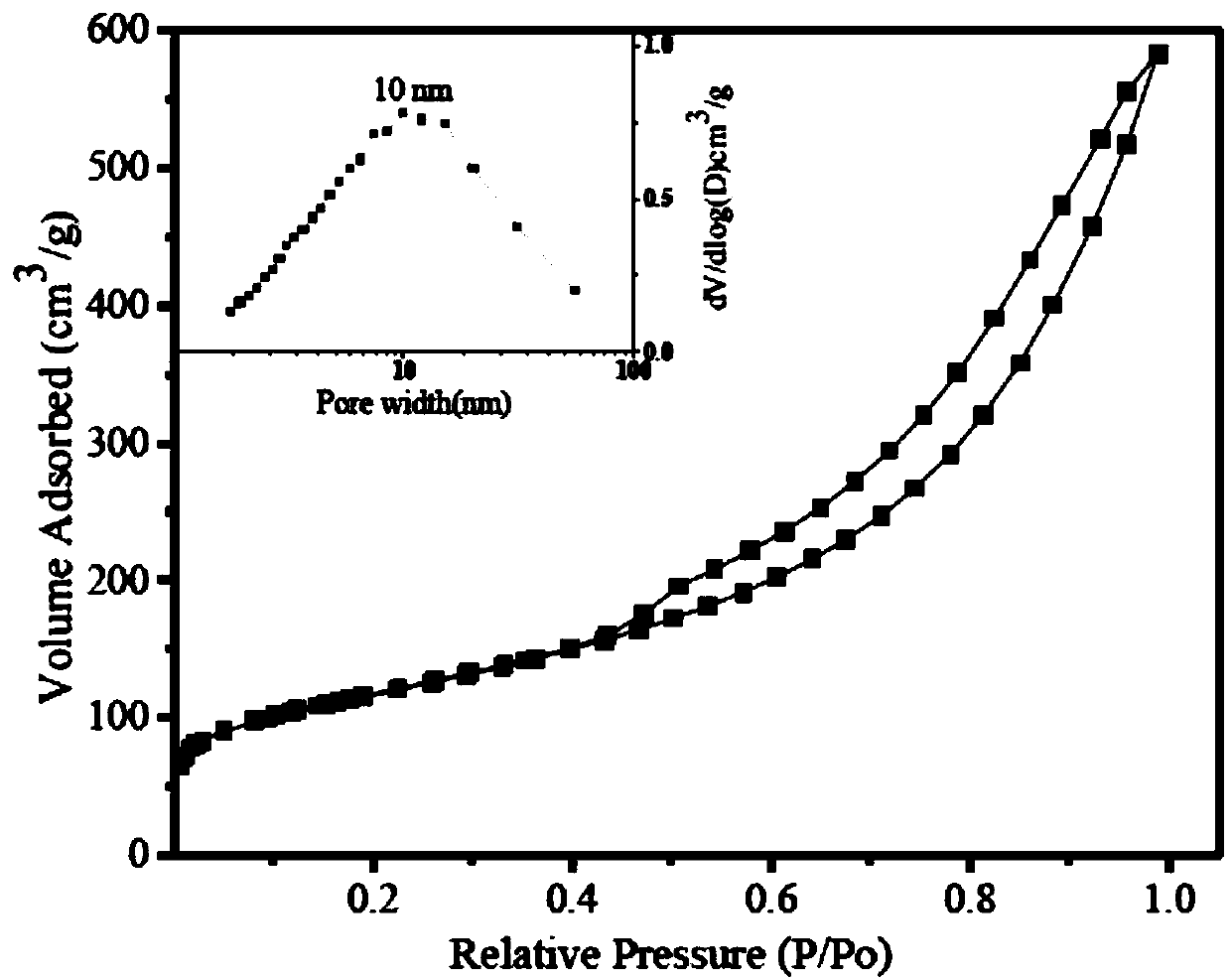

Fully sulfurized hydrofining catalyst and preparation method thereof, and distillate oil hydrofining method

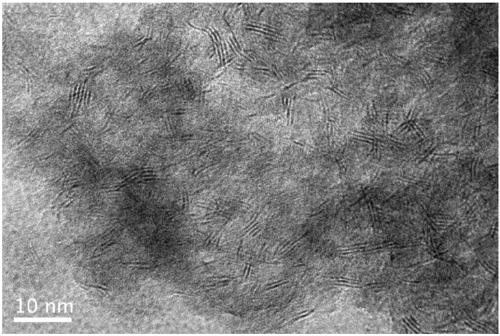

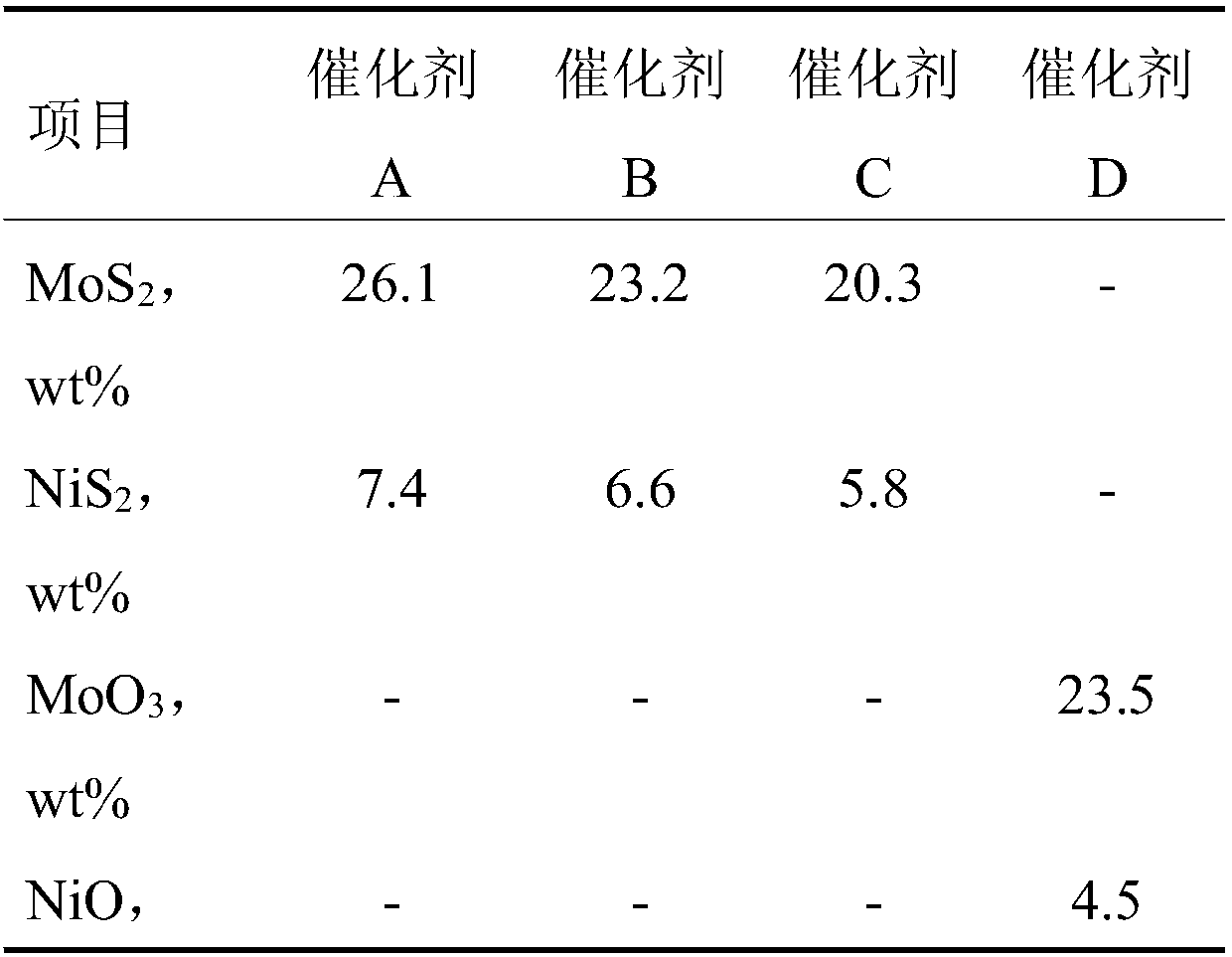

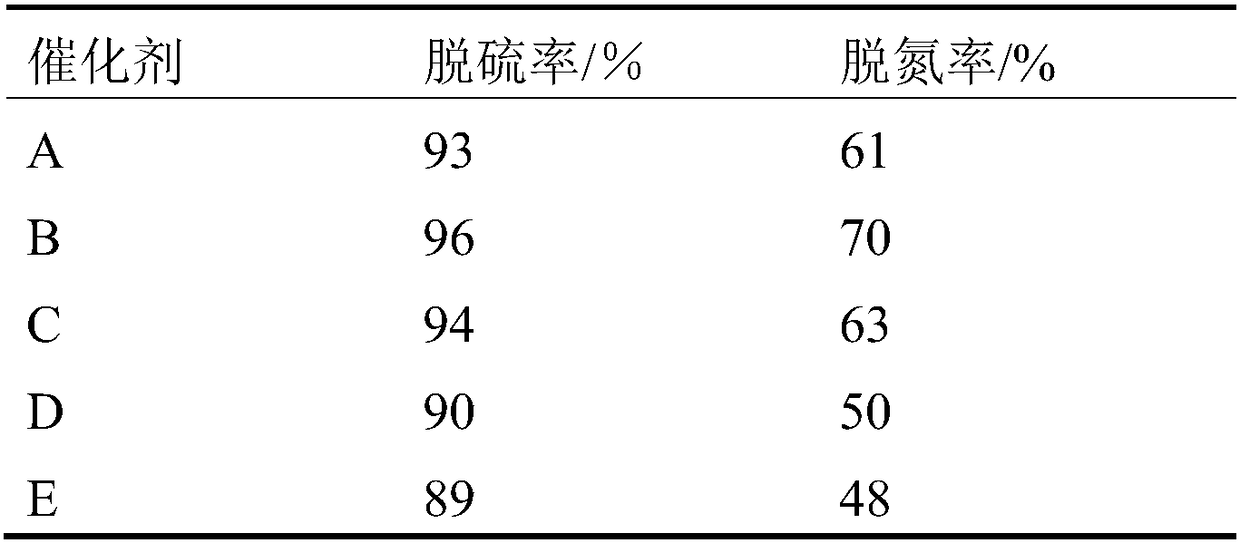

InactiveCN109647442AHigh HydrodesulfurizationHigh activityCatalyst activation/preparationHydrocarbon oils treatmentAluminium oxideDenitrification

The invention discloses a fully sulfurized hydrofining catalyst and a preparation method thereof. The catalyst includes, according to the mass of the catalyst being 100%, 20.3-26.1% of MoS2, and 5.8-7.4% of NiS2, with the balance being aluminum oxide; and the specific surface area of the catalyst is 250-450 m<2> / g, and the pore volume is 0.4-0.6 mL / g. The catalyst is the fully sulfurized catalyst,so that vulcanization or activation is not needed, and therefore, the catalyst can have high hydrodesulfurization and denitrification activity, and can be used as the hydrofining catalyst. A distillate oil hydrofining method is also disclosed. The method takes the fully sulfurized hydrofining catalyst as the catalyst.

Owner:PETROCHINA CO LTD

Method for preparing loaded hydrofining catalyst

ActiveCN103007922ASimple processSave raw materialsMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsDispersityHydrodesulfurization

The invention relates to a method for preparing a loaded hydrofining catalyst. The method comprises the following steps of: dissolving metal salts into an aqueous hydrogen peroxide solution so as to obtain impregnation liquid; carrying out impregnation on a carrier by using the impregnation liquid; and drying and roasting an impregnation product so as to obtain the loaded hydrofining catalyst. The catalyst prepared by using the method disclosed by the invention is higher in active component dispersity and poor in interaction of active components and carriers, and has better hydrodesulfurization activity and hydro-dearomatization activity in comparison with a catalyst prepared by using the conventional impregnation method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydrofining catalyst composition and preparation method thereof

ActiveCN106179480AEvenly dispersedImprove coordinationMolecular sieve catalystsHydrocarbon oils refiningSurface phaseMolecular sieve

The invention discloses a hydrofining catalyst composition and a preparation method thereof. The catalyst composition is a bulk phase hydrofining catalyst and comprises hydrogenation active metal components W, Ni and Mo, an SAPO-11 molecular sieve and aluminum oxide, the content of surface phase active metal is high, the active site density is high, active metal is uniformly dispersed, the active metal is well coordinated and matched, the utilization rate of the active metal is high, and the pore structure of the catalyst is reasonable. The catalyst composition is high in mechanical strength, has high hydrodesulfurization and hydrodenitrogenation reactive properties, and is particularly suitable for being used in ultra-deep hydrodesulfurization and denitrification reactions of diesel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytically cracked oil slurry furfural extracted oil hydrogenation catalyst, and preparation method and applications thereof

ActiveCN108452842AReduce interactionIncrease profitMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveHydrodesulfurization

The invention discloses a catalytically cracked oil slurry furfural extracted oil hydrogenation catalyst, and a preparation method and applications thereof. The catalytically cracked oil slurry furfural extracted oil hydrogenation catalyst comprises a carrier and an active component; the active component is loaded by the carrier; the carrier is a composite carrier comprising TS-1 molecular sieve,gamma-Al2O3, ZrO2, and graphene; the active component is loaded onto the carrier through one time or multiple time dipping; an adopted dipping solution is a heteropoly acid solution; 100wt% of the catalytically cracked oil slurry furfural extracted oil hydrogenation catalyst comprises 1 to 30wt% of TS-1 molecular sieve, 20 to 50wt% of gamma-Al2O3, 1 to 10wt% of ZrO2, 1 to 5wt% of graphene, and 30to 40wt% of the active component. The catalytically cracked oil slurry furfural extracted oil hydrogenation catalyst is high in hydrodesulfurization and denitrification activity, and is suitable to betaken as a catalytically cracked oil slurry furfural extracted oil hydrogenation catalyst.

Owner:PETROCHINA CO LTD

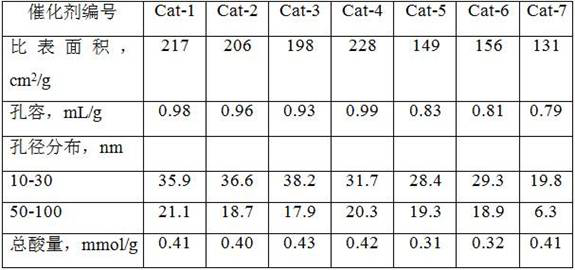

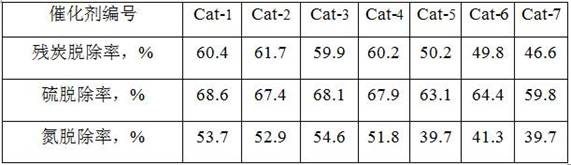

Preparation method of hydrogenation and residual carbon removal catalyst

ActiveCN111821986AIncreased porosityIncrease acidityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetakaolinChemistry

The invention discloses a preparation method of a hydrogenation and residual carbon removal catalyst. The method comprises the following steps: (1) mixing a pore-enlarging agent with pseudo-boehmite to obtain a mixture A; (2) mixing metakaolin, ammonium bicarbonate and water, carrying out sealed crystallization, and carrying out drying, roasting, dealumination treatment and drying on the crystallized material to obtain a material B; (3) carrying out ball-rolling molding on the mixture A to obtain a precursor I; and (4) mixing the material B with the precursor I, carrying out ball-rolling molding, drying, roasting, and loading an active component to obtain the hydrogenation and residual carbon removal catalyst. The catalyst prepared by the method has relatively high macroporous content andproper surface acidity, and has relatively high hydrogenation desulfurization and denitrification activity while having relatively high residual carbon removal activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Distillate oil hydrogenation catalyst and preparation method thereof

ActiveCN103785432AIncrease intrinsic activityHigh HydrodesulfurizationPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrogenActive component

The invention discloses a distillate oil hydrogenation catalyst. In terms of the weight of the oxide of an active metal component, the catalyst contains 9 to 30% of the active metal MoO3 and 2 to 10% of a group-VIII metal oxide, wherein group-VIII metal is Ni and / or Co. The hydrogenation catalyst is prepared by dipping an active component-loaded alumina carrier in a solution containing a hydrazine derivative and then carrying out hydrogen activation. A preparation method for the distillate oil hydrogenation catalyst comprises the following steps: (1) dipping the alumina carrier or alumina carrier containing an auxiliary agent by using a conventional active metal dipping solution and then carrying out drying and roasting; (2) preparing the solution containing the hydrazine derivative, dipping the material obtained in the step (1) and carrying out drying; and (3) subjecting the material obtained in the step (2) to hydrogen activation so as to obtain the finished hydrotreatment catalyst. The catalyst is easy to prepare, does not need sulfuration before usage, is applicable to hydrotreatment of heavy distillate oil and has high denitrification and desulphurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A multi-metal bulk catalyst for ultra-deep desulfurization and denitrification, its preparation method and application

ActiveCN106268850BEasy to synthesizeEasy to operateMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrogen pressureSulfur

The invention relates to a hydrofining multi-metal bulk catalyst for ultra-deep desulfurization and denitrogenation and a preparation method thereof. The multi-metal bulk catalyst is composed of a Group VIII metal, a Group IVB metal and two Group VIB metals. Mixed metal oxides composed of metals, wherein the catalyst contains 1-60wt% of Group VIII metals, 1-50wt% of Group IVB metals, and 5-60wt% of two types of Group VIB based on oxides and catalysts Metal. The invention also discloses the preparation method and application of the above-mentioned catalyst. The invention is applied in the hydrofining reaction of fuel oil containing sulfur and nitrogen. The reaction conditions are: temperature 280-400°C, hydrogen pressure 1-20MPa, hydrogen and the The volume ratio of sulfur-containing and nitrogen-containing fuel is 50-1000, and the volume space velocity of the material is 0.1-10h-1. During the reaction, the catalyst can remove sulfur and nitrogen in the diesel fraction from 500ppm to below 10ppm respectively, realizing diesel oil Ultra-deep hydrodesulfurization and ultra-deep hydrodenitrogenation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogenation catalyst and continuous production method

ActiveCN108786862ARealize continuous productionAchieve productionCatalyst activation/preparationRefining to eliminate hetero atomsHigh surfaceMetal

The invention discloses a hydrogenation catalyst and a continuous production method. The hydrogenation catalyst comprises, based on the weight of the catalyst, 61-92wt% of aluminum oxide supporter, active metal and auxiliaries, wherein the active metal is selected from one or more or from group VIII and / or group VIB metal elements and comprises based on the weight of oxide, 1-9wt% and preferably 1.0-5.0wt% of group VIII metal and 5-25wt% and preferably 10-20wt% of group VIB metal, and the weight percentage of the auxiliaries is 2-5wt% based on the weight of elements. The hydrogenation catalysthas the advantages that high surface active metal and auxiliary density in the catalyst is achieved, and the concentration of the active metal gradually increases from inside to outside along particle size. The method has the advantages that high hydrogenation active metal utilization rate is achieved, the surface acidity of the catalyst can be improved effectively, the inactivation speed of thecatalyst is slowed, continuous production of the hydrogenation catalyst is achieved, production efficiency is increased, and production cost is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrofining catalyst

ActiveCN102728372AIncrease loadGood dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDispersityBoron

The invention discloses a preparation method of a hydrofining catalyst, comprising the following steps of: mixing a complex impregnation liquid containing Group VIB and Group VIII metal, humic acid urea and boron compound with an alumina precursor, moulding, drying, and roasting to obtain the hydrofining catalyst. By the adoption of the method, loading and dispersity of active metal and a boron aid on the surface of alumina can be raised, and performance of the catalyst is further improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of hydrogenation carbon residue removal catalyst

ActiveCN111821986BIncreased porosityIncrease acidityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrodesulfurization

The invention discloses a preparation method of a hydrogenation carbon removal catalyst, which comprises the following contents: (1) mixing a pore-enlarging agent with pseudo-boehmite to obtain a mixture A; (2) mixing metakaolin, ammonium bicarbonate and Mix with water, seal and crystallize. After crystallization, the material is dried, roasted, dealuminated, and dried to obtain material B; (3) Mixture A is ball-shaped to obtain precursor I; (4) Material B and precursor I Mixing, ball forming, drying, calcining, and loading of active components to obtain a hydrogenation carbon removal catalyst. The catalyst prepared by the method has relatively high macropore content and suitable surface acidity, and the hydrogenation carbon removal catalyst has high carbon removal activity and high hydrogenation desulfurization and denitrogenation activities.

Owner:CHINA PETROLEUM & CHEM CORP +1

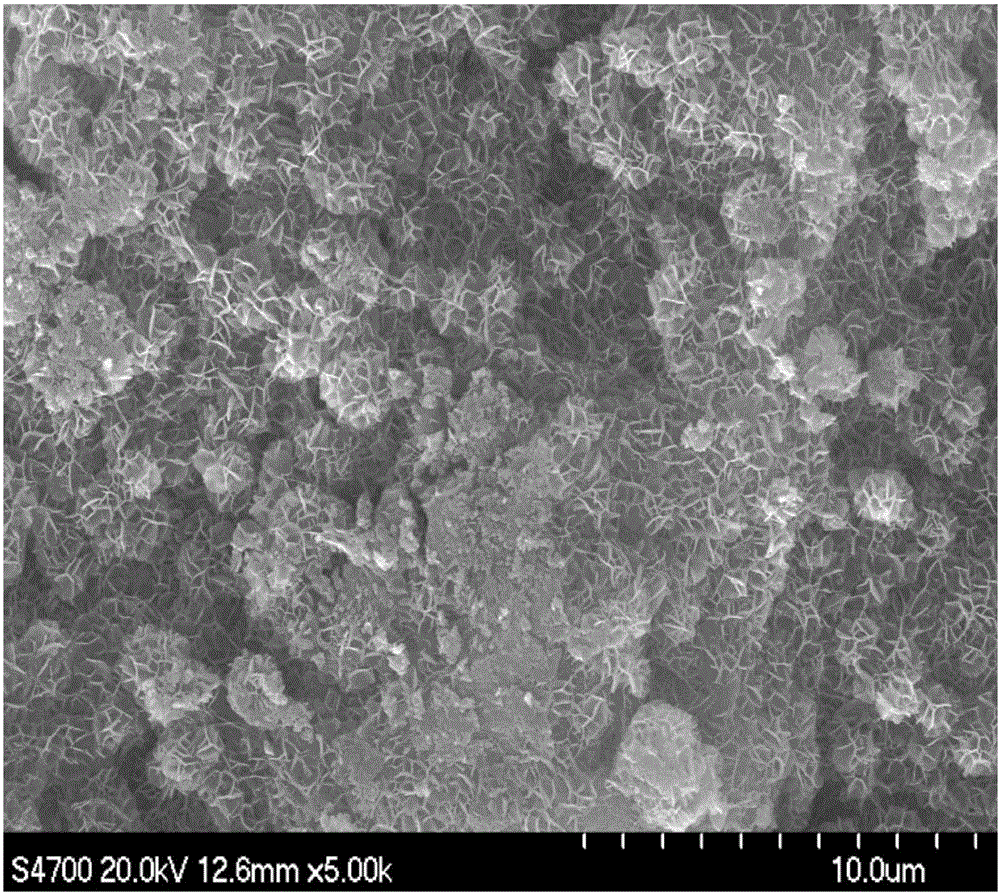

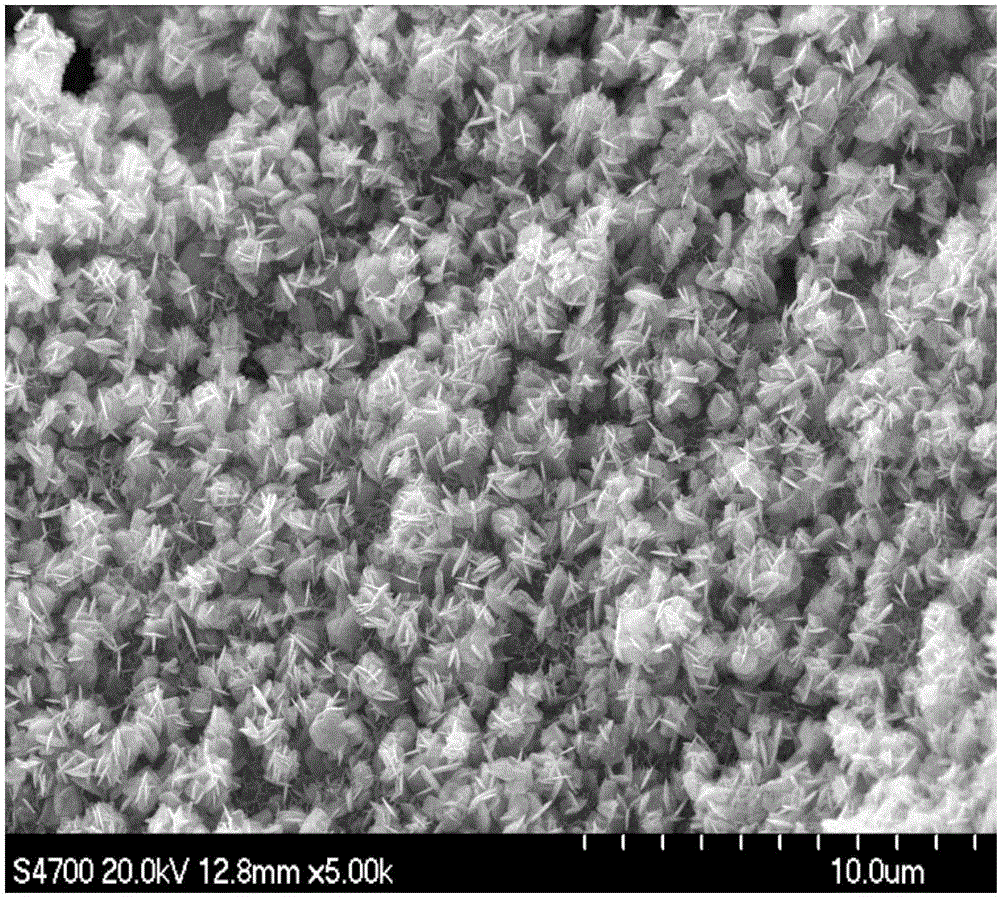

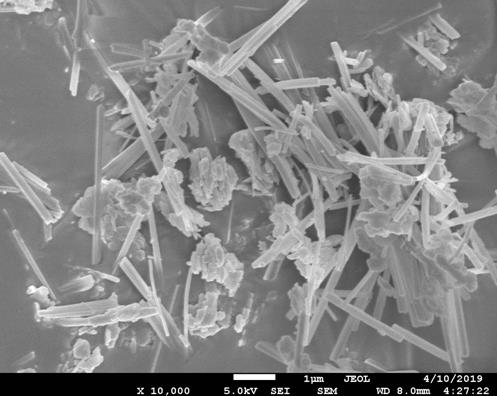

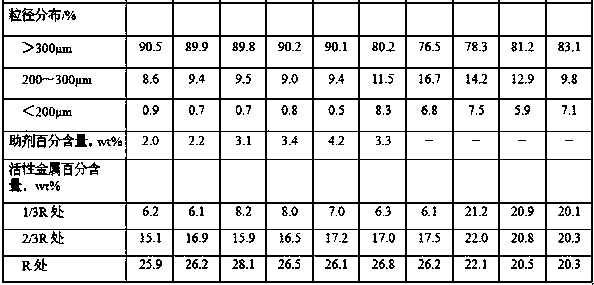

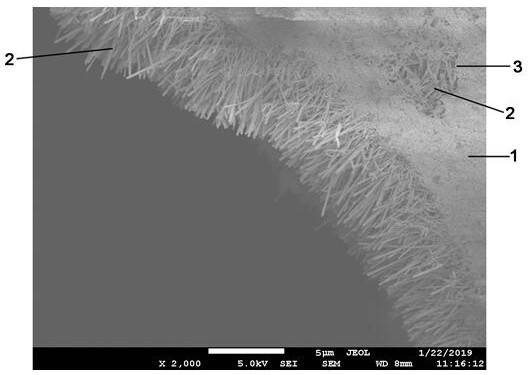

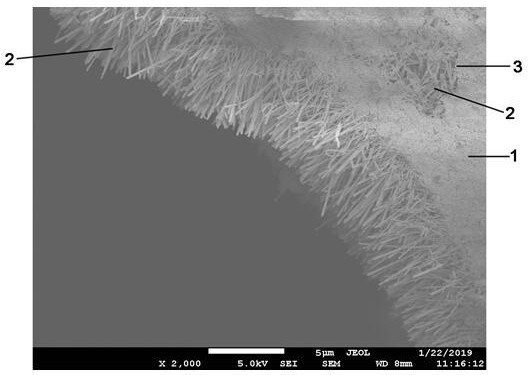

Hydrodesulfurization catalyst and preparation method thereof

ActiveCN111821988AMaintain continuityPlay a role in expanding holesCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCobalt metalPtru catalyst

The invention discloses a hydrodesulfurization catalyst and a preparation method thereof. The catalyst comprises a modified alumina-based carrier and molybdenum and tungsten metal components, whereinthe modified alumina-based carrier contains nickel and cobalt metal components; the modified alumina-based carrier comprises main body modified alumina and rod-like modified alumina, the main body modified alumina is modified alumina with micron-sized pore channels, and at least part of the rod-like modified alumina is distributed on the outer surface of the main body modified alumina and in the micron-sized pore channels with the pore diameter D of 3-7 microns. The hydrodesulfurization catalyst has high hydrodesulfurization activity and hydrogenation carbon residue removal activity when usedin a residual oil hydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrodesulfurization catalyst and preparation method thereof

ActiveCN111821988BMaintain continuityPlay a role in expanding holesCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCobalt metalPtru catalyst

The invention discloses a hydrodesulfurization catalyst and a preparation method thereof. The catalyst includes a modified alumina-based support, molybdenum and tungsten metal components, the modified alumina-based support contains nickel and cobalt metal components, and the modified alumina-based support includes bulk modified alumina and rod-shaped modified alumina The modified alumina of the main body is modified alumina with micron-scale pores, wherein at least part of the rod-shaped modified alumina is distributed on the outer surface of the main modified alumina and the pore diameter D is 3-7 μm in micron-scale pores. The hydrodesulfurization catalyst has high hydrodesulfurization activity and hydrodesulfurization carbon residue removal activity when used in residual oil hydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing low-aromatics solvent oil by hydrogenation

The invention relates to a method for producing low-aromatics solvent oil by hydrogenation. The method comprises the following steps of: passing raw material oil through a heating furnace, then fully mixing the raw material oil and hydrogen gas in an oil-gas mixer, and contacting with a hydrogenation catalyst in a lower hydrogen-oil volume ratio and under milder process conditions to undergo the common hydrogenated purification reaction. Compared with the conventional hydrogenated purification process, the method can achieve the same effect as the conventional purification process under milder process conditions. By the method, the low-sulfur and low-aromatics solvent oil products can be produced. In addition, the method also has the advantages of simple process flow, stable operation, high product properties and low energy consumption, and the new establishment of a hydrogenation device and the modification of the original device are both ok.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com