Modified gamma-alumina and hydrogenation catalyst, and preparation method and application of hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., to achieve extended service life, good industrial application prospects, good dispersibility and The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The second aspect of the present invention provides a method for preparing a modified gamma-alumina carrier, the preparation method comprising the following steps:

[0036] (1) contacting the gamma-alumina carrier with an aqueous solution containing urea and a water-soluble salt of Group VIII metal elements, performing heat treatment, then drying the heat-treated solid and then roasting to obtain a roasted solid;

[0037] (2) impregnating the calcined solid obtained in step (1) with an aqueous solution containing fluorine elements, drying and calcining to obtain a modified γ-alumina carrier.

[0038] According to the present invention, the shape of the gamma-alumina carrier can be spherical, strip-shaped, clover-shaped, cylindrical particles or amorphous powder. In the present invention, the gamma-alumina carrier is preferably cylindrical particles with a diameter of 1 mm to 5 mm.

[0039] According to the present invention, γ-Al 2 o 3 The carrier can be obtained comm...

Embodiment 1

[0090] (1) 75g gamma-alumina carrier (specific surface area 215m 2 / g, pore volume 0.60mL / g) is immersed in an aqueous solution containing 9.0g urea, 14.6g nickel nitrate hexahydrate, 4.0g ammonium nitrate and 250g deionized water (the pH value of the aqueous solution is 8), and the mixture is transferred to 500mL In an autoclave, it was heat-treated at 85°C for 18 hours, filtered, washed, then dried at 120°C for 3 hours, and calcined at 450°C for 3 hours in an air atmosphere.

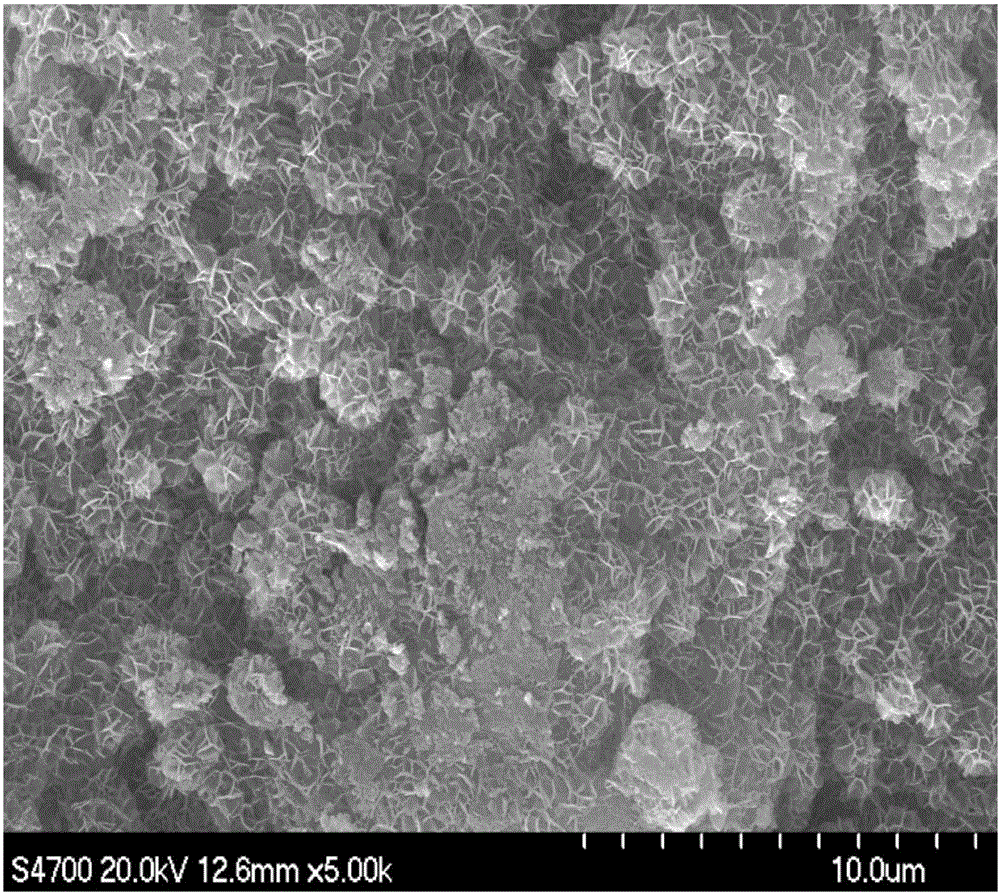

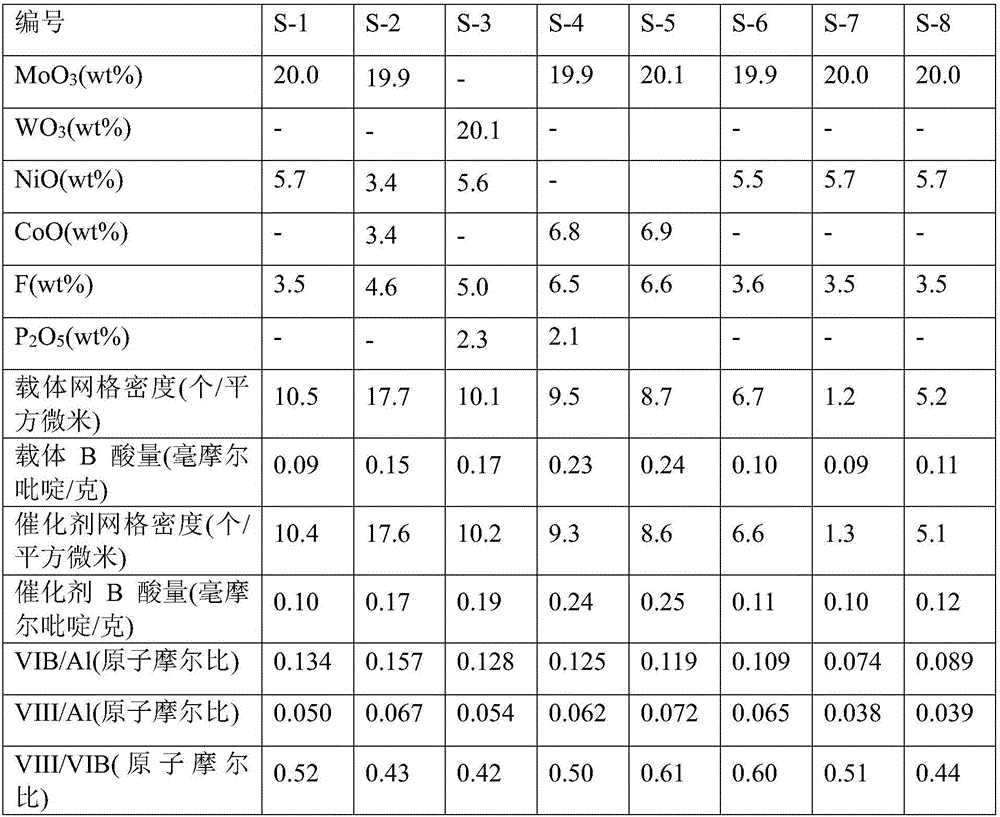

[0091] (2) The obtained solid was impregnated with 50 mL of a solution containing 7.5 g of ammonium fluoride for 1 h, dried at 120° C. for 3 hours, and calcined at 450° C. for 3 hours in an air atmosphere to obtain a modified alumina carrier. The SEM image of the modified alumina carrier is as follows figure 1 shown. from figure 1 It can be seen that the surface of the alumina carrier has a large number of network structures. The grid density and B acid content of the modified alumina support are l...

Embodiment 2

[0113] (1) 75g gamma-alumina carrier (specific surface area 255m 2 / g, pore volume 0.80mL / g) is immersed in an aqueous solution containing 9.0g urea, 14.6g cobalt nitrate hexahydrate, 4.0g ammonium nitrate and 250g deionized water (the pH value of the aqueous solution is 7.5), and the mixture is transferred to 500mL In an autoclave, it was heat-treated at 75°C for 24 hours, filtered, washed, then dried at 120°C for 3 hours, and calcined at 550°C for 2 hours in an air atmosphere.

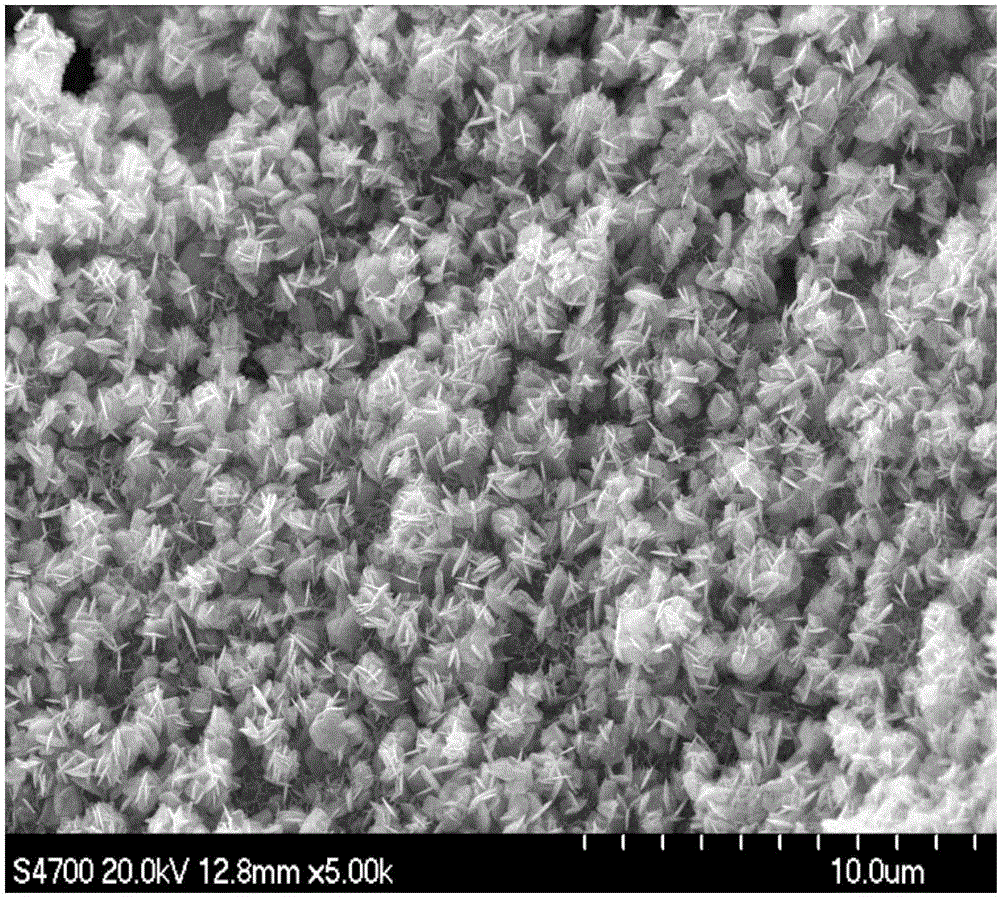

[0114] (2) The obtained solid was impregnated with 50 mL of a solution containing 10.0 g of ammonium bifluoride for 1 h, dried at 100° C. for 8 hours, and calcined at 500° C. for 2.5 hours in an air atmosphere to obtain a modified alumina carrier. The grid density and B acid content of the modified alumina support are listed in Table 1.

[0115] (3) Using 48 mL of a solution containing 14.6 g of nickel nitrate hexahydrate and 36.8 g of sodium molybdate dihydrate as the impregnating solution, impregn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com