A multi-metal bulk catalyst for ultra-deep desulfurization and denitrification, its preparation method and application

A bulk catalyst and deep desulfurization technology, applied in the petrochemical field, can solve the problems of waste, not easy to decompose, the concentrated ammonia water will pollute the environment, etc., achieve high hydrodesulfurization and hydrodenitrogenation activities, ensure sufficient contact, and the synthesis process is simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

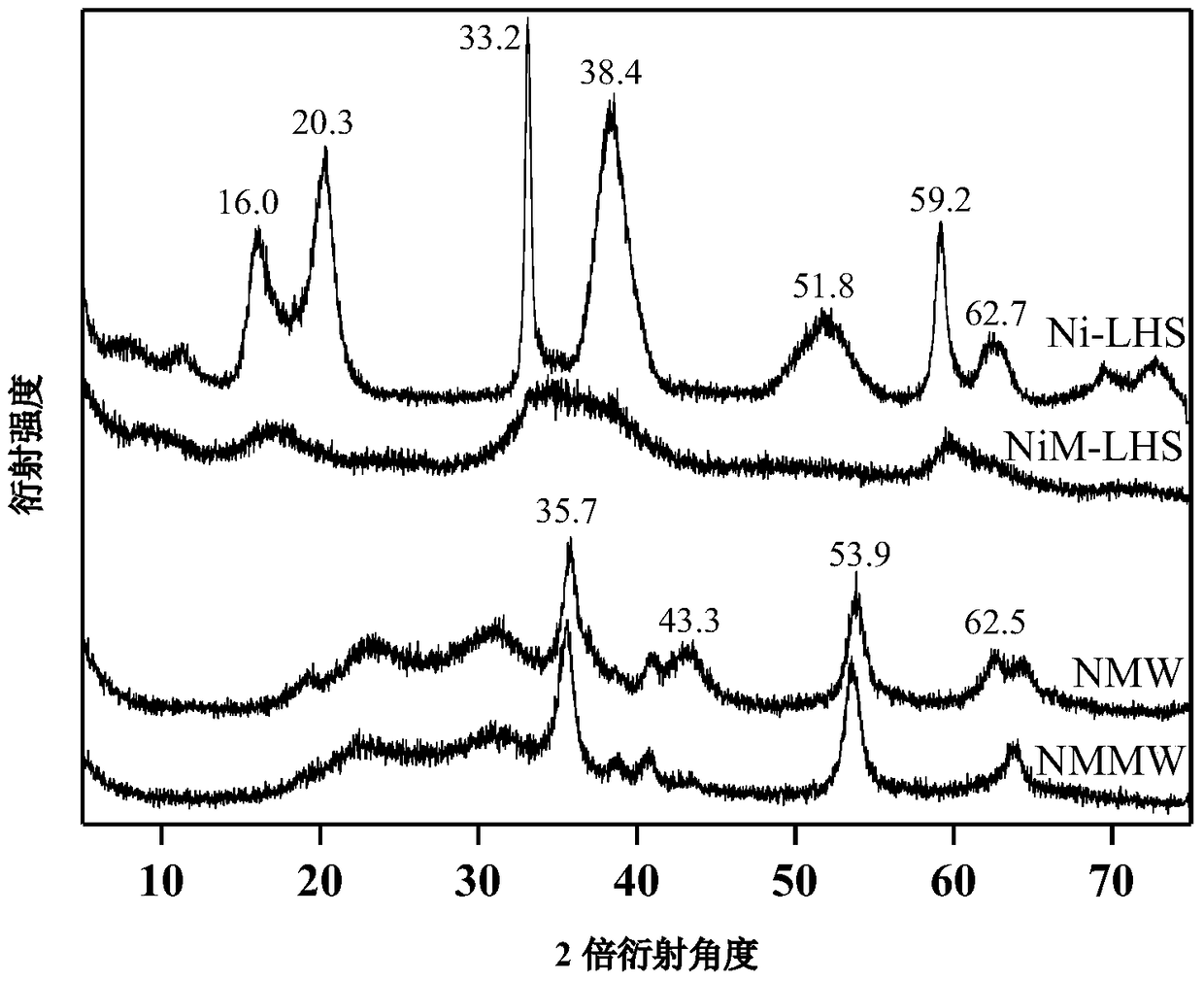

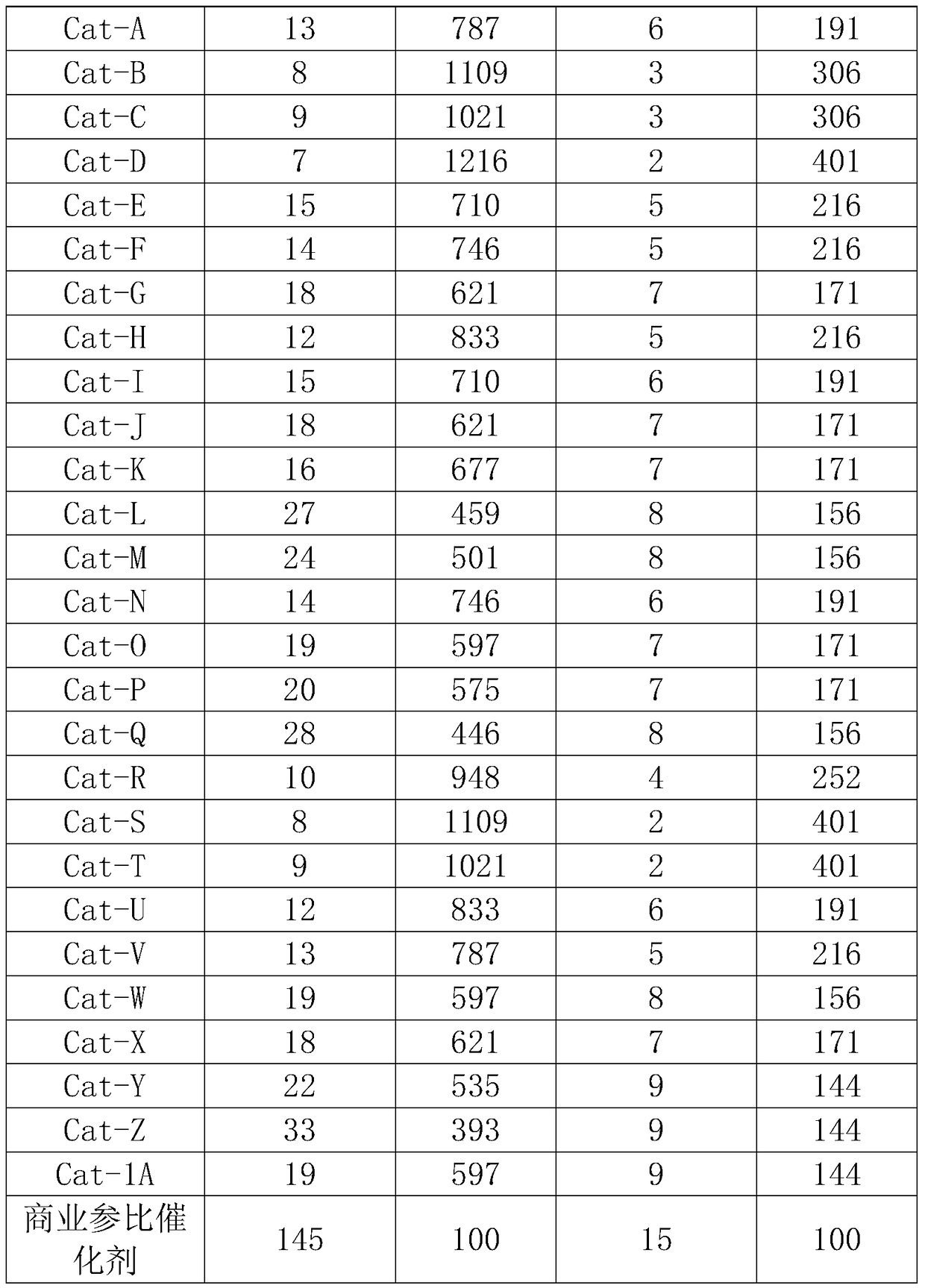

[0047] The present embodiment illustrates the preparation of the NiTiMoW bulk catalyst in the present invention:

[0048] a) Weigh 25.0g of nickel acetate (containing Ni 2+ 0.10mol), it was dissolved in 150ml of water to form a solution, and heated to the reaction temperature, then slowly dropwise added 0.2mol / L Na 2 CO 3 Aqueous solution, adjusted to pH = 11 to form a green mixed reaction solution, reflux reaction at a reaction temperature of 80°C for 20 hours; then slowly add 0.06ml of isopropyl titanate (containing Ti 4+ 0.0002mol), and reflux reaction at a reaction temperature of 80°C for 10 hours to obtain a green product; the green product obtained by the reaction was filtered and washed to obtain a catalyst precursor; the catalyst precursor was added to 250ml of water for beating and configured into a slurry precursor (a);

[0049] b) Weigh 4.9g of ammonium molybdate (containing Mo 6+ 0.025mol) and ammonium metatungstate 6.8g (containing W 6+ 0.025mol), it is disso...

Embodiment 2

[0052] The present embodiment illustrates the preparation of the NiTiMoW bulk catalyst in the present invention:

[0053] In addition to using isopropyl titanate 0.14ml (containing Ti 4+ 0.0005mol) to replace the isopropyl titanate 0.06ml (containing Ti 4+ 0.0002mol), the multimetallic bulk catalyst was prepared in the same manner as described in Example 1. The catalyst synthesized in this embodiment is brown powdered NiTiMoW catalyst, represented by Cat-B. As determined by low-temperature nitrogen adsorption, the specific surface area of the catalyst is 194m 2 / g, the pore volume is 0.22ml / g.

Embodiment 3

[0055] The present embodiment illustrates the preparation of the NiTiMoW bulk catalyst in the present invention:

[0056] In addition to using isopropyl titanate 0.29ml (containing Ti 4+ 0.0010mol) to replace the isopropyl titanate 0.06ml (containing Ti 4+ 0.0002mol), the multimetallic bulk catalyst was prepared in the same manner as described in Example 1. The catalyst synthesized in this example is brown powdered NiTiMoW catalyst, represented by Cat-C. As determined by low-temperature nitrogen adsorption, the specific surface area of the catalyst is 192m 2 / g, the pore volume is 0.22ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com