Preparation method of wax oil hydrogenation pretreatment refining agent

A wax oil, pre-hydrogenation technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of increased production cost, high price, low metal dispersion, etc., to improve utilization efficiency, high hydrodesulfurization, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

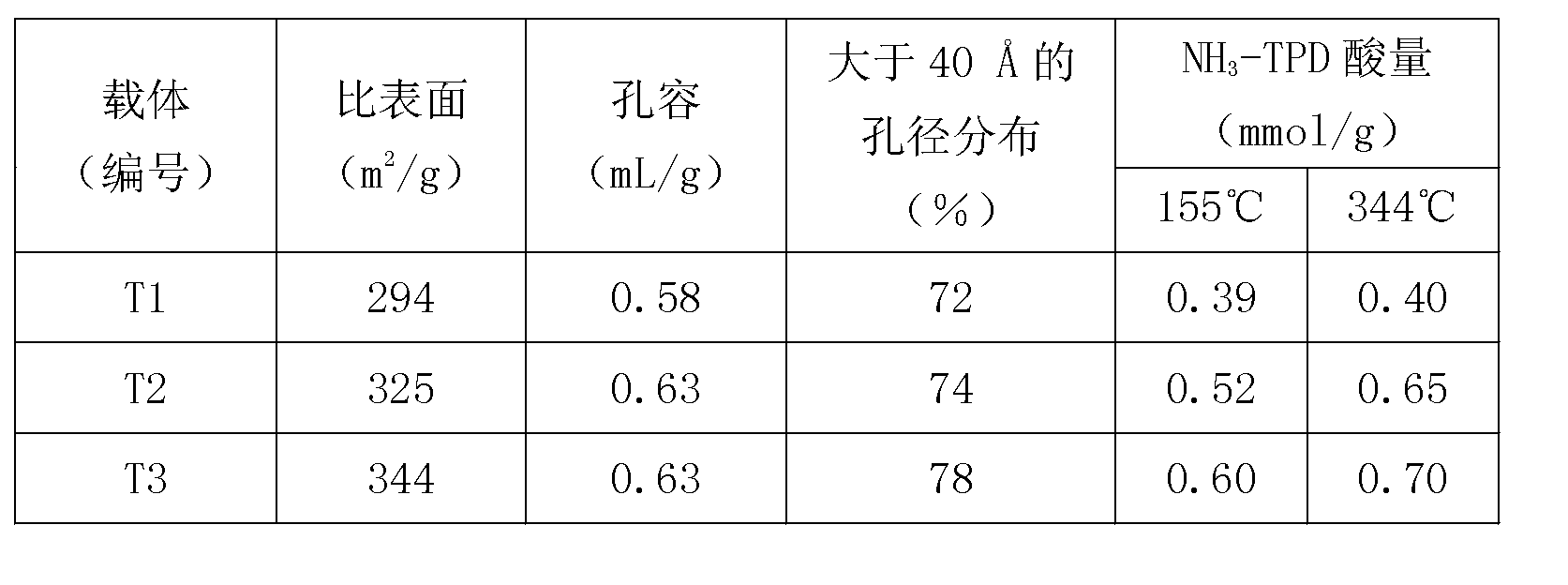

[0018] This example is a comparative example. 240g of a macroporous aluminum hydroxide dry rubber powder, whose alumina content is 70%, 6g of scallop powder, 9g of 66% concentrated nitric acid, and 10g of methyl cellulose, add deionized water, and knead in a kneader Mix evenly, and then extrude and shape through an extruder to obtain clover strips with a diameter of 1.5 mm. Dry it in an oven at 120°C for 12 hours, and bake it in a tube furnace at 500°C for 4 hours with air to obtain alumina carrier T1, whose properties are shown in Table 1.

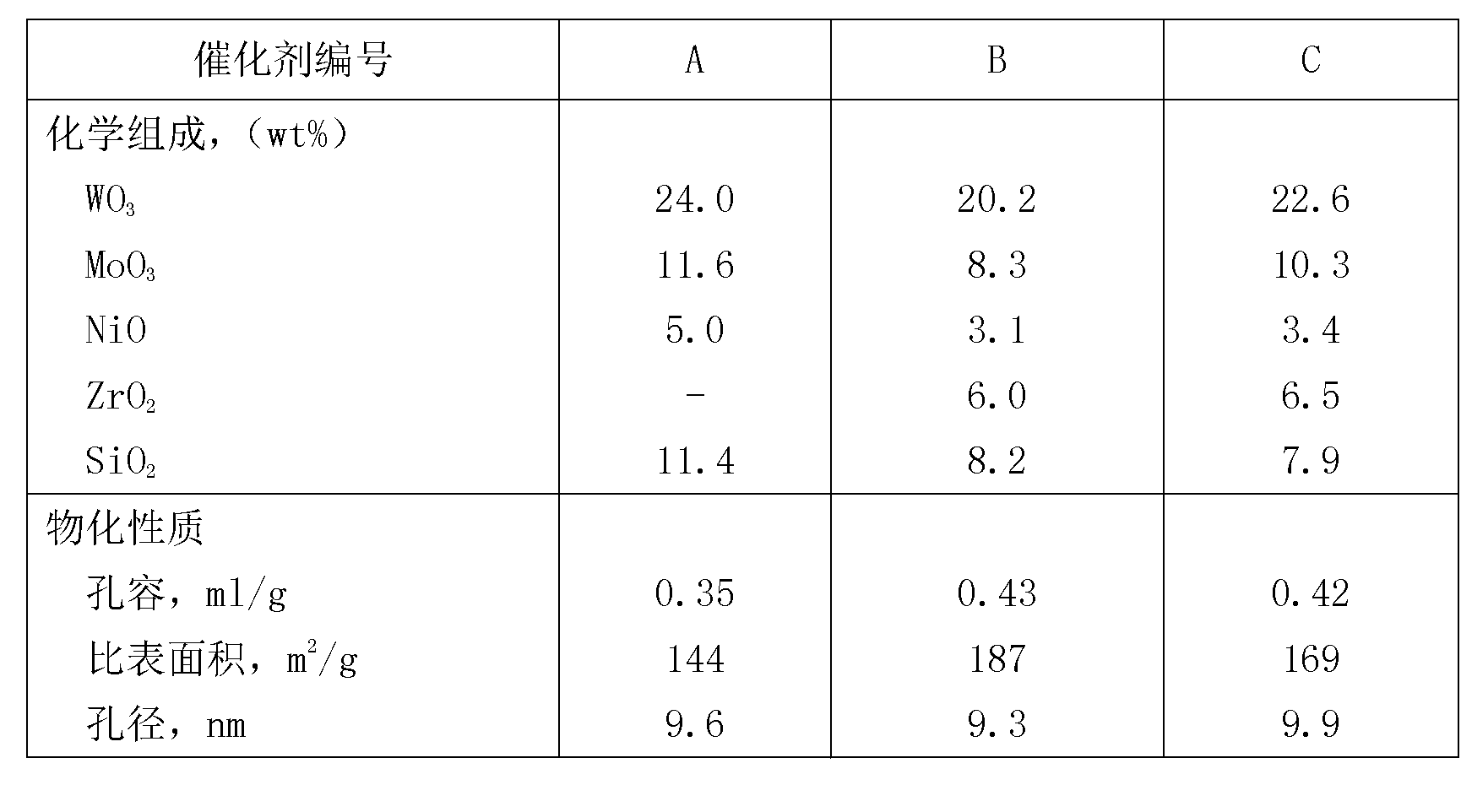

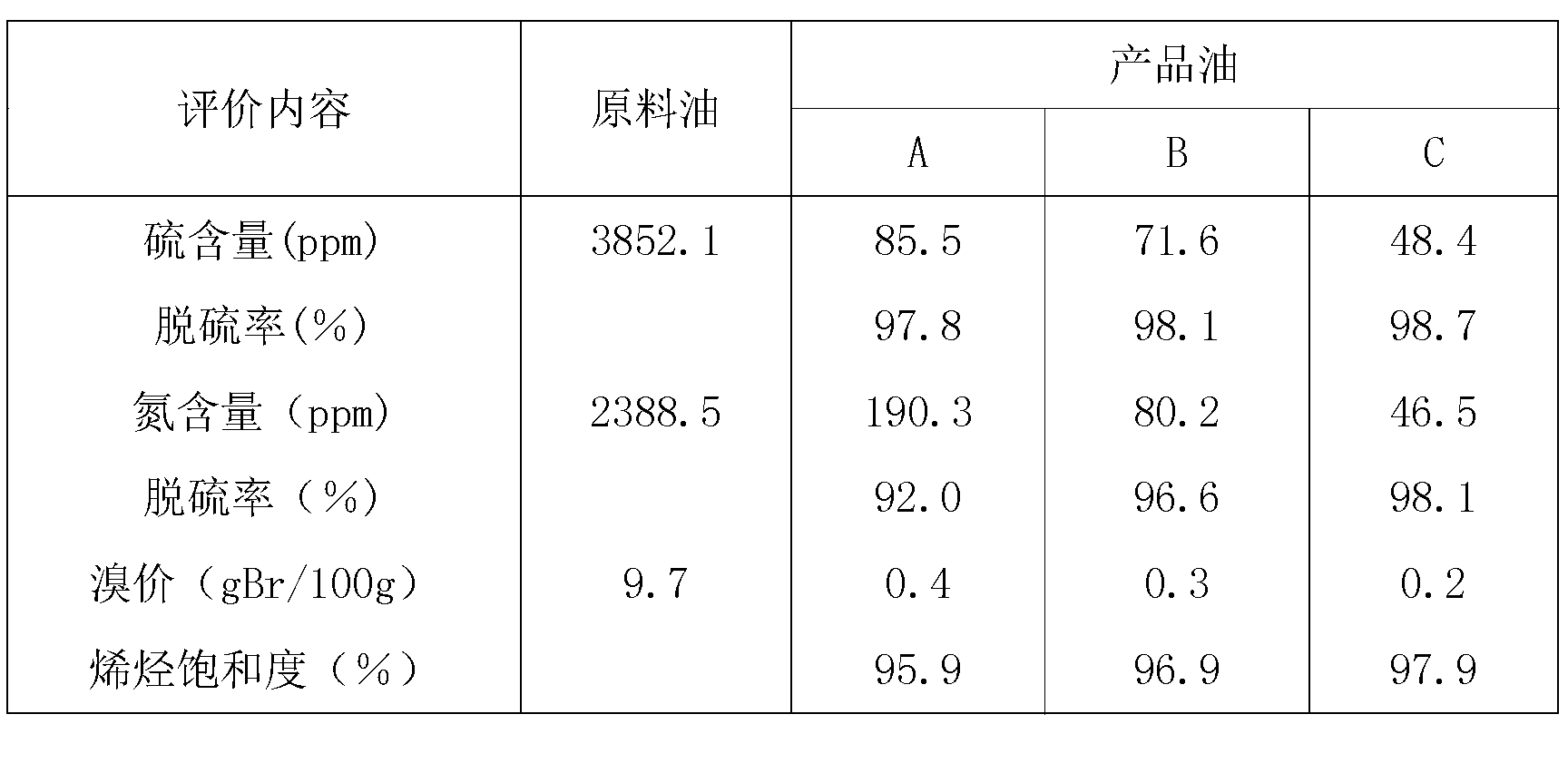

[0019] Add 140 g of the prepared alumina carrier strips to 100 mL of deionized aqueous solution containing 55 g of ammonium metatungstate hexahydrate, 24 g of ammonium heptamolybdate tetrahydrate, 35 g of nickel nitrate hexahydrate and 7 g of citric acid, and soak at room temperature for 4 hours, after separation, the wet catalyst was placed in an oven at 120°C, dried for 4 hours, and calcined at 500°C with air in a tube furnace for 4 ho...

Embodiment 2

[0021] 240g of a macroporous aluminum hydroxide dry rubber powder, whose alumina content is 70%, is mixed with 40g of zirconium hydroxide, 55g of 25% silica sol, 6g of kale powder, 9g of 66% concentrated nitric acid and methyl cellulose 10 g, added deionized water, kneaded and mixed in a kneader, and then extruded by an extruder to obtain clover strips with a diameter of 1.5 mm. Dry in an oven at 120°C for 12 hours, and bake in a tube furnace with air at 550°C for 4 hours to obtain silicon-zirconium-modified alumina carrier T2, whose properties are shown in Table 1.

[0022] Add 140 g of the prepared silicon-zirconium-modified alumina carrier strip to 100 mL of 48 g ammonium metatungstate hexahydrate, 20 g ammonium heptamolybdate tetrahydrate, 25 g nickel nitrate hexahydrate, 8 g phosphoric acid, and 6 g citric acid. Ion aqueous solution, soaked at room temperature for 4 hours, after separation, put the wet catalyst in an oven at 120°C, dried for 4 hours, and calcined in a tub...

Embodiment 3

[0024] 240 grams of a macroporous aluminum hydroxide dry rubber powder, whose alumina content is 70%, is mixed with 45g of zirconium hydroxide, 65g of 25% silica sol, 6g of turmeric powder, 9g of 66% concentrated nitric acid and polyethylene glycol Alcohol (polymerization degree 2000) 10g, add deionized water, knead and mix in a kneader, and then extrude through an extruder to obtain clover strips with a diameter of 1.5mm. Dry in an oven at 120°C for 12 hours, and bake in a tube furnace with air at 550°C for 4 hours. The properties of the obtained silicon-zirconium-modified alumina carrier T3 are shown in Table 1.

[0025] Add deionized water to 15 grams of ammonium fluoride to 200 mL, after dissolving, add 140 g of silicon-zirconium modified alumina carrier strips, soak at room temperature for 4 hours, after separation, place the wet fluorine-containing alumina strips in an oven at 120 ° C Internally dried for 4 hours, and then fired in a tube furnace at 500°C with dry air fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com