Multi-metal non-supported hydrofining catalyst, preparation method and applications thereof

A hydrofining and catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, heterogeneous catalyst chemical elements, etc., can solve the problems of high preparation cost, limited reaction degree, catalyst ratio Surface area, small pore volume, etc., to achieve the effect of ultra-deep desulfurization and ultra-deep denitrification, high hydrodesulfurization and hydrodenitrogenation activity, and catalyst activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

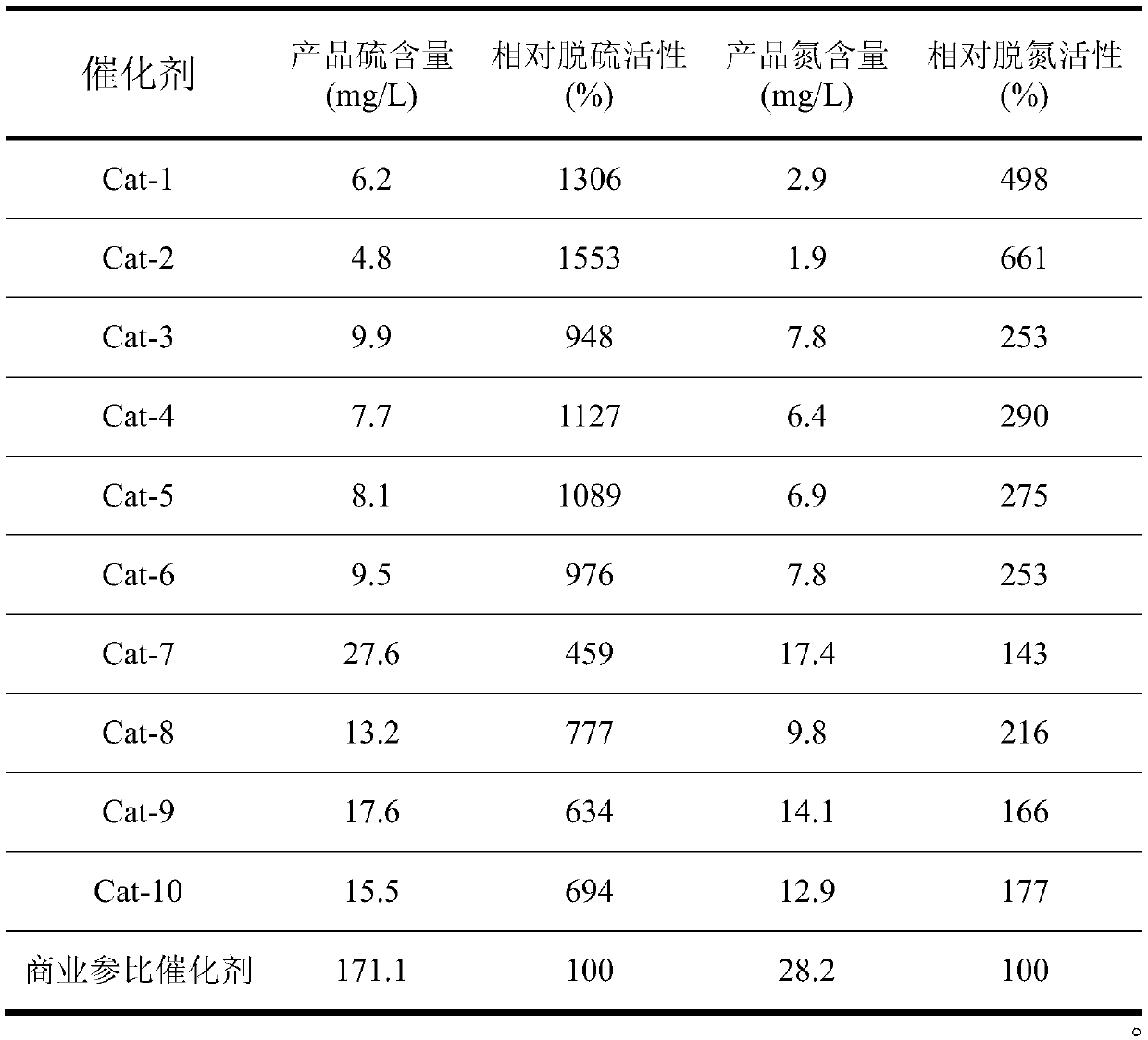

[0088] This example illustrates the use of the synthetic method of the present invention to prepare a multi-metal unsupported hydrofinishing catalyst with metal components of Al, Ni, Ti, Mo, and W:

[0089] a) Weigh 73.55g of aluminum nitrate nonahydrate, add 300ml of deionized water to make a solution, then weigh 11.76g of urea, add 500ml of deionized water to make a solution, and then stir and mix the two solutions at a constant temperature of 90 °C. And aged for 12h to obtain colloid A;

[0090] b) Weigh 136.20g of nickel nitrate hexahydrate and 10.00g of titanyl sulfate, add them to the colloid A obtained in step a) and stir to dissolve, then weigh 58.30g of sodium carbonate, add 600ml of deionized water to make a solution, and then heat it at 100°C The two solutions were stirred and mixed for 6 h under constant temperature, filtered and washed to obtain catalyst precursor B;

[0091] c) Weigh 23.48g of ammonium heptamolybdate and 32.97g of ammonium metatungstate (contain...

Embodiment 2

[0094] This example illustrates the use of the synthetic method of the present invention to prepare a multi-metal unsupported hydrofinishing catalyst with metal components of Cr, Ni, Ti, Mo, and W:

[0095] Hydrorefining was prepared in the same manner as described in Example 1, except that 52.66 g of chromium nitrate nonahydrate and 7.92 g of urea were used instead of 73.55 g of aluminum nitrate nonahydrate and 11.76 g of urea used in step a) of Example 1, respectively. Catalyst, denoted as Cat-2.

[0096] The specific surface area of Cat-2 is 184m as determined by nitrogen adsorption at low temperature 2 / g, the pore volume is 0.32ml / g.

Embodiment 3

[0098] This example illustrates the use of the synthetic method of the present invention to prepare a multi-metal non-supported hydrofinishing catalyst with metal components of Fe, Ni, Ti, Mo, and W:

[0099] Hydrorefining was prepared in the same manner as described in Example 1, except that 50.50 g of ferric nitrate nonahydrate and 7.50 g of urea were used instead of 73.55 g of aluminum nitrate nonahydrate and 11.76 g of urea used in step a) of Example 1, respectively Catalyst, denoted as Cat-3.

[0100] The specific surface area of Cat-3 is 221m as determined by nitrogen adsorption at low temperature 2 / g, the pore volume is 0.38ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com