Prevulcanizing method for hydrogenating catalyst

A hydrogenation catalyst and pre-sulfurization technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as catalyst sulfur loss, toxic additives, and environmental pollution. Achieve the effects of easy implementation, high sulfur retention and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The catalyst is presulfided according to the method provided by the invention.

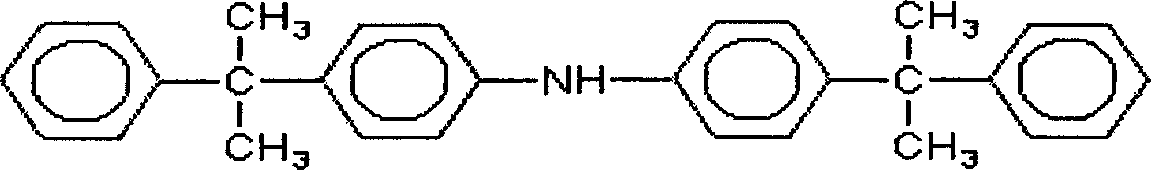

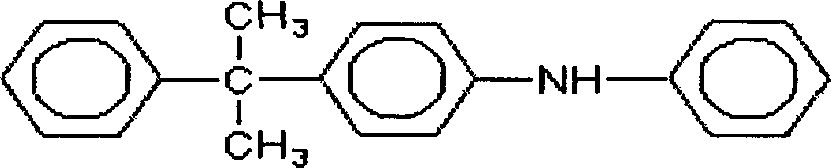

[0041] (1) 87g dodecene (1-Dodecene, boiling point 213-215°C, d 4 20 0.758) and 22g of di-tert-nonyl polysulfide (n=5), and 1.5g of a mixture of di(phenylisopropyl) diphenylamine and phenylisopropyl dianiline (wherein di(phenylisopropyl) ) diphenylamine is 95wt% by weight) mixed, and the mixture is heated at 180° C. for 2 hours to obtain a liquid product containing sulfurized olefins, and the sulfur content in the product is 9.8wt% (wherein the sulfur content is determined by microcoulometry);

[0042] (2) Take 180ml of the sulfurized olefin-containing product obtained in (1) and impregnate 80g of the hydrogenation catalyst TF-1 in a dry oxidation state, and heat the solid-liquid mixture at 160°C for 1 hour and dry it in the shade;

[0043] (3) After immersing the above product with 200ml of light diesel oil with a distillation range of 235-335°C at 25°C for 4 hours, evaporate the hydroca...

Embodiment 2

[0045] The catalyst is presulfided according to the method provided by the invention.

[0046] (1) 128g dodecene (1-Dodecene, boiling point 213~215°C, d 4 20 0.758) and 32.4g of di-tert-dodecyl polysulfide (n=5) and 2g of a mixture of di(phenylisopropyl) diphenylamine and phenylisopropyl dianiline (wherein di(phenylisopropyl) Base) diphenylamine accounted for 95wt% by weight) mixed, the above mixture was heated at 160 ° C for 1.5 hours to obtain a liquid product containing sulfurized olefins, the sulfur content in the product was 10.95wt% (wherein the sulfur content was measured by microcoulometry).

[0047] (2) Take 200ml of the sulfurized olefin-containing product obtained in (1) and impregnate 90g of dry oxidized hydrogenation catalyst TF-1, and heat the solid-liquid mixture at 150°C for 3 hours and dry it in the shade;

[0048] (3) The above product was impregnated with 220ml of gasoline with a distillation range of 150-250°C at 80°C for 6 hours, and then evaporated to d...

Embodiment 3

[0050] The catalyst is presulfided according to the method provided by the invention.

[0051] (1) 100g decene (containing α-C 10 Olefin 98%) and 25.3g di-tert-nonyl polysulfide (n=5), and the mixture of 1.69g bis(phenylisopropyl) diphenylamine and phenylisopropyl diphenylamine (wherein di(phenylisopropyl) Propyl) diphenylamine accounted for 98% by weight) mixed, heated the mixture at 160°C for 2 hours to obtain a liquid product containing sulfurized olefins, and the sulfur content in the product was 12.2wt% (wherein the sulfur content was measured by microcoulometry) .

[0052] (2) Take 150ml of the sulfurized olefin-containing product obtained in (1) and impregnate 68g of dry oxidized hydrogenation catalyst TF-1, and heat the solid-liquid mixture at 150°C for 2 hours and dry it in the shade;

[0053] (3) After immersing the above product with 186ml of light diesel oil with a distillation range of 235-335°C at 50°C for 9 hours, the hydrocarbon oil was evaporated to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com