Hydrogenation catalyst and continuous production method

A hydrogenation catalyst and catalyst technology are applied in the field of distillate oil hydrogenation, which can solve the problems of low production efficiency and unstable product quality, and achieve the effects of improving production efficiency, improving surface acidity and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

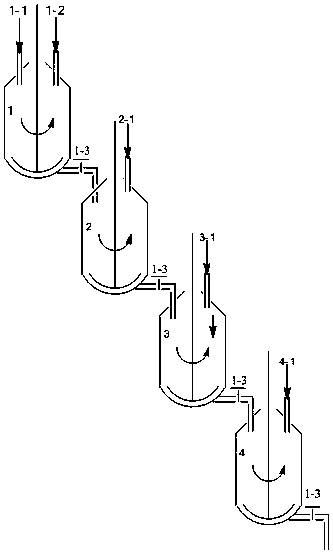

Method used

Image

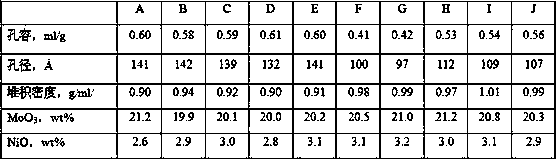

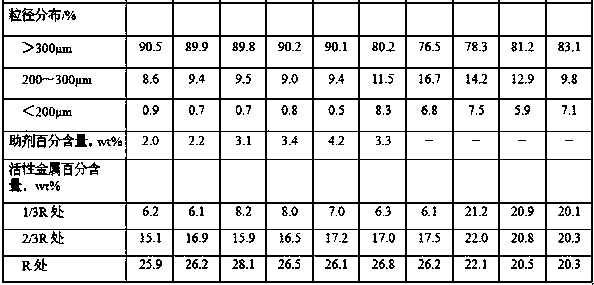

Examples

Embodiment 1

[0044] This example introduces the preparation method of Mo, Ni, ammonia original solution. In this example, only one concentration and ratio of Mo, Ni, and ammonia original solutions are prepared, and solutions of other ratios and concentrations can be prepared according to the method introduced.

[0045] Get 296g ammonium molybdate, 105g nickel nitrate is put into multi-necked flask, after adding a certain amount of deionized water, stir until the substance in the bottle is slurry, then slowly add 150g ammoniacal liquor, slowly heat after the initial reaction, Keep the solution temperature at 70-80°C for 1-2 hours, stop heating, filter the obtained solution while it is hot, and then add ammonia water to adjust the pH of the solution to 10.0-12.0 to obtain the required solution. The solution composition is MoO 3 : 58.2g / 100ml; NiO: 10.5g / 100ml.

Embodiment 2

[0047]Dimethylammonium chloride 300g, ammonium tetrafluoroborate 190g, pure water 450g, mixed, heated to 80°C under stirring, kept at constant temperature for 1h, clarified, naturally cooled to about 30°C, centrifuged to filter out the solid to obtain 300g of ionic liquid, The water content is about 3.5wt%, and the yield is 73wt%.

[0048] Add 2L of bottom water to the reaction tank and each swing tank, heat the temperature of the reaction tank to 60°C, heat each swing tank to 90°C, adjust the stirring rate of the reaction tank to 200rad / min, adjust the stirring speed of each reaction tank to 400rad / min; open the feed inlet at the upper end of the reactor, and the concentration is 100g / 100mlAl with the flow velocity of 60ml / min 2 o 3 Aluminum sulfate solution and a concentration of 100g / 100ml Al at a flow rate of 40ml / min 2 o 3 Add the sodium metaaluminate solution in the reaction tank, adjust the pH value to 8.5, and after stabilizing for 10 minutes, open the overflow port...

Embodiment 3

[0050] 400g of triethylammonium chloride, 220g of sodium hexafluorophosphate, and 450g of pure water were mixed, heated to 90°C under stirring, kept at a constant temperature for 3 hours, clarified, naturally cooled to about 30°C, and centrifuged to filter out the solid to obtain 450g of ionic liquid I. The water content is about 3.5wt%, and the yield is 72wt%.

[0051] Add 3L of bottom water to the reaction tank and each swing tank, heat the temperature of the reaction tank to 80°C, heat each swing tank to 100°C, adjust the stirring rate of the reaction tank to 300rad / min, adjust the stirring speed of each reaction tank To 500rad / min; Open the feed inlet at the upper end of the reactor, with the flow velocity of 80ml / min, the concentration is 80g / 100mlAl 2 o 3 Aluminum sulfate solution and a concentration of 100g / 100ml Al at a flow rate of 30ml / min 2 o 3 Add the sodium metaaluminate solution in the reaction tank, adjust the pH value to between 7.5, and after stabilizing fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com