Hydrotreatment method

A technology for hydrotreating and heavy distillate oil, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of low desulfurization efficiency and achieve the effects of saving operating costs, simplifying the process flow and prolonging the service life

Active Publication Date: 2013-01-16

CHINA PETROLEUM & CHEM CORP +1

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the desulfurization efficiency of this method is low, which is 45-75w%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~2

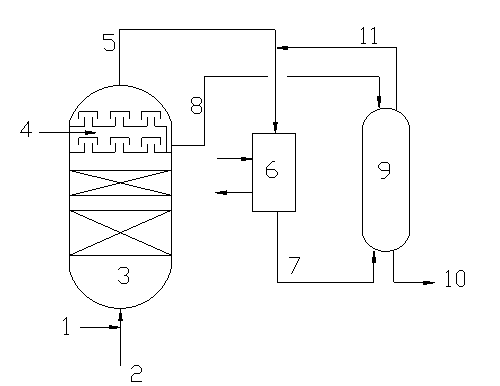

[0033] Using the present invention figure 1 The process flow shown. Wherein the properties of raw oil are shown in Table 1, the catalyst used is a commercial catalyst developed and produced by Fushun Petrochemical Research Institute, its properties are listed in Table 2, the process conditions and test results of Example 1 are shown in Table 3, and the process of Example 2 The conditions and test results are shown in Table 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a heavy distillate oil hydrotreatment method, which comprises the following steps of: mixing an inferior heavy distillate oil raw material and hydrogen, passing through an upflow reactor, and carrying out demetallization and partial desulphurization and denitrification; allowing the obtained reaction effluent to enter a gas-liquid separation apparatus arranged on the upper portion of the upflow reactor; purifying the obtained gas, allowing the gas and the obtained liquid to pass through a hydrotreatment reactor in the way of gas-liquid countercurrent so as to carry out deep desulphurization and denitrification reactions. By series connection of specially-structured upflow reactor and countercurrent reactor, refining and conversion of high-sulfur, high-nitrogen and high-metal raw materials are realized so as to obviously raise the comprehensive impurity removal effect. Therefore, it is ensured that the activity of the hydrogenation catalyst is fully performed, and the service life of the catalyst is prolonged.

Description

technical field [0001] The invention discloses a hydrogenation treatment method, in particular to a deep hydrogenation treatment method for processing high-sulfur, high-nitrogen and high-metal low-quality heavy oil. [0002] Background technique [0003] In recent years, with the shortage of crude oil resources worldwide and the increasingly inferior quality of crude oil, the properties of raw materials processed by hydrotreating units have also become increasingly heavy and inferior, and the relative density, sulfur content and nitrogen content of crude oil have continued to increase. rise. At present, due to the different processes of catalytic hydrogenation, the nitrogen content of the raw materials processed by domestic hydrogenation units is also different. However, no matter what the process is, the processing of lower-quality raw materials has become a must for all refiners and needs to be solved. The main solution to this problem lies in the improvement of catalyst...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G65/04

Inventor 彭冲刘涛黄新露王仲义

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com