Preparation method of indium phosphide quantum dots

An indium quantum and phosphating technology, which is applied in the field of semiconductor nanomaterial preparation, can solve problems such as difficult to balance the nucleation and growth process of quantum dots, widening of quantum dot size distribution, and affecting quantum dot performance. Simple operation and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In order to solve the current problem that it is difficult to prepare indium phosphide quantum dots with uniform size distribution, the invention discloses a method for preparing indium phosphide quantum dots, which includes the following steps: a. preparing a uniform indium precursor solution; b. At the first temperature, phosphine is added to the indium precursor solution to form a mixed system with indium phosphide nanocrystal nuclei, and the first temperature is in the range of 100-130°C; c, the mixed system is heated to The second temperature is maintained for a period of time; d, the mixed system is adjusted to a third temperature, and precursor substances required for synthesizing the shell are added to form indium phosphide quantum dots with shell coating.

[0027] In the present invention, the selection range of the first temperature is 100-130°C, more preferably, 115-125°C. At the reaction temperature, add indium phosphide into the indium precursor solution in...

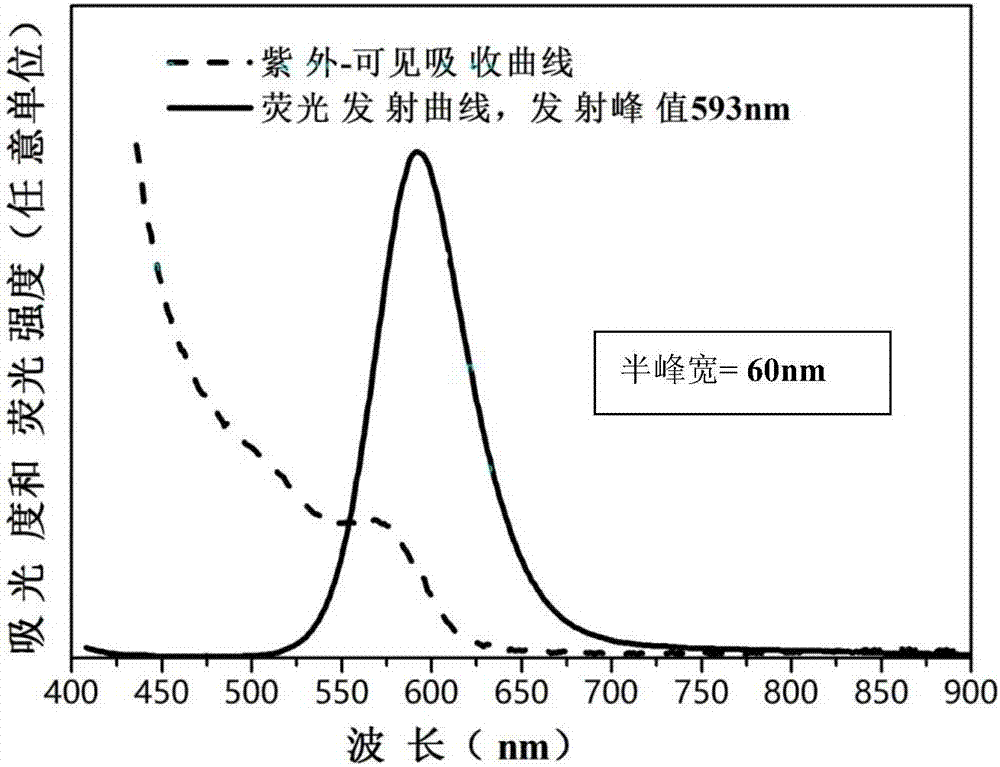

Embodiment 1

[0044] Indium phosphide quantum dot sample 1 with a fluorescence emission peak of 593 nm was prepared. Specific steps are as follows:

[0045] (1) Preparation of zinc oleate (Zn-OA): add zinc acetate, oleic acid and 1-octadecene in a three-necked flask, heat until dissolved, and pass into N 2 , react for 1h, cool down to room temperature, and obtain a clear and transparent solution of Zn-OA with a concentration of 0.5M;

[0046] (2) Preparation of sulfur-trioctylphosphine (S-TOP): under Ar environment, elemental sulfur and trioctylphosphine were mixed and dissolved to obtain a S-TOP solution with a concentration of 2M;

[0047] (3) Preparation of indium phosphide quantum dots with a core-shell structure: add In(OAc) to a three-necked flask 3 (300mg), Zn(OAc) 2 (100mg), oleic acid (1mL) and 1-octadecene (10mL), heated to 120°C to fully dissolve, and passed through N 2 , keep warm for 120min to obtain a clear and transparent solution. Cool down to 100°C, pass a certain amou...

Embodiment 2

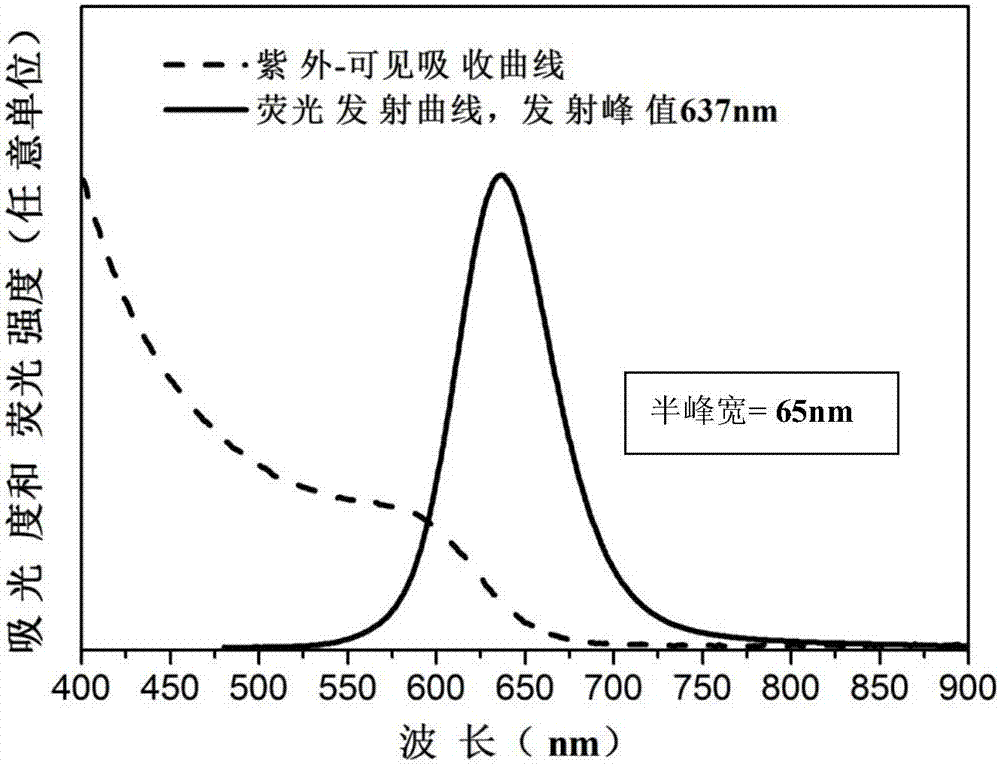

[0056] Indium phosphide quantum dot sample 3 with a fluorescence emission peak of 637 nm was prepared. Specific steps are as follows:

[0057] The preparation steps of the quantum dots are basically the same as in Example 1. After cooling down to 100°C, a larger amount of pH than in Example 1 is introduced. 3 gas to obtain the indium phosphide quantum dots at the required fluorescence emission peak position.

[0058] According to calculation, the quantum yield of the indium phosphide quantum dot sample 3 is 63%.

[0059] image 3 It is the ultraviolet-visible absorption and fluorescence emission spectrogram of the indium phosphide quantum dot sample 3 prepared in embodiment 2, from image 3 It can be seen that the emission peak is 637nm, and the half-maximum width is 65nm.

[0060] By comparing the data in the above examples and comparative examples, it can be found that the technical means of "low temperature nucleation-heating aging-high temperature cladding" of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com